Introduction: Navigating the Global Market for small cnc machine for aluminum

In today’s competitive landscape, sourcing a small CNC machine for aluminum presents a significant challenge for international B2B buyers. The demand for precision machining in sectors such as aerospace, automotive, and manufacturing has increased, requiring machines that can handle the unique properties of aluminum, including its softness and thermal conductivity. Buyers must navigate a complex array of options, from desktop models to industrial-grade machines, each tailored to specific applications and production needs.

This comprehensive guide aims to equip decision-makers with the knowledge necessary to make informed purchasing choices. It covers various types of small CNC machines suitable for aluminum, detailing their capabilities and ideal use cases. Furthermore, the guide provides insights into supplier vetting processes, ensuring that buyers can identify reputable manufacturers and secure the best deals. Cost considerations are also explored, helping businesses assess the return on investment and long-term savings associated with high-quality machinery.

By addressing these critical areas, this guide empowers B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—to streamline their procurement processes. With a focus on practical solutions and actionable insights, this resource is designed to enhance operational efficiency and drive growth in the competitive field of aluminum machining.

Understanding small cnc machine for aluminum Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Desktop CNC Routers | Compact size, cost-effective, suitable for small parts | Prototyping, hobbyist projects | Pros: Affordable, space-saving. Cons: Limited machining capacity. |

| Mini CNC Milling Machines | Higher precision, capable of 3D machining | Small-scale production, custom parts | Pros: High accuracy, versatile. Cons: Higher initial investment. |

| 4-Axis CNC Routers | Additional rotary axis for complex shapes | 3D milling, intricate designs | Pros: Enhanced capabilities for 3D work. Cons: More complex setup. |

| Industrial CNC Routers | Larger work area, robust construction | Mass production, heavy-duty applications | Pros: High throughput, durability. Cons: Requires significant investment. |

| CNC Plasma Cutters | Uses plasma for cutting, ideal for thicker materials | Sheet metal fabrication, signage | Pros: Fast cutting speeds, efficient. Cons: Less precision than milling. |

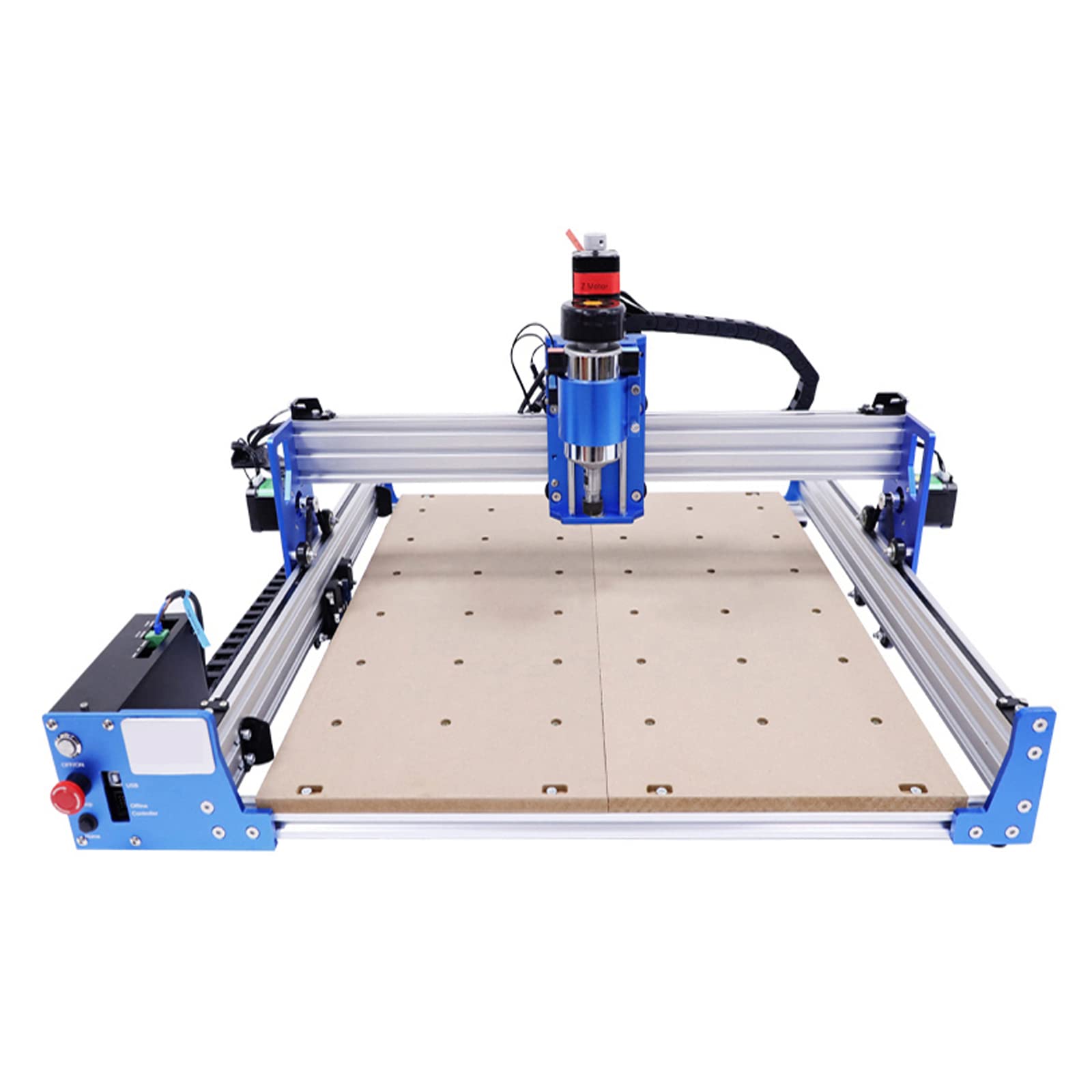

What Are Desktop CNC Routers and Their B2B Relevance?

