Contents

Manufacturing Insight: Small Batch Injection Molding

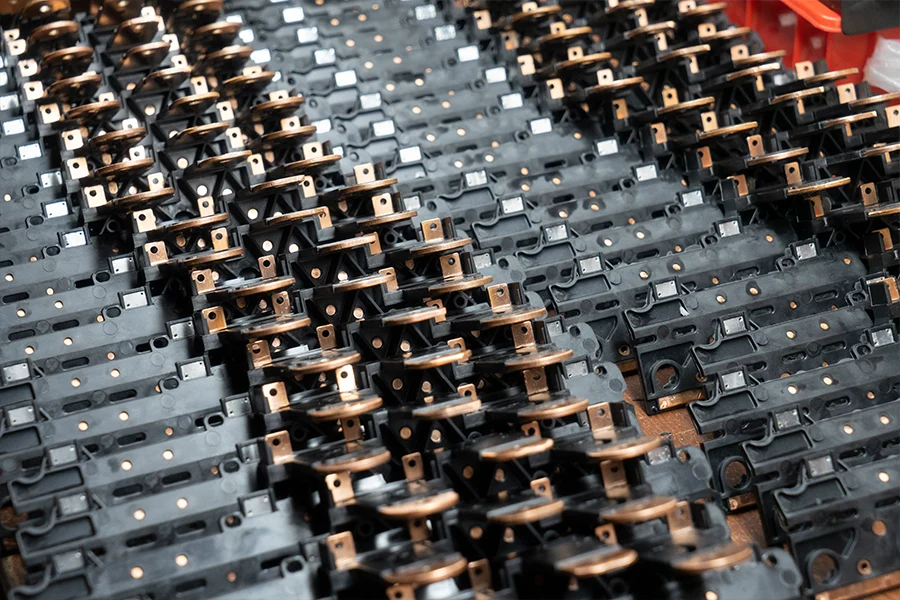

Small Batch Injection Molding: Accelerate Low-Volume Production with Precision

For product developers and engineering teams facing the critical gap between prototyping and full-scale manufacturing, small batch injection molding presents a strategic solution. Traditional tooling costs and lead times often render low-volume production economically unfeasible, delaying market entry and increasing risk. Honyo Prototype directly addresses this challenge through integrated Rapid Tooling and Injection Molding services engineered for technical excellence and speed.

Our specialized small batch process leverages precision-engineered aluminum or soft steel molds, manufactured in-house using advanced CNC and EDM techniques. This Rapid Tooling approach slashes conventional lead times by up to 70% while maintaining tight tolerances (±0.005 inches) and material integrity across engineering-grade resins—from ABS and PC to medical-grade PEEK and LSR. Each small batch run (typically 100–10,000 parts) undergoes rigorous in-process quality verification, ensuring dimensional consistency and surface finish compliance without the capital investment of hardened steel tooling.

The efficiency extends to project initiation. Honyo’s Online Instant Quote platform provides transparent, geometry-driven cost and lead time estimates within hours—not days—eliminating quoting delays that stall development cycles. Upload your CAD file, specify materials and volumes, and receive actionable data to validate manufacturability and budget early in the design phase. This seamless integration of rapid tooling expertise, technical molding capability, and digital accessibility empowers engineering teams to de-risk product launches, conduct validated market testing, and maintain agile supply chains for specialized components.

Transition from prototype to producible reality without compromise. Honyo Prototype delivers the speed, precision, and responsiveness small batch production demands.

Technical Capabilities

Small batch injection molding is a manufacturing process optimized for low to medium production volumes, typically ranging from 100 to 10,000 units. It leverages rapidly produced molds made from aluminum or steel to enable fast turnaround, with a T1 (first trial) sample achievable within 7 days when using optimized workflows and mold materials such as Aluminum. This approach is ideal for prototyping, pilot runs, and initial market testing.

Mold selection between aluminum and steel depends on required durability, part complexity, and production volume. Aluminum molds offer faster machining and lower cost, making them suitable for quick-turn applications under lower cycle counts. Steel molds provide extended tool life and are preferred for higher volume or more precise geometries.

Commonly processed thermoplastics include ABS and Nylon, selected for their mechanical properties, ease of processing, and broad applicability across industries.

