Guide Contents

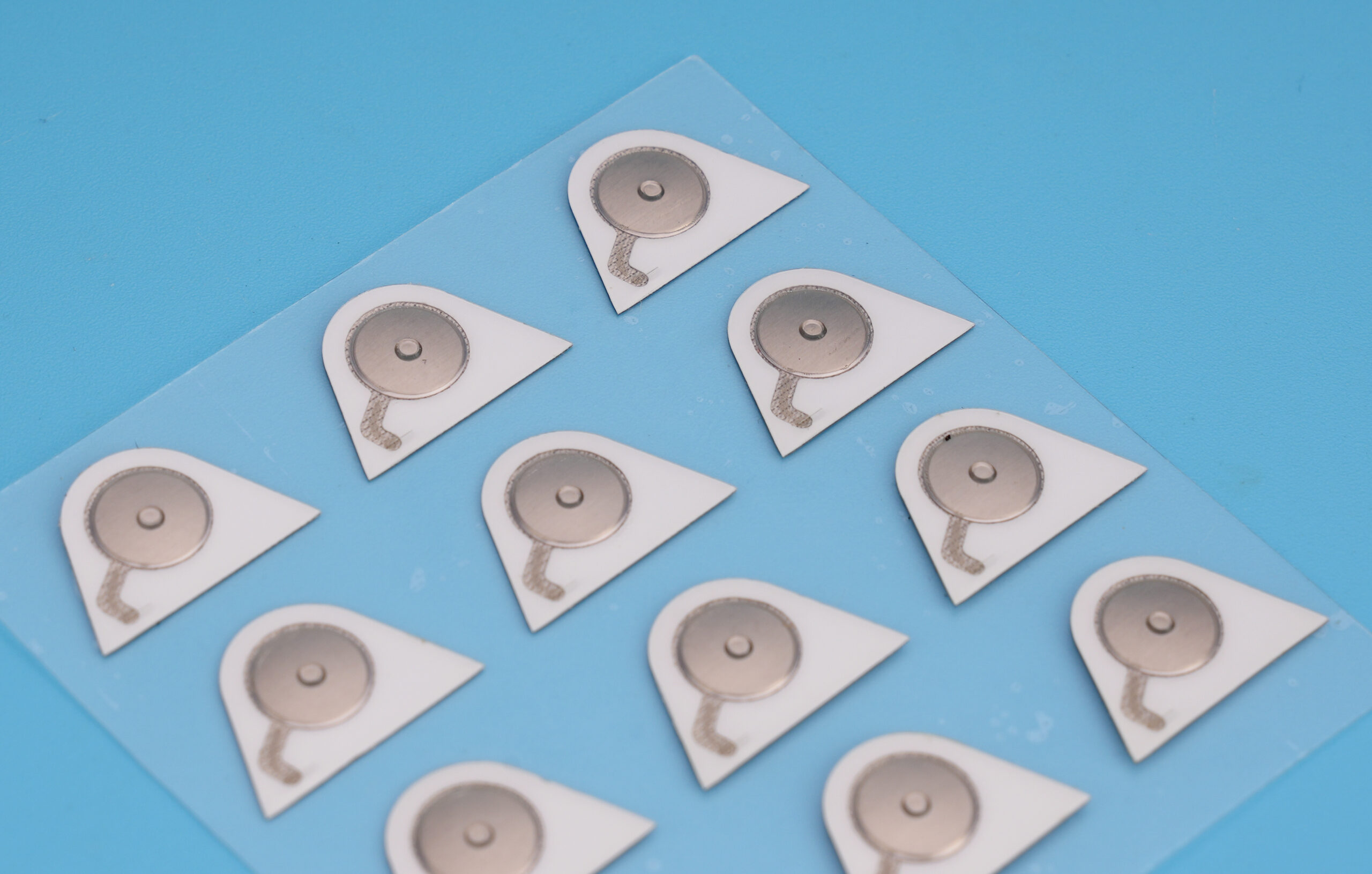

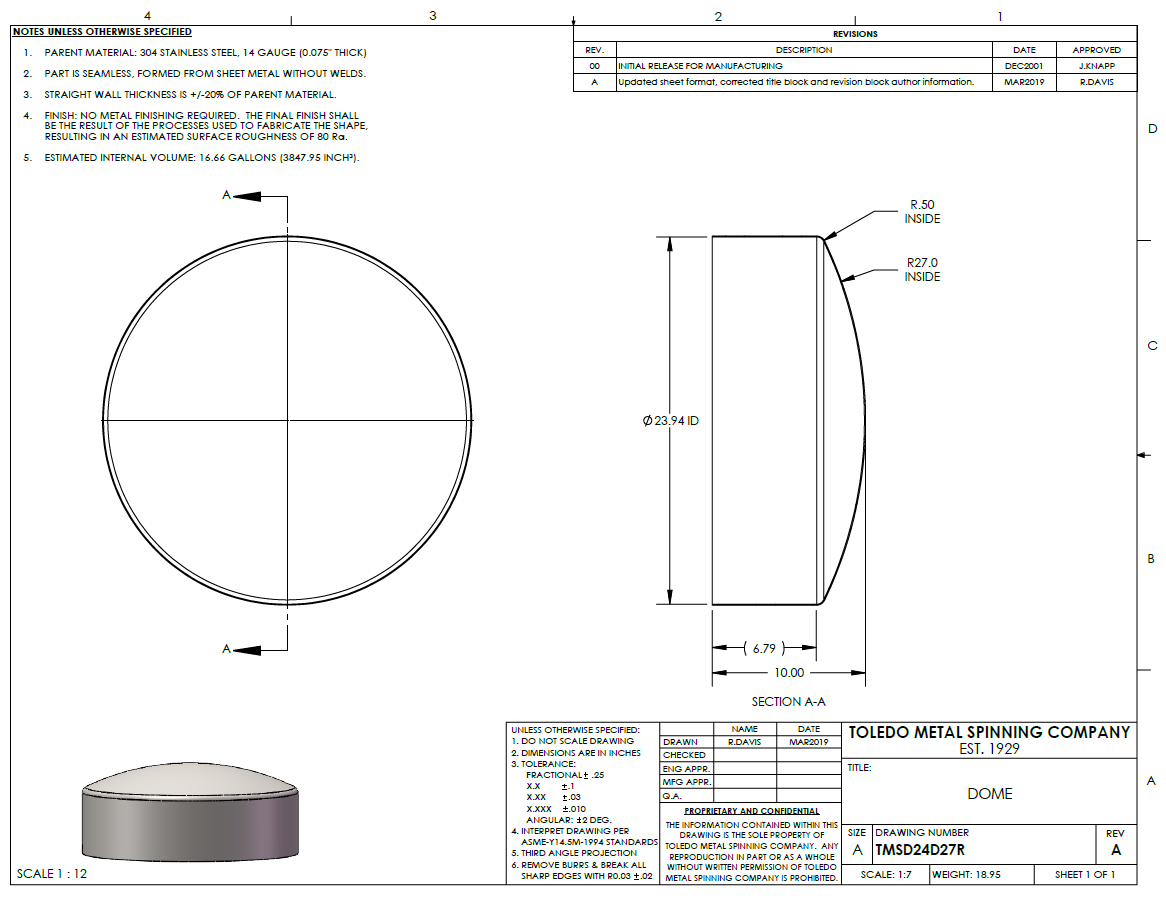

Project Insight: Sheet Metal Dome

Manufacturing Insight: Sheet Metal Dome

In today’s fast-paced hardware innovation landscape, sheet metal domes aren’t just components—they’re critical to product performance, safety, and time-to-market. Precision ensures structural integrity and fit-for-purpose functionality, while speed accelerates prototyping and validation cycles, allowing startups to iterate faster and capture market opportunities.

Why Precision Matters for Sheet Metal Domes

Micron-level tolerances for seamless integration with seals and gaskets, ensuring airtight/watertight enclosures.

Consistent curvature and dimensional accuracy critical for structural stability and aesthetic quality.

Zero-defect manufacturing to prevent costly rework or delays in product launches.

Why Speed is Non-Negotiable in Product Development

Rapid prototyping cycles—prototype in 3 days, iterate in 7—accelerating time-to-market by up to 50%.

Real-time design feedback via digital twin simulations to catch issues before production.

Agile production scaling from 1 to 10,000+ units without lead time penalties.

Honyo’s Digital Manufacturing Advantage

Online Instant Quote: Get real-time pricing in seconds—no more waiting days for quotes. Our AI-driven platform analyzes your design files, material specs, and quantities to deliver accurate cost estimates instantly.