Desktop CNC routers are compact machines designed for small-scale operations, making them ideal for prototyping and hobbyist projects. Their affordability and space-saving design appeal to small businesses and startups looking to enter the aluminum machining market without substantial capital investment. However, they have limitations in terms of machining capacity and may not be suitable for high-volume production runs.

How Do Mini CNC Milling Machines Enhance Precision?

Mini CNC milling machines offer higher precision than desktop routers and can handle more complex 3D machining tasks. They are well-suited for small-scale production and custom part fabrication, making them a popular choice among manufacturers focused on quality and accuracy. While they require a higher initial investment, the long-term benefits of improved precision and versatility can justify the cost for serious B2B buyers.

What Advantages Do 4-Axis CNC Routers Provide for Complex Designs?

4-axis CNC routers come equipped with an additional rotary axis, enabling them to create intricate 3D shapes and designs that standard machines cannot. This capability is particularly beneficial for industries that require detailed mold making or artistic applications. However, the complexity of setup and programming may pose challenges for less experienced operators, which should be considered by potential buyers.

Why Choose Industrial CNC Routers for High-Volume Production?

Industrial CNC routers are built for heavy-duty applications and larger work areas, making them suitable for mass production environments. Their robust construction ensures durability and high throughput, which is essential for businesses that need to meet large orders efficiently. However, the significant investment required may not be feasible for smaller operations, so buyers must evaluate their production needs carefully.

How Do CNC Plasma Cutters Differ from Other Types?

CNC plasma cutters utilize plasma technology to cut through thicker aluminum sheets and other metals quickly. They are ideal for sheet metal fabrication and signage applications, providing fast cutting speeds and efficiency. However, while they excel in speed, they may not offer the precision required for intricate designs compared to milling machines, making them a better fit for specific B2B applications.

Key Industrial Applications of small cnc machine for aluminum

| Industry/Sector | Specific Application of small cnc machine for aluminum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision components manufacturing | High accuracy and lightweight parts reduce fuel costs | Certifications for aerospace standards, precision capabilities, and lead times |

| Automotive | Custom parts and prototypes | Faster prototyping leads to reduced time-to-market | Material compatibility, flexibility in design changes, and tooling options |

| Electronics | Enclosures and heat sinks manufacturing | Improved thermal management and device longevity | Precision machining options, surface finish requirements, and material grades |

| Marine | Custom fittings and components | Enhanced corrosion resistance and lightweight structures | Resistance to marine conditions, specific alloy needs, and dimensional accuracy |

| Art and Design | Custom sculptures and decorative items | Unique designs that attract higher market value | Versatility in design capabilities, material handling, and finishing options |

How Are Small CNC Machines Used in Aerospace Applications?

In the aerospace industry, small CNC machines for aluminum are utilized to manufacture precision components such as brackets, housings, and structural parts. These components require high accuracy due to stringent safety standards and performance requirements. By using CNC technology, manufacturers can achieve tight tolerances while maintaining lightweight properties essential for fuel efficiency. International buyers should consider sourcing machines that meet specific aerospace certifications and have proven reliability in high-precision applications.

What Role Do Small CNC Machines Play in Automotive Prototyping?

In the automotive sector, small CNC machines are pivotal for creating custom parts and prototypes. They enable manufacturers to quickly iterate designs, which significantly reduces the time-to-market for new vehicles. The ability to work with various aluminum alloys allows for the production of lightweight components that enhance vehicle performance. Buyers should focus on machines that offer flexibility in tooling and material compatibility to accommodate rapid design changes and various production needs.

Why Are Small CNC Machines Important for Electronics Manufacturing?

Small CNC machines are essential in the electronics industry for fabricating enclosures, heat sinks, and other components from aluminum. These applications benefit from the material’s excellent thermal conductivity and lightweight characteristics, which are crucial for device performance and longevity. Buyers should prioritize CNC machines that provide precision machining capabilities and can achieve the required surface finishes to ensure optimal thermal management.

How Do Small CNC Machines Enhance Marine Component Production?

In marine applications, small CNC machines are used to create custom fittings and components that are both lightweight and resistant to corrosion. The unique properties of aluminum make it an ideal choice for marine environments, where durability and weight savings are critical. Buyers in this sector should look for machines capable of working with specific aluminum alloys that provide enhanced resistance to marine conditions while ensuring dimensional accuracy in production.

What Benefits Do Small CNC Machines Offer in Art and Design?

Small CNC machines for aluminum are increasingly used in the art and design sector to create custom sculptures and decorative items. Their ability to produce intricate designs with high precision allows artists and designers to realize their creative visions effectively. The versatility of these machines enables users to experiment with various finishes and textures, adding significant value to their work. Buyers should consider machines that offer a range of design capabilities and material handling options to support diverse artistic projects.

3 Common User Pain Points for ‘small cnc machine for aluminum’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision Cuts on Aluminum

The Problem: B2B buyers often struggle with achieving precision in cuts when using small CNC machines for aluminum. The challenge arises from the soft and malleable nature of aluminum, which can lead to tool wear and suboptimal cutting results. Buyers may find that their machines are not equipped with the appropriate tooling or settings, resulting in rough finishes, dimensional inaccuracies, or even complete machining failures. This not only affects the quality of the final products but can also lead to increased material wastage and additional costs.

