Contents

Manufacturing Insight: Sheet Metal Dome Fabrication

Precision Sheet Metal Dome Fabrication Solutions from Honyo Prototype

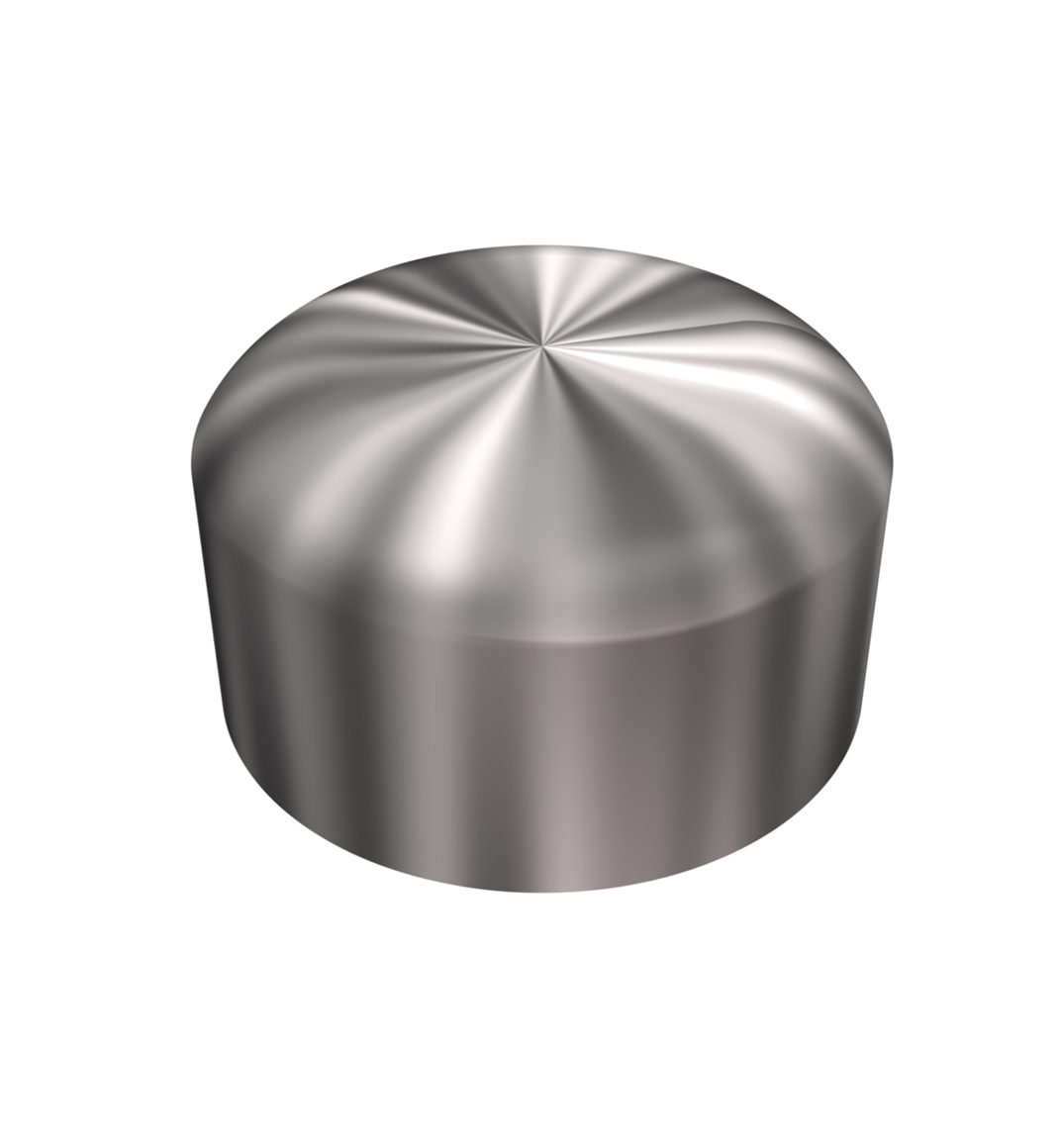

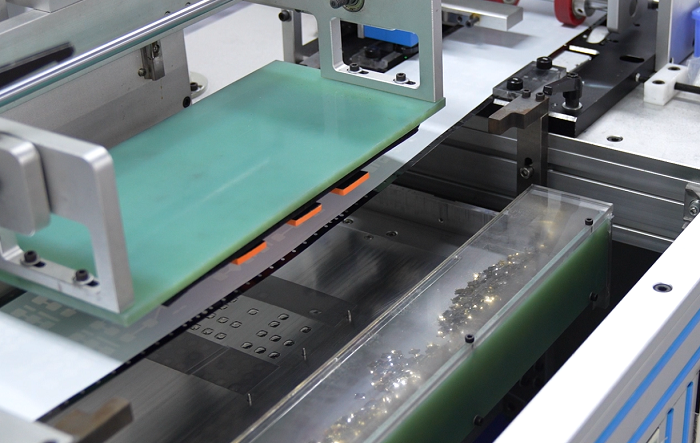

Honyo Prototype delivers advanced sheet metal fabrication expertise, specializing in the precise and reliable production of complex sheet metal domes for demanding industrial applications. Our engineering-driven approach ensures domes meet exacting specifications for structural integrity, dimensional accuracy, and surface finish, whether required for enclosures, pressure components, aesthetic housings, or specialized mechanical assemblies. Leveraging state-of-the-art CNC punching, laser cutting, precision bending, and seamless welding capabilities, we handle diverse materials including stainless steel, aluminum, and specialty alloys to achieve tight tolerances and consistent repeatability.

Our comprehensive sheet metal dome fabrication services encompass full design for manufacturability (DFM) support, prototyping, low to high-volume production, and integrated secondary operations such as finishing, hardware insertion, and assembly. We understand the critical role domes play in your product’s performance and aesthetics, committing to rigorous quality control throughout the manufacturing process to eliminate defects and ensure on-time delivery. Eliminate quoting delays and gain immediate cost visibility for your dome projects with Honyo’s Online Instant Quote system. Simply upload your 3D CAD file or technical drawing to receive a detailed, transparent fabrication quote within hours, accelerating your design-to-production workflow significantly. Partner with Honyo Prototype for technically superior sheet metal dome solutions backed by responsive engineering support and streamlined procurement. Initiate your project with confidence using our instant quoting platform today.

