Contents

Manufacturing Insight: Sheet Metal Fabrication Denver Co

Precision Sheet Metal Solutions for Denver Manufacturers

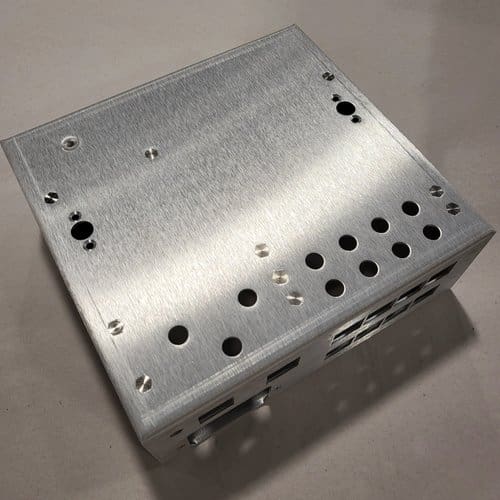

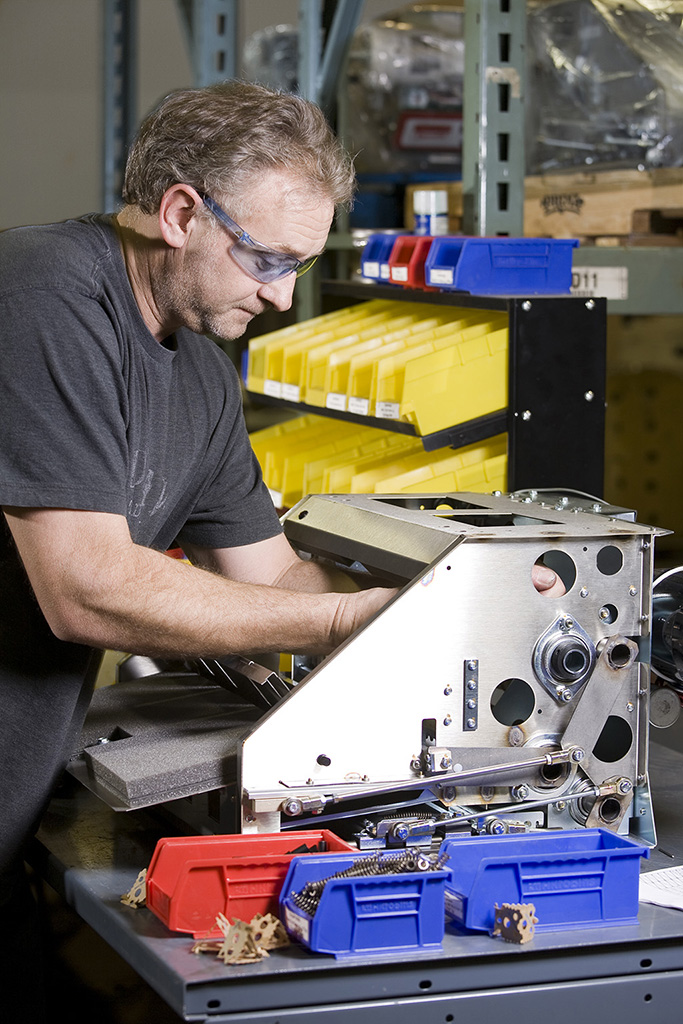

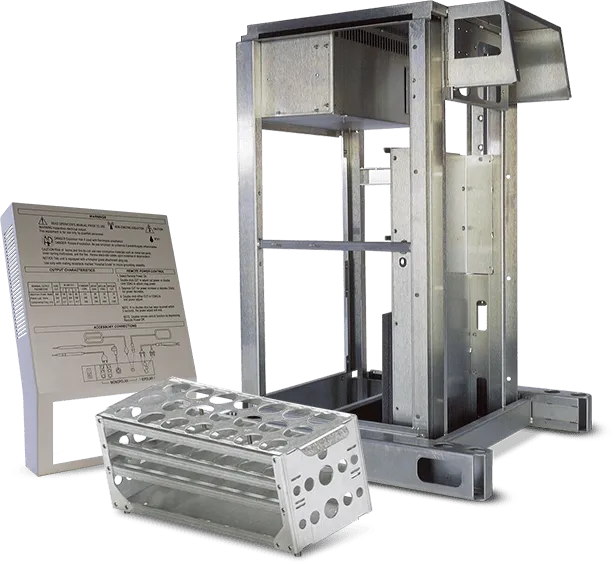

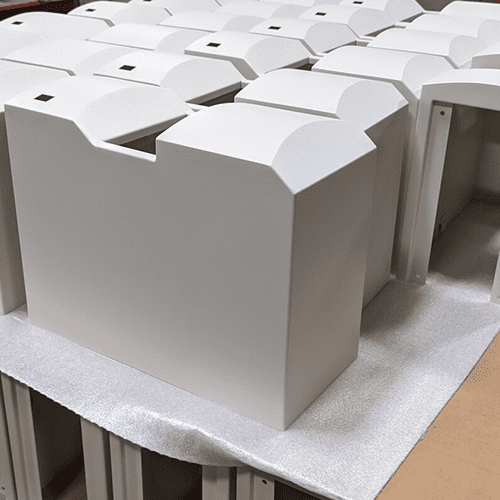

Honyo Prototype delivers advanced sheet metal fabrication services engineered to meet the exacting demands of Colorado’s industrial, aerospace, and technology sectors. Located strategically to serve the Denver metropolitan area, our ISO 9001-certified facility combines state-of-the-art machinery—including multi-axis laser cutters, CNC turret presses, and robotic welding cells—with deep technical expertise in materials ranging from aluminum alloys to stainless steel and specialty composites. We excel in producing complex components with tight tolerances down to ±0.005 inches, supporting prototyping through high-volume production with rigorous in-process quality validation.

For Denver-area businesses requiring rapid turnaround without compromising precision, our Online Instant Quote system eliminates traditional procurement delays. Simply upload your STEP or DWG file to receive a detailed, transparent cost estimate in minutes—not days—enabling faster project initiation and supply chain responsiveness. This digital workflow, backed by our engineering team’s review, ensures manufacturability feedback is integrated before production begins, reducing costly revisions.

Partner with Honyo Prototype for sheet metal fabrication in Denver CO where technical excellence, local logistics efficiency, and digital quoting innovation converge to accelerate your product development lifecycle. Initiate your project with confidence through our secure online portal today.

Technical Capabilities