The Solution: To overcome this issue, it’s essential to invest in high-quality carbide tooling specifically designed for aluminum machining. These tools have unique cutting geometries that optimize performance and extend tool life. Additionally, B2B buyers should ensure they properly set the machine’s parameters, such as spindle speed and feed rate, to align with aluminum’s properties. It is recommended to conduct a series of test cuts with different settings to find the optimal configuration for specific aluminum grades. Documentation from tooling manufacturers can provide valuable insights into recommended speeds and feeds. Utilizing CNC simulation software can also help visualize and adjust tool paths before actual machining, reducing the risk of errors.

Scenario 2: Overheating and Tool Damage During Aluminum Machining

The Problem: Another common pain point is overheating during the machining process, which can lead to tool damage and decreased machining efficiency. Aluminum, while generally easy to machine, has a high thermal conductivity that can cause heat buildup, especially during prolonged cutting operations. This overheating not only affects the tool’s lifespan but can also compromise the dimensional stability of the workpiece, leading to further production delays and costs.

The Solution: To mitigate overheating, buyers should focus on using appropriate cooling techniques, such as flood coolant systems or high-pressure mist systems. These methods help dissipate heat and maintain tool integrity during machining. Additionally, selecting tools with coatings designed for aluminum can significantly improve heat resistance and reduce friction. It is also advisable to regularly inspect the cooling systems and maintain optimal coolant levels to ensure effective heat management. Implementing a consistent tool replacement schedule based on usage and thermal monitoring can further enhance performance and prolong tool life.

Scenario 3: Limited Versatility for Diverse Aluminum Applications

The Problem: Many B2B buyers find that their small CNC machines lack the versatility needed to handle various aluminum applications, from simple sheet cutting to complex 3D milling. This limitation can hinder their ability to cater to diverse customer demands, especially in industries like aerospace and automotive, where precision and adaptability are crucial. The inability to switch between tasks or accommodate different aluminum types can lead to lost business opportunities and increased operational costs.

The Solution: Buyers should consider investing in modular CNC systems that offer flexibility in tooling and attachments. These machines allow for quick changes between different cutting tools and configurations, enabling users to handle a wide range of aluminum applications efficiently. Furthermore, opting for machines with multi-axis capabilities can enhance their ability to produce intricate designs and parts. Training staff on the machine’s capabilities and proper tool selection will also be vital. Regularly updating the CNC software to incorporate new features and capabilities can keep the machinery relevant and capable of meeting evolving market needs. Exploring partnerships with suppliers who can provide tailored solutions for specific applications can also enhance operational versatility.

Strategic Material Selection Guide for small cnc machine for aluminum

What Materials Are Commonly Used in Small CNC Machines for Aluminum?

When selecting materials for small CNC machines designed for aluminum machining, it is essential to consider the properties, advantages, and limitations of each material. Below are analyses of four common materials used in these machines.

Aluminum Alloys: The Go-To Choice for CNC Machines

Key Properties: Aluminum alloys, such as 6061 and 7075, are lightweight yet strong, with excellent corrosion resistance and thermal conductivity. They can withstand moderate temperatures and pressures, making them suitable for various machining applications.

Pros & Cons: The primary advantage of aluminum alloys is their versatility and ease of machining, which leads to lower manufacturing complexity. However, they can be more expensive than other materials, and certain alloys may not be as durable under extreme conditions.

Impact on Application: Aluminum alloys are ideal for applications requiring lightweight components, such as in the aerospace and automotive industries. Their compatibility with various media, including oil and water-based coolants, enhances their usability in CNC machining.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM or DIN, particularly when sourcing materials from different regions. Additionally, understanding local preferences for specific aluminum grades can influence procurement decisions.

Steel: A Durable Alternative

Key Properties: Steel offers high strength and durability, with excellent wear resistance and the ability to withstand high temperatures and pressures. However, it is heavier than aluminum, which may impact the machine’s overall weight and mobility.

Pros & Cons: Steel’s durability makes it suitable for heavy-duty applications, but its higher cost and complexity in machining can be drawbacks. It requires more robust tooling and may lead to longer production times.

Impact on Application: Steel is often used in applications where strength is paramount, such as in heavy machinery or structural components. Its compatibility with various cutting fluids is also a plus.

Considerations for International Buyers: Compliance with industry standards is critical, especially in regions with stringent regulations. Buyers should also consider the availability of specific steel grades in their local markets.

Plastics: Lightweight and Cost-Effective

Key Properties: Plastics, such as acrylic and polycarbonate, are lightweight and resistant to corrosion and chemicals. They can handle lower temperatures and pressures compared to metals, making them suitable for specific applications.

Pros & Cons: The primary advantage of plastics is their cost-effectiveness and ease of machining. However, they may not be suitable for high-stress applications, and their thermal properties can limit their use in high-temperature environments.

Impact on Application: Plastics are often used for prototypes or components that require aesthetic appeal, such as signage or decorative elements. Their compatibility with various media is generally good, but caution is needed with solvents.

Considerations for International Buyers: Buyers should be aware of the specific grades of plastics that meet local regulations and standards. Additionally, understanding the environmental impact of plastic use can guide procurement strategies.

Composites: The Future of Lightweight Materials

Key Properties: Composite materials, such as carbon fiber reinforced plastics, offer high strength-to-weight ratios and excellent corrosion resistance. They can withstand moderate temperatures and pressures, making them suitable for advanced applications.

Pros & Cons: The main advantage of composites is their lightweight nature combined with exceptional strength. However, they can be expensive and may require specialized machining tools and techniques.

Impact on Application: Composites are increasingly used in aerospace, automotive, and high-performance applications where weight savings are critical. Their compatibility with various media is generally favorable.

Considerations for International Buyers: Buyers should consider the availability of composite materials in their regions and ensure compliance with international standards. Additionally, understanding the specific machining requirements for composites is essential for successful implementation.