Technical Capabilities

Sheet metal dome fabrication involves precision manufacturing processes including laser cutting, bending, and welding to produce structural or enclosure components. The selection of materials such as Aluminum, Steel, ABS, and Nylon significantly influences the feasibility and methodology of each process. Below is a technical specification summary for each process based on material compatibility and standard industry practices.

| Process | Material | Thickness Range | Tolerances | Surface Finish Considerations | Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum | 0.5 mm – 12 mm | ±0.1 mm | Smooth edge, minimal dross; may require deburring | Highly suitable; reflective nature managed with appropriate laser settings |

| Steel (Mild) | 0.8 mm – 20 mm | ±0.1 mm | Oxide layer possible; post-process cleaning advised | Excellent compatibility; high precision and edge quality | |

| ABS | 1 mm – 6 mm | ±0.2 mm | Melted, sealed edges; slight charring possible | Limited use; typically not recommended for structural domes | |

| Nylon | 1 mm – 6 mm | ±0.2 mm | Melted edges with thermal distortion risk | Not ideal for laser cutting due to poor heat resistance | |

| Bending | Aluminum | 0.5 mm – 10 mm | ±0.2° angular, ±0.1 mm | Smooth finish; risk of surface marking | Requires controlled V-die and tooling to prevent cracking |

| Steel (Mild) | 0.8 mm – 15 mm | ±0.2° angular, ±0.1 mm | Minimal deformation with proper tooling | Excellent bendability; springback must be compensated | |

| ABS | Not recommended | N/A | High risk of cracking under stress | Thermoplastic behavior makes cold bending impractical | |

