Introduction: Navigating the Global Market for silver mirror acrylic sheet

In today’s competitive landscape, sourcing silver mirror acrylic sheets presents a unique challenge for international B2B buyers. These versatile materials, renowned for their lightweight, shatter-resistant properties, serve a plethora of applications across various industries. However, navigating the complexities of product specifications, supplier reliability, and cost-efficiency can be daunting, especially for businesses operating in diverse markets such as Africa, South America, the Middle East, and Europe, including regions like Vietnam and Germany.

This comprehensive guide aims to demystify the global market for silver mirror acrylic sheets by addressing critical aspects that influence purchasing decisions. From exploring the different types of acrylic mirrors available—such as various thicknesses and finishes—to understanding their practical applications in interior design, signage, and creative projects, this resource equips buyers with essential insights. Additionally, we will delve into strategies for vetting suppliers, ensuring quality control, and optimizing costs to maximize value.

By leveraging the information provided in this guide, B2B buyers can make informed decisions that enhance their procurement processes. Whether you are seeking custom sizes, specific finishes, or reliable shipping options, this guide empowers you to navigate the complexities of sourcing silver mirror acrylic sheets effectively, ensuring that your business remains competitive and responsive to market demands.

Understanding silver mirror acrylic sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Silver Mirror Acrylic | Single-sided mirror finish, available in various thicknesses | Interior decor, signage, display cases | Pros: Lightweight, shatter-resistant; Cons: Limited outdoor durability. |

| Double-Sided Silver Mirror Acrylic | Reflective surface on both sides, thicker for enhanced durability | Retail displays, artistic installations | Pros: Versatile use, enhanced aesthetics; Cons: Higher cost. |

| Colored Silver Mirror Acrylic | Available in various colors (e.g., rose gold, blue) | Creative projects, custom signage | Pros: Unique visual appeal; Cons: Color may fade over time. |

| Frosted Silver Mirror Acrylic | Semi-opaque finish that diffuses light | Privacy screens, decorative partitions | Pros: Provides privacy while maintaining light; Cons: Reduced reflectivity. |

| Impact-Resistant Silver Mirror Acrylic | Designed for high durability and impact resistance | High-traffic areas, safety applications | Pros: Enhanced safety features; Cons: Heavier and more expensive. |

What are the Characteristics of Standard Silver Mirror Acrylic Sheets?

Standard silver mirror acrylic sheets are characterized by their single-sided reflective finish, available in various thicknesses, typically ranging from 1/16″ to 1/8″. These sheets are lightweight and shatter-resistant, making them ideal for applications where safety is a concern, such as in homes and commercial spaces. B2B buyers should consider the indoor-only usage limitation, as exposure to outdoor elements may lead to deterioration over time.

How Does Double-Sided Silver Mirror Acrylic Benefit B2B Buyers?

Double-sided silver mirror acrylic sheets feature a reflective surface on both sides, providing enhanced durability and versatility. This type is thicker than standard sheets, making it suitable for retail displays and artistic installations where aesthetics are paramount. While the cost is higher, the value derived from its dual functionality can justify the investment for businesses looking to create stunning visual displays.

What Applications Utilize Colored Silver Mirror Acrylic Sheets?

Colored silver mirror acrylic sheets offer a variety of hues, such as rose gold and blue, allowing for creative flexibility in design. These sheets are perfect for custom signage and artistic projects where visual appeal is crucial. However, B2B buyers should be aware that the color may fade over time, especially in direct sunlight, which could impact the longevity of their investment.

What Advantages Do Frosted Silver Mirror Acrylic Sheets Provide?

Frosted silver mirror acrylic sheets possess a semi-opaque finish that diffuses light, making them ideal for privacy screens and decorative partitions. They provide an elegant solution for businesses needing to maintain privacy without sacrificing light. However, buyers should note that this type reduces reflectivity compared to standard options, which may not be suitable for all applications.

Why Choose Impact-Resistant Silver Mirror Acrylic Sheets?

Impact-resistant silver mirror acrylic sheets are designed to withstand high levels of stress and impact, making them ideal for high-traffic areas and safety applications. Their enhanced safety features are particularly beneficial for commercial spaces that prioritize durability. While these sheets tend to be heavier and more expensive, their long-term cost-effectiveness can be appealing to B2B buyers looking for reliable solutions.

Key Industrial Applications of silver mirror acrylic sheet

| Industry/Sector | Specific Application of silver mirror acrylic sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail and Display | Store fixtures and displays | Lightweight, shatter-resistant alternative to glass | Custom sizes and thickness options; UV resistance for outdoor displays |

| Interior Design and Architecture | Decorative wall panels and ceilings | Enhances aesthetics and creates a sense of space | Thickness and finish options; ease of installation |

| Automotive | Interior trim and dashboard elements | Durable, lightweight, and easy to mold | Compatibility with automotive standards; color matching requirements |

| Hospitality | Mirrors in hotels and restaurants | Cost-effective, easy to clean, and safe | Customization for size and shape; non-toxic materials for safety |

| Signage and Advertising | Promotional displays and signage | High reflectivity for eye-catching visibility | Custom printing options; weather resistance for outdoor applications |

How is silver mirror acrylic sheet used in the retail and display industry?

In retail environments, silver mirror acrylic sheets are extensively utilized for store fixtures and displays. Their lightweight and shatter-resistant properties make them ideal substitutes for traditional glass, reducing the risk of breakage and injury. Retailers benefit from the aesthetic appeal these sheets provide, enhancing product visibility and creating engaging displays. Buyers should consider custom sizes and thickness options, as well as UV resistance for outdoor displays, to ensure longevity and durability.

What role does silver mirror acrylic sheet play in interior design and architecture?