Summary Table of Material Selection for Small CNC Machines

| Material | Typical Use Case for small cnc machine for aluminum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Aerospace components, automotive parts | Lightweight and versatile | Higher cost and limited durability in extremes | Medium |

| Steel | Heavy machinery, structural components | High strength and durability | Higher cost and complex machining | High |

| Plastics | Prototypes, decorative elements | Cost-effective and easy to machine | Limited high-stress application suitability | Low |

| Composites | Aerospace, high-performance applications | High strength-to-weight ratio | Expensive and requires specialized tools | High |

In summary, selecting the right material for small CNC machines for aluminum involves understanding the properties, advantages, and limitations of each option. It is crucial for international buyers to consider compliance with local standards and the specific needs of their applications.

In-depth Look: Manufacturing Processes and Quality Assurance for small cnc machine for aluminum

What Are the Main Stages in the Manufacturing Process of Small CNC Machines for Aluminum?

The manufacturing process of small CNC machines designed for aluminum machining comprises several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the machine’s performance, durability, and accuracy.

How Is Material Prepared for CNC Machine Manufacturing?

The first step in manufacturing involves sourcing high-quality materials, typically aluminum alloys, which are known for their lightweight and corrosion-resistant properties. Material preparation includes cutting aluminum sheets or extrusions to specified dimensions, followed by rigorous inspections to ensure they meet the required standards. This stage often employs techniques such as laser cutting or shearing to achieve precise dimensions and eliminate any defects that could affect the machine’s performance.

What Forming Techniques Are Used in CNC Machine Production?

Forming techniques are essential for shaping the machine components. Processes such as CNC machining, milling, and turning are employed to create intricate designs and ensure tight tolerances. For aluminum, manufacturers often utilize high-speed machining to manage the material’s softness and thermal conductivity. This step is critical, as it determines the machine’s ability to handle high cutting forces and produce complex shapes required in various applications.

How Is the Assembly Process Conducted for CNC Machines?

Assembly of the CNC machine follows the forming stage, where all machined components are meticulously assembled. This process typically involves the installation of the CNC control system, motors, and other electronic components. Precision is crucial here, as misalignments can lead to operational inefficiencies. Manufacturers often conduct initial checks during assembly to ensure that all parts fit correctly and function as intended.

What Finishing Techniques Enhance the Quality of CNC Machines?

Finishing processes, such as anodizing or powder coating, are applied to enhance the durability and aesthetic appeal of CNC machines. Anodizing provides a protective layer that improves corrosion resistance, while powder coating can offer additional protection and a variety of color options. These finishing techniques also play a role in improving the surface finish of the machine, which is crucial for minimizing friction and wear during operation.

How Is Quality Assurance Implemented in the Manufacturing of CNC Machines for Aluminum?

Quality assurance (QA) is paramount in the production of CNC machines, particularly when dealing with international B2B buyers. Adhering to international standards, such as ISO 9001, ensures that manufacturers maintain high-quality production processes. Additionally, industry-specific certifications like CE and API are often required for compliance in various markets.

What Are the Key QC Checkpoints in CNC Machine Production?

Quality control checkpoints are implemented at various stages of the manufacturing process, including:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards. Any subpar materials are rejected to prevent downstream issues.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the production process. This includes measuring tolerances and verifying that all components are manufactured according to design specifications.

-

Final Quality Control (FQC): Once the CNC machine is fully assembled, a comprehensive inspection is performed. This includes functional tests to ensure that the machine operates correctly and meets performance standards.

What Testing Methods Are Commonly Used in QC for CNC Machines?

Common testing methods for CNC machines include:

- Dimensional Inspection: Utilizing calipers and gauges to measure critical dimensions and tolerances.

- Functional Testing: Verifying the machine’s operational capabilities, including speed, accuracy, and response to commands.

- Performance Testing: Assessing the machine’s ability to handle specified workloads and cutting conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, ensuring the quality of CNC machines is vital. Here are actionable steps to verify supplier QC processes:

-

Supplier Audits: Conducting regular audits of potential suppliers helps assess their manufacturing processes, quality control measures, and adherence to international standards. This can include on-site visits to evaluate their facilities and operations.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports that outline the results of QC inspections, testing, and any corrective actions taken. This documentation provides insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These organizations can conduct unbiased evaluations of the manufacturing processes and the final products to ensure compliance with agreed specifications.

What Are the QC and Certification Nuances for International B2B Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe need to be aware of specific QC and certification nuances. Different markets may have varying regulatory requirements, making it essential to understand local compliance standards. For instance, European buyers often prioritize CE certification, while clients in the Middle East may require specific industry certifications relevant to their sector.

Additionally, buyers should consider the language and cultural differences that might affect communication regarding quality expectations. Establishing clear quality standards and continuous communication can help mitigate misunderstandings and ensure that the final products meet the required specifications.

Conclusion

The manufacturing processes and quality assurance practices for small CNC machines designed for aluminum machining are integral to delivering reliable and high-performance equipment. By understanding these processes and implementing thorough quality checks, international B2B buyers can ensure they invest in machines that meet their operational needs and uphold industry standards. Through diligent supplier verification and adherence to quality protocols, businesses can establish long-term partnerships that drive efficiency and productivity in their manufacturing operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘small cnc machine for aluminum’

When sourcing a small CNC machine for aluminum, it’s essential to take a structured approach to ensure you make an informed decision. This guide outlines a comprehensive checklist designed to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Start by outlining the specific technical requirements for your CNC machine. Consider factors such as the types of aluminum alloys you will work with, desired machining accuracy, and the complexity of the shapes you need to produce. Clearly defined specifications will help you narrow down your options and ensure compatibility with your production needs.

- Consider the size and weight of the machine, especially if space constraints exist in your facility.