| Nylon | Not recommended | N/A | Poor form stability and high elasticity | Not suitable for standard press brake forming | |

| Welding | Aluminum | ≥2 mm typical | ±0.5 mm alignment | Requires post-weld finishing; oxidation possible | TIG or MIG preferred; needs shielding gas and skilled technique |

| Steel (Mild) | ≥1 mm typical | ±0.5 mm alignment | Spatter possible; grindable to smooth finish | Highly weldable; commonly done with MIG or spot welding | |

| ABS | Not applicable | N/A | Solvent or ultrasonic welding only | Not compatible with arc or laser welding; limited structural integrity | |

| Nylon | Not applicable | N/A | Limited to hot-plate or vibration welding | Not suitable for metal-based welding processes |

General Observations

Laser cutting is highly effective for Aluminum and Steel sheet metal domes, providing tight tolerances and clean edges. Bending operations are standard for metals but not feasible for ABS and Nylon due to their thermoplastic nature and low yield strength under forming stress. Welding is structurally viable only for Aluminum and Steel, with process selection dependent on joint design and environmental requirements. ABS and Nylon domes are typically fabricated via molding or additive manufacturing rather than sheet metal techniques.

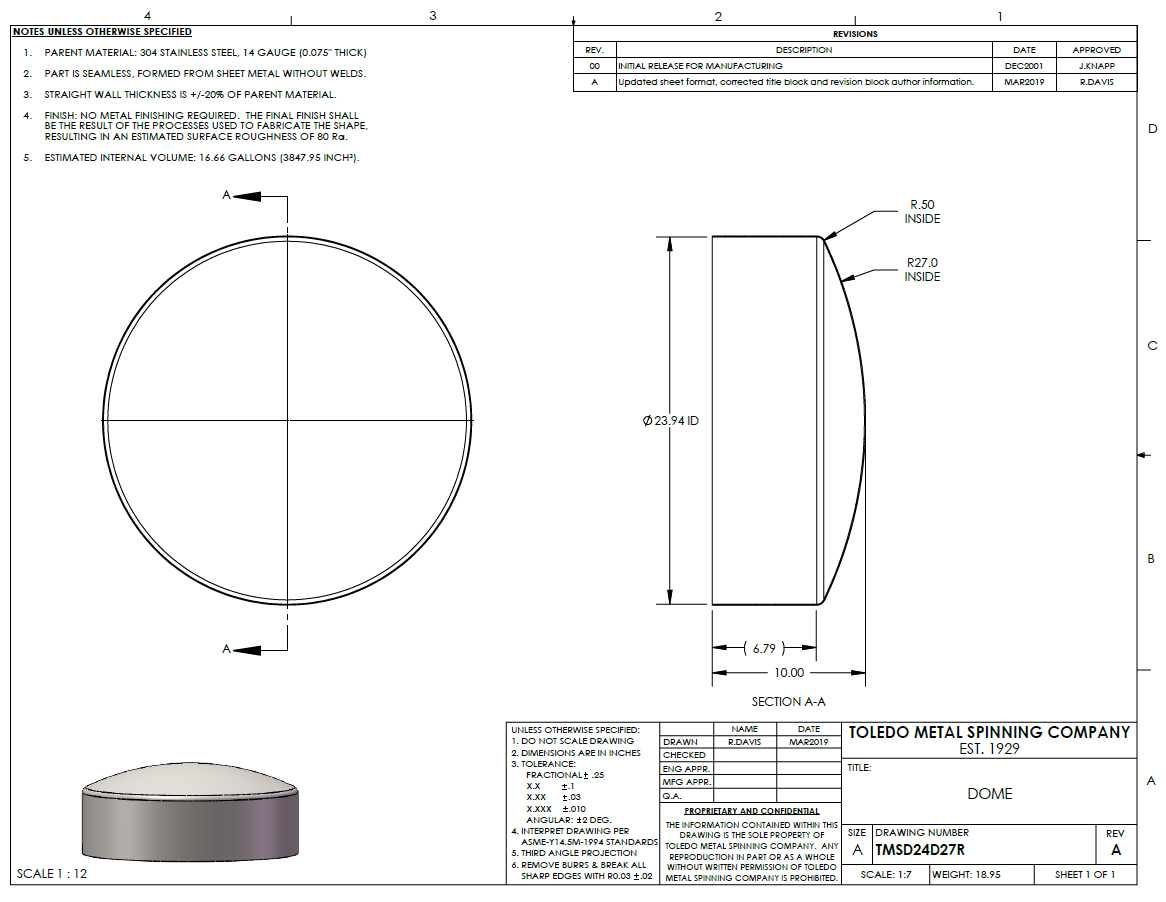

From CAD to Part: The Process

Honyo Prototype executes sheet metal dome fabrication through a rigorously controlled five-stage workflow optimized for precision domes requiring deep drawing, stretch forming, or hydroforming. This process ensures geometric accuracy, material integrity, and on-time delivery for complex curved components.

CAD Upload

Customers initiate the process by uploading native 3D CAD files (STEP, IPT, SLDPRT, or Parasolid formats) via our secure customer portal. For dome geometries, we specifically validate surface continuity, draft angles, and minimum radius-to-thickness ratios against material capabilities. Our system automatically checks for manufacturability thresholds such as a minimum dome height-to-diameter ratio of 0.15 and maximum depth limitations based on material ductility.

AI Quote Generation

Within 90 minutes, our AI-powered quoting engine analyzes the dome geometry against 12,000+ historical production datasets. It calculates cost drivers unique to domes: deep-draw tooling complexity (progressive vs. compound dies), material waste factors for circular blanks, and required press tonnage (typically 300–1,200 tons for diameters 50–500mm). The quote includes explicit allowances for springback compensation and secondary operations like flange trimming or edge rolling, with material utilization efficiency metrics provided.

