Guide Contents

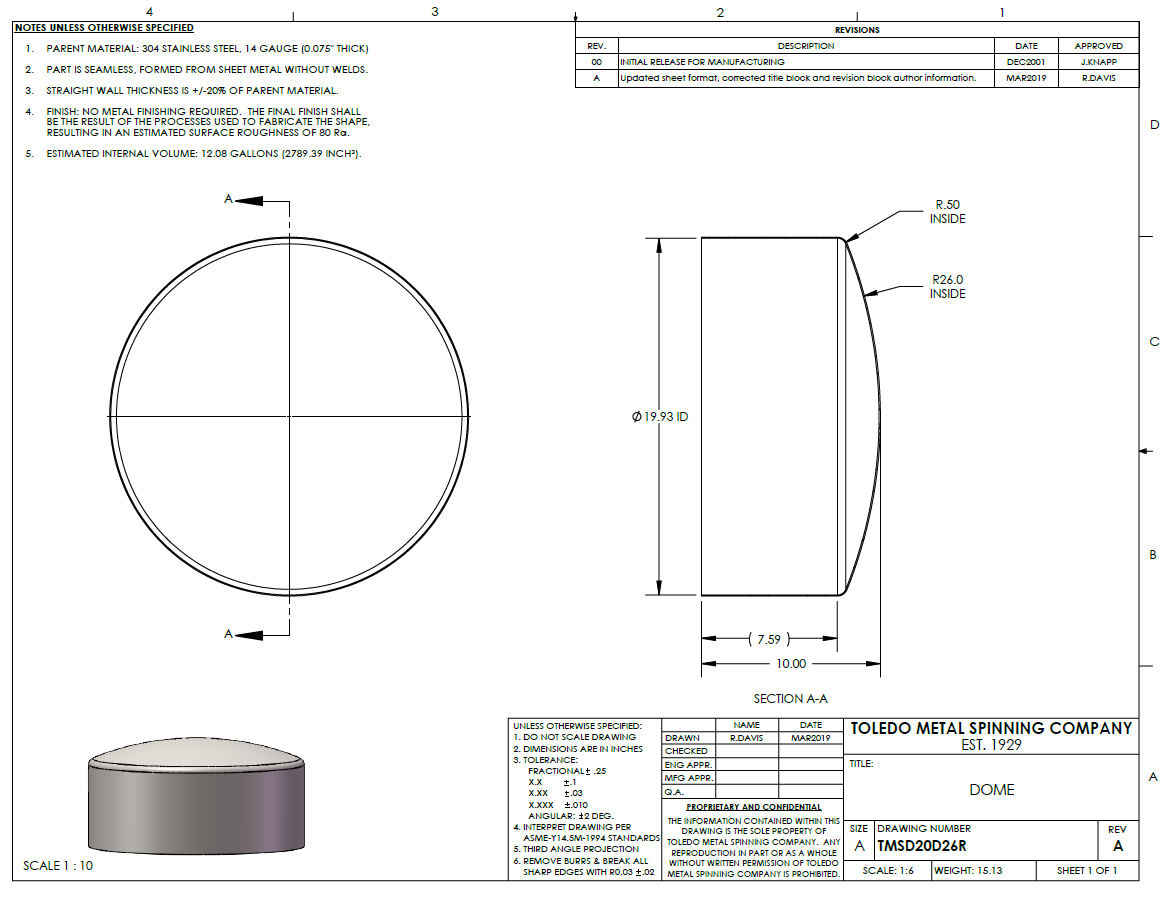

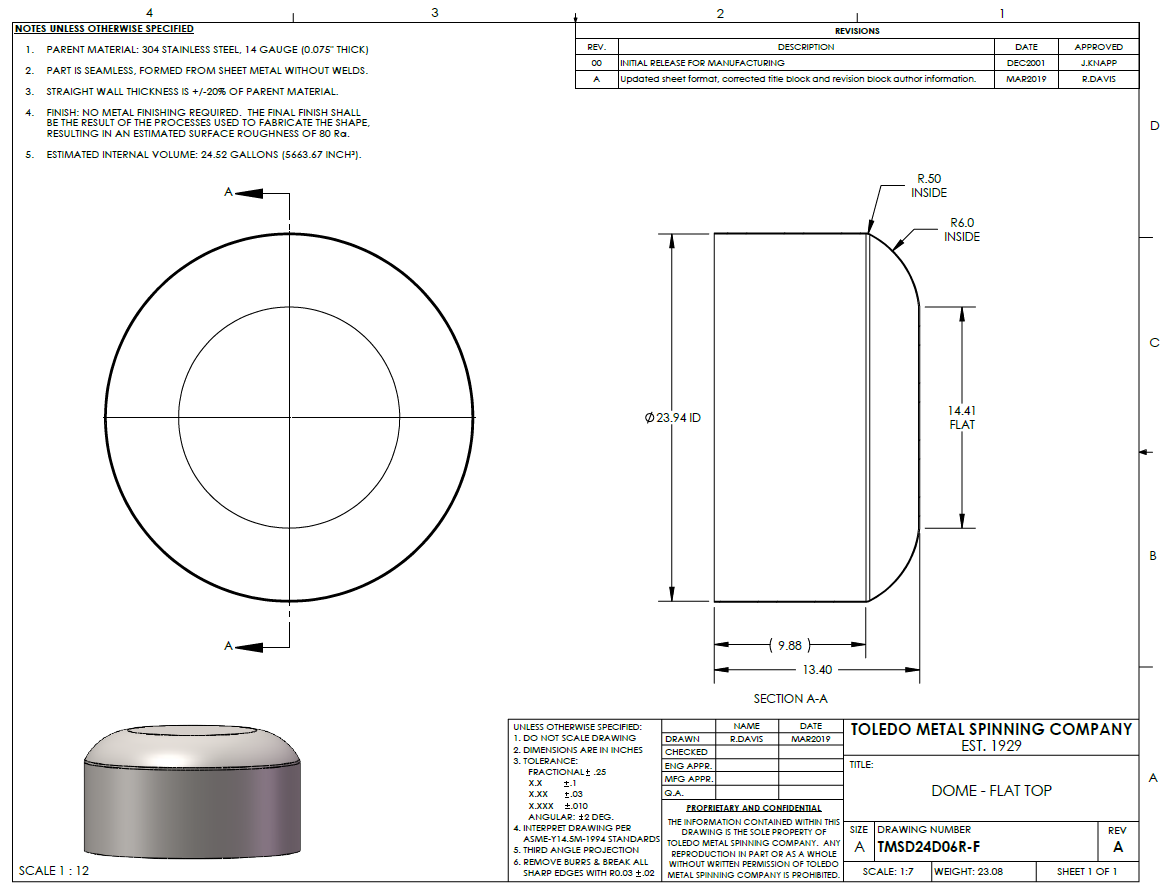

Project Insight: Sheet Metal Dome Fabrication

Manufacturing Insight: Precision-Driven Dome Fabrication for Rapid Prototyping

Why Speed and Precision Matter in Dome Development

Domed enclosures, brackets, and chassis components demand micron-level tolerances to ensure structural integrity, thermal management, and aesthetic consistency—critical for hardware startups iterating toward market-ready products.

Traditional fabrication methods often introduce delays, inconsistent curvature, or hidden costs, leading to costly redesigns and missed launch windows.

Precision in dome geometry directly impacts performance: from airflow efficiency in cooling systems to electromagnetic shielding in electronics, where even 0.1mm deviations can compromise functionality.

Honyo’s Digital Manufacturing Advantage

Online Instant Quote: Upload your CAD file and receive a real-time, transparent cost breakdown within seconds—no manual quotes, no hidden fees, and no waiting days for estimates.

AI-Powered Design Optimization: Our platform automatically analyzes your dome design for manufacturability, suggesting tweaks to reduce material waste, simplify assembly, and cut costs without sacrificing quality.

Fast Turnaround: Prototype in 3–5 days, with production batches delivered in under 2 weeks—accelerating your time-to-market while maintaining aerospace-grade precision.

