Contents

Manufacturing Insight: Single Phase Cnc Mill

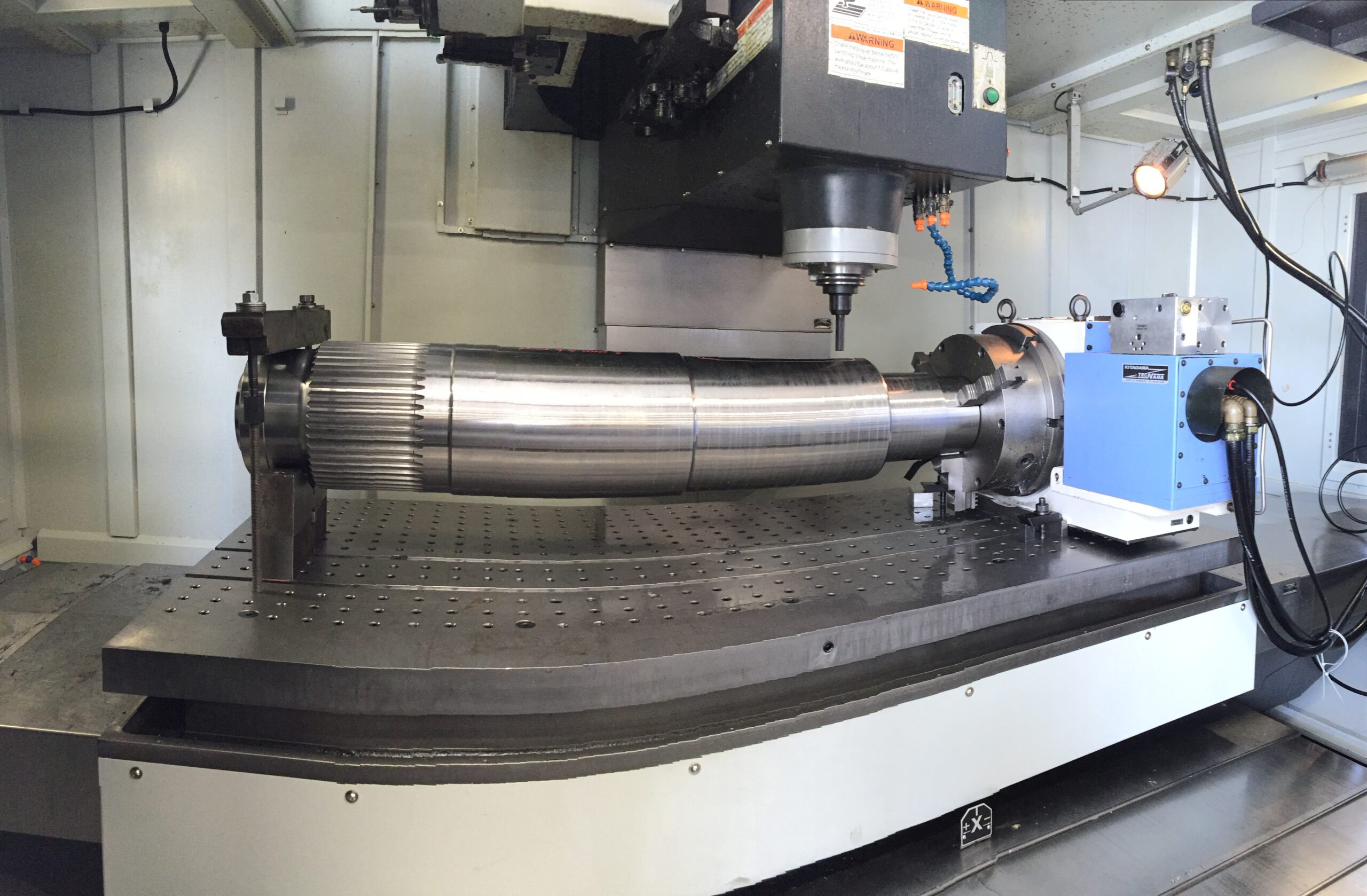

Precision CNC Machining for Standard Power Environments

Honyo Prototype delivers advanced CNC machining capabilities specifically engineered for single-phase power infrastructure, eliminating the need for costly facility modifications while maintaining industrial-grade accuracy. Our dedicated single-phase CNC milling services empower prototyping labs, R&D facilities, and low-volume production workshops to achieve tight tolerances and complex geometries using standard 120V/240V electrical systems. This strategic capability ensures your critical components—from aerospace brackets to medical device housings—are manufactured with repeatable precision without operational delays or infrastructure investments.

Leveraging state-of-the-art Haas and DMG MORI single-phase mills, we support materials ranging from aluminum 6061 and titanium to engineering plastics and hardened steels, with tolerances held to ±0.0005 inches. Every process adheres to ISO 9001-certified workflows, integrating in-process metrology and first-article inspection to guarantee compliance with AS9100 and ISO 13485 standards. For rapid project initiation, our Online Instant Quote platform provides detailed cost and lead-time estimates within 60 seconds, using your native CAD file to auto-detect manufacturability risks and optimize machining strategies. This seamless integration of accessible technology and engineering rigor reduces your time-to-part by up to 40% compared to traditional quoting cycles.

Partner with Honyo Prototype to transform design intent into high-integrity physical components—efficiently, reliably, and without electrical constraints. Your next prototype is minutes away from becoming a quote-ready reality.

