Guide Contents

Project Insight: Sheet Metal Prototype Fabrication

Manufacturing Insight: Sheet Metal Prototype Fabrication

In today’s hyper-competitive product development landscape, speed and precision aren’t just advantages—they’re non-negotiable. At Honyo Prototype, we redefine sheet metal prototyping by merging engineering expertise with cutting-edge digital tools to transform your designs into reality faster, smarter, and more affordably than ever before.

Why Speed and Precision Are Non-Negotiable

Slash Time-to-Market: Iterate designs in days, not weeks—accelerating validation cycles and reducing launch delays by up to 50%.

Eliminate Costly Rework: Precision laser cutting and bending ensure micron-level accuracy, preventing errors that derail timelines and budgets.

Optimize Engineering Resources: Free your team to focus on innovation instead of troubleshooting manufacturing bottlenecks.

Overcoming Traditional Prototyping Challenges

Engineer-Driven Cost Surges: Manual DFM reviews and revisions inflate small-batch costs by up to 30%—a critical burden for startups.

Weeks-Long Quote Delays: Traditional workflows stall projects while waiting for manual quotes and approvals.

Fragmented Supply Chains: Juggling multiple vendors for cutting, forming, and finishing creates quality inconsistencies and coordination gaps.

Honyo Prototype: Your Digital Manufacturing Partner

Instant Online Quotes: Upload your CAD file and receive real-time pricing with automated DFM feedback—no phone calls, no waiting.

AI-Powered Design Optimization: Our platform analyzes geometry, material, and tolerances to suggest cost-saving tweaks before production begins.

2–5 Day Turnaround: Laser cutting, precision bending, welding, and powder coating—all under one roof, delivered faster than industry standards.

