Contents

Manufacturing Insight: Sheet Metal Dome

Precision Sheet Metal Domes: Engineered for Performance at Honyo Prototype

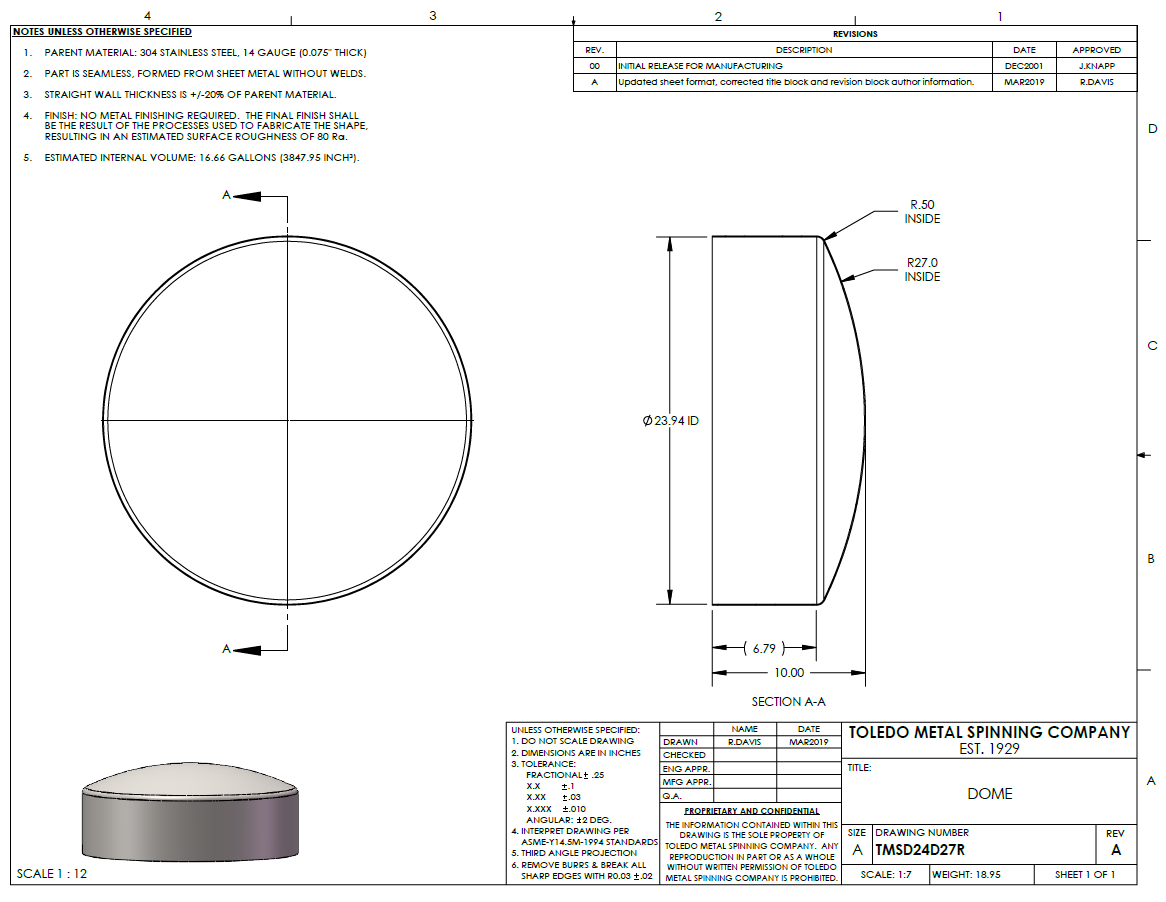

Sheet metal domes represent a critical component in applications demanding structural integrity, aerodynamic efficiency, and precise geometric complexity—from aerospace enclosures to medical device housings and consumer electronics. Achieving consistent repeatability in dome geometry, wall thickness uniformity, and surface finish requires advanced forming capabilities and deep material science expertise, particularly when managing challenges like springback, distortion, and tight tolerance control.

Honyo Prototype delivers end-to-end sheet metal fabrication services engineered specifically for complex geometries like domes, leveraging state-of-the-art CNC press brakes, precision laser cutting, and robotic welding systems. Our process integrates rigorous material selection guidance, in-house tooling design for custom radii, and real-time metrology validation to ensure every dome meets exacting dimensional and functional requirements. We specialize in low-volume, high-mix prototyping and bridge production, supporting alloys from aluminum 5052 and 6061 to stainless steel 304/316 and titanium, with tolerances held to ±0.005″ consistently.