Below are the technical specifications for small batch injection molding with a focus on rapid T1 delivery:

| Parameter | Specification |

|---|---|

| Mold Material | Aluminum (e.g., 7075-T6, 6061-T6), Steel (e.g., P20, H13, 420 Stainless) |

| Mold Life | Aluminum: 5,000–15,000 cycles; Steel: 50,000–100,000+ cycles |

| Lead Time for T1 Sample | 5–7 days (Aluminum molds typical); 10–14 days (Steel molds) |

| Production Volume | 100–10,000 units per batch |

| Surface Finish | As-machined, polished (SPI finishes up to SPI-A2), texture, or bead blast |

| Tolerances | ±0.05 mm (±0.002″) typical; tighter tolerances achievable with steel molds |

| Common Resins | ABS (acrylonitrile butadiene styrene), Nylon (PA6, PA66, glass-filled options) |

| Resin Drying Requirements | ABS: 80°C for 2–4 hrs; Nylon: 80–90°C for 4–6 hrs (critical for quality) |

| Mold Complexity | 2-plate or 3-plate designs, side actions, lifters, hot runners (optional) |

| Part Weight Range | 1–500 grams |

| Cycle Time Range | 20–60 seconds (depends on part geometry, material, and wall thickness) |

| Gate Types | Pin, edge, submarine, hot tip |

| Secondary Operations | De-gating, tumbling, annealing, UV coating, pad printing, assembly |

This specification enables rapid validation of part design and function, with Aluminum molds being the preferred choice when T1 delivery in 7 days is required. Steel molds are recommended when extended durability or higher surface precision is necessary. ABS and Nylon are well-suited for this process due to their favorable melt flow and mechanical performance.

From CAD to Part: The Process

Honyo Prototype Small Batch Injection Molding Process Overview

Honyo Prototype specializes in rapid, high-precision small batch injection molding for prototyping and low-volume production. Our streamlined workflow minimizes lead times while ensuring manufacturability and part quality. The process begins when a client uploads their part geometry and requirements through our secure customer portal.

CAD Upload and Initial Processing

Clients submit native or neutral CAD files (STEP, IGES, Parasolid, or native SOLIDWORKS) via our encrypted web portal. The system automatically validates file integrity, checks for common geometry errors (e.g., non-manifold edges, missing surfaces), and confirms material compatibility based on initial client specifications. This step ensures downstream processes operate on clean, production-ready data.

AI-Powered Instant Quoting

Uploaded CAD data feeds into our proprietary AI quoting engine, which analyzes part complexity, material selection, tolerances, and batch size (typically 1–5,000 units). The engine cross-references real-time data on material costs, machine availability, and historical production metrics to generate a detailed quote within 2 hours. Quotes include itemized costs for tooling (soft steel or pre-hardened), molding, secondary operations, and delivery. Crucially, the AI flags potential manufacturability risks before formal DFM review.

Engineer-Reviewed DFM Analysis

All projects undergo mandatory Design for Manufacturing (DFM) review by our in-house tooling and process engineers. Unlike automated-only services, Honyo combines AI-generated insights with human expertise to evaluate:

Wall thickness uniformity and rib design

Draft angles and undercuts requiring complex tooling

Gate location optimization for cosmetic and structural requirements

Material flow simulation to prevent weld lines or air traps

Engineers provide actionable feedback within 24 hours, often suggesting geometry tweaks that reduce cost by 15–30% without compromising function. Clients approve revisions digitally before tooling proceeds.

Production Execution

Approved designs move to tool fabrication using CNC machining or EDM, typically completed in 7–10 days for single-cavity molds. Production occurs on our electric injection molding presses (50–500 tons), monitored via IoT sensors for real-time pressure, temperature, and cycle time validation. Every batch includes:

First-article inspection with CMM reports (per AS9102 or client-specified standards)

In-process dimensional checks at 30-minute intervals

Material certification and lot traceability

Secondary operations (e.g., tapping, labeling, assembly) in our integrated cleanroom

Quality-Controlled Delivery

Finished parts undergo final visual and dimensional validation against the original CAD model. All shipments include:

Certificate of Conformance with batch-specific data

Material test reports (MTRs)

Packing list with serialized traceability

Real-time logistics tracking via our client portal

Standard lead time from CAD approval to delivery is 10–15 business days, with expedited options available. We maintain ISO 9001-certified processes throughout, ensuring consistency for batches as small as 50 units.

This integrated approach eliminates traditional quoting bottlenecks, reduces time-to-part by 40% versus conventional vendors, and provides full transparency from design through delivery—all optimized for the unique demands of low-volume, high-mix manufacturing.

Start Your Project

Looking for small batch injection molding solutions with fast turnaround and high precision? Honyo Prototype offers low-volume production ideal for prototyping, pilot runs, and bridge manufacturing. Our in-house factory in Shenzhen ensures tight quality control, cost efficiency, and rapid iteration.

Contact Susan Leo today to discuss your project requirements and get a competitive quote.

Email: [email protected]

Leverage our expertise in small batch manufacturing to accelerate your product development cycle.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.