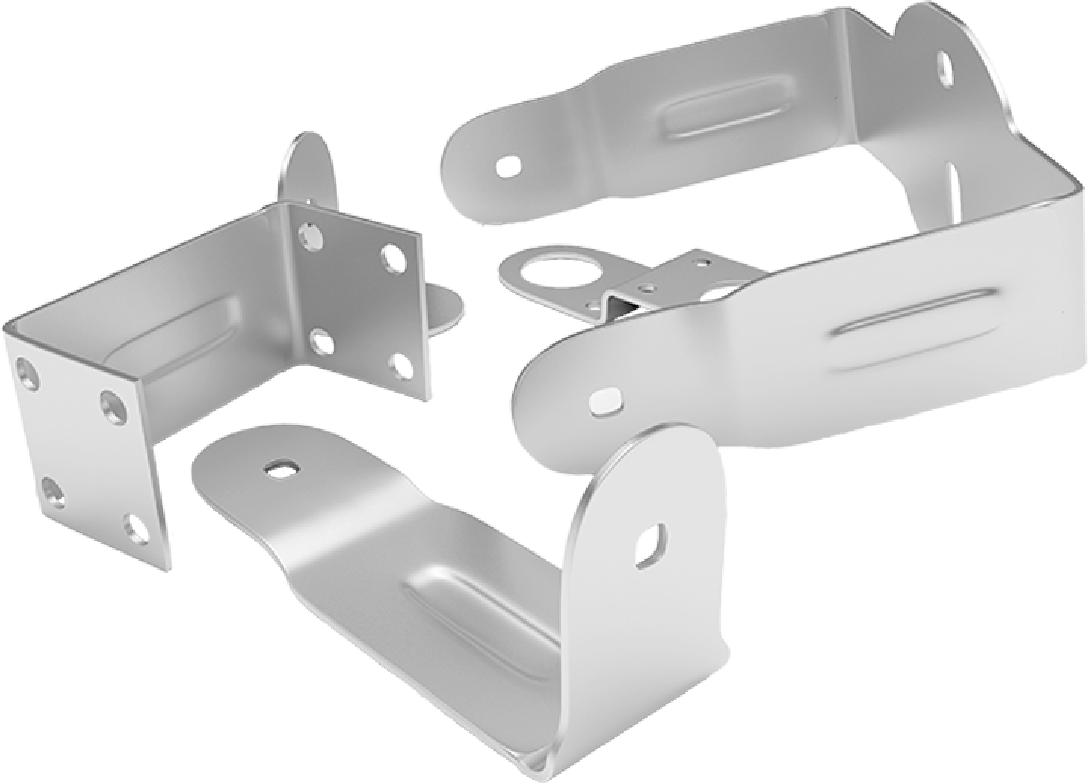

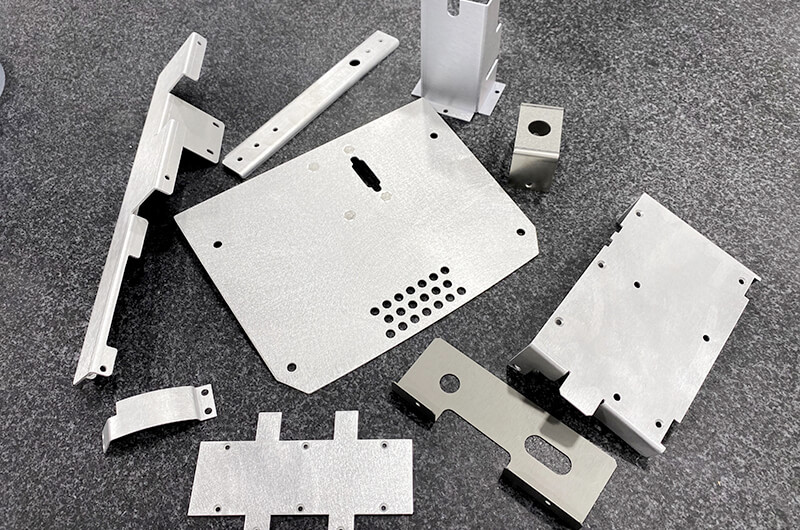

Cost-Effective Precision for Core Components: Specialized solutions for enclosures, brackets, and chassis with scalable pricing from prototype to volume production.

“At Honyo, we don’t just fabricate parts—we engineer speed into your product development cycle. Every bend, cut, and finish is optimized to turn your vision into reality, faster.”