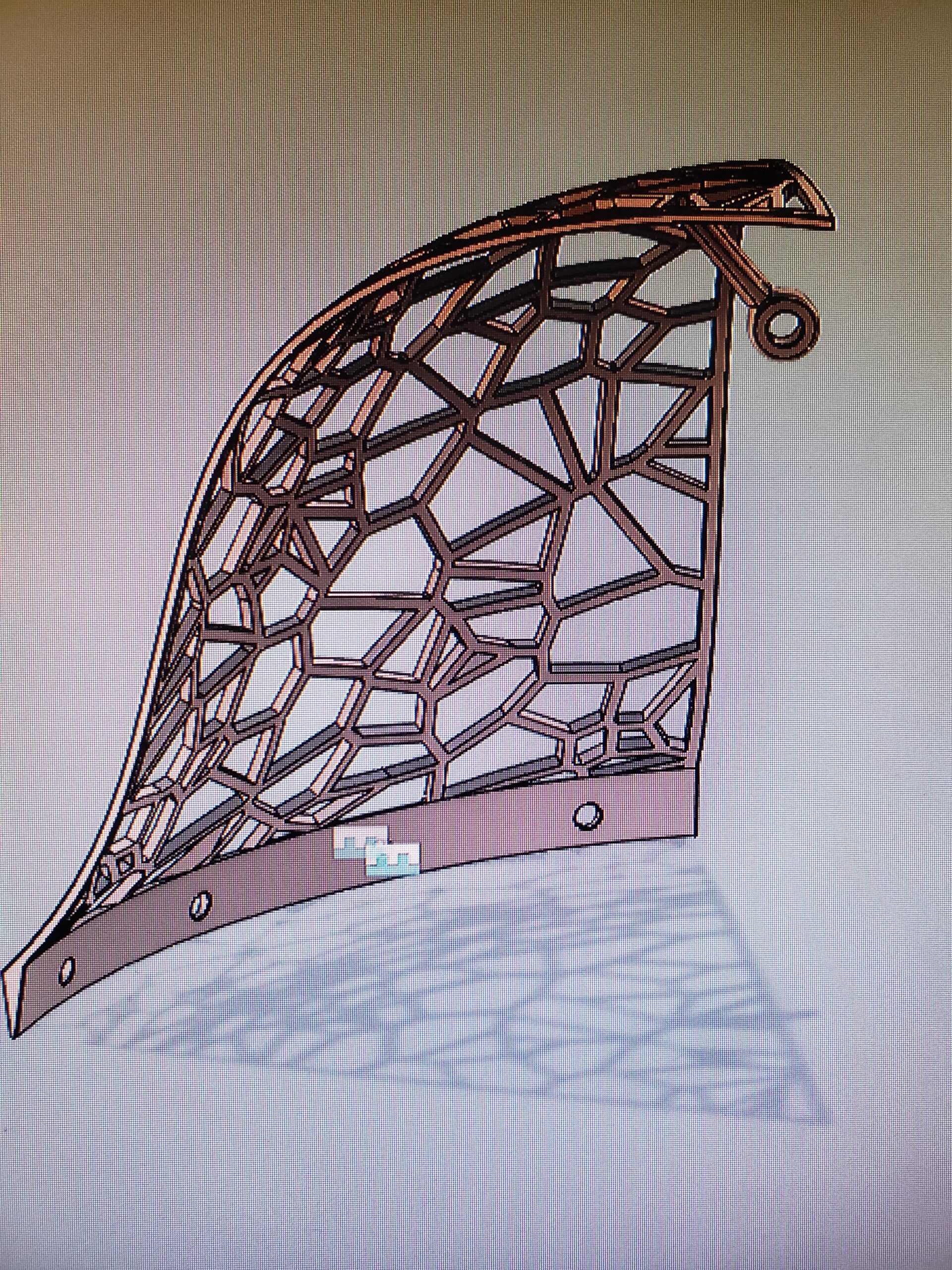

End-to-End Dome Fabrication Process

Laser Cutting: Fiber laser systems achieve ±0.05mm accuracy on complex geometries, eliminating material distortion and ensuring perfect fit for assembly.

Precision Bending & Welding: Robotic tooling and automated welding create seamless, structurally sound domes—eliminating weak points and ensuring consistent curvature across all units.

