Guide Contents

Project Insight: Sheet Metal Design Services

Speed & Precision: The Cornerstones of Modern Product Development

In today’s hyper-competitive hardware landscape, speed and precision aren’t just advantages—they’re survival necessities. Delays in prototyping or production can derail timelines, increase costs, and erode market opportunities. At Honyo Prototype, we’ve redefined sheet metal fabrication through digital innovation, transforming complex manufacturing into a streamlined, predictable process that accelerates time-to-market without sacrificing quality.

Online Instant Quote: Real-Time Cost Transparency

Receive accurate, transparent pricing within seconds—no waiting for manual quotes

AI-powered Design for Manufacturability (DFM) feedback embedded directly in your quote

Real-time adjustments to optimize material selection, geometry, and finishing for maximum cost efficiency

AI-Powered Design Optimization

Automated checks for non-standard bend radii, excessive welding, and complex geometries

Smart recommendations for common materials (e.g., AL 6061, SS 304) and standard finishes to reduce lead times

Precision tolerance analysis to eliminate rework and ensure first-time-right production

Guidance to avoid costly secondary operations (e.g., welding pre-plated metals)

Rapid Turnaround Without Compromising Quality

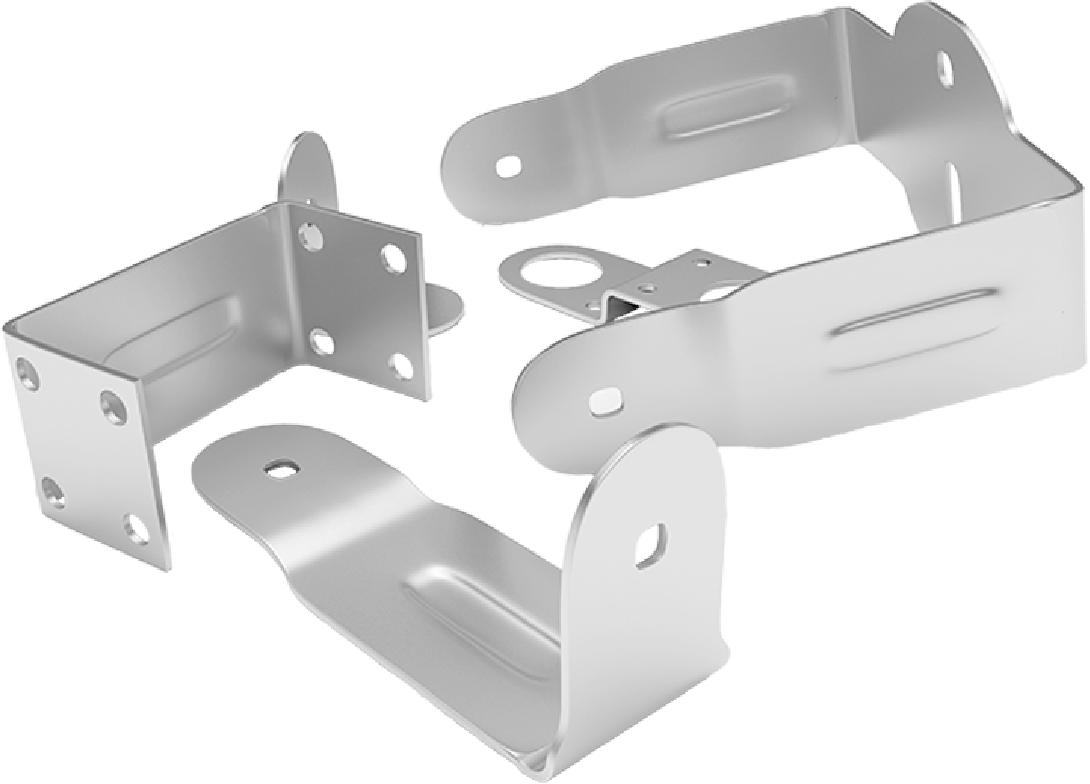

Prototype delivery in 3–5 days for enclosures, brackets, and chassis

Fully integrated workflow: laser cutting → bending → welding → powder coating in a single facility

Strict quality control with ±0.1mm tolerances across all processes

At Honyo Prototype, we don’t just fabricate parts—we engineer speed into every step of your product journey. From concept to completion, our digital platform ensures your vision is realized faster, smarter, and more affordably than ever before.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Advanced Technology Suite