Honyo Prototype provides precision sheet metal fabrication services in Denver, CO, with advanced capabilities in laser cutting, bending, and welding. Our facility supports a range of materials including aluminum, steel, ABS, and nylon, enabling versatile production for prototyping and low-to-mid volume manufacturing. Below are the technical specifications for our core fabrication processes.

| Process | Material Compatibility | Thickness Range | Tolerance | Equipment Type | Max Work Envelope | Additional Notes |

|---|---|---|---|---|---|---|

| Laser Cutting | Aluminum, Steel, ABS, Nylon | 0.015″ – 0.375″ (Al), 0.015″ – 0.500″ (Steel), 0.030″ – 0.250″ (ABS, Nylon) | ±0.005″ per cut | Fiber Laser & CO2 Laser Systems | 4′ x 8′ (1219 x 2438 mm) | High-precision cutting with minimal heat-affected zone; suitable for intricate geometries |

| CNC Bending | Aluminum, Steel | 0.015″ – 0.250″ | ±0.5° angular, ±0.010″ linear | CNC Press Brakes (up to 100-ton) | Up to 10 ft bed length | Capable of complex forming with tight bend radii; includes coining and air bending |

| MIG/TIG Welding | Aluminum, Steel | 0.030″ – 0.500″ | ±0.015″ alignment | MIG & TIG Welding Stations | Full weldment assembly up to 60″ x 48″ | Certified welders; welds meet AWS D1.1 standards; post-weld machining available |

| Plastic Forming & Joining | ABS, Nylon | 0.060″ – 0.250″ | ±0.020″ | Thermal Bending & Solvent Welding | Up to 48″ x 96″ panels | Non-metallic fabrication with edge conditioning and custom fitments |

All processes are supported by in-house engineering review, CAD/CAM integration, and first-article inspection. Secondary operations such as deburring, tapping, hardware insertion, and surface finishing are also available. Honyo Prototype maintains ISO 9001-compliant quality systems to ensure consistency and reliability across all fabricated components.