- Assess the machine’s capabilities, such as 3-axis vs. 5-axis machining, based on your project requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in CNC machines for aluminum. Look for manufacturers with a proven track record in your industry and geographic region.

- Utilize online marketplaces and directories to find a list of potential suppliers.

- Check for customer reviews and testimonials to gauge the reliability and service quality of each supplier.

Step 3: Evaluate Supplier Certifications

Before making a purchase, verify that suppliers hold necessary certifications, such as ISO 9001 for quality management. Certifications indicate adherence to industry standards and can be a marker of product reliability.

- Request documentation that confirms their compliance with international standards.

- Inquire about their manufacturing processes to ensure they meet quality control measures.

Step 4: Assess Machine Features and Capabilities

Examine the features of the CNC machines being offered. Look for machines equipped with robust spindles, precise motion control systems, and the ability to handle high cutting forces typical in aluminum machining.

- Consider advanced features like automatic tool changers and integrated software for improved efficiency.

- Evaluate the machine’s compatibility with various cutting tools suitable for aluminum.

Step 5: Request Demonstrations and Samples

Whenever possible, ask suppliers for demonstrations of their machines in action. This will provide you with a first-hand understanding of the machine’s performance and capabilities.

- Request sample cuts on the type of aluminum you intend to use to assess the machine’s precision and surface finish.

- Observe the machine’s ease of operation and any potential learning curve for your team.

Step 6: Understand Warranty and Support Options

Inquire about warranty terms and the level of support provided post-purchase. A robust warranty can protect your investment, while good customer support ensures that you can resolve any issues quickly.

- Look for extended warranty options that cover parts and labor.

- Evaluate the availability of training for your team to maximize the machine’s capabilities.

Step 7: Compare Pricing and Financing Options

Finally, compare the pricing structures of different suppliers while considering the total cost of ownership, including maintenance and operational costs. Explore financing options that may be available to ease the purchasing process.

- Ensure you understand any hidden costs, such as shipping and installation fees.

- Consider the long-term savings offered by higher-quality machines, even if they come at a higher initial price.

By following this checklist, you will be well-equipped to make an informed decision when sourcing a small CNC machine for aluminum, ultimately enhancing your production capabilities and efficiency.

Comprehensive Cost and Pricing Analysis for small cnc machine for aluminum Sourcing

What Are the Key Cost Components for Sourcing Small CNC Machines for Aluminum?

When sourcing small CNC machines for aluminum, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials directly impacts the machine’s performance and durability. High-grade components such as robust spindles and precision motion control systems are essential for efficient aluminum machining. The cost of raw materials varies significantly based on market conditions and supplier relationships.

-

Labor: Labor costs encompass not only the assembly and manufacturing workforce but also skilled technicians required for programming and maintenance. In regions with a skilled labor shortage, costs can escalate, influencing the overall price of the CNC machine.

-

Manufacturing Overhead: This includes utilities, facility costs, and administrative expenses. Manufacturers often distribute these costs across their product lines, which can affect pricing strategies.

-

Tooling: Specialized tooling, such as carbide router bits designed for aluminum, is necessary for achieving high-quality finishes. The initial investment in tooling may be substantial but is critical for long-term operational efficiency.

-

Quality Control (QC): Rigorous quality control processes ensure that machines meet specifications and standards, particularly for industries that require high tolerances. These QC measures contribute to the overall cost but are vital for maintaining product integrity.

-

Logistics: Shipping and handling costs can vary based on distance, shipping methods, and the machine’s size and weight. For international buyers, understanding Incoterms is essential, as they determine who bears the costs and risks during transportation.

-

Margin: Manufacturers typically include a profit margin in their pricing, which can vary widely based on market competition and brand reputation.

How Do Price Influencers Impact the Cost of Small CNC Machines for Aluminum?

Several factors can influence the price of small CNC machines for aluminum:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Buyers should negotiate minimum order quantities (MOQ) to maximize cost savings.

-

Specifications and Customization: Machines with specialized features or custom specifications tend to be more expensive. Buyers should assess their exact needs to avoid overpaying for unnecessary capabilities.

-

Materials: The type of aluminum alloys and other materials used in machine construction can significantly affect pricing. Higher-quality materials may increase initial costs but can lead to lower maintenance and replacement expenses over time.

-

Quality and Certifications: Machines that come with industry certifications (e.g., ISO standards) may have a higher price tag but assure buyers of quality and reliability. This is particularly important for sectors like aerospace and automotive.

-

Supplier Factors: The reputation, location, and reliability of the supplier can influence costs. Established suppliers may offer better after-sales support, impacting the total cost of ownership.

-

Incoterms: Understanding shipping terms can help buyers negotiate better deals and avoid unexpected costs related to tariffs, duties, and shipping delays.

What Buyer Tips Can Help Optimize Costs When Sourcing CNC Machines?

When sourcing small CNC machines for aluminum, B2B buyers should consider the following strategies:

-

Negotiation: Always engage in negotiations with suppliers. Understanding the market and establishing strong relationships can lead to better pricing and favorable terms.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), which includes purchase price, operating costs, maintenance, and potential downtime. A lower initial price may not equate to long-term savings.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local regulations that may affect pricing.

-

Request Samples: Before committing to a purchase, request samples or demonstrations to evaluate the machine’s performance and suitability for your specific needs.

-

Stay Informed: Keep abreast of market trends and innovations in CNC technology. Understanding advancements can provide leverage during negotiations and help in making informed purchasing decisions.

Disclaimer on Indicative Prices

Pricing for small CNC machines can vary widely based on specifications, supplier relationships, and market conditions. The figures provided in this analysis are indicative and should be verified with specific suppliers for accurate quotations.

