Contents

Manufacturing Insight: Sheet Metal Hydroforming

Precision Hydroforming for Complex Sheet Metal Components

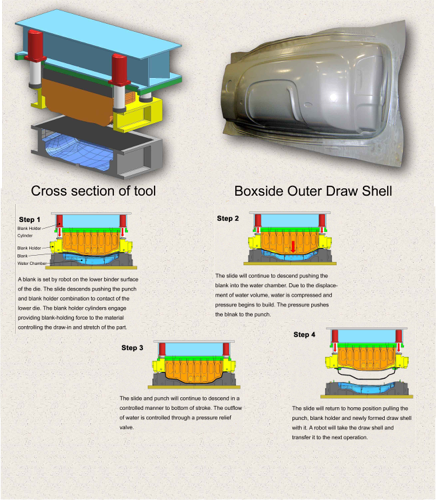

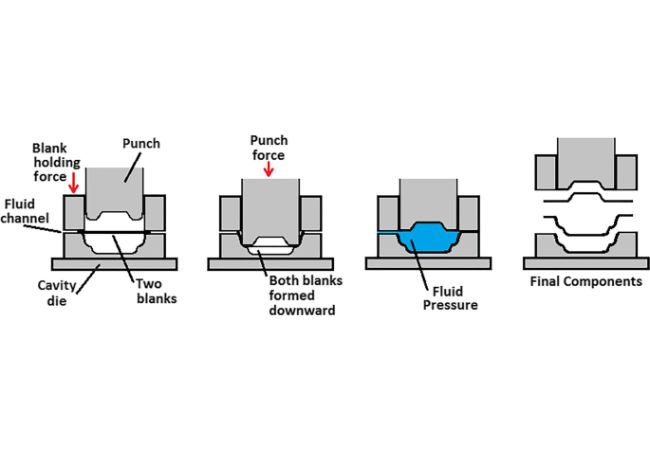

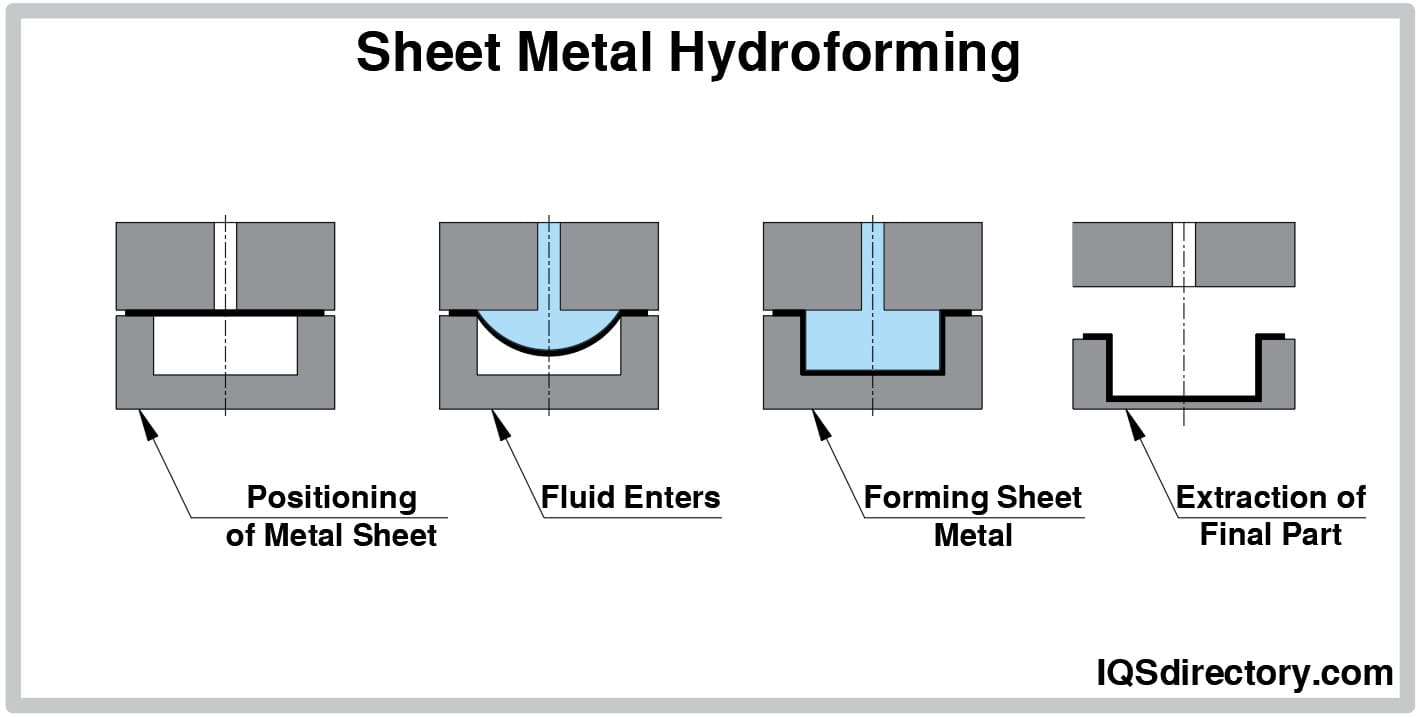

Sheet metal hydroforming represents a significant advancement over conventional stamping and deep-drawing processes, utilizing pressurized fluid to uniformly form intricate geometries with exceptional dimensional accuracy and minimal material thinning. This technology excels in producing structurally robust, lightweight components with smooth surface finishes—critical for aerospace, medical, and automotive applications where part integrity and tight tolerances are non-negotiable. Unlike rigid die methods, hydroforming accommodates complex curves, variable wall thicknesses, and integrated features in fewer operations, reducing weld seams and secondary processing while optimizing material utilization.

At Honyo Prototype, our Sheet Metal Fabrication services integrate state-of-the-art hydroforming with decades of precision engineering expertise. We specialize in transforming challenging designs into high-integrity production-ready parts, leveraging advanced CNC-controlled systems to maintain tolerances as tight as ±0.05 mm. Our end-to-end capabilities span prototyping through low-to-mid volume production, supported by in-house tooling design, material science consultation, and rigorous quality validation including first-article inspection and SPC data reporting. Clients benefit from reduced lead times, minimized scrap rates, and seamless scalability from validation to volume manufacturing—all backed by our ISO 9001-certified processes.

Accelerate your development cycle with Honyo’s Online Instant Quote platform. Upload your 3D model or technical drawing to receive a detailed, transparent cost estimate within hours—not days—enabling rapid design-for-manufacturability feedback and procurement decisions. Eliminate project delays by accessing real-time pricing, lead time visibility, and material options for hydroformed and conventional sheet metal components through our secure portal. Begin optimizing your next fabrication project at honyoprototype.com/quote.

Technical Capabilities

