Contents

Manufacturing Insight: Sheet Metal Snap-Fit

Integrating Sheet Metal Snap-Fits for Accelerated Assembly and Cost Efficiency

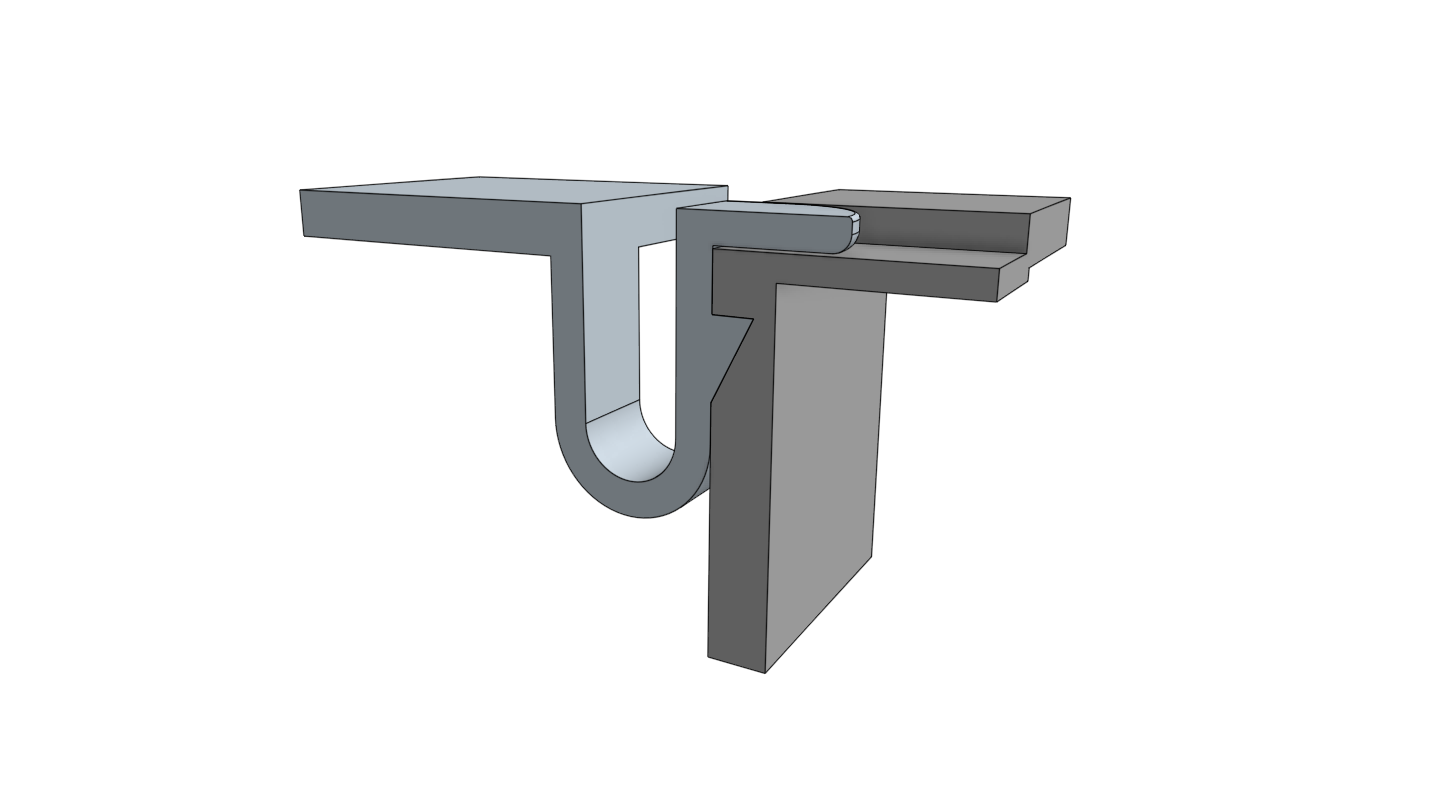

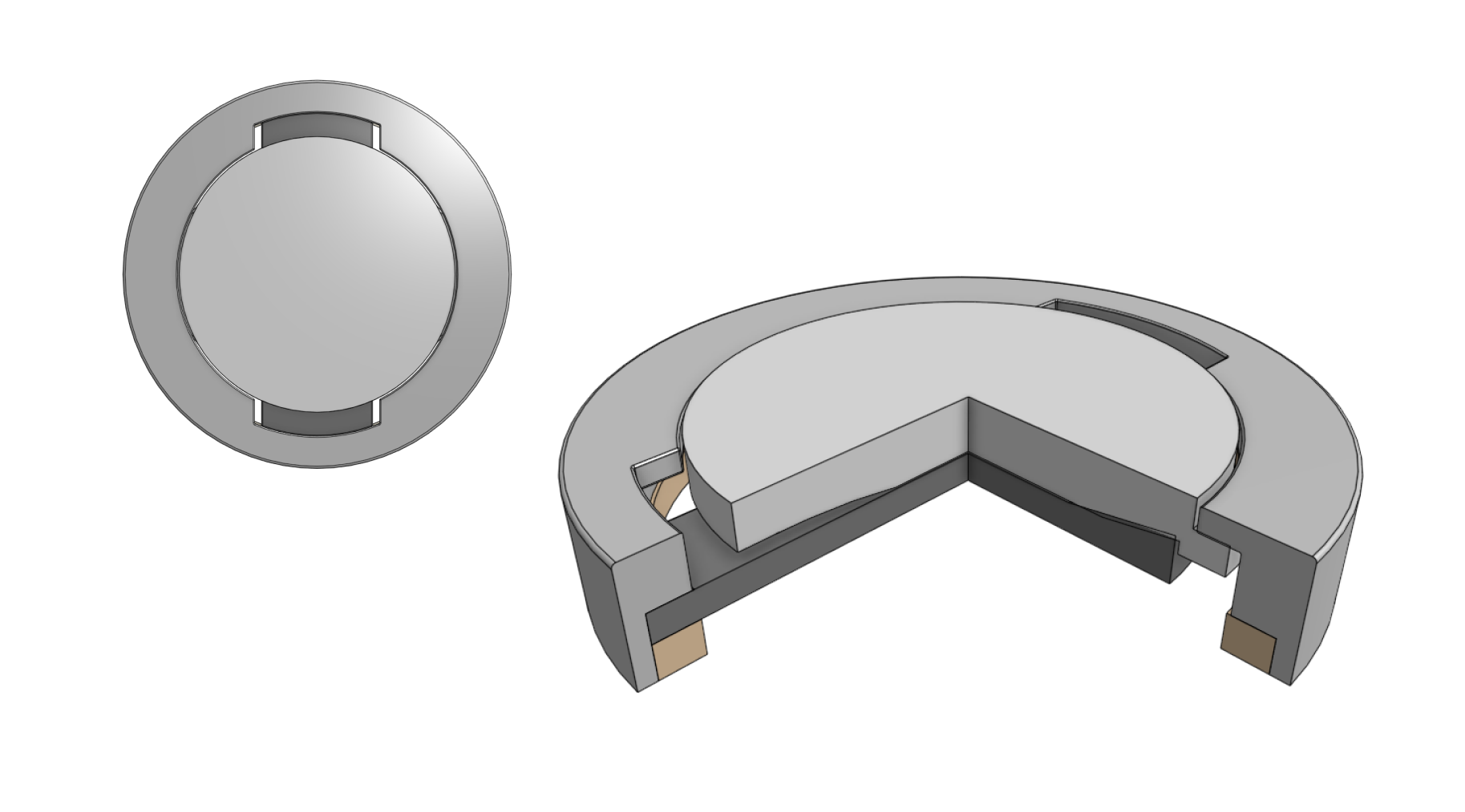

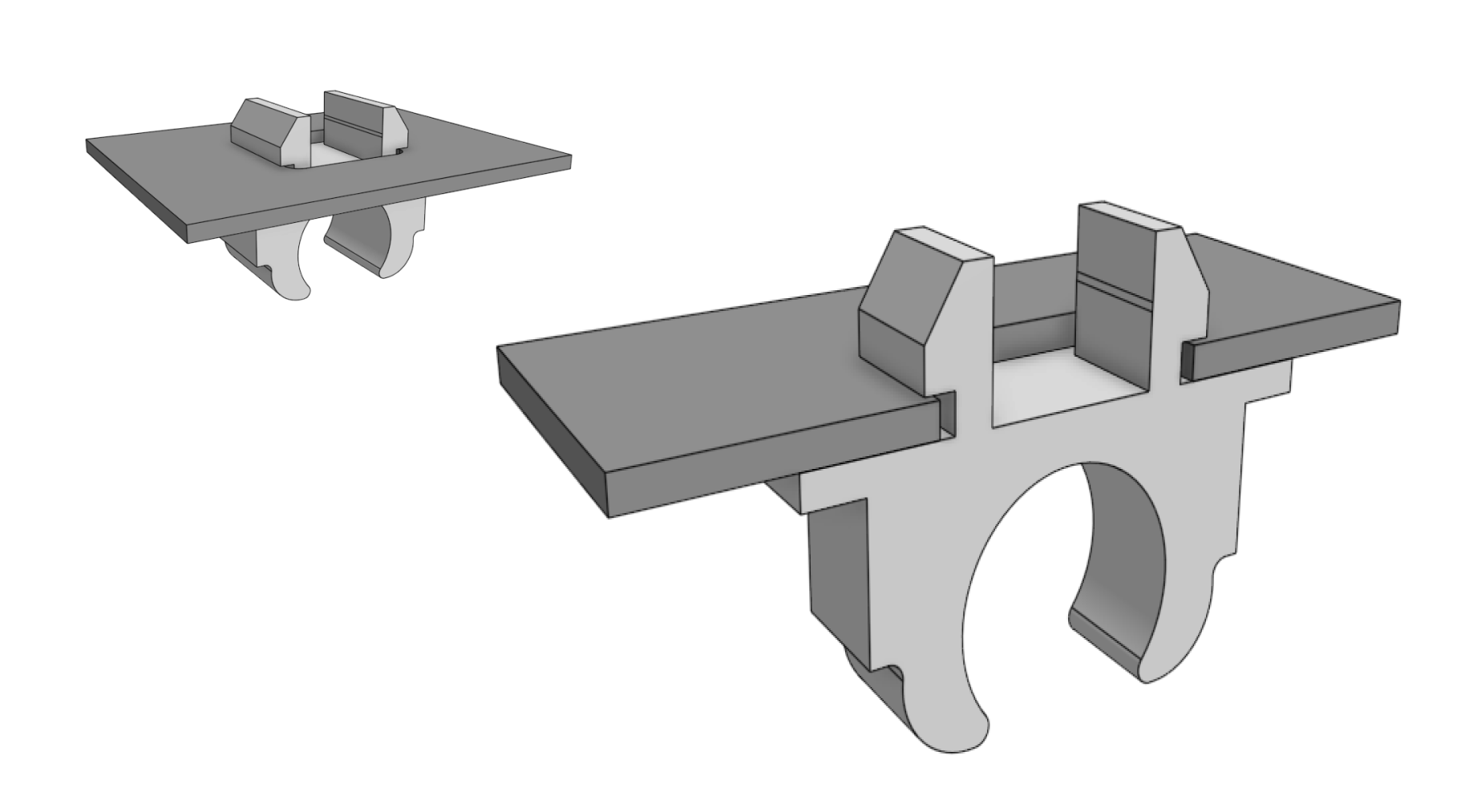

Sheet metal snap-fit joints represent a sophisticated design solution for eliminating secondary fasteners, reducing assembly time, and lowering overall part count in enclosures and structural assemblies. Achieving reliable, repeatable snap-fit functionality in sheet metal demands exceptional precision in bending, tight control over material springback, and deep understanding of geometric tolerancing relative to the chosen alloy and