AI-Powered Precision: Leverage machine learning algorithms that optimize toolpaths, predict potential issues, and ensure micron-level accuracy in every bend, cut, and weld—so your dome meets exact specifications every time.

3-Day Turnaround Guarantee: From design to delivery, our streamlined digital workflow cuts lead times by up to 50% compared to traditional manufacturers. Perfect for startups needing rapid iterations or urgent production runs.

Seamless Integration: End-to-end digital workflow from CAD to finished part, with automated quality checks at each stage—ensuring consistency and reducing human error.

At Honyo Prototype, we don’t just manufacture parts—we accelerate your product journey. Partner with us to turn your sheet metal dome designs into reality, faster and smarter than ever before.

Honyo Capabilities & Technology

Honyo’s Sheet Metal Dome Manufacturing Capabilities

At Honyo Prototype, we combine cutting-edge technology with precision engineering to deliver cost-effective, high-quality sheet metal domes tailored to your exact specifications. Whether you’re prototyping a new enclosure or scaling up production, our integrated capabilities ensure optimal functionality, durability, and speed.

Advanced Fabrication Technologies

Laser Cutting: Precision cutting of complex dome geometries from stainless steel, aluminum, or galvanized steel (0.5–6mm thickness), eliminating the need for traditional spinning processes and ensuring minimal material waste.

CNC Bending: Advanced press brakes form precise curved profiles with ±0.1° accuracy, enabling seamless integration of dome components without deformation.

Robotic Welding: Automated TIG/MIG welding ensures consistent, high-strength seams, followed by manual polishing for a flawless surface finish.

Powder Coating: Environmentally compliant finishes with superior adhesion and corrosion resistance, available in any RAL color or custom texture.

Scalable Production Capacity

From 1 prototype to 10,000+ units with zero minimum order quantities (MOQs) – perfect for startups and enterprise-scale projects.

Rapid tooling changes and flexible scheduling for quick transitions between project runs.

Dedicated production lines for high-volume orders with guaranteed on-time delivery.

Rigorous Quality Assurance

ISO 9001:2015 certified processes with full traceability from raw material to finished product.

3D scanning and CMM inspections for dimensional accuracy and surface quality at every stage.

In-process quality checks to proactively prevent defects before they occur.

Digital Manufacturing Experience

AI-Powered Instant Quote: Upload your CAD file and receive a transparent, all-inclusive cost estimate in seconds – no hidden fees, optimized for your budget.

Real-Time Project Tracking: Monitor every step of your order via our cloud platform with automated progress updates and proactive communication.

Industry-Leading Turnaround: Prototypes delivered in 3–5 days, production orders in 7–10 days with expedited options for urgent needs.

Engineered for innovation. Built for your success.

Honyo Prototype – Shenzhen, China

Materials & Surface Finishes

Material Options & Finishes for Precision Sheet Metal Domes

Material Selection Guide

Optimize your dome’s performance with Honyo’s expertly curated material portfolio—engineered for strength, weight, and cost efficiency.

Aluminum Alloys (5052, 6061-T6)

Why choose it? Lightweight (2.7 g/cm³), exceptional corrosion resistance, and high strength-to-weight ratio. Ideal for aerospace, automotive, and consumer electronics enclosures.

Honyo Advantage: Precision laser cutting for thin-gauge sheets (0.5–3mm) + anodizing options for enhanced durability and custom color finishes.

Stainless Steel (304, 316)

Why choose it? Superior corrosion resistance, hygienic properties, and structural rigidity. Perfect for medical devices, marine environments, and food-grade applications.

Honyo Advantage: Advanced welding and passivation processes ensure seamless joints and long-term performance in harsh conditions.

Mild Steel (A36, SPCC)

Why choose it? Cost-effective structural material with high formability. Best for industrial brackets, chassis, and indoor applications where budget matters.

Honyo Advantage: Powder coating or galvanization options deliver robust protection at 30% lower cost vs. stainless steel.

Surface Finish Options

Elevate aesthetics and functionality with finishes tailored to your application’s demands.

Anodizing (Type II/III)

Electrochemically hardened surface for aluminum. Enhances wear resistance and offers vibrant color customization (e.g., black, silver, blue). Critical for outdoor electronics housings.

Powder Coating

Durable, UV-resistant finish in 200+ RAL colors. Ideal for outdoor enclosures and industrial equipment. Thickness control ensures consistent coverage without compromising tolerances.