Sheet metal hydroforming is a precision manufacturing process that uses fluid pressure to form sheet metal into complex shapes using a single die. While hydroforming itself is primarily a forming technique, it is often integrated with secondary operations such as laser cutting, bending, and welding to produce complete components. Below are the technical specifications and compatibility details for these processes with common materials including Aluminum, Steel, ABS, and Nylon.

Note: ABS and Nylon are non-metallic thermoplastics and are not suitable for hydroforming or laser cutting in the same context as metals. They are included here for comparative context but are typically processed using alternative methods such as thermoforming or CNC machining.

| Process | Technical Specifications | Aluminum Compatibility | Steel Compatibility | ABS Compatibility | Nylon Compatibility |

|---|---|---|---|---|---|

| Laser Cutting | Fiber or CO₂ lasers; power range 1–6 kW; tolerance ±0.1 mm; max thickness cut: 25 mm (steel), 30 mm (aluminum) | Excellent – high reflectivity requires specialized settings | Excellent – widely used with carbon and stainless steels | Limited – possible with CO₂ lasers but risk of melting and fumes | Limited – possible with CO₂ lasers; high heat sensitivity causes warping |

| Bending | Press braking; CNC-controlled; typical tolerance ±0.25°; radius as low as 0.5× material thickness | Good – requires tooling adjustments for springback | Excellent – predictable bend characteristics | Poor – thermoplastics lack ductility for sharp bends | Moderate – can be bent with heat assistance, not standard |

| Welding | TIG, MIG, or laser welding; shielding gas required; joint preparation critical for strength | Good – requires clean surfaces and pre/post-heat treatment | Excellent – wide range of welding techniques applicable | Not applicable – joined via adhesives or ultrasonic welding | Not applicable – typically bonded or fastened mechanically |

| Hydroforming | Fluid pressure forming; pressures up to 1,500 bar; used for complex geometries; one-sided die | Suitable – lightweight, formable grades (e.g., 5xxx, 6xxx) | Suitable – low-carbon and stainless steels commonly used | Not applicable – cannot withstand high pressure or form via fluid | Not applicable – not structurally suitable for hydroforming |