In the realm of interior design and architecture, silver mirror acrylic sheets serve as decorative wall panels and ceiling features. Their reflective surface not only enhances aesthetic appeal but also creates an illusion of spaciousness in smaller areas. Designers require various thickness and finish options to suit different projects, along with ease of installation to facilitate quick and efficient deployment in commercial spaces.

How is silver mirror acrylic sheet utilized in the automotive industry?

The automotive sector employs silver mirror acrylic sheets for interior trim and dashboard elements. Their durability and lightweight nature make them an excellent choice for enhancing vehicle aesthetics without compromising performance. When sourcing, buyers must ensure compatibility with automotive standards and may need to consider specific color matching requirements to align with brand identities.

What advantages does silver mirror acrylic sheet offer in the hospitality industry?

In hospitality settings, silver mirror acrylic sheets are commonly used for mirrors in hotels and restaurants. They provide a cost-effective solution that is easy to clean and maintain, contributing to a safe environment. Sourcing considerations include customization for size and shape to meet specific design needs, as well as ensuring non-toxic materials to guarantee guest safety.

How does silver mirror acrylic sheet benefit signage and advertising?

Silver mirror acrylic sheets are effective for promotional displays and signage due to their high reflectivity, which attracts attention and enhances visibility. Businesses benefit from eye-catching designs that can be customized for various marketing campaigns. When sourcing, it’s essential to explore custom printing options and consider weather resistance, especially for outdoor applications, to ensure the longevity of the signage.

3 Common User Pain Points for ‘silver mirror acrylic sheet’ & Their Solutions

Scenario 1: Sourcing Quality Materials at Competitive Prices

The Problem: B2B buyers often face the challenge of sourcing silver mirror acrylic sheets that meet their quality standards while also being competitively priced. With a multitude of suppliers in the market, it can be overwhelming to determine which vendors offer the best value without compromising on quality. Buyers may find themselves dealing with inconsistent product quality, leading to dissatisfaction among end customers and potential project delays.

The Solution: To effectively source high-quality silver mirror acrylic sheets at competitive prices, buyers should conduct thorough market research. Start by identifying reputable suppliers known for their product reliability and customer service. Look for suppliers who provide detailed product specifications, including thickness, finish, and tolerances. Request samples to assess the material’s quality firsthand before making bulk purchases. Additionally, consider leveraging online platforms and trade shows to compare prices and negotiate bulk discounts. Establishing long-term relationships with trusted suppliers can also lead to better pricing and priority service for future orders.

Scenario 2: Managing Customization Needs

The Problem: Many B2B buyers require customized dimensions and features for their silver mirror acrylic sheets to fit specific project requirements. However, navigating the customization process can be complicated, often leading to miscommunication regarding measurements and desired finishes. This can result in delays, increased costs, and frustration when the delivered products do not meet the exact specifications.

The Solution: To streamline the customization process, buyers should provide precise measurements and detailed specifications when placing orders. When dealing with custom cuts, always communicate in inches or millimeters and specify tolerances to avoid misunderstandings. It’s beneficial to use visual aids, such as diagrams or sketches, to illustrate the desired cuts and features. Engage with suppliers who offer robust customer support and are willing to assist in refining your specifications. Utilizing an online order form can also enhance accuracy, as it often includes fields for specific requests such as hole placements and edge treatments. Always confirm the order details before finalizing to ensure everything aligns with project needs.

Scenario 3: Ensuring Durability and Maintenance

The Problem: Buyers often struggle with the long-term durability and maintenance of silver mirror acrylic sheets, especially in environments where they may be exposed to chemicals or physical stress. Unlike glass, acrylic can be susceptible to scratches and damage from harsh cleaning agents, which can affect the appearance and functionality of the product over time.

The Solution: To ensure the longevity of silver mirror acrylic sheets, it’s crucial to educate buyers on proper care and maintenance practices. Advise them to use only mild, non-abrasive cleaners and soft cloths for cleaning to prevent scratching. Additionally, recommend that they conduct a suitability test with small pieces before using any cleaning agents on larger installations. For applications in high-traffic or outdoor environments, suggest opting for thicker sheets, as they tend to be more resilient. Buyers should also be informed about the importance of protecting the backing of the acrylic sheet from solvents and chemicals, which can degrade the reflective surface. Providing maintenance guidelines alongside the purchase can enhance customer satisfaction and encourage repeat business.

Strategic Material Selection Guide for silver mirror acrylic sheet

What Are the Key Materials for Silver Mirror Acrylic Sheets?

When selecting materials for silver mirror acrylic sheets, understanding the properties, advantages, and limitations of different types is crucial. Below, we analyze four common materials used in conjunction with silver mirror acrylic sheets, focusing on their performance, applications, and considerations for international B2B buyers.

How Do Different Types of Acrylic Affect Performance?

1. Extruded Acrylic

Key Properties: Extruded acrylic is known for its excellent clarity and impact resistance. It can withstand temperatures up to 70°C (158°F) and is less prone to shattering compared to glass.

Pros & Cons: This material is lightweight and easy to fabricate, making it suitable for a variety of applications. However, it is more susceptible to scratching and chemical damage compared to cast acrylic, which may limit its use in harsher environments.

Impact on Application: Extruded acrylic is ideal for indoor applications where aesthetics are essential, such as in retail displays or decorative panels. However, its lower resistance to chemicals means it may not be suitable for environments where exposure to solvents is common.

Considerations for International Buyers: Buyers should ensure compliance with local standards like ASTM and ISO for safety and performance. In regions like Europe, the REACH regulation may impact the selection of materials, necessitating awareness of chemical safety.

2. Cast Acrylic

Key Properties: Cast acrylic offers superior optical clarity and weather resistance, with a temperature tolerance of up to 90°C (194°F). It also has better scratch resistance compared to extruded acrylic.