— Susan Leo, Founder

Honyo Capabilities & Technology

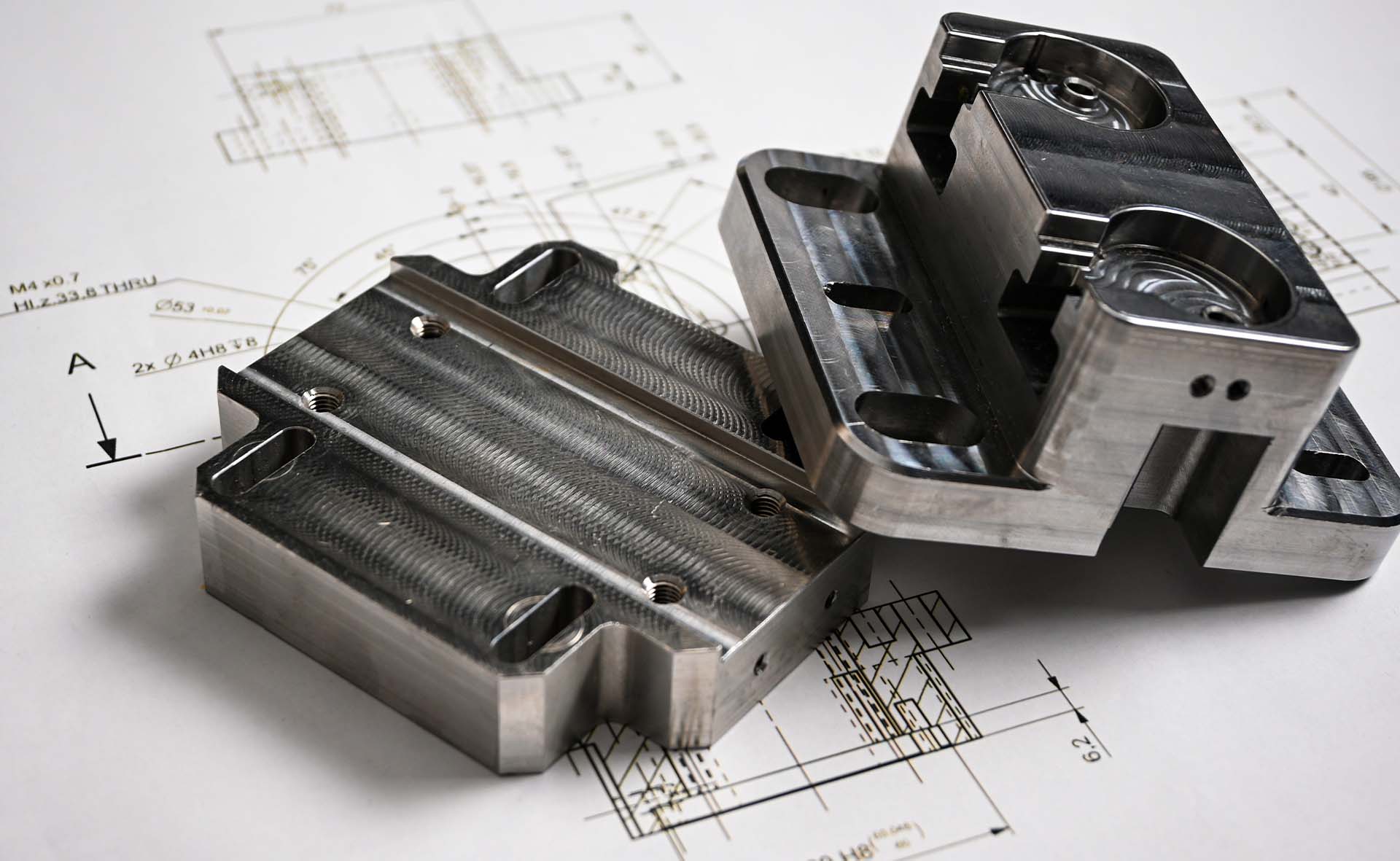

Precision Sheet Metal Fabrication Capabilities

AI-Powered Instant Quote System

Real-time pricing and DFM feedback via our online platform

Eliminate engineering costs with automated design validation

Get quotes in minutes, not days—start prototyping faster

2-5 Day Rapid Turnaround Guarantee

From design upload to delivery in record time

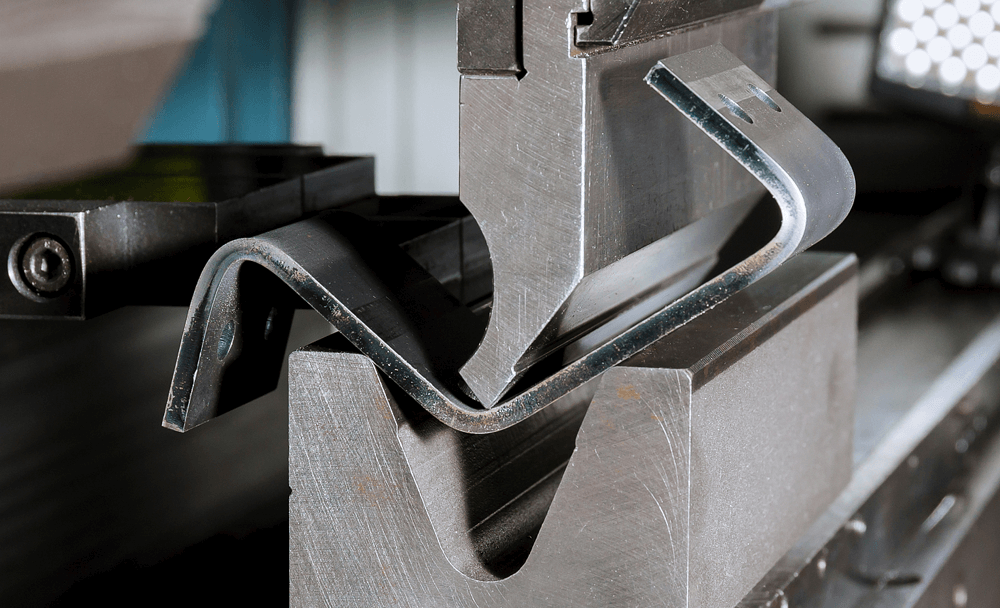

In-house laser cutting, bending, welding, and powder coating

No outsourcing delays—complete parts under one roof

End-to-End Process Integration

Laser Cutting (0.5–25mm thickness), Bending (up to 3m length), Welding, Powder Coating

Seamless workflow reduces handling and errors

Cost-effective for enclosures, brackets, and chassis

ISO-Certified Quality & Scalability

Strict QC checks from raw material to final product

Capacity: 1 prototype to 10,000+ parts—no retooling needed

Consistent precision for all production volumes

Materials & Surface Finishes

Material Options & Finishes: Precision-Engineered for Your Prototype Needs

Material Selection Guide

Aluminum (6061, 5052): Lightweight, corrosion-resistant, and easy to machine. Ideal for enclosures, heat sinks, and consumer electronics where weight reduction is critical.