Powder Coating Integration: In-house finishing for corrosion resistance, UV stability, and custom color matching—all within a single streamlined workflow.

Cost-Effective Scalability: From single prototypes to high-volume runs, our digital platform optimizes production for maximum efficiency—delivering up to 25% lower costs than traditional fabricators while maintaining ISO-certified quality.

At Honyo Prototype, we don’t just make parts—we engineer solutions. With Susan Leo’s vision driving our innovation, we empower hardware startups to turn bold ideas into reality faster, smarter, and more affordably than ever before.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Precision Sheet Metal Dome Fabrication Technologies

Laser Cutting: Achieve micron-level precision (±0.05mm tolerance) for complex dome geometries. Supports materials from 0.5mm to 12mm thickness across 250+ alloys, with minimal heat-affected zones to preserve structural integrity.

CNC Bending: Multi-axis adaptive tooling for seamless curvature transitions. Automated setups reduce lead time by 40% compared to manual methods, ensuring consistent radii for flawless dome profiles.

Robotic Welding: TIG/MIG welding for leak-proof, structurally sound joints. Fully automated processes guarantee uniform weld quality across all dome assemblies.

Powder Coating: Electrostatic application with 5µm precision for corrosion-resistant finishes. Choose from 100+ RAL colors and matte/gloss textures for enhanced aesthetics and durability.

Scalable Production from Prototype to Mass Production

Zero MOQ: Start with a single prototype for validation, then scale seamlessly to 10,000+ units without retooling costs or hidden fees.

Cost-Optimized Workflow: Proprietary process optimization slashes fabrication costs by up to 30% for enclosures, brackets, and chassis—delivering industry-leading value for startups and enterprises.

Just-in-Time Manufacturing: Dynamic scheduling ensures on-time delivery even for urgent orders, with real-time production tracking and flexible volume adjustments.

AI-Powered Digital Platform for Seamless Ordering

Instant Online Quote: Upload your CAD file in seconds to receive real-time pricing, material recommendations, and DFM insights—no manual quotes or waiting.

AI-Driven Design Optimization: Our platform automatically flags manufacturability issues and suggests cost-saving tweaks (e.g., material thickness adjustments, bend radius optimizations) to accelerate production.

50% Faster Turnaround: Streamlined workflows deliver prototypes in 3 days and production orders in 7–10 days—industry-leading speed for complex sheet metal components.

ISO-Certified Quality Assurance

End-to-End QC: 100% dimensional inspection and surface finish checks at every production stage, certified to ISO 9001 standards for flawless consistency.

30-Day Quality Guarantee: Risk-free confidence with our no-questions-asked replacement policy for any manufacturing defects.

Full Material Traceability: Complete documentation of material certifications, process parameters, and inspection reports for every batch—ensuring compliance and accountability.

Honyo Prototype: Where innovation meets precision. From concept to delivery, we engineer solutions that empower your hardware journey.

Materials & Surface Finishes

Material Options & Finishes for Precision Dome Fabrication

Material Selection Guide

Aluminum (6061, 5052, 7075): Lightweight, corrosion-resistant, and highly formable. Ideal for aerospace enclosures and consumer electronics. 5052 excels in complex dome bending; 7075 delivers high strength for structural applications.

Stainless Steel (304, 316): Superior strength and corrosion resistance. 304 suits general-purpose enclosures; 316 handles marine/chemical environments. Perfect for rugged brackets and outdoor chassis.

Copper & Brass: Exceptional thermal/electrical conductivity. Used in RF shielding, heat sinks, and decorative domes. Requires specialized handling but unlocks unique functional and aesthetic possibilities.

Surface Finishes for Enhanced Performance & Aesthetics

Powder Coating: Durable, UV-resistant finish with 200+ color options. Ideal for outdoor enclosures—no chipping or peeling. Our automated process ensures uniform coverage on complex dome geometries.

Anodizing (Type II/III): Electrochemical hardening for aluminum that boosts corrosion resistance and allows vibrant coloration. Type III (hard coat) adds extra wear resistance for high-stress applications.

