Contents

Manufacturing Insight: Sheet Metal Fabrication Prototyping

Accelerating Precision Sheet Metal Prototyping with Honyo

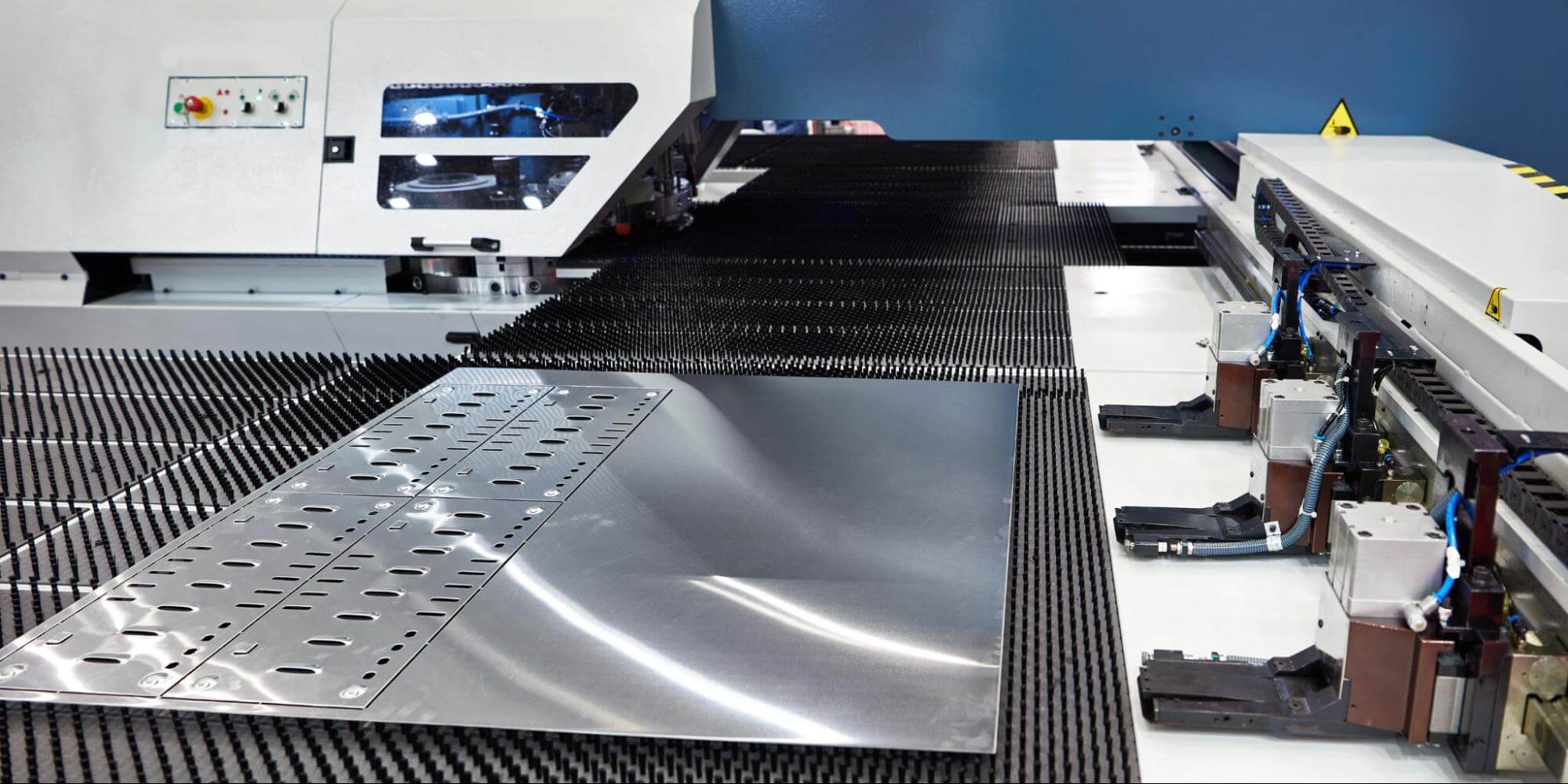

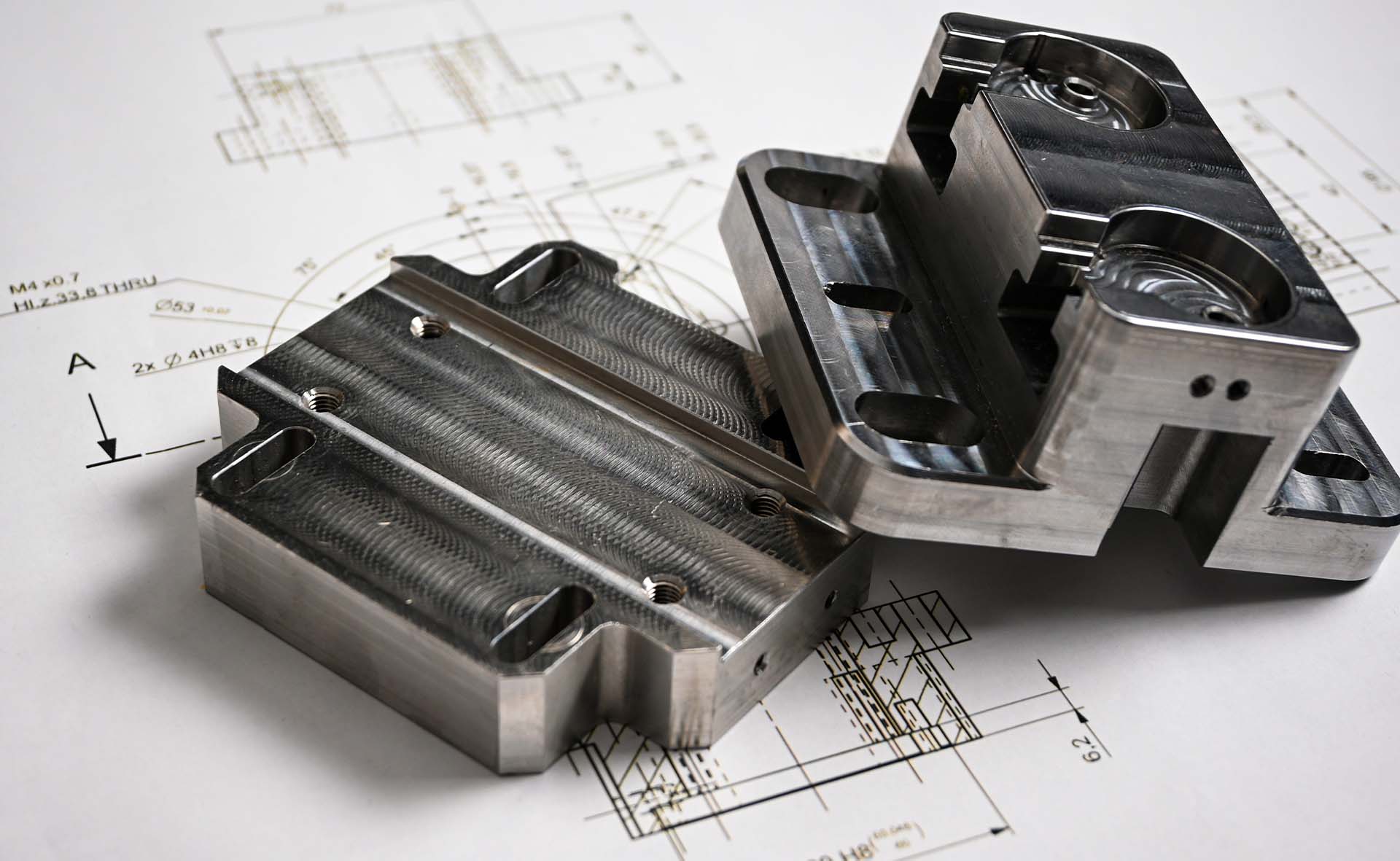

In the demanding landscape of product development, rapid and accurate sheet metal prototyping is critical for validating designs, ensuring manufacturability, and accelerating time-to-market. Traditional prototyping processes often introduce delays through manual quoting, extended lead times, and limited feedback on design feasibility. Honyo Prototype addresses these challenges with a dedicated Sheet Metal Fabrication service engineered for speed, precision, and seamless collaboration. Our end-to-end solution leverages advanced CNC punching, laser cutting, bending, and welding capabilities across materials including aluminum, stainless steel, and galvanized steel, consistently achieving tolerances down to ±0.1mm.

What sets Honyo apart is our commitment to eliminating quoting bottlenecks. Our proprietary Online Instant Quote system allows engineering teams to upload CAD files and receive detailed, transparent cost and lead-time estimates in under 60 seconds—no manual intervention required. This immediate visibility enables faster iteration cycles and informed decision-making during the critical prototyping phase. Combined with expert Design for Manufacturability (DFM) feedback and rigorous in-process quality checks, we ensure your prototypes meet functional and dimensional requirements on the first try.