For engineering teams under aggressive development timelines, our Online Instant Quote platform eliminates traditional quotation delays. Upload your STEP or DWG file, specify material and finish requirements, and receive a detailed manufacturability analysis with lead time and pricing in under 60 seconds—enabling faster iteration cycles without compromising on quality or precision.

Accelerate Your Dome Prototyping Timeline

| Service Stage | Industry Standard Lead Time | Honyo Prototype Lead Time |

|————————-|—————————–|—————————|

| Quotation Response | 2–5 business days | Under 60 seconds |

| Prototype Fabrication | 10–15 business days | 5–7 business days |

Leverage Honyo’s expertise to transform complex dome designs into validated, production-ready components. Initiate your project with confidence—submit your design for an Online Instant Quote today and experience the speed of precision manufacturing.

Technical Capabilities

Technical Specifications for Sheet Metal Dome Fabrication

The fabrication of a sheet metal dome involves precision processes including laser cutting, bending, and welding. The choice of material significantly influences process parameters, tooling requirements, and final performance. Below is a detailed comparison of applicable materials—Aluminum, Steel, ABS, and Nylon—within the context of these manufacturing operations.

| Process | Aluminum | Steel | ABS | Nylon |

|---|---|---|---|---|

| Laser Cutting | Compatible; requires high-power fiber laser (1kW+). Reflective nature demands proper beam control and assist gas (N₂ or O₂). Clean cuts achievable with minimal dross. | Excellent compatibility; CO₂ or fiber lasers effective. Oxygen assist enhances cut speed and edge quality. High precision with tight tolerances (±0.1 mm typical). | Not recommended for true laser cutting in structural applications. Can be cut with CO₂ lasers at low power, but edge melting and poor structural integrity are common. | Limited compatibility; prone to melting and charring. CO₂ lasers may mark or cut thin sheets, but not suitable for load-bearing dome structures. |

| Bending | Good formability; typical bend radii ≥1× material thickness. Springback must be compensated in tooling. Annealed grades (e.g., 5052-H32) preferred for complex curves. | High ductility in mild steel; bend radii ≥0.5× thickness achievable. Requires higher tonnage than aluminum. Tooling must account for springback and work hardening. | Not applicable for conventional press braking. Can be thermoformed, but not bent like sheet metal. Requires mold-based forming. | Not suitable for standard bending. Requires heating (thermoforming) for shaping; not compatible with metal bending tools. |

| Welding | Requires TIG or MIG with filler (e.g., 4043/5356). Pre-cleaning and inert gas shielding essential. Heat distortion control critical for domes. | Readily welded via MIG, TIG, or spot welding. Good penetration and joint strength. Post-weld treatments may be needed for corrosion resistance. | Cannot be welded using metal techniques. Joining via adhesives or ultrasonic welding possible, but not structural in dome applications. | Joining via adhesives or thermal methods; not weldable in traditional sense. Limited structural joining capability for dome assembly. |

| Typical Use in Domes | Preferred for lightweight, corrosion-resistant enclosures. Common in aerospace and outdoor enclosures. | Used for structural domes requiring high strength and durability. Typical in industrial and heavy equipment housings. | Used only in non-structural, low-stress covers or prototypes. Not suitable for sheet metal fabrication processes. | Rarely used in dome structures requiring metal-like strength. Limited to niche, non-load-bearing applications. |

Notes:

Aluminum and Steel are the only viable materials for true sheet metal dome fabrication involving laser cutting, bending, and welding.

ABS and Nylon are thermoplastics and do not conform to standard sheet metal processing workflows. Their inclusion is for comparative clarity only.

Dome geometry influences process complexity—curved profiles may require segmented bending or spinning techniques in addition to laser-cut flat patterns.

From CAD to Part: The Process

Honyo Prototype Sheet Metal Dome Manufacturing Process

Honyo Prototype executes a streamlined, technology-driven workflow for sheet metal dome fabrication, ensuring precision, cost efficiency, and rapid turnaround. The process begins with CAD file submission and concludes with certified delivery, integrating AI and engineering rigor at critical stages.