thickness. At Honyo Prototype, our Sheet Metal Fabrication services are engineered specifically to meet these demanding requirements. We leverage advanced CNC press brakes with real-time feedback systems, rigorous in-process inspection protocols, and material-specific forming expertise to consistently deliver snap-fit features that function as intended on the first assembly attempt. This capability transforms complex multi-part assemblies into streamlined, robust constructions, directly supporting your goals for faster time-to-market and reduced manufacturing costs.

Honyo’s Precision-Driven Snap-Fit Integration

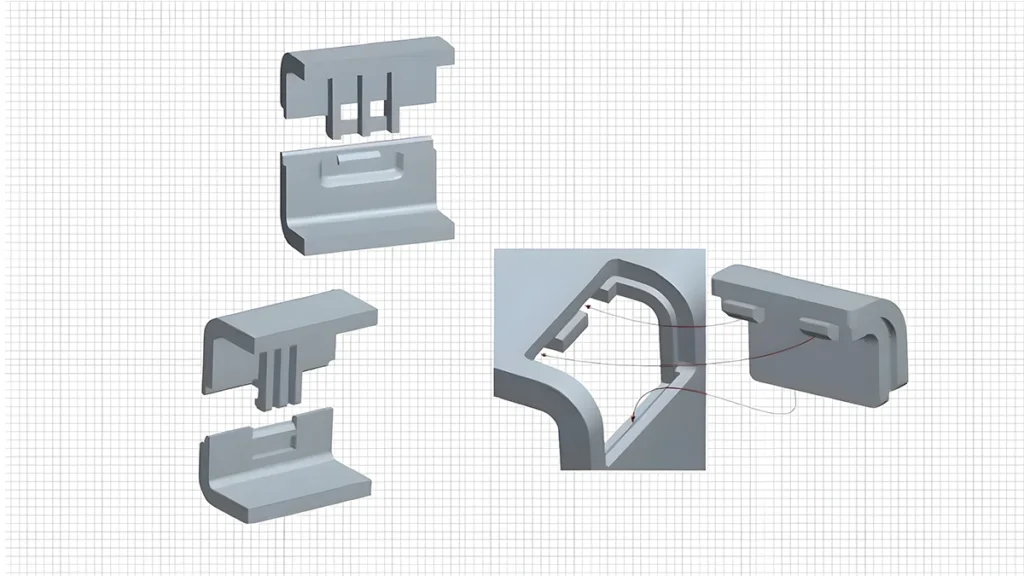

Our process begins with collaborative design for manufacturability (DFM) review, where our engineering team works with your CAD models to optimize bend radii, tab geometries, and clearance tolerances specifically for snap-fit performance within the constraints of your selected sheet metal gauge and material. We handle the full spectrum from laser cutting and precision forming to optional finishing, ensuring the critical engagement surfaces and deflection zones of your snap-fit features maintain the necessary dimensional integrity. This focus on precision engineering translates directly into reliable field performance and simplified end-user assembly for your product.

Streamline Your Prototyping Workflow with Instant Quoting

Initiating a project involving complex sheet metal features like snap-fits should be straightforward. Honyo Prototype eliminates quoting delays with our Online Instant Quote system. Upload your STEP or DXF file directly to our platform, specify material, quantity, and finish requirements, and receive a detailed, accurate manufacturing cost estimate within seconds – not days. This immediate feedback empowers rapid design iteration and accelerates your path from concept to functional prototype, ensuring your sheet metal snap-fit components move seamlessly from validation to production. Leverage Honyo’s technical expertise and responsive quoting to build better assemblies, faster.