For engineering teams prioritizing agility without compromising precision, Honyo delivers prototyping that aligns with real-world production constraints. Begin your next project with confidence: submit your design today and experience the efficiency of instant quoting paired with manufacturing expertise.

Technical Capabilities

Technical specifications for sheet metal fabrication prototyping involve key processes such as laser cutting, bending, and welding. These processes are critical in producing accurate and functional prototypes for design validation and small-batch production. Below is a summary of the technical capabilities and material considerations for each process.

| Process | Tolerance | Minimum Feature Size | Max Sheet Size | Material Compatibility (Common) | Notes |

|---|---|---|---|---|---|

| Laser Cutting | ±0.1 mm | 0.5 mm (hole diameter) | 1500 mm × 3000 mm | Aluminum (e.g., 5052, 6061), Mild Steel (e.g., CRCA, SPCC), Stainless Steel (e.g., 304, 316) | ABS and Nylon are not suitable for laser cutting due to melting and hazardous fumes; alternative methods like CNC routing recommended |

| Bending | ±0.25° (angle), ±0.2 mm (dimensional) | Bend radius ≥ 0.8 mm (material-dependent) | 1500 mm × 3000 mm | Aluminum, Steel (Mild & Stainless) | ABS and Nylon sheets can be bent using heated forming but are not compatible with standard press brake tooling; not standard in metal-focused fabrication |

| Welding | ±0.5 mm (joint alignment) | N/A (joint design dependent) | Limited by fixturing and part size | Aluminum (TIG/MIG), Mild & Stainless Steel (TIG, MIG, Spot) | ABS and Nylon are non-weldable via arc processes; joined via adhesives or solvent welding; not applicable in typical metal welding workflows |