Upload CAD

Clients initiate the process by uploading detailed 3D CAD models (IGES, STEP, or native formats) via Honyo’s secure customer portal. For domes, geometric accuracy is critical; the system validates file integrity, checks for missing features like flanges or embossments, and confirms compliance with minimum radius-to-thickness ratios (typically ≥ 3:1 for deep draws). Unsupported formats trigger immediate client notification for resubmission, minimizing delays.

AI Quote Generation

Honyo’s proprietary AI engine analyzes the CAD geometry within 24 hours, calculating material utilization, forming complexity, and secondary operation requirements. For domes, the AI specifically evaluates draw depth, aspect ratio, and potential wrinkling risks using historical press-brake and stamping data. Real-time material pricing (e.g., 304 stainless, 5052 aluminum) and machine-hour costs are factored, generating a granular quote with cost drivers transparently itemized. Clients receive options for material substitutions or design tweaks to optimize cost without engineering intervention.

DFM Analysis

Engineers conduct a formal Design for Manufacturability review, focusing on dome-specific challenges. Key checks include:

Springback compensation for curved surfaces

Blank size optimization to prevent tearing at the dome apex

Tooling feasibility assessment (e.g., progressive die vs. hydraulic press)

Tolerance stack-up validation for mating features

Clients receive a DFM report with actionable recommendations, such as adjusting radii to reduce secondary machining or modifying bead patterns to enhance structural rigidity. This phase typically reduces prototyping iterations by 40–60%.

Production

Approved designs move to production using Honyo’s automated workflow:

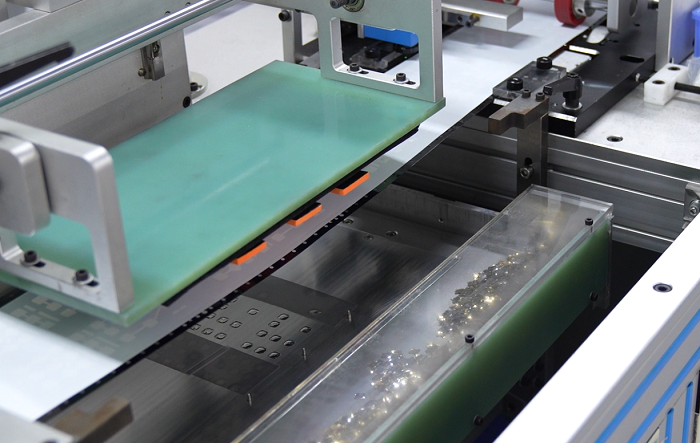

Material Prep: Laser cutting of blanks with 0.1mm positional accuracy

Forming: CNC press-brake forming (for shallow domes) or hydraulic stamping (depths >25mm) with real-time springback correction

Secondary Ops: Deburring, precision welding (if assemblies), and surface finishing (e.g., anodizing, powder coating)

In-Process Inspection: CMM verification of critical dome curvature (±0.05mm) and base flatness at 50% and 100% production stages

Delivery

All domes undergo final QA against AS9100-certified protocols, including dimensional reports and material traceability documentation. Fragile components are packaged in custom anti-static foam with humidity control. Shipments include a digital twin of the as-manufactured part for client validation. Standard lead time from CAD upload to delivery is 7–12 business days for prototypes and 15–20 days for low-volume production (1–500 units).

Typical Sheet Metal Dome Capabilities

| Parameter | Range | Notes |

|---|---|---|

| Material Thickness | 0.5mm – 3.0mm | Up to 4.0mm for aluminum alloys |

| Dome Diameter | 20mm – 600mm | Limited by press capacity (100T max) |

| Depth-to-Diameter | 0.1:1 – 0.8:1 | >0.5:1 requires progressive die |

| Tolerance (Radius) | ±0.1mm (shallow), ±0.3mm (deep) | Per ASME Y14.5 GD&T |

| Surface Finish | #4 Brush, Mill, Anodized, Powder Coat | Custom textures available |

This integrated process ensures domes meet stringent functional and aesthetic requirements while accelerating time-to-market. Honyo’s closed-loop system captures production data to refine future AI quoting accuracy and DFM guidance.

Start Your Project

Looking for high-quality sheet metal domes for your next project? Partner with Honyo Prototype for precision manufacturing and fast turnaround.

Our factory in Shenzhen is equipped to handle low to high-volume production with strict quality control and competitive pricing.

Contact Susan Leo today at [email protected] to discuss your sheet metal dome requirements and receive a personalized quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.