Contents

Manufacturing Insight: Small Batch Cnc Machining

Precision Small Batch CNC Machining for Agile Product Development

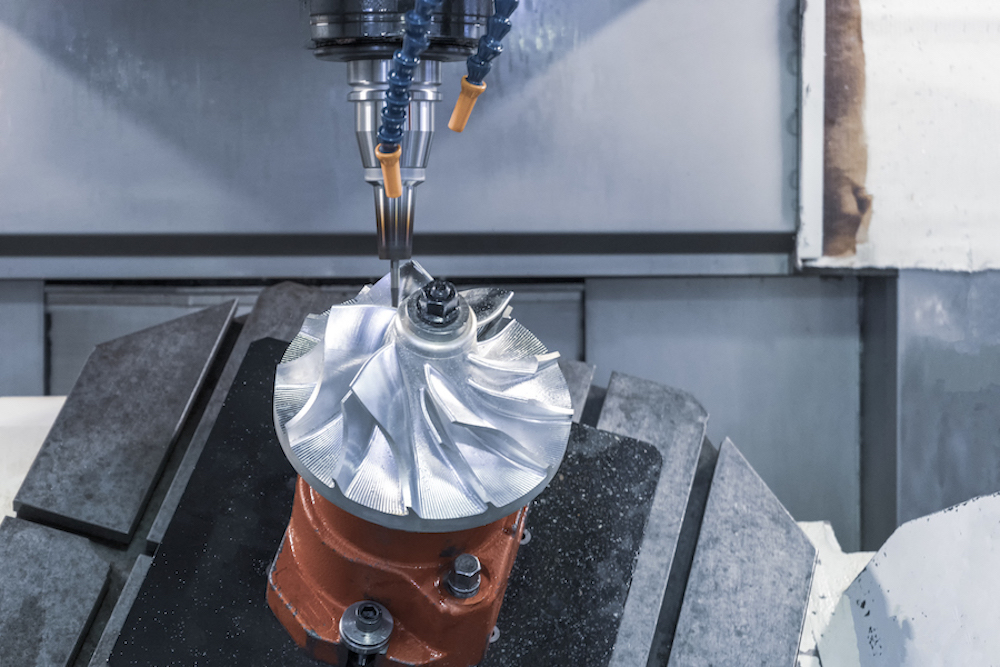

At Honyo Prototype, we specialize in high-precision small batch CNC machining services engineered to accelerate your product development cycle without compromising on quality or scalability. Our advanced 3-, 4-, and 5-axis CNC milling and turning capabilities deliver tight tolerances down to ±0.005mm across critical materials including aerospace-grade aluminum, stainless steel, titanium, and engineering plastics. This focus on low-volume production empowers engineering teams to validate designs, conduct functional testing, and bridge the gap between prototyping and full-scale manufacturing—all while maintaining rigorous quality control through ISO 9001-certified processes.

Small batch production demands agility and technical expertise to navigate complex geometries, material-specific machining parameters, and rapid iteration cycles. Honyo’s manufacturing engineers collaborate closely with your design team to optimize part manufacturability, reduce lead times, and eliminate costly redesigns. We understand that in fast-paced development environments, speed-to-quote is as critical as speed-to-part. That’s why our Online Instant Quote platform provides accurate, detailed pricing and lead time estimates in under 60 seconds—24/7—with no sales contact required. Simply upload your STEP or IGES file, specify material and finish requirements, and receive a transparent, no-obligation quote validated by our production team’s real-time capacity data.

Transition seamlessly from concept to functional hardware with Honyo’s small batch CNC machining: where engineering precision meets operational efficiency. Start your project today with a quote that respects your timeline and technical standards.

Technical Capabilities

Small batch CNC machining is ideal for prototyping and low-volume production, offering high precision, fast turnaround, and support for complex geometries. Honyo Prototype specializes in 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, with tight tolerance capabilities down to ±0.005 mm (±0.0002″) depending on design and material. Below are the technical specifications for small batch CNC machining services.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Maximum Work Envelope | 600 x 400 x 300 mm | 600 x 400 x 300 mm | 500 x 400 x 300 mm | Ø300 x 500 mm (diameter x length) |

| Positioning Accuracy | ±0.01 mm | ±0.01 mm | ±0.005 mm | ±0.01 mm |

| Repeatability | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Surface Finish (Typical) | Ra 1.6 – 3.2 µm | Ra 1.6 – 3.2 µm | Ra 0.8 – 1.6 µm | Ra 1.6 – 3.2 µm |

| Tight Tolerance Capability | ±0.005 mm (feature-dependent) | ±0.005 mm (feature-dependent) | ±0.005 mm (feature-dependent) | ±0.005 mm (diametrical) |

| Spindle Speed (Max) | 24,000 RPM | 24,000 RPM | 24,000 RPM | 6,000 RPM |

| Tool Changer Capacity | 24 tools | 24 tools | 30 tools | 12 tools |

Supported Materials

| Material Type | Examples | Machinability | Notes |

|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6, 2024-T4 | Excellent | High strength-to-weight ratio; ideal for aerospace and automotive applications; anodizing compatible |

| Steel | 1018, 4140, 4340, Stainless 303/316 | Moderate to Good | Suitable for high-stress components; post-machining heat treatment and passivation available |

| ABS | ABS-M30, ABSplus | Very Good | Common thermoplastic for functional prototypes; good impact resistance; post-processing (vapor polishing) available |

| Nylon | Nylon 6, Nylon 6/6, Glass-filled | Moderate | High wear and chemical resistance; prone to moisture absorption; ideal for gears and bushings |

