Contents

Manufacturing Insight: Sheet Metal Sheet Metal

Precision Sheet Metal Fabrication Solutions from Honyo Prototype

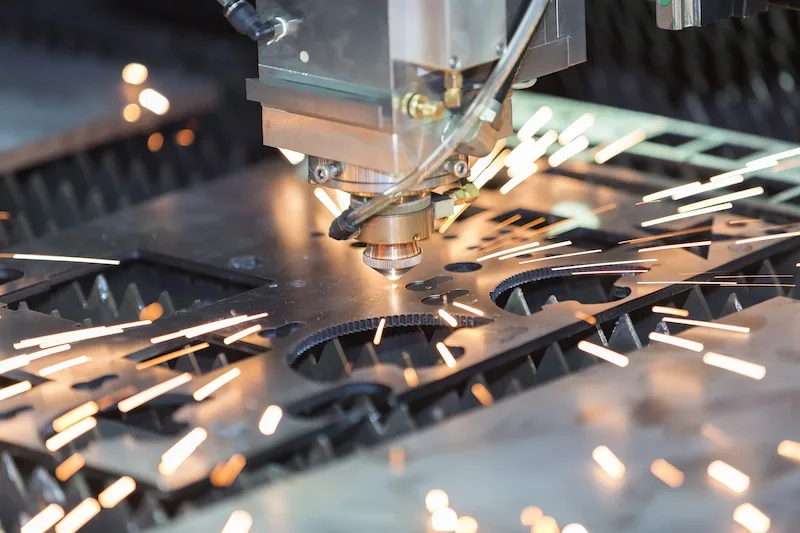

Honyo Prototype delivers advanced sheet metal fabrication services engineered to meet the exacting demands of industrial and commercial product development. Our comprehensive capabilities span laser cutting, CNC punching, precision bending, welding, and finishing for materials including aluminum, stainless steel, and cold-rolled steel. We specialize in transforming complex designs into high-integrity prototypes and low-to-mid volume production runs with rigorous attention to geometric accuracy and material integrity. Partnering with Honyo accelerates your development cycle through seamless integration of design for manufacturability analysis and rapid prototyping expertise.

A critical advantage for engineering teams is our Online Instant Quote platform. This proprietary system provides accurate, detailed cost estimates and lead times within minutes by analyzing your uploaded STEP or DWG files against real-time production parameters. Eliminate traditional quotation delays and iterate designs with confidence using live manufacturing feedback directly integrated into your workflow. This digital efficiency ensures your projects maintain momentum from initial concept to functional hardware.

Our commitment to quality is reinforced through ISO 9001-certified processes and in-house metrology, guaranteeing dimensional compliance for mission-critical applications across aerospace, medical, and industrial equipment sectors. Engage Honyo Prototype to leverage scalable sheet metal solutions that prioritize precision, speed, and collaborative engineering support.

Technical Capabilities

The term “sheet metal sheet metal” appears redundant; it is interpreted here as referring to sheet metal fabrication processes including laser cutting, bending, and welding. Below are the technical specifications relevant to these processes for common materials used in prototyping and low-volume manufacturing at Honyo Prototype. Materials include aluminum and steel (standard sheet metals), as well as ABS and nylon, which are non-metallic but occasionally processed using similar equipment with modifications.

| Parameter | Aluminum (e.g., 5052, 6061) | Steel (e.g., 1018, 304 Stainless) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide) |

|---|---|---|---|---|

| Laser Cutting | ||||

| Typical Thickness Range | 0.5 mm – 6.0 mm | 0.5 mm – 10.0 mm | 1.0 mm – 10.0 mm | 1.0 mm – 8.0 mm |

| Laser Type | Fiber laser (for reflective metals) | Fiber laser | CO₂ laser | CO₂ laser (with caution) |

| Edge Quality | Smooth, slight dross possible | Smooth, minimal dross | Clean, may char at edges | Moderate melting; requires tuning |

| Notes | Requires assist gas (N₂ or O₂) | O₂ for carbon steel, N₂ for SS | Flammable – requires extraction | High melting point; prone to warping |

| Bending | ||||

| Minimum Bend Radius | 1× material thickness | 1× (carbon), 2× (stainless) | 3× material thickness | 4× material thickness |

| Tooling | Standard V-die press brake | Standard V-die press brake | Soft tooling or custom dies | Soft tooling required |

| Springback | Moderate (aluminum) | Low (carbon), Moderate (stainless) | High | Very high |

| Maximum Bend Angle | 160° typical | 160° typical | 90°–120° (limited by elasticity) | 90° (challenging beyond) |

| Welding | ||||

| Compatible Methods | TIG, MIG, Laser | MIG, TIG, Spot, Laser | Ultrasonic, Hot Plate, Solvent | Hot Gas, Vibration, Laser (limited) |

| Heat Sensitivity | Moderate (risk of warping) | High (carbon), Moderate (stainless) | Very high (melts easily) | High (absorbs moisture, warps) |

| Joint Strength | High (properly welded) | High | Medium (depends on method) | Medium to high |

| Fixturing Requirements | Clamping needed | Clamping required | Low-force fixturing | High stability to prevent movement |

| General Considerations | Excellent formability, corrosion resistant | Durable, magnetic (carbon steel) | Low melting point, electrically insulating | High wear resistance, hygroscopic |