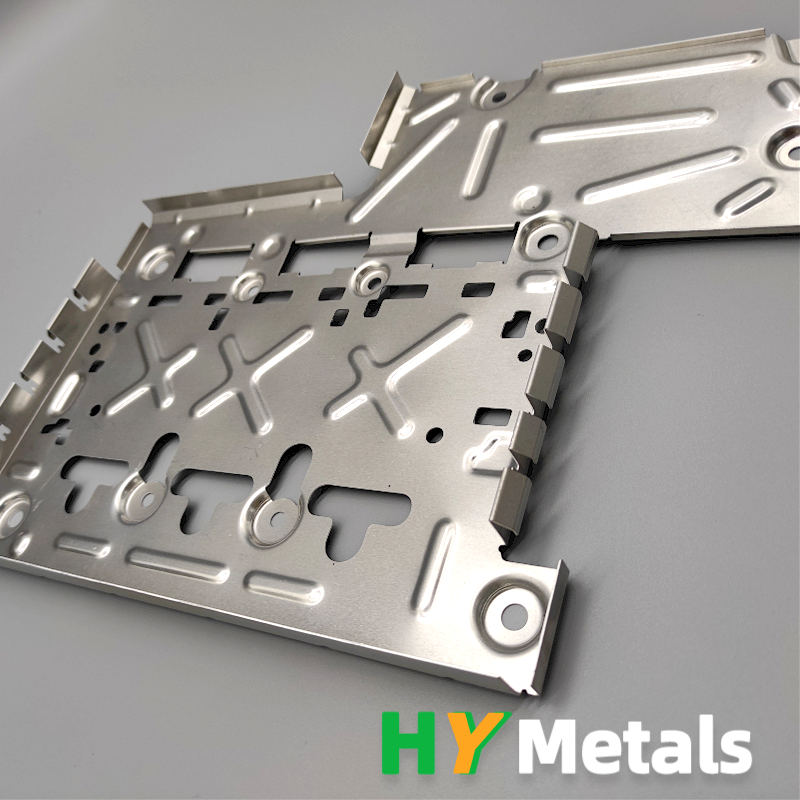

Laser Cutting: Precision ±0.1mm tolerances for materials 0.5mm–25mm thick. Optimized nesting minimizes waste and maximizes material efficiency.