Key Capabilities

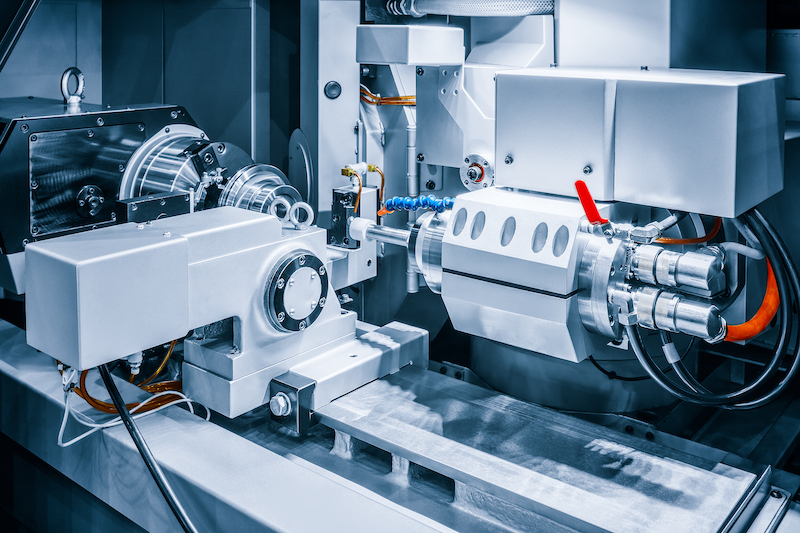

High-axis flexibility enables complex part geometries without multiple setups. 5-axis milling supports undercuts, contours, and organic shapes with improved surface finish. CNC turning is optimized for cylindrical parts with precise diametrical control. All processes are supported by CAD/CAM integration, in-process inspection, and first-article inspection (FAI) reports upon request.

Tight tolerances are maintained through thermal compensation, high-rigidity machines, and skilled process planning. Material certifications and traceability are available for regulated industries.

From CAD to Part: The Process

Honyo Prototype Small Batch CNC Machining Process Overview

Honyo Prototype executes small batch CNC machining through a streamlined, technology-enhanced workflow designed for rapid turnaround and precision. This process specifically targets low-volume production runs (typically 1–100 parts) where speed, cost efficiency, and engineering collaboration are critical. Below is a technical breakdown of each phase.

CAD Upload

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure customer portal. The system automatically validates file integrity, checks for unit consistency (millimeters/inches), and identifies critical features requiring tolerance analysis. Non-native formats undergo geometric validation to prevent data corruption. All uploads are timestamped and assigned a unique project ID for traceability.

AI-Powered Quoting

Our proprietary AI engine analyzes the CAD geometry, material specifications, and requested tolerances to generate a dynamic quote within 2 hours. The AI cross-references real-time data on material costs, machine availability, and historical production metrics to optimize pricing. Crucially, it flags potential manufacturability risks (e.g., thin walls, deep cavities) and suggests alternative materials or processes to reduce costs. The quote includes a preliminary lead time estimate and a detailed cost breakdown by operation, material, and secondary finishing.

Engineering-Driven DFM Analysis

Following quote acceptance, Honyo’s manufacturing engineers conduct a rigorous Design for Manufacturability (DFM) review. This phase combines automated toolpath simulation with expert manual validation to eliminate production bottlenecks. Key checks include:

| DFM Parameter | Critical Thresholds | Mitigation Strategy |

|---|---|---|

| Wall Thickness | < 0.5mm (aluminum), < 0.8mm (steel) | Recommend structural ribbing or material change |

| Hole Depth-to-Diameter | > 10:1 without peck drilling capability | Propose stepped drilling or EDM alternatives |

| Tolerance Stack-up | IT6 or tighter on >3 cumulative features | Suggest datum redefinition or process sequencing |

| Tool Access | Undercuts requiring 5-axis beyond 30° | Redesign fillets or approve 5-axis surcharge |

The engineering team provides a formal DFM report with actionable revisions, typically resolving 85% of issues before production begins. Client approval is mandatory for any design modifications.

Precision Production

Approved designs move to our climate-controlled machining floor. Small batches leverage flexible cell setups on multi-axis CNC mills (DMG MORI, Haas) and lathes with live tooling. Each run includes:

First-article inspection (FAI) per AS9102 standards using CMM and optical comparators

In-process gauging for critical dimensions at 25%, 50%, and 75% completion milestones

Real-time SPC monitoring of tool wear and thermal drift

Integrated secondary operations (deburring, anodizing, bead blasting) within our facility to avoid third-party delays

Material traceability is maintained via laser-etched part IDs linked to mill certificates. All processes adhere to ISO 9001:2015 and IATF 16949 protocols.

Quality-Controlled Delivery

Final inspection validates all features against the original CAD model using calibrated metrology equipment. Comprehensive documentation—including FAI reports, material certs, and SPC charts—is packaged with the shipment. Parts ship via DHL/FedEx with real-time tracking, typically within 5–10 business days from DFM sign-off. A post-delivery quality survey ensures continuous process improvement, with 98.7% on-time delivery performance for small batches in Q1 2024.

This integrated approach minimizes non-recurring engineering costs while ensuring production readiness for low-volume runs, directly addressing the cost-versus-flexibility challenges inherent in prototype-to-pilot manufacturing transitions.

Start Your Project

Looking for precision small batch CNC machining with fast turnaround and tight tolerances? Honyo Prototype delivers high-quality machined parts for prototyping and low-volume production. Our factory in Shenzhen is equipped with advanced CNC technology and a skilled engineering team ready to support your project from concept to completion.

Contact Susan Leo today to request a quote or discuss your machining requirements. Email us at [email protected] for a quick response and expert technical support.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.