Alternatives Analysis: Comparing small cnc machine for aluminum With Other Solutions

Exploring Alternatives to Small CNC Machines for Aluminum Fabrication

In the competitive landscape of aluminum fabrication, businesses often seek alternatives to small CNC machines. These alternatives can provide different capabilities, costs, and operational efficiencies, allowing companies to select the best solution tailored to their specific manufacturing needs. Below is a comparative analysis of small CNC machines for aluminum against two viable alternatives: laser cutting machines and manual machining methods.

Comparison Table

| Comparison Aspect | Small CNC Machine For Aluminum | Laser Cutting Machines | Manual Machining Methods |

|---|---|---|---|

| Performance | High precision and versatility for complex shapes | Excellent speed and precision for flat cuts | Variable precision; dependent on operator skill |

| Cost | Moderate initial investment; lower long-term costs | Higher initial costs; operational costs vary | Low initial investment; labor-intensive |

| Ease of Implementation | Requires programming knowledge and setup | User-friendly with CAD integration | Requires skilled operators; longer setup time |

| Maintenance | Regular maintenance needed; parts can be costly | Low maintenance; consumables like lasers need replacement | High maintenance; tool wear and tear |

| Best Use Case | Complex 3D parts and prototypes | Flat sheet cutting and engraving | Simple shapes and low-volume production |

Pros and Cons of Each Alternative

Laser Cutting Machines

Laser cutting technology utilizes focused beams of light to cut through materials with extreme precision. This method excels in speed and is ideal for flat aluminum sheets, making it a top choice for businesses focusing on high-volume production of 2D designs.

Pros:

– High-speed cutting with minimal material waste.

– Excellent for intricate designs and detailed patterns.

– Requires less operator skill compared to manual machining.

Cons:

– Higher initial investment and potential operational costs.

– Limited to flat materials; not suitable for 3D machining.

– Requires specialized safety measures due to the high-energy lasers.

Manual Machining Methods

Manual machining involves traditional techniques such as milling and turning, where skilled operators use hand tools to shape aluminum components. This method is often seen in workshops and smaller operations that require flexibility and lower capital expenditure.

Pros:

– Low initial investment and operational costs.

– High flexibility in production; easily adaptable to custom jobs.

– Ideal for low-volume runs and prototyping.

Cons:

– Dependent on operator skill; variability in product quality.

– Slower production rates compared to CNC or laser methods.

– Higher labor costs over time due to skilled labor requirements.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting a manufacturing solution for aluminum fabrication, B2B buyers should carefully evaluate their specific needs, including production volume, desired precision, and budget constraints. Small CNC machines offer a balanced approach for complex 3D machining, while laser cutting machines excel in speed and efficiency for flat materials. Manual machining methods may be suitable for low-volume, customized projects but require skilled operators and may not be as efficient. Ultimately, understanding the unique demands of your production processes will guide you toward the most effective solution for your business.

Essential Technical Properties and Trade Terminology for small cnc machine for aluminum

What Are the Essential Technical Properties of Small CNC Machines for Aluminum?

When selecting a small CNC machine for aluminum, several technical properties are crucial for ensuring efficiency, precision, and overall performance in production. Here are some of the key specifications:

1. Material Grade

The material grade of aluminum used in the CNC machine’s construction impacts its durability and performance. Common aluminum alloys for CNC machining include 6061, 7075, and 2024, each offering different mechanical properties and machinability. For B2B buyers, selecting a machine made from high-grade materials ensures longevity and reduces maintenance costs.

2. Cutting Tolerance

Cutting tolerance refers to the allowable deviation from a specified dimension in the machined part. In aluminum CNC machining, tighter tolerances (e.g., ±0.01 mm) are often required for applications in sectors like aerospace and automotive. Understanding tolerance levels is vital for buyers to ensure that the CNC machine meets the specific needs of their projects, particularly when precision is paramount.

3. Spindle Speed

Spindle speed, measured in revolutions per minute (RPM), indicates how fast the cutting tool rotates. Higher spindle speeds are essential for machining softer metals like aluminum, as they enable efficient material removal and a better surface finish. B2B buyers should consider the spindle speed capabilities when choosing a CNC machine, as it directly affects productivity and quality.

4. Feed Rate

The feed rate is the speed at which the cutting tool moves through the material. It is typically measured in millimeters per minute (mm/min). An optimized feed rate enhances machining efficiency and can reduce tool wear. Buyers must evaluate the feed rate options provided by the machine, as this will influence both operational costs and output quality.

5. Axis Configuration

CNC machines can come with various axis configurations, such as 3-axis, 4-axis, or 5-axis. A 5-axis machine offers greater flexibility, allowing for the machining of complex shapes without needing to reposition the workpiece. For businesses requiring intricate designs, investing in a 5-axis machine can significantly improve workflow and reduce setup times.

What Are Common Trade Terms in CNC Machining?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms relevant to small CNC machines for aluminum:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC machines, buyers may seek OEM products to ensure quality and reliability, as these manufacturers are often recognized for their advanced engineering and manufacturing capabilities.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For CNC machines, understanding the MOQ helps buyers plan their purchases and manage inventory effectively. It’s particularly relevant for businesses looking to scale their operations.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific goods or services. In the CNC machining industry, submitting an RFQ can help buyers compare prices and terms from different manufacturers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to navigate shipping logistics, costs, and risks effectively.

5. G-code

G-code is the programming language used to control CNC machines. It dictates the movements and operations of the machine, including the speed, feed rate, and tool path. Familiarity with G-code is important for technical decision-makers, as it influences the machine’s functionality and the complexity of the parts produced.

By grasping these essential properties and terms, B2B buyers can make informed decisions when investing in small CNC machines for aluminum, ensuring they select the right equipment to meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the small cnc machine for aluminum Sector

What Are the Current Market Dynamics for Small CNC Machines for Aluminum?