Additional Notes:

Aluminum and steel are the primary materials used in sheet metal prototyping due to their structural integrity, formability, and compatibility with industrial fabrication equipment. ABS and Nylon, while common in prototyping, are thermoplastics and not suitable for laser cutting (without specialized systems), bending on press brakes, or arc welding. Their use in this context is typically limited to non-structural enclosures or components fabricated via alternative methods such as CNC machining or 3D printing. For hybrid assemblies, mechanical fastening or adhesive bonding is used to integrate plastic components with sheet metal parts.

From CAD to Part: The Process

Honyo Prototype Sheet Metal Fabrication Prototyping Process

Honyo Prototype streamlines sheet metal prototyping through an integrated digital workflow designed for speed, accuracy, and manufacturability. Our process begins with seamless CAD integration and concludes with certified delivery, ensuring rapid iteration for engineering validation. Below is a detailed technical overview of each phase.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, DWG, DXF, or native SolidWorks/Inventor formats) via our secure online portal. Our system automatically validates geometry integrity, checks for missing features (e.g., fillets, chamfers), and confirms unit consistency (mm/inch). Invalid files trigger immediate feedback specifying required corrections, reducing submission delays. All data undergoes ISO 27001-compliant encryption during transfer and storage.

AI-Powered Quoting Engine

Uploaded designs enter our proprietary AI quoting system, which analyzes 200+ geometric and material parameters to generate instant cost and lead time estimates. The algorithm factors in material waste optimization, machine setup complexity, secondary operations (e.g., tapping, welding), and regional resource availability. Quotes include granular cost breakdowns (material, labor, finishing) with 90% accuracy for standard geometries, validated against 50,000+ historical production runs. Complex designs exceeding AI confidence thresholds are escalated to senior engineers within 2 business hours.

Engineering-Led DFM Analysis

Every design undergoes mandatory Design for Manufacturability (DFM) review by our ASME-certified engineers. This phase identifies and resolves critical issues before production:

| Common DFM Issue | Honyo Resolution Protocol | Impact Mitigated |

|---|---|---|

| Bend radius < material thickness | Recommend adjusted radius or alternative material grade | Prevents cracking at bends |

| Hole-to-edge distance < 2x material thickness | Propose relocated holes or stepped features | Eliminates deformation risks |

| Unbendable nested features | Redesign for sequential bending or laser cuts | Avoids assembly failures |

| Tolerance stack-ups | Optimize GD&T callouts per ASME Y14.5 | Ensures fit/function accuracy |

Clients receive a formal DFM report with annotated CAD markups and actionable revision suggestions. 78% of prototypes require ≤2 DFM iterations, accelerating time-to-test.

Precision Production and Quality Control

Approved designs move to our automated production floor featuring Amada CNC punch presses, Bystronic fiber lasers (±0.1mm accuracy), and TruBend press brakes. Key protocols include:

Material certification is tracked via blockchain-secured lot numbers, with full traceability from coil to shipment. First-article inspections verify critical dimensions per ISO 286-2, while in-process checks monitor bend angles (±1° tolerance) and hole positional accuracy. All prototypes undergo flatness validation (≤0.5mm/m²) and deburring verification per customer specifications.

Certified Delivery and Documentation

Completed prototypes ship in ESD-safe, crush-proof packaging with serialized labels matching the work order. Each delivery includes:

FAI report with CMM scan data (PDF/Excel)

Material test certificates (ASTM A653/A363 compliance)

Process validation records (laser power logs, bend sequence parameters)

DFM closure documentation confirming all resolved issues

Standard lead time is 3–5 business days from DFM approval, with expedited 72-hour options for urgent validations. All shipments include real-time GPS tracking and customs documentation for global clients.

This closed-loop process ensures engineering teams receive functionally accurate prototypes that reflect final production intent, enabling reliable testing while minimizing iteration costs. Honyo’s integration of AI-driven quoting with hands-on DFM expertise bridges the gap between design intent and manufacturable reality, with 95% of clients transitioning validated prototypes directly to volume production using identical process parameters.

Start Your Project

Looking to accelerate your product development with precision sheet metal fabrication prototyping? Partner with Honyo Prototype for fast, reliable, and high-quality prototyping services directly from our state-of-the-art facility in Shenzhen.

Our in-house manufacturing capabilities enable rapid turnaround times without compromising on accuracy or material integrity—ideal for low-volume prototypes and pre-production validation.

Contact Susan Leo today to discuss your project requirements or request a quote.

Email: [email protected]

Let’s bring your designs to life with engineering precision and manufacturing excellence.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.