Pros & Cons: While cast acrylic is more durable and offers a higher-quality finish, it is generally more expensive and can be more challenging to fabricate due to its rigidity.

Impact on Application: This material is well-suited for outdoor applications or areas with high foot traffic, such as signage and protective barriers. Its durability makes it a preferred choice for high-end projects.

Considerations for International Buyers: Buyers should consider the higher cost when budgeting for projects. Compliance with international standards, such as DIN in Germany, is also crucial for ensuring product quality.

3. Polycarbonate

Key Properties: Polycarbonate is a high-performance thermoplastic that is extremely impact-resistant, withstanding temperatures from -40°C to 120°C (-40°F to 248°F).

Pros & Cons: Its exceptional strength makes it ideal for safety applications, but it can be more expensive than acrylic and may yellow over time when exposed to UV light.

Impact on Application: Polycarbonate is often used in environments requiring high durability, such as safety shields and protective covers. Its ability to withstand extreme conditions makes it suitable for outdoor applications.

Considerations for International Buyers: Buyers must consider UV protection when selecting polycarbonate for outdoor use. Compliance with safety standards is essential, especially in regions with stringent regulations.

4. Glass

Key Properties: Traditional glass mirrors offer high clarity and scratch resistance, with a temperature tolerance of up to 300°C (572°F).

Pros & Cons: While glass provides a premium look and feel, it is heavy and prone to shattering, which can increase shipping costs and risk during installation.

Impact on Application: Glass is often preferred in luxury applications, such as high-end retail and interior design. However, its weight and fragility may limit its use in certain environments.

Considerations for International Buyers: Buyers should be aware of shipping regulations regarding glass products, especially in regions with high import tariffs. Compliance with local safety standards is also necessary to avoid liability issues.

Summary Table of Material Selection for Silver Mirror Acrylic Sheets

| Material | Typical Use Case for silver mirror acrylic sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Extruded Acrylic | Indoor decorative panels | Lightweight and easy to fabricate | Susceptible to scratching | Low |

| Cast Acrylic | Outdoor signage and high-traffic areas | Superior clarity and weather resistance | More expensive and harder to fabricate | Medium |

| Polycarbonate | Safety shields and protective covers | Extremely impact-resistant | Can yellow over time | High |

| Glass | High-end retail and luxury applications | Premium look and feel | Heavy and prone to shattering | Medium |

This strategic material selection guide provides valuable insights for B2B buyers looking to choose the right silver mirror acrylic sheet for their specific applications, ensuring compliance and suitability for diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for silver mirror acrylic sheet

What Are the Key Stages in the Manufacturing Process of Silver Mirror Acrylic Sheets?

The manufacturing of silver mirror acrylic sheets involves several critical stages that ensure the final product meets both aesthetic and functional requirements. The primary steps include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality extruded acrylic sheets. These sheets are often chosen for their clarity, lightweight properties, and shatter resistance compared to traditional glass. The acrylic is cut to the desired dimensions, with a focus on maintaining tight tolerances to ensure uniformity in the final product.

-

Forming Techniques: The acrylic sheets undergo a metal coating process, typically involving the application of a reflective silver layer on one side of the sheet. This is achieved through vacuum deposition or sputtering, where a thin layer of metal is deposited onto the acrylic surface. This technique not only enhances the reflective properties but also ensures durability.

-

Assembly: Once the reflective layer is applied, the sheets are often covered with a protective backing paint. This backing serves to protect the mirror surface from scratches and environmental factors. During this stage, customizations such as drilling holes or edge polishing may be applied based on client specifications.

-

Finishing Touches: The final step involves quality checks and surface finishing to ensure a glossy and flawless appearance. This may include additional polishing and cleaning processes to eliminate any imperfections that could affect the reflective quality of the acrylic.

How Is Quality Assurance Implemented in the Manufacturing of Silver Mirror Acrylic Sheets?

Quality assurance is a fundamental aspect of the production process for silver mirror acrylic sheets. Adhering to international standards and implementing rigorous quality control checkpoints ensures that the final product meets customer expectations.

-

Relevant International Standards: Manufacturers often comply with ISO 9001 standards, which set the criteria for a quality management system. This certification demonstrates a commitment to continuous improvement and customer satisfaction. Additionally, industry-specific certifications such as CE marking for safety or API standards may be relevant depending on the end-use applications of the acrylic sheets.

-

Quality Control Checkpoints: The quality control process typically involves several checkpoints, including:

– Incoming Quality Control (IQC): This stage assesses the raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During manufacturing, operators perform checks at various stages to monitor for defects or deviations from the production process.

– Final Quality Control (FQC): After assembly, the finished products are inspected for overall quality, including reflection quality, dimensional accuracy, and surface finish. -

Common Testing Methods: Various testing methods are employed to ensure product quality. These may include:

– Visual Inspection: Checking for surface defects or imperfections.

– Reflectivity Tests: Measuring the reflective quality to ensure it meets industry standards.

– Dimensional Checks: Using calipers or laser measurement tools to verify that dimensions fall within tolerance levels.

How Can B2B Buyers Verify the Quality Control Practices of Suppliers?

For B2B buyers, especially those operating in international markets such as Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are some actionable steps:

-

Conducting Audits: Buyers should consider conducting on-site audits of potential suppliers to evaluate their manufacturing processes and quality control systems. This firsthand assessment can provide insights into the supplier’s adherence to quality standards and overall operational efficiency.

-

Reviewing Quality Reports: Requesting quality control documentation, including test reports and certification records, can help verify a supplier’s commitment to quality. These documents should outline the testing methods used and the results obtained, providing transparency into the quality assurance process.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can further validate the quality of products before shipment. These independent inspectors can provide an unbiased assessment of the manufacturing process, ensuring that products meet specified quality standards.