Technical Capabilities

Sheet metal snap-fit features are mechanical joints designed to assemble components without fasteners or adhesives, commonly used in prototyping and low-volume production. When integrating snap-fits into sheet metal designs, manufacturing processes such as laser cutting, bending, and occasionally welding must be considered to ensure dimensional accuracy, material compatibility, and structural integrity. While snap-fits are more commonly associated with plastics like ABS and Nylon, they can be adapted to sheet metal (aluminum and steel) with appropriate design adjustments.

Below is a technical specification overview for sheet metal snap-fit designs, highlighting compatibility with laser cutting, bending, welding, and applicable materials.

| Parameter | Laser Cutting Compatibility | Bending Compatibility | Welding Compatibility | Material Suitability (Aluminum) | Material Suitability (Steel) | Material Suitability (ABS) | Material Suitability (Nylon) | Notes |

|---|---|---|---|---|---|---|---|---|

| Minimum Feature Size | 0.5 mm (typical) | N/A | N/A | Good | Good | Limited (not sheet metal) | Limited (not sheet metal) | Smaller features possible in metal; plastics require mold tooling |

| Tolerances | ±0.1 mm – ±0.2 mm | ±0.1° – ±1° angular | ±0.5 mm positional | High precision achievable | High precision achievable | Not applicable | Not applicable | Critical for snap-fit engagement depth and retention force |

| Bend Radius | N/A | 1× material thickness (min) | N/A | 0.5–1.0 mm typical | 0.5–1.5 mm typical | N/A | N/A | Must be accounted for in snap geometry layout |

| Snap Arm Design | Can cut intricate profiles | Bend-form snap geometry | Not required for snap | Suitable with strain consideration | Suitable with strain consideration | Common in injection molding | Common in injection molding | Sheet metal arms must stay below yield strength during deflection |

| Retention Force | Depends on geometry | Affected by springback | N/A | Moderate (elastic modulus ~70 GPa) | High (elastic modulus ~200 GPa) | Low–Moderate | Low (high elongation) | Steel offers higher retention; aluminum preferred for lighter assembly |

| Process Integration | Primary cutting method | Required for 3D forms | Only if joining subassemblies | Fully compatible | Fully compatible | Not compatible | Not compatible | Welding used selectively, not for snap function |

| Thermal Impact | Localized HAZ (minimal) | None | Heat distortion risk | Slight (annealing possible) | Moderate (hardness change) | Degrades at high temp | Melts/deforms >80°C | Avoid welding near snap features |

| Surface Finish | Smooth, burr-free (deburred) | Paint/coat after forming | Post-weld finishing | Anodizing available | Powder coating common | Molded-in finish | Machined or molded | Critical for friction and wear in repeated engagement |

Notes on Material Use:

Aluminum (e.g., 5052, 6061): Preferred for lightweight, corrosion-resistant sheet metal snap-fits. Easily laser cut and bent. Limited weldability without specialized processes (e.g., TIG or MIG with filler).

Steel (e.g., mild steel, stainless 304): Offers high strength and durability. Suitable for high-retention snap designs. Laser cutting and bending are standard; welding is common but may require post-process stress relief.

ABS & Nylon: Not applicable to sheet metal processes. These thermoplastics are used in molded snap-fits, not laser-cut or bent sheet forms. Included for comparison only.

Design Recommendations:

Use generous fillets in snap arms to reduce stress concentration.

Account for springback in bending operations, especially in high-strength steels.

Laser cutting allows precise slot and notch features for snap engagement, but edge quality must be controlled.

Avoid welding in proximity to snap features due to potential warpage or material property changes.

This table supports engineering decisions when developing hybrid or all-metal enclosures and assemblies using Honyo Prototype’s manufacturing capabilities.