From CAD to Part: The Process

Honyo Prototype executes sheet metal fabrication services for clients in Denver, CO, and nationwide through a standardized, technology-driven workflow. While Honyo operates centralized manufacturing facilities in California, we serve Denver-based clients with seamless logistics and dedicated support. Our process ensures precision, speed, and cost transparency from initial design to final delivery.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, DWG, DXF, or native SOLIDWORKS) via our secure online portal. The system validates file integrity and extracts critical geometric data, material specifications, and finish requirements. All uploads are protected under ISO 27001-compliant security protocols to safeguard intellectual property. Denver clients receive immediate upload confirmation with a unique project ID for tracking.

AI-Powered Quoting

Our proprietary AI engine analyzes the CAD geometry, material type, thickness, quantity, and surface finish to generate an instant preliminary quote. The algorithm factors in real-time material pricing, machine availability, and geometric complexity metrics such as bend counts, cut paths, and feature density. Quotes include detailed cost breakdowns for fabrication, finishing, and shipping to Denver ZIP codes, typically returned within 2 business hours. This eliminates manual quoting delays while maintaining accuracy within 5% of final production costs.

Automated DFM Analysis

Following quote acceptance, the system performs an automated Design for Manufacturability (DFM) review. The AI checks for sheet metal-specific constraints including minimum bend radii relative to material thickness, hole-to-edge distances, flange width feasibility, and nestability. Common Denver-project issues like inadequate clearance for brake press tooling or non-standard material grades trigger specific remediation suggestions. Engineers receive a color-coded DFM report with actionable recommendations within 24 hours, reducing prototyping iterations by up to 70%.

Production Execution

Approved designs enter production at our California facility using industry-leading equipment. Laser cutting employs Amada LC series machines with ±0.005″ tolerance, followed by precision forming on CNC press brakes (TruBend 7030 series). Secondary operations include tapping, welding (TIG/MIG), and finishing (powder coating, anodizing). Every Denver-bound order undergoes in-process inspections at critical stages, with first-article reports provided for quantities over 50 units. All components comply with ISO 9001:2015 and AS9100D standards.

Delivery to Denver

Completed orders are packaged with anti-corrosion VCI paper and shipped via preferred carriers (UPS, FedEx, or dedicated freight). Standard delivery to Denver averages 3–5 business days from shipment date. Expedited options include:

| Shipping Method | Origin | Transit Time to Denver | Tracking Integration |

|---|---|---|---|

| Ground Freight | Fremont, CA | 3 business days | Real-time GPS |

| Air Express | Fremont, CA | 1–2 business days | Integrated carrier |

| Dedicated Fleet | Fremont, CA | Same/next day | Direct Honyo portal |

Clients receive automated shipment notifications with tracking links and delivery confirmation. Denver-based quality teams can schedule dock appointments for urgent projects, ensuring seamless integration into local supply chains. Honyo maintains 98.5% on-time delivery performance for the Rocky Mountain region through strategic logistics partnerships.

Start Your Project

Looking for reliable sheet metal fabrication services in Denver, CO? Partner with Honyo Prototype for precision manufacturing and fast turnaround. Our engineering team, led by Susan Leo, specializes in custom sheet metal solutions for prototyping and low-volume production.

Although our fabrication facility is based in Shenzhen—offering advanced capabilities and cost efficiency—we provide seamless service to clients across North America, including Denver.

For project inquiries or to request a quote, contact Susan Leo directly at [email protected]. Let’s build your next prototype with precision and speed.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.