The small CNC machine market for aluminum is witnessing significant growth, driven by advancements in automation and increasing demand for precision machining across various industries. Factors such as the lightweight nature of aluminum, its corrosion resistance, and versatility make it a preferred choice in sectors like aerospace, automotive, and electronics. Emerging markets in Africa and South America are rapidly industrializing, leading to an increased need for efficient manufacturing solutions. Additionally, European nations, particularly Germany and Vietnam, are focusing on enhancing their manufacturing capabilities, leading to a surge in CNC machine adoption.

Current B2B tech trends include the integration of Industry 4.0 technologies, such as IoT and AI, allowing for real-time monitoring and predictive maintenance. These innovations enhance operational efficiency and reduce downtime, making CNC machines more appealing to international buyers. Moreover, the rise of e-commerce platforms has simplified the sourcing process, enabling buyers to access a wider range of suppliers and products with ease. As businesses prioritize agility and adaptability, the demand for small CNC machines tailored for aluminum machining is expected to grow, making it crucial for buyers to stay informed about market trends and technological advancements.

How Is Sustainability Influencing Sourcing Decisions for Small CNC Machines?

Sustainability is becoming a critical factor in the sourcing of small CNC machines for aluminum. The environmental impact of manufacturing processes, including energy consumption and waste generation, is prompting businesses to seek eco-friendly solutions. Buyers are increasingly looking for machines that minimize energy use, utilize recyclable materials, and incorporate waste reduction practices. This shift not only helps in compliance with regulations but also enhances brand reputation.

Ethical sourcing practices are also gaining importance. Companies are expected to maintain transparency in their supply chains, ensuring that materials are sourced responsibly. Certifications such as ISO 14001 for environmental management and the use of green materials are becoming key differentiators for suppliers. For instance, manufacturers that adopt sustainable practices, such as using biodegradable lubricants and energy-efficient components, are likely to attract environmentally conscious buyers. Emphasizing sustainability in sourcing decisions not only aligns with corporate social responsibility goals but also opens opportunities for collaboration with like-minded partners in the industry.

What Is the Historical Evolution of Small CNC Machines for Aluminum?

The evolution of small CNC machines for aluminum can be traced back to the mid-20th century when the first numerical control (NC) machines were introduced. Initially, these machines were primarily used for large-scale manufacturing, but as technology advanced, CNC systems emerged, offering enhanced precision and flexibility. The introduction of microcontrollers in the 1980s made it feasible to produce smaller, more affordable CNC machines, which democratized access for smaller businesses.

In recent years, technological advancements such as computer-aided design (CAD) and computer-aided manufacturing (CAM) software have revolutionized the way aluminum components are designed and produced. Today, small CNC machines are equipped with sophisticated software that allows for intricate designs and complex machining processes, making them indispensable tools in various industries. This historical context underscores the ongoing innovation in the sector, setting the stage for future developments that will further enhance capabilities and efficiency in aluminum machining.

Frequently Asked Questions (FAQs) for B2B Buyers of small cnc machine for aluminum

-

How do I choose the right small CNC machine for aluminum machining?

Selecting the appropriate small CNC machine for aluminum requires careful consideration of several factors. First, assess your specific machining needs, including the types of aluminum alloys and the complexity of the parts you intend to produce. Look for machines with robust spindles and high rigidity to handle the cutting forces associated with aluminum. Additionally, evaluate the machine’s precision, speed, and tool compatibility. Finally, factor in your budget, as investing in a higher-quality machine can lead to long-term cost savings through enhanced productivity and reduced maintenance. -

What is the best CNC machine type for small-scale aluminum production?

For small-scale aluminum production, a desktop or mini CNC router is often the best choice. These machines are typically compact, cost-effective, and capable of handling various aluminum profiles and sheets. Look for models that feature high-speed spindles and specialized router bits designed for aluminum to ensure optimal cutting performance. If your projects involve intricate designs or 3D milling, consider a machine with a fourth or fifth axis for added flexibility and precision in machining. -

What are the key considerations for international trade of CNC machines?

When engaging in international trade for CNC machines, consider factors such as import regulations, tariffs, and trade agreements that may affect costs. It’s crucial to verify the machine’s compliance with local standards and certifications in your country. Additionally, assess the reliability of your supplier, focusing on their reputation, warranty policies, and after-sales support. Logistics are also vital; ensure that you have a clear understanding of shipping costs, delivery times, and potential customs duties to avoid unexpected expenses. -

How can I vet suppliers for small CNC machines for aluminum?

To vet suppliers effectively, start by researching their background and reputation in the CNC industry. Look for reviews and testimonials from previous customers to gauge their reliability and quality. Request references and check their manufacturing capabilities, including certifications like ISO for quality assurance. Additionally, assess their customer service responsiveness and willingness to provide technical support. Engaging in direct communication can also help clarify any uncertainties regarding their products and services. -

What customization options should I consider when purchasing a CNC machine?

Customization options can significantly enhance the performance of your CNC machine for aluminum. Consider features like programmable software, tool changers, and additional axes for complex machining tasks. You may also want to explore specific tooling options designed for aluminum, such as high-speed spindles and specialized router bits. Additionally, inquire about software compatibility and the ability to integrate with your existing systems for seamless operation. Finally, assess whether the supplier can accommodate your unique production needs and specifications. -

What is the typical minimum order quantity (MOQ) for CNC machines?

The minimum order quantity (MOQ) for CNC machines can vary widely depending on the manufacturer and the specific model. Many suppliers offer single units for small businesses or startups, while others may have higher MOQs for bulk purchases or custom machines. When negotiating with suppliers, clarify the MOQ and explore options for trial purchases or demo machines. This approach can help you evaluate the machine’s performance without committing to a large order upfront. -

What payment terms are common for international purchases of CNC machines?