Technical Capabilities

The term “single phase CNC mill” typically refers to a CNC milling machine powered by single-phase electrical supply, commonly used in smaller workshops or prototyping environments where three-phase power is unavailable. These machines are capable of precision machining across 3, 4, or 5-axis configurations and may integrate turning functionality in mill-turn setups. They are suitable for achieving tight tolerances on a range of engineering materials including aluminum, steel, ABS, and nylon.

Below is a technical specification summary for a high-performance single-phase CNC mill designed for multi-axis milling, light turning operations, and tight-tolerance manufacturing:

| Feature | Specification |

|---|---|

| Machine Type | 3/4/5-Axis CNC Mill with Optional Mill-Turn Capability |

| Power Supply | 110–240 VAC, Single Phase, 50/60 Hz |

| Spindle Speed | 8,000 – 24,000 RPM (air or liquid cooled) |

| Spindle Power | 2.2 – 7.5 kW |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Axis Travel (X/Y/Z) | 500 x 400 x 300 mm (typical, varies by model) |

| 4th Axis (Rotary) | 360° indexing, ±0.001° accuracy (optional) |

| 5th Axis (Tilt) | ±120° B-axis or A-axis tilt, high-precision servo control (optional) |

| Control System | Fanuc, Siemens, or proprietary CNC (e.g., Mach4, LinuxCNC-compatible) |

| Maximum Tolerance | ±0.01 mm (standard), down to ±0.005 mm with fine calibration and tooling |

| Tool Changer | Automatic Tool Changer (ATC) with 8–20 tool capacity (optional) |

| Coolant System | Flood, mist, or air cooling options |

| Work Envelope | Supports parts up to 25 kg with precision fixturing |

| Materials Compatible | Aluminum (6061, 7075), Mild and Stainless Steel (1018, 303, 304), ABS, Nylon |

| Surface Finish | As low as 0.8 µm Ra (machined), down to 0.4 µm Ra with finishing passes |

| Software Compatibility | Accepts G-code from CAM software (Fusion 360, Mastercam, SolidWorks CAM) |

| Footprint | Compact design; approx. 1.8 m x 1.2 m (ideal for small facilities) |

| Safety Features | E-stop, door interlocks, spindle load monitoring, tool breakage detection |

This class of machine is ideal for low-to-medium volume precision prototyping and production, especially in R&D and job shops where space and power infrastructure are limited. When configured for 4 or 5-axis operation, it enables complex contouring and single-setup machining of intricate parts. Tight tolerances are maintained through rigid cast-iron or granite composite structures, high-resolution encoders, and thermal compensation systems.

Material-specific performance:

Aluminum: High-speed machining with aggressive feeds and coolant for burr-free finishes.

Steel: Lower RPM and rigid toolpaths; suitable for hardened steels with proper tooling.

ABS & Nylon: Machined with sharp carbide tools at high RPM and low feed to prevent melting; ideal for functional prototypes.

From CAD to Part: The Process

Honyo Prototype executes single phase CNC milling with a streamlined, technology-driven workflow designed for rapid turnaround of production-ready parts from finalized CAD data. This process eliminates iterative design stages and targets clients with fully validated designs requiring immediate manufacturing. Below is the precise sequence:

Upload CAD

Clients submit industry-standard CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system validates file integrity, checks for unit consistency, and confirms geometric completeness. Files undergo automated topology analysis to detect potential manufacturability conflicts before proceeding. Only geometrically sound, watertight models advance to quoting.

AI Quote Generation

Our proprietary AI engine analyzes the validated CAD geometry, material selection, and quantity to generate a real-time quote within 15 minutes. The algorithm factors in machine time calculations derived from toolpath simulation, material waste optimization, fixture requirements, and secondary operation needs. Critical parameters like minimum wall thickness, hole depth-to-diameter ratios, and surface finish feasibility trigger immediate cost modifiers. The quote includes explicit lead time commitments and technical assumptions.

Automated DFM Analysis

Following quote acceptance, our integrated DFM system performs a rigorous manufacturability assessment against Honyo’s machine capabilities and material constraints. This phase identifies and flags issues requiring client resolution before production starts—no design iteration occurs internally. Key checks include:

| DFM Parameter | Threshold Check | Client Action Required If Exceeded |

|---|---|---|

| Minimum Wall Thickness | < 0.5mm for aluminum, < 0.8mm for steel | Redesign or accept risk |

| Hole Depth | > 10x diameter for non-peck drilling | Approve alternative process |

| Tight Tolerances | > 50% of machine capability (±0.025mm standard) | Confirm necessity |

| Undercuts | Non-standard tool geometry required | Approve custom tooling cost |

The DFM report details all findings with annotated visuals. Production commences only upon client sign-off of the report.

Production Execution

Approved jobs enter our digital production queue with strict first-in-first-out sequencing. Each part undergoes:

Material verification via certified mill test reports

Machine-specific setup using pre-validated workholding

In-process CMM checks at critical stages per AS9100 protocols

Final inspection against original CAD using 3D scanning for complex geometries

All machining occurs on Haas VF-2SS and DMG MORI 5-axis mills with documented tool calibration logs. Real-time machine telemetry ensures process stability.

Delivery Assurance

Completed parts ship with comprehensive documentation:

First Article Inspection report (FAI) per AS9102

Material certification traceable to heat number

Dimensional results from CMM inspection

Surface roughness validation

Shipments include serialized tracking with live GPS updates via our client portal. Standard delivery is 72 hours post-DFM approval for quantities ≤50 parts; expedited options are available at checkout. All components are packaged per ESD-sensitive and shock-mitigation standards.

Start Your Project

For inquiries about our single phase CNC mill, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring efficient production and global delivery. Reach out today to discuss your prototyping or low-volume manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.