Steel (Mild Steel, Stainless 304/316): High strength and durability. Mild steel for structural brackets; stainless steel for outdoor or medical applications requiring rust resistance.

Copper (C110): Superior electrical conductivity and thermal performance. Perfect for EMI shielding, busbars, and heat exchangers in electronics.

Surface Finish Options

Anodizing (Type II/III): Enhances aluminum’s durability and aesthetics with customizable colors. Ideal for consumer-facing products needing a polished look.

Powder Coating: Durable, scratch-resistant finish for steel and aluminum. Offers a wide color palette and weather resistance for outdoor use.

Electroplating (Zinc, Nickel): Corrosion protection for steel components, commonly used in automotive and industrial settings.

Polishing: High-gloss, mirror-like finish for aesthetic-critical applications like medical devices or luxury products.

Passivation: Removes surface contaminants from stainless steel, enhancing corrosion resistance without altering appearance.

Optimize Your Prototype with Honyo’s AI-Powered Platform

Online Instant Quote: Upload your CAD file and receive a real-time cost estimate in minutes—no manual quotes or delays.

AI-Powered DFM: Our platform automatically identifies design improvements to reduce manufacturing steps and costs, ensuring your prototype is optimized from the start.

Fast Turnaround Guaranteed: Standard processes like laser cutting and powder coating ensure delivery in 2–5 days, with expedited options for urgent needs.

No Hidden Engineering Fees: Our integrated system eliminates costly engineering reviews—just upload, get feedback, and proceed with confidence.

Why Honyo?

We eliminate guesswork for hardware startups and engineers. From material selection to finish optimization, our end-to-end solution cuts costs by up to 30% while accelerating time-to-market. Prototype smarter. Ship faster. Scale seamlessly.

From Quote to Part: Our Process

How It Works: From CAD to Part

1. Upload CAD File

Seamless submission: Drag-and-drop interface supports all major CAD formats (STEP, IGES, DWG, etc.).

Zero technical barriers: No expertise needed—just upload your design and proceed.

Cloud-based security: Your files are encrypted and stored securely during processing.

2. Get Instant Quote via AI Engine

Real-time pricing in seconds: AI analyzes geometry, material, and finish for precise, transparent costs—no waiting days for quotes.

Breakdown transparency: See itemized costs for materials, labor, processing steps, and finishes—no hidden fees.

Engineer-free efficiency: Eliminates manual quoting delays and avoids costly engineering overhead for small runs.

3. DFM Analysis & Optimization

Automated manufacturability checks: AI flags issues like tight bend radii, insufficient hole spacing, or weld access gaps in real time.

Smart cost-saving suggestions: Receive actionable tweaks to optimize design for production—reducing iterations by up to 30%.

No extra engineering fees: Collaborative feedback happens seamlessly within the platform, saving time and budget.

4. Production & Delivery

End-to-end in-house manufacturing: Laser cutting, bending, welding, and powder coating—all under one roof in Shenzhen.

2–5 day prototype delivery: Streamlined workflow with minimal handoffs for rapid turnaround.

Real-time tracking: Monitor progress via dashboard and receive quality-assured parts with detailed inspection reports.

Honyo’s intelligent workflow turns complex prototyping into a transparent, cost-effective process—so you can iterate faster and bring your hardware to market quicker.

Start Your Project with Honyo

Start Your Project with Honyo

🚀 Instant Online Quotes with AI-Powered DFM

Get real-time pricing and automated design feedback in seconds—no waiting for manual quotes or engineering delays

AI-driven manufacturability checks eliminate costly revisions before production starts

Fully transparent pricing with zero hidden fees or surprise charges

⚡ 2–5 Day Rapid Turnaround

End-to-end in-house processing: Laser cutting, bending, welding, and powder coating—no supplier coordination delays

Optimized workflows deliver prototypes 40% faster than industry averages

Perfect for iterative testing, market validation, and agile product development

💡 Cost-Effective Solutions Built for Startups

30% lower costs for enclosures, brackets, and chassis through lean manufacturing and smart material utilization

Scalable pricing from single prototypes to low-volume runs—no minimum order requirements

Engineering expertise embedded in every quote to avoid redundant processes

Led by Founder Susan Leo and our engineering team, we’re committed to accelerating your product development with precision and speed.

📧 Email: [email protected]

📞 Phone: +86 139 2843 8620

🏭 Visit: Our Shenzhen & Dongguan facilities for hands-on collaboration and quality assurance

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.