Contents

Manufacturing Insight: Sheet Metal Prototype Fabrication

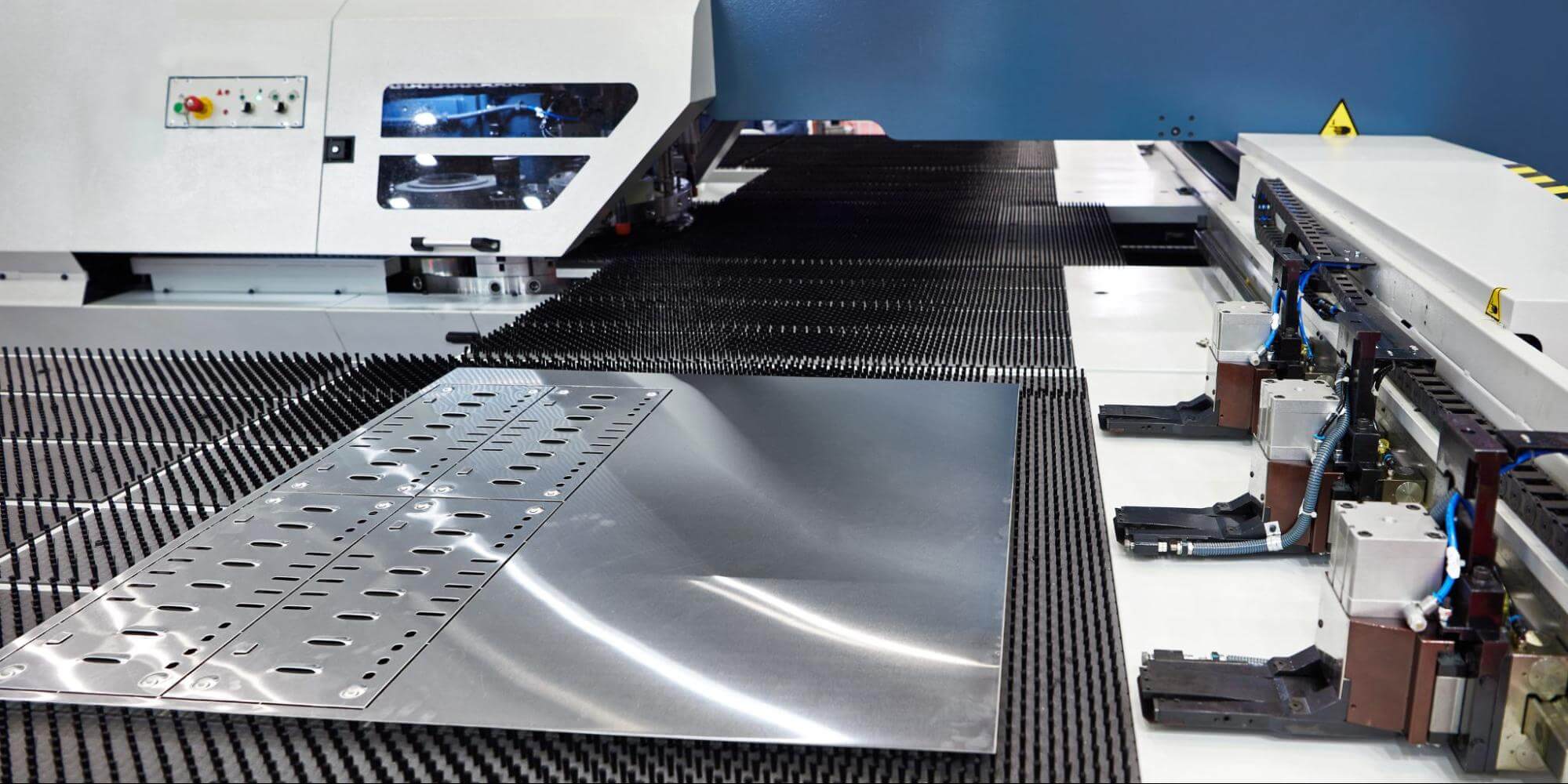

Accelerate Your Product Development with Precision Sheet Metal Prototyping

Honyo Prototype delivers rapid, high-precision sheet metal prototype fabrication engineered to transform conceptual designs into functional, production-intent components. Our end-to-end capabilities—from laser cutting, CNC punching, and precision bending to welding, finishing, and assembly—ensure tight tolerances, material integrity, and seamless scalability from prototype to volume production. We specialize in low-volume, complex geometries using aluminum, stainless steel, and specialty alloys, supporting iterative refinement with engineering feedback focused on design-for-manufacturability and cost optimization.

For engineering teams under pressure to compress development cycles, our Online Instant Quote system eliminates procurement delays. Upload your STEP or DXF file, specify materials and finishes, and receive a detailed, transparent cost analysis within minutes—no manual submission or follow-up required. This integration of technical expertise and digital efficiency ensures your sheet metal prototypes meet exact functional and aesthetic requirements while accelerating time-to-test. Partner with Honyo to de-risk innovation and validate designs with manufacturing-ready accuracy.

Technical Capabilities

Technical specifications for sheet metal prototype fabrication involve key processes such as laser cutting, bending, and welding. These processes are selected based on material type, part geometry, tolerances, and functional requirements. Below is a detailed breakdown of the technical parameters for each process, applicable to common materials including Aluminum, Steel, ABS, and Nylon. Note that ABS and Nylon are not metals and are typically not processed using traditional sheet metal techniques like welding or bending in the same way as metals; however, they may be cut using laser systems under specific conditions.