Note: ABS and nylon are not sheet metals but are included for comparative purposes as they are sometimes fabricated using adapted sheet processing equipment. True sheet metal processes are optimized for metals such as aluminum and steel. For non-metallic materials, parameters must be carefully adjusted to avoid melting, burning, or deformation.

From CAD to Part: The Process

Honyo Prototype executes sheet metal fabrication through a rigorously defined digital workflow designed for speed, accuracy, and manufacturability. This process eliminates traditional quoting delays and ensures designs are optimized before physical production begins. The sequence is strictly followed for every project:

Upload CAD

Customers initiate the process by uploading native or neutral format CAD files (STEP, IGES, DWG, DXF, or native SolidWorks/Inventor) via our secure customer portal. The system performs an immediate automated validation check for file integrity, unit consistency, and geometric completeness. Invalid submissions trigger real-time feedback to the customer for correction, preventing downstream errors. This stage establishes the single source of truth for all subsequent manufacturing operations.

AI Quote Generation

Validated CAD data feeds directly into our proprietary AI-driven quoting engine. This system analyzes over 200 geometric and material parameters—including part complexity, feature density, bend counts, hole patterns, material grade/thickness, surface finish requirements, and batch size—to calculate a precise cost model. Unlike manual quoting, the AI factors in real-time material pricing, machine utilization rates, and historical production data to deliver a firm, transparent quote within 2 hours. The output includes a detailed cost breakdown and estimated lead time, with no human intervention required at this stage.

DFM Analysis and Engineering Collaboration

Upon quote acceptance, our Deep Manufacturing Feasibility (DFM) protocol activates. Honyo engineers conduct a multi-layered review using specialized software integrated with our production equipment library. Critical manufacturability checks include:

| Parameter Category | Key Checks | Resolution Protocol |

|---|---|---|

| Geometric Tolerances | Bend allowances, minimum flange lengths, hole-to-edge distances | Automated flagging with recommended adjustments |

| Material Constraints | Grain direction impact, minimum bend radii for specified alloy | Material substitution suggestions if needed |

| Process Optimization | Nesting efficiency, tooling requirements, secondary operation sequencing | Revised flat pattern generation with yield improvement |

| Quality Assurance | Critical feature accessibility for inspection, weld accessibility | Revised GD&T callouts or inspection plan proposal |

This phase mandates direct engineer-to-engineer dialogue. Honyo’s team provides a formal DFM report with actionable recommendations, not just warnings. Customers approve revisions via the portal before proceeding, ensuring alignment on any necessary design modifications.

Production Execution

Approved designs move to our connected shop floor. Honyo utilizes a fully digital thread from CAM programming to machine execution:

Nesting & CAM: AI-optimized nesting maximizes material utilization; CAM programs are auto-generated and validated against machine kinematics

Cutting: Fiber laser systems (up to 4kW) process materials from 0.5mm to 25mm thickness with ±0.1mm accuracy

Forming: CNC press brakes with automatic tool changers execute complex bend sequences using real-time springback compensation

Secondary Operations: Deburring, welding (TIG/MIG), and surface finishing occur under controlled environmental conditions

In-Process Verification: Critical dimensions are checked at defined control points using CMM and optical comparators

All process parameters are logged to our MES for full traceability, with non-conformances triggering automatic engineering escalation.

Delivery and Documentation

Completed parts undergo final QA against the approved drawing and customer-specific requirements. Each shipment includes:

First article inspection report (FAIR) with dimensional data

Material test certificates (MTRs) traceable to heat number

Process validation records for critical operations

Packing list with serialized part tracking

Shipments are dispatched via customer-preferred carriers with real-time logistics visibility. Honyo maintains a 99.2% on-time delivery rate for sheet metal projects, with standard lead times of 5-10 business days for prototypes and low-volume production. Post-delivery, production data feeds into our continuous improvement loop to refine future AI quoting accuracy and DFM guidelines.

Start Your Project

For all your sheet metal prototyping and production needs, contact Susan Leo at [email protected]. With our advanced manufacturing facility located in Shenzhen, we deliver high-precision sheet metal solutions tailored to your specifications—fast, reliable, and cost-effective. Partner with Honyo Prototype for seamless sheet metal fabrication from concept to delivery.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.