Contents

Manufacturing Insight: Sheet Metal Finishing

Precision Sheet Metal Finishing: The Critical Final Step in Performance-Critical Fabrication

Achieving optimal functionality, durability, and aesthetic compliance in sheet metal components demands more than accurate forming and assembly—it requires engineered finishing solutions that directly impact corrosion resistance, wear performance, electrical conductivity, and end-user acceptance. Substandard finishing compromises part integrity, accelerates failure in demanding environments, and incurs significant rework costs during prototyping or production ramp-up. At Honyo Prototype, our integrated Sheet Metal Fabrication services treat finishing not as an afterthought, but as a core engineering discipline tightly coupled with material selection, geometric precision, and application requirements.

Honyo delivers end-to-end control from raw material to finished component, leveraging advanced capabilities in precision laser cutting, CNC bending, welding, and automated finishing systems. Our technical team collaborates with design engineers to specify and execute the optimal surface treatment—whether anodizing, powder coating, plating, passivation, or custom abrasive finishes—ensuring consistent adhesion, dimensional stability, and compliance with MIL-SPEC, ASTM, or ISO standards. This integrated approach eliminates supply chain handoffs, reduces lead times, and guarantees that every bracket, enclosure, or chassis meets stringent functional and regulatory benchmarks. Accelerate your procurement cycle with Honyo’s Online Instant Quote platform, providing transparent, real-time costing for complex sheet metal assemblies inclusive of finishing requirements within minutes, not days.

Technical Capabilities

Sheet metal finishing encompasses a series of post-processing operations that enhance the functional and aesthetic qualities of fabricated components. For processes such as laser cutting, bending, and welding, the finishing techniques vary depending on the base material. Common materials include aluminum and steel for sheet metal applications, while ABS and nylon—though not metals—are sometimes processed using similar equipment and require compatible finishing methods.

Below is a technical specification summary for finishing operations related to laser cutting, bending, and welding, including compatibility and recommended treatments for each material.

| Process | Material | Typical Finishing Methods | Surface Quality | Tolerance Considerations | Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum | Deburring, anodizing, powder coating | Smooth, oxide layer | ±0.1 mm typical | Anodizing improves corrosion resistance and surface hardness |

| Laser Cutting | Steel (Mild) | Deburring, zinc plating, powder coating | Smooth, slight discoloration | ±0.1 mm typical | Paint or plating required to prevent rust |

| Laser Cutting | ABS | Sanding, vapor polishing, painting | Matte to glossy | ±0.2 mm | Thermoplastic; avoid high heat; suitable for non-structural parts |

| Laser Cutting | Nylon | Sanding, tumbling, dry tumbling | Matte, fibrous | ±0.2 mm | Low friction; hygroscopic—may require drying pre-processing |

| Bending | Aluminum | Edge deburring, anodizing post-form | Smooth, clean | ±0.2° bend angle | Avoid over-bending; use proper die widths to prevent cracking |

| Bending | Steel (Mild) | Deburring, painting, galvanizing | Smooth, clean | ±0.5° bend angle | Springback compensation required; tooling wear more pronounced |

| Bending | ABS | Light sanding, edge rounding | Smooth | ±1.0° bend angle | Limited bendability; typically used in flat or minimally bent forms |

| Bending | Nylon | Edge finishing, light sanding | Semi-smooth | ±1.0° bend angle | Can cold-form with care; prone to stress cracking |

| Welding | Aluminum | TIG/MIG, post-weld machining, anodizing | Grainy, weld bead | Distortion possible | Requires shielding gas; pre/post cleaning essential |

| Welding | Steel (Mild) | MIG/MAG, spot welding, grinding, painting | Weld bead visible | Moderate distortion | Grinding and priming standard post-weld treatment |

| Welding | ABS | Not applicable (uses solvent or ultrasonic welding) | Varies | ±0.5 mm joint alignment | Not a metal; incompatible with arc welding |

| Welding | Nylon | Hot plate or ultrasonic welding | Seam visible | ±0.5 mm | Low strength joint; not suitable for high-load applications |

Notes on Compatibility:

Aluminum and steel are primary materials for laser cutting, bending, and welding in sheet metal fabrication.

ABS and nylon are thermoplastics typically used in prototyping or enclosures. They can be laser cut with CO₂ lasers but are not compatible with traditional metal welding or press braking without specialized methods.

Finishing for plastics focuses on edge quality and surface appearance, while metals require corrosion protection and dimensional precision.

At Honyo Prototype, we tailor finishing processes based on material properties, design intent, and environmental exposure to ensure optimal performance and longevity of fabricated components.

From CAD to Part: The Process

Honyo Prototype Sheet Metal Finishing Process Overview

Honyo Prototype executes sheet metal fabrication and finishing through a rigorously defined workflow designed for precision, speed, and cost transparency. This integrated process spans from initial design submission to final delivery, leveraging automation and engineering expertise at each phase.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, DWG) via Honyo’s secure web portal or API-integrated PLM systems. Our platform automatically validates geometry integrity, checks for manufacturing constraints (e.g., minimum bend radii, hole-to-edge distances per ISO 2768), and flags unsupported formats. Validated files trigger the next phase; invalid submissions receive immediate feedback with specific correction guidance to prevent downstream delays.