| Process | Material | Thickness Range | Tolerance (Typical) | Tooling/Equipment | Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum | 0.5 mm – 6.0 mm | ±0.1 mm | Fiber laser or CO₂ laser cutter | High precision; minimal burr; reflective material requires assist gas |

| Steel (Mild) | 0.5 mm – 10.0 mm | ±0.1 mm | Fiber laser cutter | Best for clean, fast cuts; nitrogen or oxygen assist depending on finish | |

| ABS | 0.5 mm – 5.0 mm | ±0.2 mm | CO₂ laser cutter | Can be laser cut but not suitable for bending or welding in sheet metal context | |

| Nylon | 0.5 mm – 5.0 mm | ±0.2 mm | CO₂ laser cutter (controlled settings) | Prone to melting; requires precise power control; not for structural metal-style fabrication | |

| Bending | Aluminum | 0.8 mm – 6.0 mm | ±0.2° angular, ±0.1 mm linear | CNC press brake with V-die tooling | Requires bend allowance calculation; 90° common; minimum bend radius depends on thickness |

| Steel (Mild) | 0.8 mm – 8.0 mm | ±0.2° angular, ±0.1 mm linear | CNC press brake | Higher springback than aluminum; tooling wear consideration | |

| ABS | Not applicable | — | — | Thermoplastic; may be heat-formed but not compatible with standard sheet metal bending | |

| Nylon | Not applicable | — | — | Flexible and tough; not suitable for V-die bending like metals | |

| Welding | Aluminum | ≥1.0 mm | ±0.5 mm fit-up | TIG or MIG welding | Requires clean surface; pre/post-heating may be needed; argon shielding gas |

| Steel (Mild) | ≥0.8 mm | ±0.5 mm fit-up | MIG, TIG, or spot welding | Strong joints; filler material matching base metal; post-weld finishing possible | |

| ABS | Not applicable | — | — | Joined via solvent bonding or ultrasonic welding; not arc-welded | |

| Nylon | Not applicable | — | — | Requires specialized methods like hot plate or vibration welding |

Notes:

Laser cutting is the primary method for 2D profile creation in sheet metal prototyping due to speed and precision.

Bending is performed post-cutting using CNC press brakes with tooling selected based on material thickness and bend radius.