Mirror/Brushed Polishing: Premium aesthetic finishes for architectural and high-end consumer products. Mirror polish maximizes reflectivity; brushed finish offers a modern, scratch-resistant texture.

Electroplating (Nickel, Zinc): Thin metallic coatings for conductivity or corrosion protection. Zinc plating (galvanization) is cost-effective for steel; nickel plating enhances electrical properties.

How to Choose the Right Material for Your Dome Project

Environmental Factors: Outdoor exposure? Prioritize stainless steel 316 or anodized aluminum. Indoor use? Aluminum or copper suffices.

Mechanical Requirements: High load-bearing needs? 7075 aluminum or stainless steel. Lightweight needs? 5052 aluminum offers best formability.

Conductivity & Thermal Needs: Electrical applications? Copper or brass. Thermal management? Aluminum with anodizing for heat dissipation.

Budget Constraints: Aluminum offers the best cost-to-performance ratio for most startups. Stainless steel is premium but longer-lasting; copper is niche but essential for specific uses.

Why Honyo Prototype Is Your Smart Manufacturing Partner

🌐 Online Instant Quote: AI-driven platform delivers real-time pricing for sheet metal dome fabrication—no delays, no hidden fees. Just upload your design and get an accurate quote in seconds.

🤖 AI-Powered Optimization: Our system analyzes your project requirements to recommend the most efficient material, process, and finish combinations—maximizing performance while minimizing costs. Leverage our expertise in laser cutting, bending, and welding for flawless dome geometries.

⏱️ Rapid Turnaround: 3-5 day delivery for prototypes, with scalable production for volume orders—so you can iterate and launch faster than ever.

Designed for hardware startups and engineers who demand precision, speed, and cost efficiency. All projects optimized for Shenzhen-based manufacturing excellence.

From Quote to Part: Our Process

How It Works: From CAD to Part

1. Upload CAD File

Submit your design in any standard format (STEP, IGES, DWG, STL) through our intuitive web portal.

AI-powered validation ensures file compatibility and flags potential issues before processing—no manual intervention required.

Start your project in seconds: no waiting, no hassle.

2. Get Instant Quote (AI Engine)

Receive a real-time, transparent quote within 10 seconds—no days-long back-and-forth.

Our proprietary AI analyzes geometry, material, and process requirements to calculate precise costs, including all setup fees, materials, and shipping.

Compare pricing across materials and quantities instantly—no hidden fees, no surprises.

3. DFM Analysis & Optimization

Automated Design for Manufacturability (DFM) review identifies cost-saving opportunities and production challenges specific to dome geometries.

Receive actionable feedback (e.g., bend radius adjustments, material thickness recommendations) to optimize structural integrity and reduce costs.

Collaborate seamlessly with our engineering team—data-driven insights, not guesswork.

4. Production & Delivery

Precision manufacturing at our Shenzhen facility: laser cutting, bending, welding, and powder coating with automated quality control.

Real-time tracking from production to delivery—monitor every step via your client portal.

Fast turnaround: Most dome fabrication orders ship in 3–5 business days, with expedited options available.

Experience the future of sheet metal fabrication—where innovation meets efficiency. From design to delivery, Honyo Prototype delivers cost-effective, high-precision solutions for hardware startups and engineers.

Start Your Project with Honyo

Start Your Project with Honyo

AI-Powered Precision, Delivered Fast

Instant Online Quote: Upload your CAD file for an accurate, real-time estimate in seconds—no delays, no guesswork.

Fast Turnaround: Prototypes in 3–5 days; production in 10–14 days—optimized for speed without compromising quality.

Cost-Effective Solutions: Up to 30% lower costs than industry averages with transparent pricing and no hidden fees.

End-to-End Manufacturing: Laser cutting, bending, welding, and powder coating—all in-house for seamless quality control.

Founder-Led Expertise, Startup-Focused

Susan Leo and our engineering team specialize in scalable sheet metal solutions for hardware startups and enterprises.

We optimize your design for manufacturability and cost-efficiency from day one.

Ready to get started? Contact us today:

Email: [email protected]

Phone: +86 139 2843 8620

Visit: Schedule a tour of our Shenzhen and Dongguan facilities to see our advanced manufacturing capabilities.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.