What Are the Nuances of Quality Control for International B2B Buyers?

B2B buyers operating in different regions may encounter specific nuances related to quality control that they should be aware of:

-

Regional Regulations: Different countries may have varying regulations regarding product safety and quality. For instance, European buyers may require CE marking, while other regions may have their own standards. Understanding these requirements is crucial for compliance and market entry.

-

Communication Barriers: Language and cultural differences can pose challenges in ensuring quality standards are met. Establishing clear communication channels and documentation processes can help mitigate misunderstandings and ensure that both parties are aligned on quality expectations.

-

Supply Chain Considerations: The complexity of international supply chains can impact quality assurance. Factors such as transportation conditions, handling practices, and customs regulations may affect the final product. Buyers should work closely with suppliers to establish protocols that maintain quality throughout the supply chain.

-

Building Long-Term Relationships: Establishing long-term relationships with reliable suppliers can enhance quality assurance. Regular communication and feedback can help suppliers continuously improve their processes and better meet the evolving needs of B2B buyers.

In conclusion, understanding the manufacturing processes and quality assurance measures for silver mirror acrylic sheets is essential for B2B buyers. By focusing on these critical areas, buyers can ensure they source high-quality products that meet their specific requirements, ultimately leading to successful partnerships and business growth.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘silver mirror acrylic sheet’

When sourcing silver mirror acrylic sheets, a structured approach is essential for ensuring quality and suitability for your specific application. This guide provides a comprehensive checklist to help B2B buyers navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Begin by clearly outlining your technical requirements for the acrylic sheets. Consider factors such as thickness, size, and specific applications (e.g., decorative, safety, or functional uses).

– Thickness: Thicker sheets generally offer better reflection quality and durability.

– Size: Ensure that the dimensions meet your project needs or consider custom sizing options.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers who specialize in acrylic materials. Look for companies with a proven track record in the industry.

– Market Presence: Evaluate their experience in supplying silver mirror acrylic sheets and their geographical reach, especially in your target regions.

– Customer Reviews: Check online reviews and testimonials to gauge customer satisfaction and product quality.

Step 3: Evaluate Potential Suppliers

Before making a decision, it’s crucial to assess the shortlisted suppliers. Request detailed company profiles, including their manufacturing processes and quality control measures.

– Certifications: Verify any relevant certifications or industry standards they meet, such as ISO 9001.

– References: Ask for references from other businesses in similar industries to gain insights into their reliability.

Step 4: Request Samples for Quality Assessment

Before committing to a large order, request samples of the silver mirror acrylic sheets. This allows you to evaluate the quality and suitability of the product for your specific application.

– Reflection Quality: Examine the clarity and reflectiveness of the samples.

– Durability Tests: Assess how the material holds up against scratches and solvents, as the backing can be susceptible to damage.

Step 5: Confirm Customization Options

If your project requires specific modifications, such as custom cutting or hole drilling, confirm that the supplier can accommodate these needs.

– Customization Details: Inquire about their ability to provide edge polishing, rounded corners, or pre-drilled holes.

– Lead Times: Understand the lead times associated with custom orders, as this can impact your project timeline.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions about pricing structures, including bulk order discounts and payment terms.

– Transparent Pricing: Ensure that all costs are clearly outlined, including shipping and handling fees.

– Negotiation: Don’t hesitate to negotiate terms that align with your budget and payment processes.

Step 7: Finalize the Order and Confirm Delivery

Once you have selected a supplier and agreed on the terms, finalize the order. Ensure that you confirm the delivery schedule and any warranties or return policies.

– Documentation: Keep a record of all communications and agreements for reference.

– Quality Assurance: Specify any quality assurance checks upon delivery to ensure the received product meets your specifications.

By following these steps, you can streamline the sourcing process for silver mirror acrylic sheets, ensuring you choose a reliable supplier and high-quality materials tailored to your business needs.

Comprehensive Cost and Pricing Analysis for silver mirror acrylic sheet Sourcing

What Are the Key Cost Components in Sourcing Silver Mirror Acrylic Sheets?

When evaluating the cost structure for silver mirror acrylic sheets, several key components should be considered. These include:

-

Materials: The primary material for acrylic sheets is extruded acrylic resin, which can vary in quality and price. Silver mirror acrylic typically has a metallic coating applied, which influences the cost. Higher-quality coatings provide better reflectivity and durability, impacting the overall price.

-

Labor: Labor costs can fluctuate based on the manufacturing location. Skilled labor may be required for precision cutting, polishing, and finishing processes, especially for customized orders.

-

Manufacturing Overhead: This encompasses the costs associated with running manufacturing facilities, including utilities, equipment maintenance, and indirect labor. Efficient operations can help to keep these costs lower.

-

Tooling: For custom dimensions or specific designs, tooling costs may be incurred. This includes the expense of creating molds or specialized cutting tools.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes adds to the overall cost. This is critical, particularly for international buyers who may require certifications or specific quality standards.

-

Logistics: Shipping and handling costs can vary widely, especially for international shipments. Factors such as distance, shipping method, and packaging requirements will all influence logistics costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit, which can vary based on market conditions and competition.

How Do Price Influencers Affect Silver Mirror Acrylic Sheet Pricing?

Several factors can influence the pricing of silver mirror acrylic sheets, particularly for B2B transactions:

-

Volume/MOQ: Suppliers often provide better pricing for larger orders or minimum order quantities (MOQs). Bulk purchases can lead to significant cost savings.

-

Specifications/Customization: Custom sizes, thicknesses, or additional features (like edge polishing or hole drilling) can increase the price. It’s essential to communicate specific requirements early in the sourcing process.