Polishing (Mirror or Brushed)

High-gloss or satin finishes for aesthetic-driven applications like architectural elements or premium consumer products. Achieved through precision grinding and buffing.

Electroplating (Nickel, Zinc)

Thin metallic coatings for conductivity (e.g., nickel for EMI shielding) or corrosion resistance (zinc for steel). Compatible with complex geometries for seamless integration.

Passivation

Chemical treatment for stainless steel to remove free iron and maximize corrosion resistance. Mandatory for medical and food processing equipment.

How to Choose the Right Material for Your Dome

Tailor your selection to real-world requirements with these key factors:

Environmental Exposure: Coastal or chemical environments demand 316 stainless steel or anodized aluminum. Indoor use? Mild steel with powder coating delivers maximum value.

Weight Sensitivity: Aerospace or portable devices benefit from 5052 aluminum (40% lighter than steel). Structural rigidity? 304 stainless steel is optimal.

Budget Constraints: Mild steel + powder coating reduces costs by 30% vs. stainless steel for non-critical applications.

Functional Requirements: Electrical components need conductive finishes (e.g., nickel plating); thermal management leverages aluminum’s natural heat dissipation.

🚀 Experience the Honyo Advantage

Innovate faster, scale smarter, and cut costs with our AI-driven manufacturing platform:

AI-Powered Instant Quotes

Upload your CAD file to get precise cost estimates in seconds—no manual quotes, no delays.

5-Day Prototype Turnaround

Automated workflows accelerate development cycles by 40% vs. industry standards.

End-to-End Digital Transparency

Track every step—from laser cutting to powder coating—via real-time updates on our cloud platform.

“At Honyo, we don’t just fabricate sheet metal domes—we engineer solutions that turn your vision into reality, faster and smarter.”

— Susan Leo, Founder

From Quote to Part: Our Process

How It Works: From CAD to Part

1. Upload CAD File – Instant Validation

Seamlessly upload STEP, STL, IGES, or DXF files through our intuitive platform

AI-powered validation checks for manufacturability and file integrity in seconds

Receive immediate feedback on potential issues, eliminating costly redesigns

2. Get Instant Quote – AI-Powered Pricing

Real-time, transparent cost estimates generated by our intelligent engine

Breakdown includes material, processing, and shipping with zero hidden fees

Compare pricing for different materials (e.g., stainless steel, aluminum) and quantities in one click

3. DFM Analysis – Proactive Optimization

Expert engineers review your design for sheet metal dome specifics: spinning feasibility, radius optimization, and material thickness compatibility

Data-driven suggestions to reduce costs while maintaining structural integrity (e.g., adjusting bend radii for smoother spinning)

Optimize for cost-effective production without sacrificing precision or functionality