Summary:

Hydroforming is a metal-specific process best suited for Aluminum and Steel. These materials integrate well with laser cutting, bending, and welding in high-precision fabrication workflows. ABS and Nylon, being thermoplastic polymers, are incompatible with hydroforming and require alternative processing methods. For hybrid assemblies involving both metal and plastic components, secondary joining techniques such as mechanical fastening or adhesive bonding are recommended.

From CAD to Part: The Process

Honyo Prototype specializes in rapid prototyping and low-volume production, with sheet metal hydroforming being a specialized process we manage through certified partner networks rather than in-house equipment. Our streamlined workflow ensures technical rigor while maintaining speed for B2B clients. Below is the precise sequence for hydroforming projects:

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via our secure portal. Our system performs automated geometry validation, checking for watertight solids, minimum wall thickness compliance (typically ≥0.5mm for hydroforming), and feature feasibility. Invalid files trigger immediate notifications with specific error diagnostics, reducing iteration cycles.

AI-Powered Quoting with Engineering Oversight

Uploaded designs enter our proprietary AI quoting engine, which analyzes 12+ dimensional and geometric parameters against historical hydroforming datasets. The system generates preliminary cost and lead time estimates within 2 business hours, but crucially, all quotes undergo mandatory review by our senior process engineers. This hybrid approach ensures the AI output accounts for material-specific factors like stainless steel 304 flow stress curves or aluminum 5052 anisotropy, preventing underquoting on complex geometries.

Engineering DFM Analysis

Post-quote approval, our manufacturing engineering team conducts a formal Design for Manufacturability review focused on hydroforming physics. Key analyses include:

Blank development simulation to minimize material waste

Pressure trajectory optimization to prevent wrinkling or thinning beyond 25%

Seal ring geometry validation for the fluid chamber

Tolerance stack-up assessment for critical ±0.1mm features

The DFM report details actionable modifications, such as recommending crown radii adjustments for deep-drawn sections, with annotated CAD markups provided within 72 hours.

Partner Production Execution

Approved designs move to our pre-vetted hydroforming partners. Honyo engineers oversee the entire production phase through:

First-article inspection reports per AS9102 standards

Real-time pressure/temperature monitoring data shared via secure API

In-process dimensional checks at 25%, 50%, and 100% production milestones

We enforce strict material traceability, requiring mill certificates for all AL6061-T6 or SS316L blanks used. Typical lead time from DFM sign-off to completed parts is 15-20 business days for quantities under 500 units.

Quality-Controlled Delivery

All hydroformed components undergo final validation against the original CAD model using 3D laser scanning. Critical dimensions are verified with CMM reports showing GD&T compliance. Parts ship with:

Material certification documentation

First-article inspection package

Process parameter log (max pressure, fluid viscosity, cycle time)

Standard delivery includes protective VCI packaging with humidity indicators, with air freight options for urgent requirements. Our quality management system is ISO 9001:2015 certified, ensuring full auditability.

Note: Hydroforming suitability is confirmed during DFM; we proactively recommend alternative processes like progressive stamping for high-volume runs (>5,000 units) or laser forming for simpler geometries to optimize client costs. This structured workflow maintains Honyo’s 98.7% on-time delivery rate for complex sheet metal projects.

Start Your Project

Discover the precision and efficiency of sheet metal hydroforming with Honyo Prototype. Our advanced manufacturing capabilities in Shenzhen deliver high-quality, complex metal components with tight tolerances and superior surface finish—ideal for prototyping and low-to-mid volume production.

For expert support and project inquiries, contact Susan Leo at [email protected].

Lead Time

As fast as 7–10 days for prototypes

Materials

Stainless steel, aluminum, copper, brass, and specialty alloys

Max Forming Area

Up to 1200 mm × 800 mm

Pressure Capacity

Up to 400 MPa for high-detail reproduction

All production is managed in-house at our Shenzhen facility, ensuring strict quality control and seamless scalability.

Reach out today to discuss your design requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.