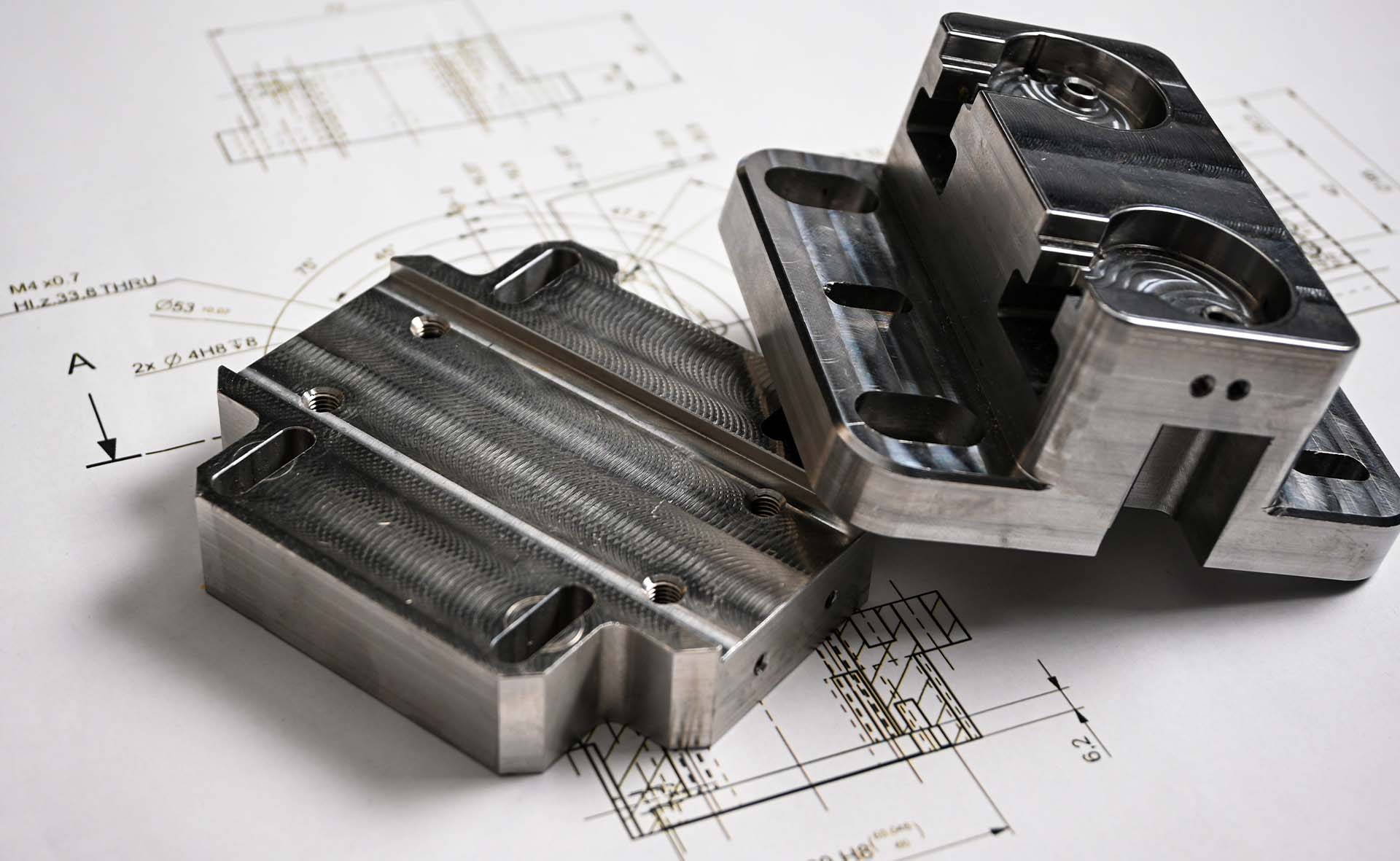

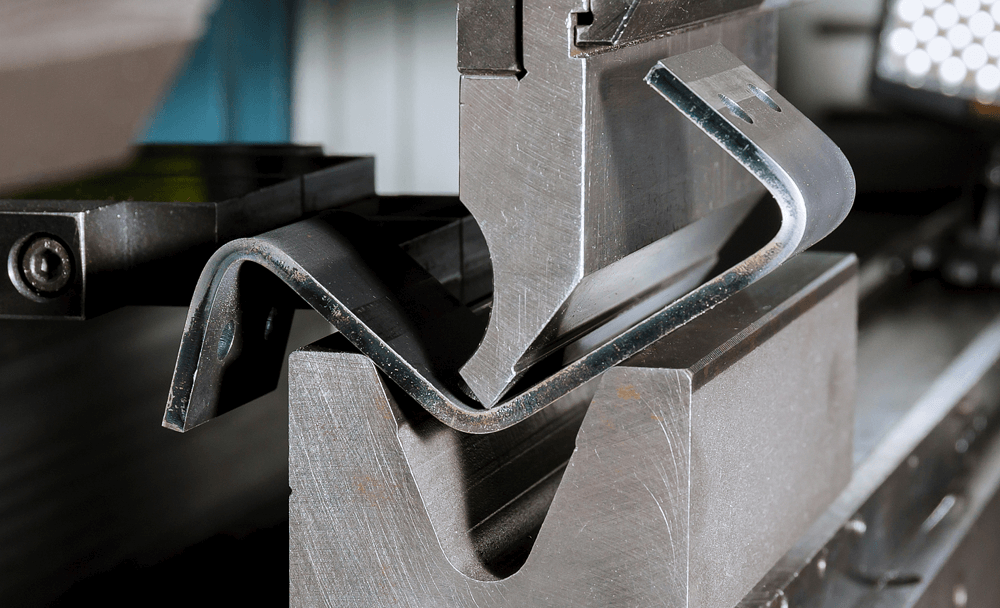

CNC Bending: ±0.5° angle accuracy with multi-axis capabilities. Standard bend radii pre-configured to reduce costs and improve manufacturability.

Robust Welding: TIG/MIG processes with post-weld polishing. Avoids welding pre-plated metals to preserve coating integrity.