-

Materials and Quality: The type of acrylic and the quality of the mirror finish can significantly impact cost. High-quality materials that offer better performance and longevity will generally command higher prices.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers may offer better service and quality assurance, potentially justifying higher costs.

-

Incoterms: The chosen Incoterms (International Commercial Terms) will dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting overall pricing.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Don’t hesitate to negotiate prices, especially for bulk orders. Suppliers may have room for flexibility, particularly if they see a long-term partnership potential.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also logistics, potential tariffs, and the expected lifespan of the product. A lower upfront cost may not always mean better value if the quality is inferior.

-

Understanding Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, labor costs, and material availability. Being aware of these nuances can help in making informed purchasing decisions.

-

Supplier Evaluation: Take the time to assess potential suppliers thoroughly. Look for those with a solid track record of quality and service, as this can save costs related to returns or replacements down the line.

Disclaimer on Indicative Prices

Prices for silver mirror acrylic sheets can fluctuate based on market conditions, supplier pricing strategies, and raw material costs. The figures provided in this analysis are indicative and should be verified with suppliers for the most accurate and current pricing.

Alternatives Analysis: Comparing silver mirror acrylic sheet With Other Solutions

Exploring Alternatives to Silver Mirror Acrylic Sheets

When considering materials for reflective surfaces, it’s essential to evaluate alternatives to silver mirror acrylic sheets that may offer varying benefits and drawbacks. This analysis will highlight two viable alternatives: traditional glass mirrors and polished stainless steel sheets. Each option presents unique characteristics that can influence a buyer’s decision based on specific application needs.

| Comparison Aspect | Silver Mirror Acrylic Sheet | Traditional Glass Mirror | Polished Stainless Steel Sheet |

|---|---|---|---|

| Performance | High reflectivity, lightweight, shatter-resistant | Excellent reflectivity, heavy, fragile | Durable, resistant to corrosion, offers a unique aesthetic |

| Cost | Generally lower cost (approx. $4.73/sq ft) | Higher cost (approx. $10-$20/sq ft) | Mid-range cost (approx. $5-$15/sq ft) |

| Ease of Implementation | Easy to cut and fabricate, ideal for custom sizes | Requires specialized cutting tools, heavier to handle | Requires machining tools, challenging for intricate designs |

| Maintenance | Susceptible to chemical damage, easy to clean | Requires careful handling to avoid breakage, easy to clean | Highly durable and easy to maintain, resistant to damage |

| Best Use Case | Indoor applications, decorative projects, safety mirrors | High-end applications, furniture, bathrooms | Industrial environments, modern design aesthetics |

What Are the Pros and Cons of Traditional Glass Mirrors?

Traditional glass mirrors are renowned for their superior reflectivity and clarity, making them a preferred choice for high-end applications. Their aesthetic appeal is unmatched, often used in luxury settings like hotels and upscale retail stores. However, the fragility of glass makes it a less practical option for environments where impacts are likely, such as in schools or public spaces. Additionally, the cost of glass mirrors is generally higher, and they can be cumbersome to install due to their weight.

How Does Polished Stainless Steel Compare?

Polished stainless steel sheets are another alternative that offers a unique reflective quality with a modern aesthetic. They are exceptionally durable and resistant to corrosion, making them suitable for industrial environments or outdoor applications. The polished finish provides a sleek look; however, they do not achieve the same level of reflectivity as acrylic or glass mirrors. Furthermore, the installation process can be more complex, requiring specialized tools and techniques for cutting and shaping.

Conclusion: Which Solution is Right for Your Business?

Selecting the appropriate reflective material hinges on your specific application needs, budget constraints, and desired aesthetics. For projects requiring lightweight and versatile solutions, silver mirror acrylic sheets present an attractive option. If premium quality and clarity are paramount, traditional glass mirrors may be worth the investment despite their fragility. Conversely, if durability and a modern look are required, polished stainless steel sheets could be the ideal choice. By weighing these factors, B2B buyers can make informed decisions that align with their operational requirements and market demands.

Essential Technical Properties and Trade Terminology for silver mirror acrylic sheet

What Are the Key Technical Properties of Silver Mirror Acrylic Sheets?

1. Material Grade

Silver mirror acrylic sheets are typically made from extruded acrylic, which is lighter and more shatter-resistant than glass. This material is crucial for applications requiring durability and safety, such as in high-traffic areas or environments with potential impact risks. For B2B buyers, understanding material grade ensures they select products that meet safety and performance standards for their specific applications.

2. Thickness

The thickness of silver mirror acrylic sheets can vary, commonly available in 1/16″ to 1/8″. Thickness impacts both the weight and the reflectivity of the sheet; thicker sheets generally provide a better reflection and are more robust. For businesses, selecting the correct thickness is vital to balance aesthetic appeal with functional requirements, especially in design and architectural projects.

3. Tolerance Levels

Tolerance refers to the permissible limit of variation in dimensions. For silver mirror acrylic sheets, standard tolerances are +/- 1/8″ for pre-cut sizes and +/- 1/32″ for custom cuts. Understanding these tolerances is essential for manufacturers and fabricators who require precise dimensions for seamless integration into their products, ensuring consistent quality and performance.

4. Surface Finish

A glossy surface finish is typical for silver mirror acrylic sheets, providing a reflective quality similar to glass mirrors. This finish not only enhances aesthetic appeal but also influences light transmission and durability. B2B buyers should consider the surface finish when selecting materials for projects, as it affects both appearance and functionality in applications such as retail displays and interior design.

5. Opacity

Silver mirror acrylic sheets are opaque, offering a complete reflection without transparency. This property is crucial for applications where privacy or light control is required. For businesses, choosing the right level of opacity ensures that the product meets specific design and functional needs.

Which Trade Terminology Should B2B Buyers Understand When Purchasing Silver Mirror Acrylic Sheets?