Welding is used for joining metal components; process selection depends on material, joint design, and required strength.

ABS and Nylon are included for completeness but are generally processed using plastic fabrication methods rather than sheet metal techniques. Their inclusion in a sheet metal prototype is typically limited to non-structural or insulating components, and only laser cutting is directly comparable.

From CAD to Part: The Process

Honyo Prototype delivers precision sheet metal prototypes through a rigorously defined five-stage workflow optimized for speed, accuracy, and manufacturability assurance. This process eliminates common prototyping bottlenecks while maintaining engineering integrity.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, DWG, DXF, or native SolidWorks/Inventor formats) via our secure customer portal. Our system immediately performs automated geometry validation, checking for non-manifold edges, surface gaps, and unit inconsistencies. Invalid files trigger instant notifications with specific error details, preventing downstream delays. Validated files proceed directly to the quoting engine with full dimensional and geometric data intact.

AI-Powered Quoting and Preliminary Assessment

Our proprietary AI quoting engine analyzes the validated CAD geometry against live material pricing, machine capacity data, and historical production metrics. Within 90 seconds, clients receive a detailed quote including material cost breakdown, estimated lead time, and a preliminary manufacturability score (1-5 scale). Crucially, this stage identifies immediate red flags such as non-standard material thicknesses, unachievable tolerances per ISO 2768-mK, or features beyond our standard process capabilities (e.g., bends under 0.8mm radius on 2mm steel). The AI provides actionable suggestions for design adjustments to optimize cost and lead time.