Powder Coating: 80+ RAL color options, electrostatic application for uniform coverage. Environmentally compliant curing processes.

AI-Powered Instant Quoting & DFM Optimization

Get real-time quotes in under 60 seconds via our web platform—no manual estimates needed.

AI-driven DFM analysis identifies cost-saving opportunities: standard bend radii, common materials, simplified geometries.

Instant feedback on design flaws (e.g., sharp corners, excessive welds) to prevent rework and accelerate time-to-market.

Scalable Production & Fast Turnaround

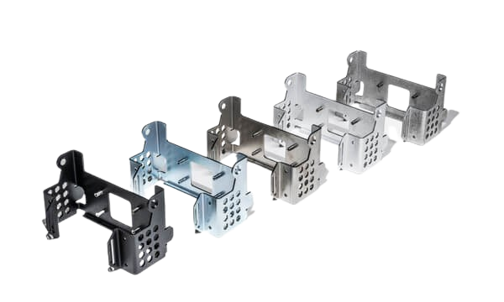

Seamlessly scale from 1 prototype to 10,000+ units without retooling delays.

30% faster average lead times than industry standards, with 3-day expedited options for urgent projects.

Lean manufacturing ensures consistent quality and cost efficiency at any volume.

ISO-Certified Quality Assurance

100% first-article inspection and statistical process control at every production stage.

ISO 9001:2015 certified with full traceability for aerospace, medical, and industrial applications.

Materials & Surface Finishes

Material Options & Finishes: Optimize Your Design for Cost & Performance

Choosing the right materials and finishes is critical to balancing performance, cost, and aesthetics in sheet metal fabrication. At Honyo Prototype, our AI-powered platform delivers instant design analysis and cost estimates, enabling you to optimize your design for manufacturability (DFM) before production begins. With expert guidance and a streamlined workflow, we ensure your project achieves the fastest turnaround times—48 hours for prototypes, 5–7 days for production runs—without compromising quality.

Material Selection Guide

Aluminum (6061-T6, 5052-H32)

Best for: Lightweight enclosures, brackets, and aerospace components.

Why: Excellent strength-to-weight ratio, corrosion resistance, and ease of machining. 5052-H32 excels in marine environments; 6061-T6 offers superior weldability.

Cost tip: Standard grades reduce lead times by 20% vs. specialty alloys.

Steel (Mild Steel, Stainless 304/316)

Best for: Structural brackets, industrial chassis, and outdoor enclosures.

Why: Mild steel (e.g., 1018) is cost-effective for non-corrosive environments; stainless steel (304/316) delivers unmatched corrosion resistance for medical or marine use.

Cost tip: Avoid stainless for non-critical applications—mild steel + powder coating cuts costs by 30%.

Copper

Best for: Heat sinks, electrical enclosures, and EMI shielding.

Why: Exceptional thermal/electrical conductivity, but requires specialized handling to prevent oxidation during fabrication.

Cost tip: Use only when conductivity is non-negotiable—alternatives like aluminum with conductive coatings may save 25%+ in costs.

Surface Finish Options

Anodizing (Type II/III)

Best for: Aluminum parts requiring durability + aesthetics (e.g., consumer electronics).

Why: Enhances corrosion resistance, wear resistance, and color customization. Type III (hard anodizing) adds 2x thickness for heavy-duty use.

Powder Coating

Best for: Steel components needing vibrant colors + abrasion resistance (e.g., industrial machinery).

Why: Eco-friendly, uniform coverage, and 50% more durable than liquid paint. Ideal for high-volume projects.

Electroplating (Zinc, Nickel)

Best for: Steel parts in automotive or outdoor settings.

Why: Zinc plating prevents rust at low cost; nickel plating adds shine for visible components.

Avoid: Welding pre-plated metal—post-fabrication plating maintains finish integrity.

Polishing & Painting

Best for: Architectural elements or premium consumer products (polishing) or low-budget prototypes (painting).

Note: Painting is less durable than powder coating—use only for indoor, non-critical applications.

Smart Selection Strategies for Maximum Cost Efficiency

Prioritize standard materials: 6061 aluminum and 1018 steel are readily available, reducing lead times by 15–20% vs. exotic alloys.

Opt for common finishes: Powder coating or anodizing deliver 80% of performance benefits at 60% of specialty finish costs.