DFM Analysis

All dome designs undergo mandatory Design for Manufacturability review by our tooling engineers. Key dome-specific checks include:

| DFM Parameter | Critical Threshold | Action if Violated |

|---|---|---|

| Wall thickness reduction | >25% of original | Redesign dome profile or recommend alternative material |

| Grain direction alignment | Not radial to dome apex | Mandate blank orientation specification |

| Minimum radius | <8x material thickness | Propose multi-stage forming sequence |

| Springback prediction | >0.5° angular deviation | Integrate CNC radius compensation in tool path |

This phase includes FEA simulation of material flow during forming to prevent wrinkling or tearing, with tolerance stack-up analysis for critical spherical radii (±0.1mm achievable).

Production Execution

Approved designs move to production using our dedicated dome fabrication cell:

Blanking: Laser cutting of circular blanks with 0.05mm positional accuracy

Forming: Hydraulic presses (500–1,200 ton capacity) with CNC-controlled draw depth and blank holder force; domes >200mm diameter use hydroforming for uniform wall thickness

Secondary Operations: In-die flange curling, precision grinding of sealing surfaces, and automated deburring

In-Process Verification: First-article inspection of dome profile using coordinate measuring machines with 3D surface deviation mapping against CAD nominal

Delivery and Certification

Final domes undergo comprehensive quality validation before shipment:

Full FAI report per AS9102 with spherical radius measurements at 8 azimuthal points

Material certification traceable to mill test reports

Dimensional inspection package including wall thickness mapping at crown, mid-radius, and flange zones

Protective packaging with custom foam inserts preventing deflection during transit

Standard lead time from CAD approval to delivery is 12–18 days for quantities ≤500 units, with expedited 7-day options for critical applications. All deliverables include digital quality records accessible via customer portal.

Start Your Project

Looking for precision sheet metal dome fabrication? Partner with Honyo Prototype for high-quality, custom solutions tailored to your specifications. With our advanced manufacturing capabilities and strategic location in Shenzhen, we deliver fast turnaround and consistent quality for prototyping and low-volume production.

Contact Susan Leo today at [email protected] to discuss your project requirements and get a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.