4. Production & Delivery – Accelerated Timeline

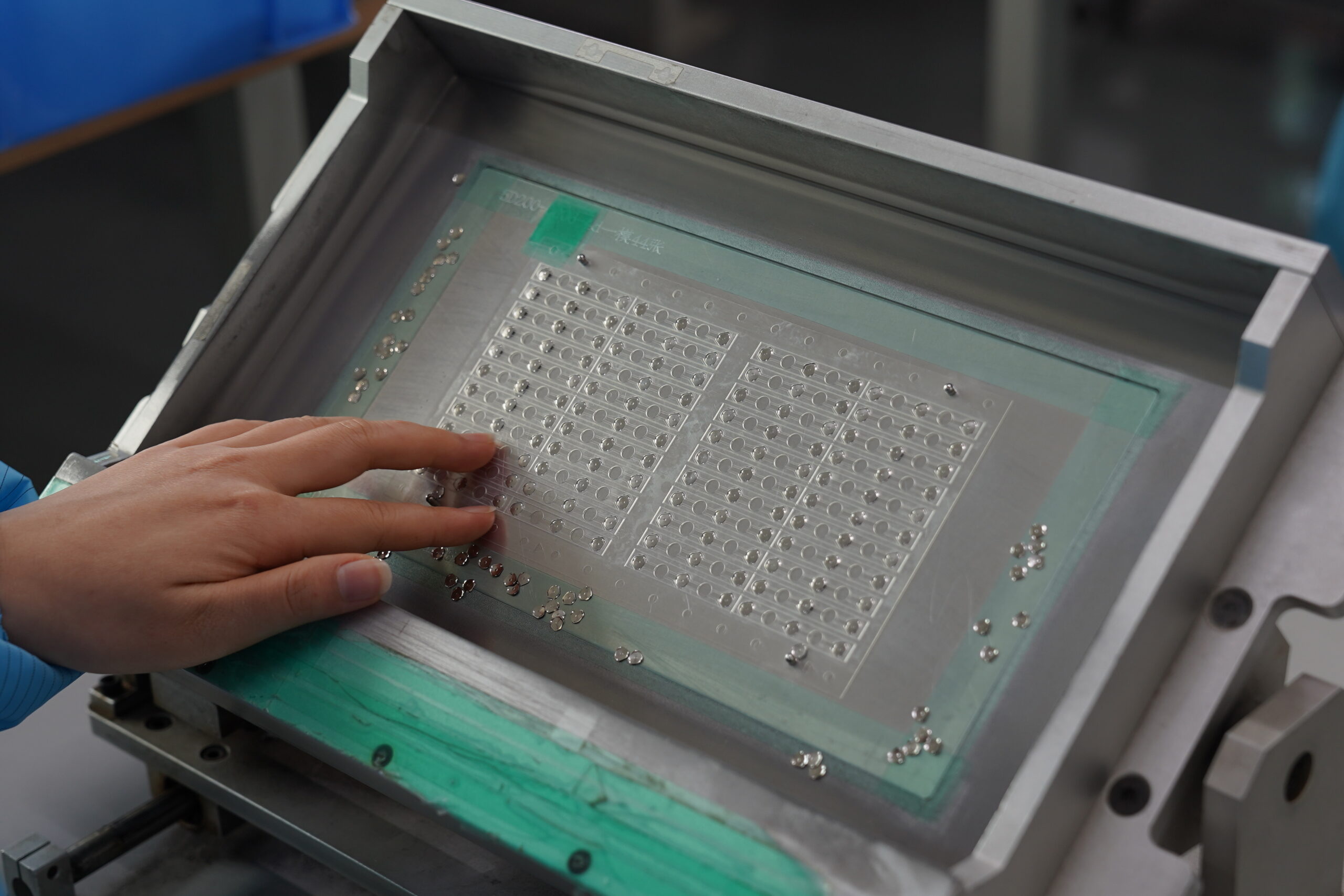

Automated laser cutting for blanking, precision spinning for dome shaping, and robotic welding for seamless assembly

Integrated powder coating for flawless finishes and corrosion resistance

Real-time production tracking; delivered in days, not weeks – with Shenzhen-based logistics for global speed

Honyo Prototype redefines sheet metal dome fabrication: where AI-driven precision meets agile manufacturing. From CAD to delivery, we turn complexity into simplicity – so you can focus on innovation, not logistics.

Start Your Project with Honyo

Start Your Project with Honyo: Precision Sheet Metal Domes, Delivered Fast

Honyo Prototype combines cutting-edge technology with engineering expertise to deliver high-precision sheet metal domes tailored to your exact specifications. Whether you’re prototyping a new enclosure or scaling production, our streamlined process ensures speed, quality, and cost-efficiency.

Why Choose Honyo for Sheet Metal Domes?

AI-Powered Instant Quote Engine: Upload your design and get real-time pricing in seconds. No more waiting days for quotes—our platform analyzes geometry, material, and quantity to deliver accurate estimates instantly.

Optimized Manufacturing Workflow: From laser cutting to powder coating, our integrated processes eliminate bottlenecks. Typical lead times: 3-5 days for prototypes, 7-10 days for production runs.

Cost-Effective Precision: 20-30% lower costs vs. industry average for custom enclosures and chassis. Transparent pricing with no hidden fees—every step optimized for your budget.

How It Works

Upload & Analyze: Submit your CAD file or sketch via our web platform. Our AI engine evaluates optimal material usage and fabrication sequence.

Instant Quote & Approval: Receive a detailed quote with cost breakdown and lead time. Approve with one click.

Production & Tracking: Our Shenzhen team starts production within 24 hours. Monitor progress in real-time through our customer portal.

Delivery: On-time delivery with full quality assurance. Ready for integration into your product.

Ready to Build?

Contact Susan Leo & Team: [email protected] | +86 139 2843 8620

Visit Our Facilities: Discover our Shenzhen and Dongguan manufacturing hubs by appointment.

No Minimum Orders: Perfect for startups scaling from prototype to volume production.

Innovate faster. Build smarter. Let’s make it happen—today.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.