Design for manufacturability (DFM):

Use standard bend radii (e.g., 1x material thickness) to avoid tooling changes.

Minimize welding points—laser-cut joints reduce labor costs by 25%.

Avoid intricate geometries that require secondary operations (e.g., custom notches).

Leverage Honyo’s AI platform: Upload your design for real-time DFM feedback—our system identifies cost-saving opportunities like material substitutions, finish optimizations, and tolerance adjustments to reduce production costs by up to 25%.

Ready to optimize your design?

Get an instant quote in seconds via Honyo’s AI-powered platform. See real-time cost estimates, DFM recommendations, and lead times—then start production in 48 hours.

→ Get Your Free Quote Now

Innovation meets efficiency. Let’s build faster, smarter, together.

From Quote to Part: Our Process

From CAD to Part: The Honyo Advantage

At Honyo Prototype, we’ve redefined sheet metal fabrication through a seamless, AI-powered workflow that turns your CAD design into precision parts with unmatched speed and transparency. From upload to delivery, every step is optimized to accelerate your hardware innovation.

1. Upload CAD File: Drag-and-Drop Simplicity

Seamless compatibility: Support for STEP, IGES, STL, DWG, and all major CAD formats—no conversion hassles.

Instant processing: Upload in seconds; our system auto-validates files and prepares them for AI analysis.

No manual entry: Eliminate human error with automated data extraction and validation.

2. Instant AI-Powered Quote: Real-Time Transparency

Quotes in seconds, not days: AI analyzes geometry, materials, and processes to deliver a precise cost breakdown instantly.

Full cost visibility: See itemized pricing for materials, labor, finishing, and shipping—zero hidden fees.

Dynamic optimization: Adjust tolerances, materials, or features in real time to see cost impacts immediately.

3. Proactive DFM Analysis: Optimize for Cost & Speed

AI-driven design review: Identify manufacturability risks (e.g., non-standard bend radii, tight tolerances, or excessive weld points).

Actionable cost-saving tips: Receive smart suggestions like using common materials, simplifying geometries, or standardizing finishes.

Rapid iteration: Update your CAD file and re-quote in under a minute—no back-and-forth delays.

4. Precision Production & Fast Delivery

Automated smart manufacturing: Laser cutting, precision bending, robotic welding, and powder coating—all coordinated via our AI-driven production platform.

End-to-end visibility: Track progress in real time through your secure customer portal—from material sourcing to final inspection.

Guaranteed timelines: Prototypes in 5 business days, production runs in 7–10 days—consistently on schedule.

“Design for manufacturing, not just for function.”

Honyo’s AI doesn’t just quote—it collaborates to eliminate waste, reduce costs, and get your parts to market faster. Ready to innovate? Upload your CAD and get your instant quote today.

Start Your Project with Honyo

Start Your Project with Honyo: Precision, Speed, and Cost Efficiency

AI-Powered Instant Quoting – Get Your Quote in Minutes

Upload your design to our online platform for real-time cost analysis and manufacturability feedback

AI-driven insights optimize geometry, material choices, and processes to eliminate waste

Receive a detailed quote in seconds – no waiting, no hidden fees

Design for Manufacturability (DFM) Expertise

Tailored optimizations for enclosures, brackets, and chassis to maximize cost efficiency

Leverage industry best practices:

✓ Standard bend radii & common materials (e.g., stainless steel, aluminum)

✓ Simplified geometries to reduce tooling and labor costs

✓ Avoid welding pre-plated metal and unnecessary post-processing

Receive actionable feedback before production begins to avoid costly revisions

Rapid Turnaround Without Compromise

Prototype lead times as fast as 3 days – ideal for hardware startups needing speed-to-market

Agile workflows scale seamlessly from single prototypes to volume production

Integrated laser cutting, bending, welding, and powder coating in-house for seamless coordination

Founder-Led Commitment to Excellence

Led by Susan Leo, with 10+ years of precision manufacturing expertise

Personalized support from concept to delivery – we treat your project as our own

State-of-the-art facilities in Shenzhen & Dongguan for quality control and collaboration

Ready to Transform Your Vision into Reality?

Contact Honyo Prototype Today:

📧 [email protected]

📞 +86 139 2843 8620

📍 Visit our Shenzhen/Dongguan facilities for a tailored consultation

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.