From CAD to Part: The Process

Honyo Prototype Sheet Metal Snap-Fit Manufacturing Process

Honyo Prototype specializes in precision sheet metal snap-fit fabrication, leveraging an integrated digital workflow to ensure functional reliability and rapid turnaround. This process addresses the unique challenges of sheet metal snap-fits—including material springback, bend tolerances, and critical interference geometry—through rigorous engineering validation at every stage. Below is a detailed technical overview of our standardized workflow.

CAD Upload and Initial Validation

Customers submit 3D CAD models (STEP, Parasolid, or native formats) via our secure portal. Our system immediately performs automated geometry validation, checking for minimum bend radii, flange widths, and interference zone clearances specific to sheet metal snap-fit design rules. For example, the system flags designs where the snap arm length falls below 3× material thickness or where bend allowances could compromise the intended deflection force. This initial scan prevents non-viable submissions from progressing, reducing rework cycles.

AI-Powered Quoting with Material Science Integration

Our proprietary AI quoting engine analyzes the validated CAD data alongside real-time material availability, tooling constraints, and historical production data. Unlike generic quoting systems, it incorporates material-specific parameters such as yield strength, Young’s modulus, and springback coefficients for common sheet metals (e.g., 5052-H32 aluminum, 304 stainless steel). The engine calculates achievable interference tolerances—for instance, confirming whether a 0.25mm interference fit is feasible for 1.0mm cold-rolled steel given typical ±0.1mm bend tolerances. Quotes include explicit design feasibility notes, such as “Snap arm deflection exceeds 15% of material thickness; risk of plastic deformation.”

Engineering-Led DFM Analysis

All projects undergo mandatory Design for Manufacturability (DFM) review by our sheet metal engineering team. This phase focuses on snap-fit critical dimensions:

Verification of bend deduction and k-factor adjustments to maintain interference geometry

Simulation of snap engagement force using material stress-strain curves

Validation of minimum feature sizes (e.g., snap hooks ≥0.8mm for laser cutting)

Assessment of assembly sequence to prevent over-travel damage

The DFM report provides actionable feedback, such as recommending a 0.15mm reduction in interference to accommodate springback in 6061-T6 aluminum. Clients receive annotated CAD markups and tolerance stack-up analyses before approval.

Precision Production Execution

Approved designs move to production under strict process controls:

Material certification (e.g., ASTM A666 for stainless steel) with batch traceability

Laser cutting with ±0.1mm positional accuracy for critical snap features

Press brake forming using calibrated tooling and real-time angle monitoring (±0.5°)

In-process CMM checks on interference zones and bend radii per ISO 2768-mK

For snap-fits, we implement first-article functional testing: measuring insertion/withdrawal force with calibrated load cells and validating 10+ assembly/disassembly cycles to confirm no permanent deformation.

Delivery with Performance Documentation

Shipments include comprehensive quality documentation:

Dimensional reports highlighting snap-fit critical features (interference, arm length, hook radius)

Material test reports with hardness verification

Functional test data (force-displacement curves from cycle testing)

Assembly instructions specifying maximum insertion speed to avoid snap fracture

All parts ship in anti-static packaging with protective fixtures to maintain snap geometry integrity during transit. Typical lead time from CAD upload to delivery is 8–12 business days for quantities under 500 units, with expedited options for prototyping.

This closed-loop process ensures sheet metal snap-fits achieve reliable mechanical performance in final assemblies, eliminating field failures caused by unaddressed manufacturing variables. Honyo’s integration of material science, DFM rigor, and functional validation delivers production-ready snap-fit components with first-time-right success.

Start Your Project

Looking for precision sheet metal snap-fit solutions? Partner with Honyo Prototype for expert design support and rapid manufacturing.

Our Shenzhen-based factory delivers high-quality, functional prototypes and low-volume production with fast turnaround.

Contact Susan Leo today at [email protected] to discuss your project requirements and get a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.