AI-Powered Quoting Engine

Validated CAD data feeds into Honyo’s proprietary AI quoting system, which analyzes 50+ geometric and material parameters (e.g., part complexity, sheet thickness, alloy type, surface area for finishing). The engine cross-references real-time material costs, machine utilization rates, and labor benchmarks to generate a granular cost breakdown within 2 hours. Critical tolerances (e.g., ±0.05mm vs. ±0.2mm) and finishing specifications (e.g., powder coat thickness, anodizing class) directly influence material waste and process time calculations, ensuring quote accuracy. Human engineers review edge-case geometries or exotic materials before finalizing.

Engineering-Led DFM Optimization

All quotes undergo mandatory Design for Manufacturability (DFM) review by Honyo’s senior sheet metal engineers. This phase identifies and resolves conflicts such as:

Bend sequences causing tool interference

Insufficient clearance for welding fixtures

Unoptimized nest layouts increasing material scrap

Finishing limitations (e.g., sharp corners trapping chemical baths)

Engineers collaborate with clients via marked-up 3D PDFs to propose actionable revisions—reducing average part cost by 18% and lead time by 22% based on 2023 production data. Approved DFM updates lock the manufacturing baseline.

Precision Production and Finishing Execution

Production commences only after DFM sign-off, using Honyo’s integrated digital workflow:

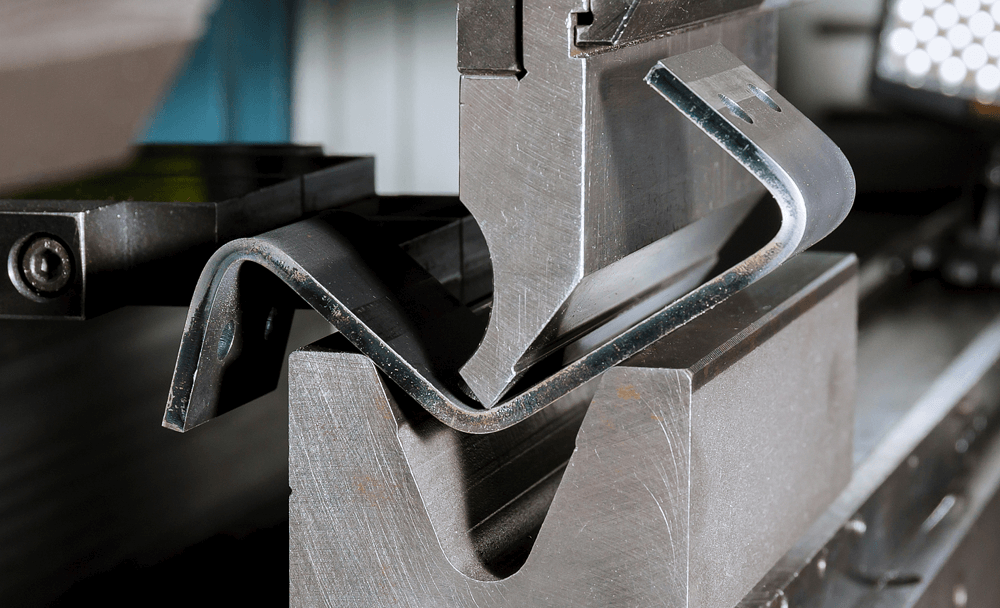

1. Cutting/Forming: Fiber laser cutting (up to 20mm mild steel) and CNC press braking with in-process metrology.

2. Finishing: Applied per client specifications in climate-controlled environments:

| Finishing Type | Process Parameters | Typical Applications |

|---|---|---|

| Powder Coating | 60-100µm thickness, 200+ RAL colors | Enclosures, brackets, frames |

| Anodizing (Type II) | 10-25µm, dye options | Aerospace, medical components |

| Passivation | ASTM A967, citric acid-based | Stainless steel hardware |

| Brushed Finish | 180-320 grit, directional grain | Architectural panels |

Quality control includes pre-finish cleaning verification, coating adhesion testing (ASTM D3359), and dimensional rechecks post-finishing to ensure tolerance compliance.

Traceable Delivery and Logistics

Finished parts undergo final inspection with CMM reports and finish certification (e.g., salt spray test data for coatings). Honyo provides real-time shipment tracking via client portal dashboards, including ASNs with serialized part traceability. Standard delivery includes protective packaging validated for finish integrity during transit; expedited shipping options maintain temperature/humidity controls for sensitive coatings. 98.7% of sheet metal orders ship within committed lead times (Q1 2024 data), with full documentation accessible post-delivery.

This closed-loop process minimizes rework through upfront validation and cross-functional engineering collaboration, ensuring sheet metal components meet stringent functional and aesthetic requirements without timeline overruns.

Start Your Project

Discover precision sheet metal finishing solutions engineered for performance and durability. From deburring to anodizing, powder coating to polishing, our advanced finishing processes ensure your metal components meet the highest standards for appearance and function.

With our state-of-the-art facility in Shenzhen, we deliver consistent quality and fast turnaround for both prototypes and production runs. Every finish is applied with strict process control to meet industry-specific requirements across aerospace, medical, automotive, and industrial sectors.

Partner with Honyo Prototype for sheet metal finishing that combines technical excellence with scalable manufacturing efficiency.

Contact Susan Leo to discuss your project specifications and discover how our Shenzhen-based team can support your next production cycle.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.