Payment terms for international purchases of CNC machines typically include options like upfront payments, deposits, or letters of credit. Most suppliers will require a percentage of the total cost as a deposit before production, with the balance due upon delivery or installation. Always discuss and agree upon payment terms in advance to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially when dealing with overseas suppliers. -

How do I ensure quality assurance for CNC machines received from international suppliers?

Ensuring quality assurance starts with selecting reputable suppliers known for their quality control processes. Request documentation such as certificates of conformity and inspection reports for the machines. Consider arranging for a third-party inspection service to verify the machine’s specifications and functionality before shipment. Upon receiving the machine, conduct a thorough inspection to ensure it meets your quality standards and operational requirements. Establishing clear communication with your supplier about quality expectations can also enhance trust and reliability in the purchasing process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Small Cnc Machine For Aluminum Manufacturers & Suppliers List

1. CNC Machines – Budget Options for Aluminum Milling

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Budget CNC machines for milling aluminum are being discussed, with specific models like PrintNC, Shapeoko, and Onefinity mentioned. Users express concerns about rigidity and spindle power for effective aluminum milling. A 2.2kw spindle on the Shapeoko HDM is noted as a potential option. The budget limit for users is around $5k, and there is a preference to avoid 220v setups. Recommendations includ…

2. STYLECNC – Best CNC Routers for Aluminum

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: 2025 Best CNC Routers for Aluminum, Brand: STYLECNC, Table Sizes: 2′ x 3′, 4′ x 4′, 4′ x 8′, 5′ x 10′, Functions: Cutting, Carving, Engraving, Milling, Turning, Drilling, Axis: 3 Axis, 4th Axis, 4 Axis, 5 Axis, Capability: 2D Machining, 2.5D Machining, 3D Machining, Price Range: $2,580.00 – $150,000.00. Suitable for both beginners and professionals, capable of machining various aluminum types (202…

3. ShopSabre – CNC Routers

Domain: shopsabre.com

Registered: 2002 (23 years)

Introduction: Aluminum & Brass Machining

IS-A Series CNC Router

– Industrial Use

– Commercial Use

– Auto Unload – High efficiency Nested Based Sheet Processing

– Starting at $99,995.00

IS-M Series CNC Router

– Industrial Use

– Commercial Use

– Dedicated High Production

– High Accuracy

– Starting at $57,995.00

Industrial Series (IS)

– Machine Tool Grade CNC at a Fraction of the Price!

– Industrial Use

– Comme…

4. Laguna – CNC Router for Aluminium 2×3

Domain: practicalmachinist.com

Registered: 2000 (25 years)

Introduction: CNC router for aluminium, 2×3 size, suitable for prototype work, compatible with 220V power supply, designed for cutting aluminium 6061, 3/8 to 5/8 plates. Suggested brands include Laguna (Chinese made), Cammaster (US made), Shopsabre (US made), and Iridium (Canadian). Recommended spindle: HSD, 2-3 hp, 18000 rpm. Additional considerations include the need for coolant during cutting.

5. CNC Routers – Low Cost vs. Heavy-Duty Options

Domain: arrmaforum.com

Registered: 2015 (10 years)

Introduction: Low cost CNC routers are generally not suitable for machining aluminum; they are more appropriate for wood and PCB projects. For machining aluminum, a heavy-duty CNC mill is recommended, which can be expensive (around $40k for machines like those used by M2C and JBI). Users suggest considering used CNC mills like Haas or retrofitted Bridgeport models, which require 3-phase electric, space, and the…

6. DATRON – High-Speed CNC Machines for Non-Ferrous Metals

Domain: datron.com

Registered: 1995 (30 years)

Introduction: DATRON CNC machines are designed for high-speed machining of non-ferrous metals like aluminum. Key features include:

– High-speed spindles reaching up to 60,000 RPM.

– Efficient chip evacuation using pressurized air and ethanol coolant, eliminating secondary cleanup and coolant disposal costs.

– Optimized carbide CNC tool designs for superior part finishes and lower cycle times.

– Large work area …

7. Hobby Machinist – CNC Machine Options for Aluminum

Domain: hobby-machinist.com

Registered: 2010 (15 years)

Introduction: CNC machines being considered for aluminum and other materials include: 1. Avid CNC BenchtopPro 2424 2. Phantom CNC in a 4′ x 4′ size 3. Langmuir MR1. The user is looking for a machine with a working area of 2′ x 2′, but is open to larger options. The discussion includes considerations for drilling performance with high spindle RPMs versus lower RPMs, and the user is particularly interested in dri…

Strategic Sourcing Conclusion and Outlook for small cnc machine for aluminum

As the demand for precision and efficiency in aluminum machining continues to rise, strategic sourcing of small CNC machines tailored for this purpose is essential for B2B buyers across diverse markets. By investing in high-quality CNC routers and milling machines, businesses can enhance their production capabilities, ensuring they meet the stringent requirements of industries such as aerospace, automotive, and electronics. The right machine not only improves operational efficiency but also delivers superior surface finishes, reduces waste, and ultimately lowers production costs.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must prioritize equipment that aligns with their specific production needs and budget constraints. Considerations such as machine versatility, cutting speed, and precision are critical in selecting the right technology. Emphasizing the importance of understanding local market dynamics and supplier reliability will further enhance sourcing strategies.

Looking ahead, the landscape for small CNC machines in aluminum fabrication is poised for growth. As technological advancements continue to emerge, now is the time for B2B buyers to leverage strategic sourcing practices to stay competitive. Engage with reputable suppliers, explore cutting-edge solutions, and position your business for success in the evolving manufacturing sector.