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. For B2B buyers, understanding OEM relationships is essential when sourcing silver mirror acrylic sheets, as it can indicate quality assurance and reliability in supply chains.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Knowing the MOQ helps businesses plan their inventory and budget effectively, ensuring they meet production needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products. B2B buyers should utilize RFQs to compare costs and negotiate terms with various suppliers, ensuring they receive competitive pricing for silver mirror acrylic sheets.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers, as they clarify shipping costs, risks, and delivery responsibilities, which can significantly affect overall procurement strategy.

5. Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times is critical for B2B buyers to ensure that production schedules align with project timelines, preventing delays in project execution.

By comprehending these technical properties and trade terms, B2B buyers can make informed decisions regarding silver mirror acrylic sheets, ensuring optimal selection for their specific applications and efficient procurement processes.

Navigating Market Dynamics and Sourcing Trends in the silver mirror acrylic sheet Sector

What Are the Current Market Dynamics and Key Trends Influencing the Silver Mirror Acrylic Sheet Sector?

The global market for silver mirror acrylic sheets is experiencing robust growth, driven by several key factors. Firstly, the increasing demand for lightweight and shatter-resistant materials in various industries, including construction, automotive, and interior design, is propelling the adoption of acrylic sheets over traditional glass. B2B buyers are particularly attracted to the versatility of silver mirror acrylic sheets, which can be easily fabricated and customized to meet specific project requirements.

Emerging technologies such as advanced laser cutting and CNC machining are enhancing the capabilities of manufacturers, allowing for more intricate designs and faster production times. This trend is particularly significant for international buyers from regions like Africa and South America, where rapid urbanization is driving the need for innovative building materials. Additionally, the rise of e-commerce platforms has simplified the sourcing process, enabling businesses to procure customized sheets from global suppliers with ease.

Another noteworthy trend is the growing popularity of decorative applications in retail and hospitality sectors. Silver mirror acrylic sheets are increasingly used in signage, displays, and interior decor, providing aesthetic value alongside functionality. As sustainability becomes a focal point in procurement strategies, the demand for eco-friendly options within this sector is anticipated to rise, prompting suppliers to explore greener manufacturing processes.

How Is Sustainability and Ethical Sourcing Shaping the Silver Mirror Acrylic Sheet Market?

Sustainability and ethical sourcing are becoming integral to procurement decisions in the silver mirror acrylic sheet sector. The environmental impact of production processes, including the use of non-renewable resources and potential waste generation, is under scrutiny from both consumers and regulatory bodies. Buyers are increasingly prioritizing suppliers who adopt sustainable practices, such as utilizing recycled materials and implementing waste reduction strategies.

Certifications such as ISO 14001, which focus on effective environmental management systems, are gaining traction among manufacturers. These certifications not only provide assurance of compliance with environmental standards but also enhance a supplier’s reputation in the marketplace. For B2B buyers, partnering with certified suppliers can mitigate risks associated with environmental liabilities and enhance corporate social responsibility initiatives.

Moreover, the shift towards ‘green’ materials is prompting innovations in the acrylic manufacturing process. Suppliers are exploring bio-based alternatives and low-impact production methods to create silver mirror acrylic sheets that align with eco-friendly objectives. Buyers can leverage these developments to enhance their product offerings and meet the growing consumer demand for sustainable solutions in various applications, from home decor to commercial installations.

What Is the Evolution of Silver Mirror Acrylic Sheets in the B2B Landscape?

The evolution of silver mirror acrylic sheets has transformed their role in the B2B landscape significantly. Initially developed as a lightweight alternative to glass, these sheets gained popularity due to their versatility and ease of use. Over the years, advancements in manufacturing techniques have improved the quality and durability of acrylic mirrors, making them suitable for a wider range of applications.

In the early stages, the primary applications were limited to decorative uses, but the market has expanded to include functional uses in industries such as automotive and aerospace, where weight and safety are paramount. As technology has advanced, the ability to customize these sheets has opened new avenues for design, allowing businesses to incorporate unique finishes and shapes tailored to their specific needs.

Today, the market is characterized by increasing customization options, enhanced sustainability practices, and a focus on innovation, positioning silver mirror acrylic sheets as a key player in the broader landscape of materials used across various industries. For B2B buyers, understanding this evolution is crucial for making informed sourcing decisions that align with both current market demands and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of silver mirror acrylic sheet

-

How do I ensure the quality of silver mirror acrylic sheets when sourcing from international suppliers?

To ensure quality, request samples before committing to larger orders. Conduct thorough research on potential suppliers, including checking their certifications and customer reviews. Utilize third-party inspection services to assess product quality before shipment. Additionally, consider suppliers with a solid return policy and warranty, which indicates confidence in their product quality. -

What is the best thickness for silver mirror acrylic sheets for durability and reflection quality?

A thickness of 1/8 inch (approximately 3mm) is generally recommended for optimal durability and reflection quality in silver mirror acrylic sheets. Thicker sheets tend to provide better reflection and are less prone to warping or damage. For applications requiring enhanced strength, consider even thicker options, but balance this with the weight and application requirements. -

What customization options are available for silver mirror acrylic sheets?

Most suppliers offer various customization options such as cutting to specific dimensions, edge finishing, and hole drilling. You can also request custom colors or coatings depending on the supplier’s capabilities. Ensure to communicate your specific needs clearly, providing detailed measurements and any drawings necessary to avoid misunderstandings. -

What are the typical minimum order quantities (MOQs) for silver mirror acrylic sheets?

Minimum order quantities can vary significantly between suppliers, typically ranging from 10 to 100 sheets. Some suppliers may accommodate smaller orders, particularly for custom sizes, while others may have higher thresholds. Always verify MOQs during initial discussions to align your purchasing strategy with supplier capabilities. -

What payment terms should I expect when purchasing silver mirror acrylic sheets internationally?