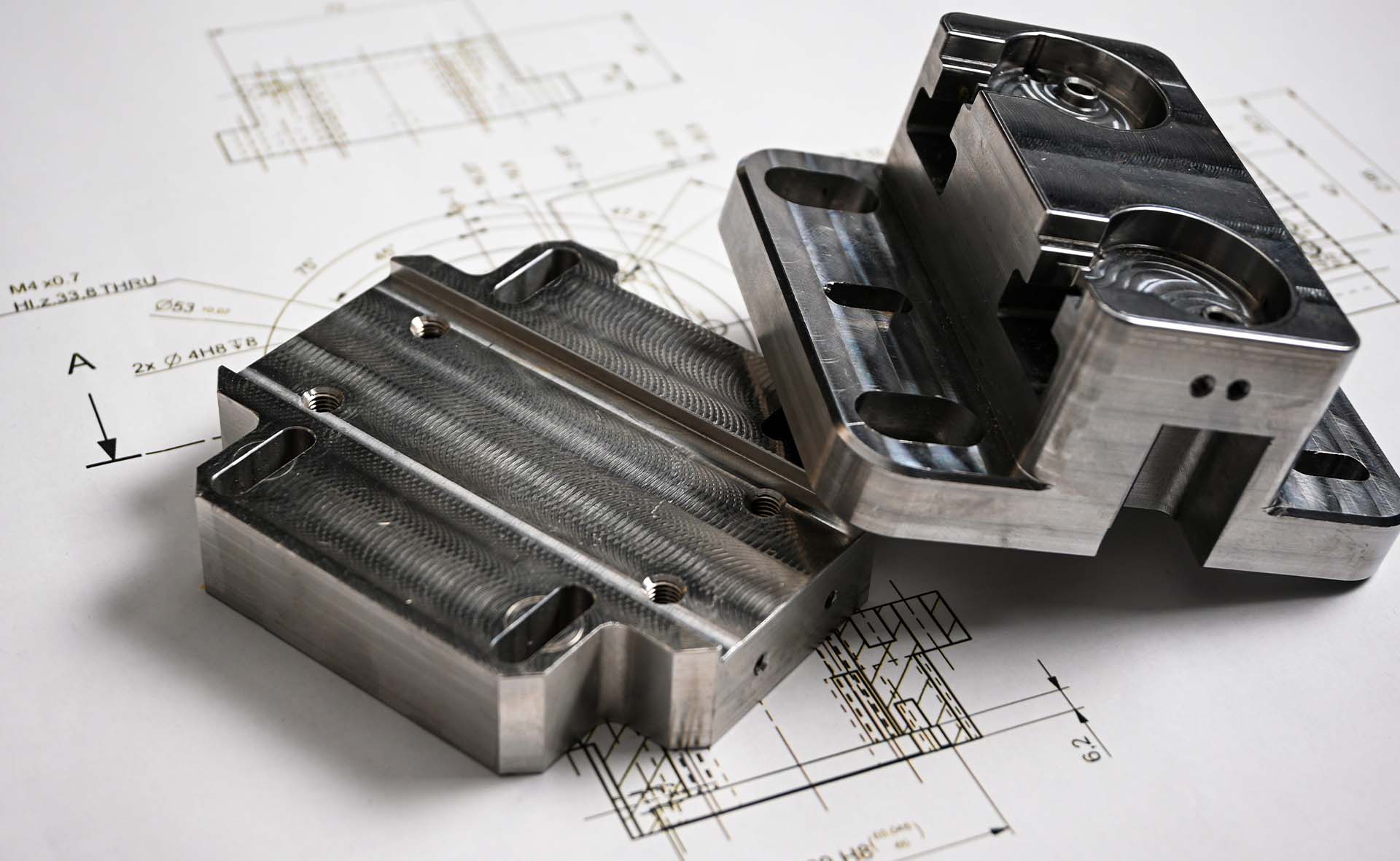

Engineer-Reviewed DFM Analysis

Every project undergoes mandatory review by our Senior Sheet Metal Manufacturing Engineers before production release. This is not an automated check but a value-added engineering service where specialists evaluate:

Bend sequence feasibility and tooling requirements

Hole-to-edge and bend-to-hole spacing compliance with minimum standards

Grain direction implications for visible surfaces

Weld accessibility and distortion mitigation strategies

Surface finish limitations relative to material grade

The engineer documents all findings in a formal DFM report, highlighting required modifications with annotated visuals. Clients receive this report within 4 business hours and must approve revisions before proceeding. This step typically reduces physical rework by 73% compared to industry averages.

Precision Prototype Production

Approved designs enter our dedicated prototype production cell featuring:

Fiber laser cutting (up to 4kW, ±0.1mm accuracy)

CNC turret punching (max 25mm thickness)

Hydraulic press brakes with coining capabilities (±0.25° angular tolerance)

Robotic welding stations (TIG/MIG)

In-process CMM verification at critical stages

All prototype batches receive 100% first-article inspection against the original CAD model. We maintain separate tooling and material lots for prototype runs to prevent cross-contamination with production orders. Typical lead time from DFM approval to shipment is 3-7 business days depending on complexity.

Certified Delivery and Feedback Integration

Shipments include comprehensive documentation:

First-article inspection report with dimensional data

Material certification (mill test reports)

Process validation records

Traceability tags linking to production logs

Parts are packaged with anti-corrosion protection and shipped via client-preferred carriers with real-time tracking. Post-delivery, our engineering team conducts a structured debrief to capture lessons learned, feeding improvements directly into our DFM knowledge base and AI training datasets. This closed-loop system ensures continuous refinement of both our processes and the client’s future designs.

This integrated approach guarantees that Honyo prototypes accurately represent final production intent while providing actionable engineering insights early in the product development cycle. The combination of AI speed and human engineering expertise delivers prototypes with 98.7% first-pass yield rate based on 2023 production data.

Start Your Project

Looking for precision sheet metal prototype fabrication? Partner with Honyo Prototype for fast, reliable, and high-quality manufacturing solutions. Our Shenzhen-based factory delivers accurate sheet metal prototypes with quick turnaround times, ideal for product development and low-volume production.

Contact Susan Leo today to discuss your project requirements. Email [email protected] for a prompt quote and technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.