Payment terms often depend on the supplier’s policies, but common arrangements include a 30% deposit upon order confirmation and the remaining balance before shipment. Some suppliers may offer net payment terms, such as 30 or 60 days after delivery. Discuss payment options upfront to ensure clarity and agreement on terms. -

How can I manage logistics for importing silver mirror acrylic sheets from overseas?

To manage logistics effectively, partner with a reliable freight forwarder experienced in handling acrylic materials. They can assist with customs clearance, shipping methods, and compliance with international regulations. Additionally, consider using Incoterms (e.g., FOB, CIF) to clarify responsibilities for shipping costs and risks. -

What should I consider regarding the packaging of silver mirror acrylic sheets for international shipping?

Proper packaging is crucial to prevent damage during transit. Ensure that the supplier uses protective materials like bubble wrap, corner protectors, and sturdy boxes. Verify that the packaging is suitable for the specific climate and handling conditions of the destination country. Request details on their packaging methods to ensure they meet your standards. -

Are there any specific regulations I need to be aware of when importing silver mirror acrylic sheets into my country?

Regulations can vary widely by country, so it’s essential to research import laws specific to acrylic materials. This may include safety standards, labeling requirements, and import duties. Consulting with a customs broker or legal expert familiar with import regulations can help ensure compliance and avoid potential delays or fines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Silver Mirror Acrylic Sheet Manufacturers & Suppliers List

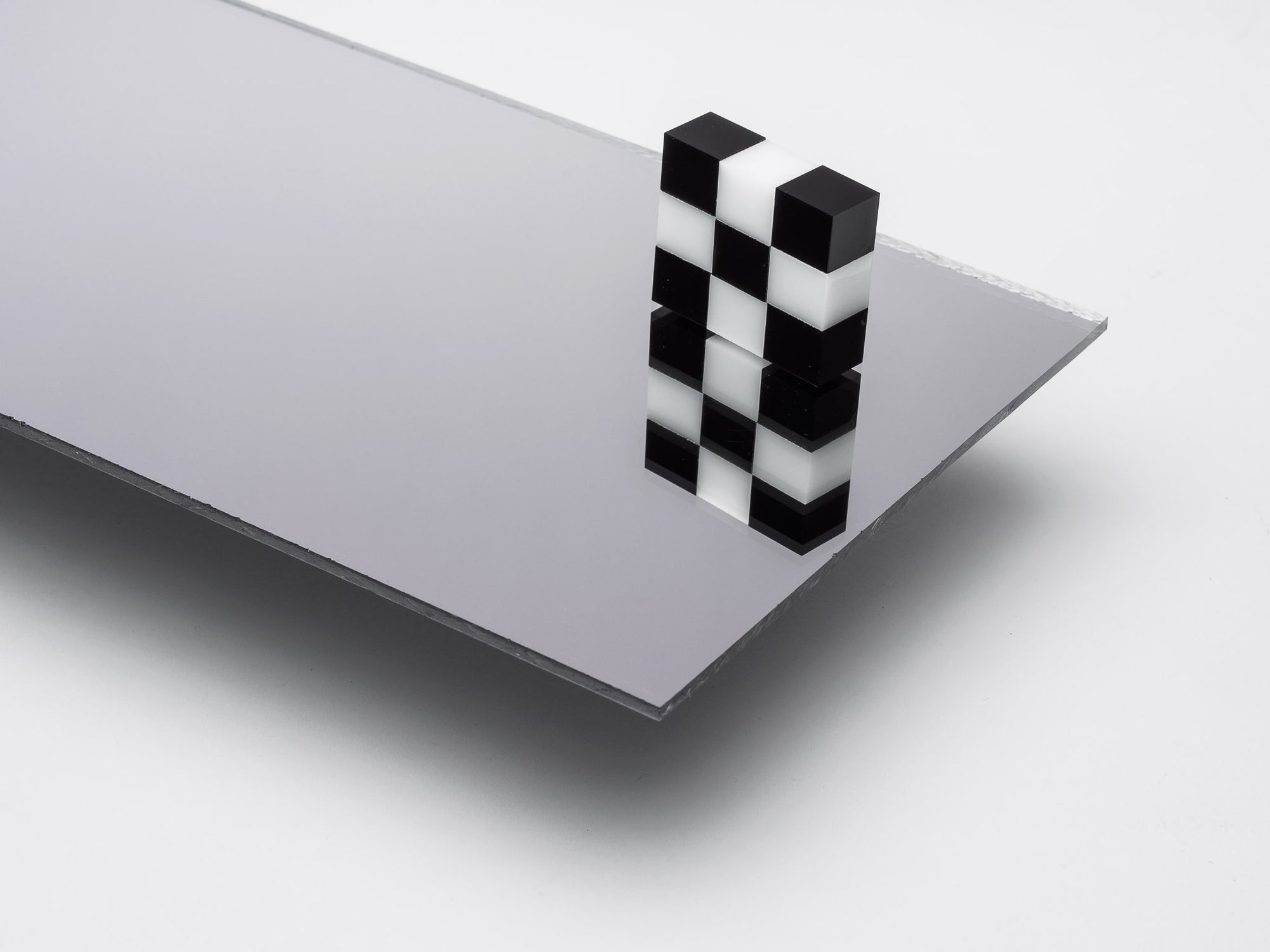

1. Canal Plastic – Silver Mirror Acrylic Sheet

Domain: canalplastic.com

Registered: 2004 (21 years)

Introduction: {“product_name”: “Silver Mirror Acrylic Sheet”, “price”: “$4.73”, “dimensions”: [“6″ x 12″”, “12” x 12″”, “12” x 18″”, “12” x 24″”, “18” x 24″”, “18” x 32″”, “24” x 24″”, “24” x 36″”, “24” x 48″”, “2” x 2″”, “Sample”, “48” x 96″ (Full Sheet)”], “thickness_options”: [“1/16″ (0.060″ / 1.5mm)”, “1/8″ (0.118″ / 3.0mm)”, “1/4″ (0.220″ / 5.6mm)”], “tolerances”: “Pre-cut dimension tolerances are +/- 1/8″…

2. Houston Acrylic – Mirror Acrylic Collection

Domain: houstonacrylic.com

Registered: 2020 (5 years)

Introduction: Collection: Mirror Acrylic

Available Thicknesses: 1/16″, 1/8″

Available Sizes: 9″x12″, 12″x19″, 18″x24″, 24″x35″

Product Variants:

– 1/8″ Pale Gold Mirror Acrylic Sheet

– 1/8″ Yellow Gold Mirror Acrylic Sheet

– 1/8″ Clear (Silver) Mirror Acrylic

– 1/8″ Rose Gold Mirror Acrylic

– 1/8″ Pink Mirror Acrylic

– 1/8″ Red Mirror Acrylic Sheet

– 1/8″ Green Mirror Acrylic Sheet

– 1/8″ Purple Mirror Acrylic …

3. TT Plastic Land – Silver Mirror Acrylic Sheet

Domain: ttplasticland.com

Registered: 2004 (21 years)

Introduction: Product Name: Silver Mirror Acrylic Sheet

Price: $4.75

Shipping: Calculated at checkout

Key Features:

– Sleek Radiance: Modern and sophisticated appearance.

– Contemporary Silver Tint: Versatile and chic.

– Alternative to Glass Mirrors: Lightweight, shatterproof, and customizable.

Usage and Applications:

– Pop Displays: Attention-grabbing displays.

– Event Decor: Adds drama to events.

– Pedestal…

4. Display Wholesale – Cast Silver Mirror Acrylic Sheet

Domain: display-wholesale.com

Registered: 2008 (17 years)

Introduction: Cast Silver Mirror Acrylic 4′ x 8′ x 6.0 mm (1/4″)\nPrice: $220.00\nShipping: Free UPS Ground Same Day Shipping for orders over $100 to Lower 48 US States. Local pick-up or delivery available within 50 miles of California office.\nFeatures: \n- Cast Acrylic 4′ x 8′ Sheets\n- Optical Characteristic: Low Internal Stress Level\n- Superior Quality\n- Light Stability\n- Lightweight compared to glass\nC…

5. Custom Made Better – Mirror Acrylic Sheets Collection

Domain: custommadebetter.com

Registered: 2020 (5 years)

Introduction: Mirror Acrylic Sheets Collection includes various colors and thicknesses. Thickness options: 1/8″, 1/16″, 1/4″, 1/32″. Color options include: Clear, Glacier Blue, Silver, Pale Gold, Brown, Lime, Copper, Blush, Aqua, Bright Red, Green, Blue, Pink, Emerald Green, Turquoise, and Steel Blue. Prices range from $1.49 to $19.95 depending on the size and color.

6. Acme Plastics – Glowforge®-Compatible Silver Mirror Acrylic Sheets

Domain: acmeplastics.com

Registered: 1997 (28 years)

Introduction: Glowforge®-Compatible 12″ x 19″ x 1/8″ Silver Mirror Acrylic Sheets – 5 Pack

7. Inventables – Silver Mirrored Acrylic Sheet

Domain: inventables.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “Silver Mirrored Acrylic Sheet”, “regular_price”: “$21.60 USD”, “product_variants”: [{“size”: “12 in × 24 in”, “thickness”: “1/8 in”, “price”: “$21.60 USD”, “availability”: “Sold out”}, {“size”: “18 in × 24 in”, “thickness”: “1/8 in”, “price”: “$33.91 USD”, “availability”: “Sold out”}, {“size”: “8 in × 12 in”, “thickness”: “1/8 in”, “price”: “$6.24 USD”, “availability”: “Sold out”…

8. Americana Acrylics – Silver Mirror Acrylic Sheet

Domain: americanacrylics.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “Silver Mirror Acrylic Sheet”, “price_range”: “$0.00 – $193.60”, “features”: [“Great for laser cutting”, “Bright mirror finish”, “Budget-friendly”, “Non-toxic”, “Environmentally friendly”, “Consistent thickness”], “sizes_available”: [“4×4”, “5×7”, “6×9”, “6×12”, “8×10”, “8×12”, “8.5×11”, “9×12”, “11×17”, “12×12”, “12×18”, “12×20”, “12×24”, “18×24”, “20×28”, “24×24”, “24×36”, “48×9…

Strategic Sourcing Conclusion and Outlook for silver mirror acrylic sheet

In today’s competitive market, leveraging silver mirror acrylic sheets as a versatile solution can significantly enhance product offerings across various industries. These sheets not only provide a lightweight and shatter-resistant alternative to glass but also offer customization options that cater to specific application needs. For B2B buyers, understanding the intricacies of sourcing these materials—such as thickness, cutting tolerances, and protective measures—is vital to ensure optimal performance and longevity.

Strategic sourcing is essential for maximizing value, reducing costs, and fostering strong supplier relationships. Buyers should prioritize suppliers who offer transparent pricing, customization capabilities, and robust customer support to streamline their procurement processes. Additionally, considering factors like regional availability and shipping logistics will facilitate timely project execution, particularly for international buyers from Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for innovative and aesthetically pleasing materials like silver mirror acrylic sheets is expected to grow. Now is the time to explore new partnerships and invest in high-quality products that meet evolving market needs. Engage with trusted suppliers today to secure your competitive edge in this dynamic landscape.