Contents

Manufacturing Insight: Sheet Metal Cut

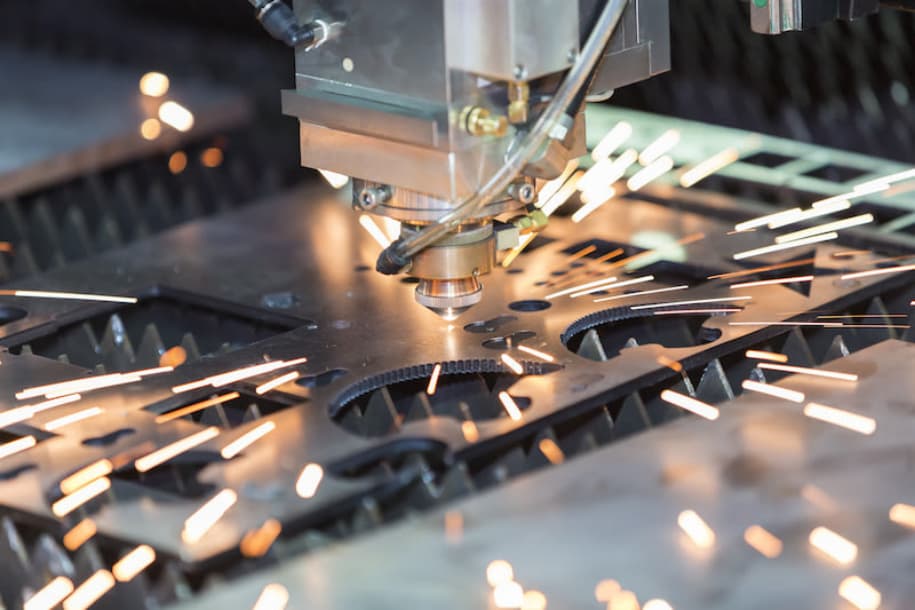

Precision Sheet Metal Cutting for Rapid Prototyping and Low-Volume Production

At Honyo Prototype, we transform your sheet metal designs into high-accuracy components with industry-leading speed and reliability. Our advanced sheet metal fabrication services, centered on precision laser cutting, deliver tight tolerances down to ±0.1mm across materials ranging from 0.5mm to 6.0mm thickness—including aluminum, stainless steel, and mild steel. Whether you require intricate prototypes or bridge-production parts, our automated laser systems ensure clean edges, consistent repeatability, and seamless integration with secondary processes like bending, welding, and finishing.

Eliminate quoting delays that stall your engineering timelines. Honyo’s Online Instant Quote platform provides real-time pricing and manufacturability feedback within minutes of uploading your DXF or STEP file. No manual submissions, no waiting for emails—just immediate clarity on cost, lead time, and design feasibility. This end-to-end digital workflow, backed by our ISO 9001-certified processes, accelerates your path from concept to physical part without sacrificing quality.

Why engineers and procurement teams choose Honyo for sheet metal cutting:

Traditional quoting cycles often extend beyond 72 hours, creating bottlenecks in agile development. Honyo’s integrated system reduces this to under 5 minutes while highlighting potential design optimizations upfront.

| Capability | Honyo Standard | Industry Average |

|---|---|---|

| Quote Turnaround | < 5 minutes | 24–72 hours |

| Laser Cutting Tolerance | ±0.1mm | ±0.2mm–±0.3mm |

| Prototype Lead Time | As fast as 3 days | 7–10+ days |

Upload your design today and experience how our precision sheet metal fabrication—powered by instant quoting and engineered for speed—keeps your projects moving. Your complex geometries, exacting standards, and aggressive deadlines are precisely why we exist.

Technical Capabilities

Sheet Metal Cut – Technical Specifications (Laser Cutting, Bending, Welding)

The following table outlines key technical specifications for sheet metal fabrication processes—laser cutting, bending, and welding—applicable to common materials including aluminum, steel, ABS, and nylon. These parameters are typical for industrial prototyping and low-to-medium volume production at Honyo Prototype.

| Process | Material | Thickness Range | Tolerance (Cut) | Tolerance (Bend) | Laser Power Requirement | Bend Radius (Min) | Welding Method (Recommended) | Notes |

|---|---|---|---|---|---|---|---|---|

| Laser Cutting | Aluminum | 0.5 mm – 12 mm | ±0.1 mm | N/A | 1 kW – 4 kW | N/A | TIG or MIG (post-cut) | Reflective material; requires high-power fiber lasers for thick sections |

| Laser Cutting | Steel (Mild) | 0.5 mm – 20 mm | ±0.1 mm | N/A | 1 kW – 6 kW | N/A | MIG or Spot Welding | Optimal cut quality with oxygen or nitrogen assist gas |

| Laser Cutting | ABS | 1 mm – 6 mm | ±0.2 mm | N/A | Low power CO₂ (100–300 W) | N/A | Not recommended | Thermoplastic; prone to melting and fumes; not typically welded |

| Laser Cutting | Nylon | 1 mm – 8 mm | ±0.2 mm | N/A | CO₂ laser (150–400 W) | N/A | Hot plate or ultrasonic | Limited weldability; hygroscopic—requires pre-drying |

| Bending | Aluminum | 0.8 mm – 10 mm | N/A | ±0.2° / ±0.1 mm | N/A | 0.8× material thickness | Not applicable | Use soft tooling to avoid surface marring |

| Bending | Steel (Mild) | 0.8 mm – 15 mm | N/A | ±0.2° / ±0.1 mm | N/A | 1.0× material thickness | Not applicable | Springback compensation required in tooling design |

| Bending | ABS | 1 mm – 5 mm | N/A | ±0.5° / ±0.3 mm | N/A | 2.0× material thickness | Not applicable | Limited cold forming; heat-assisted bending preferred |

| Bending | Nylon | 1 mm – 6 mm | N/A | ±0.5° / ±0.3 mm | N/A | 2.5× material thickness | Not applicable | Requires preheating for tight bends to prevent cracking |

| Welding | Aluminum | 1 mm – 12 mm | N/A | N/A | N/A | N/A | TIG or Laser Welding | Requires shielding gas; joint prep critical for porosity control |

| Welding | Steel (Mild) | 1 mm – 20 mm | N/A | N/A | N/A | N/A | MIG, TIG, or Spot Welding | High weld strength; post-weld grinding often needed |

| Welding | ABS | 3 mm – 8 mm (joined) | N/A | N/A | N/A | N/A | Solvent or ultrasonic welding | Not fusion-welded; limited structural use |

| Welding | Nylon | 3 mm – 10 mm (joined) | N/A | N/A | N/A | N/A | Hot gas or vibration welding | Requires precise temperature control; joint design critical |

Notes on Process Compatibility

Laser cutting is highly effective for metals such as aluminum and steel, offering precision and clean edges. ABS and nylon can be laser cut with CO₂ systems but require ventilation due to fume generation. Bending is primarily suited for ductile materials—metals perform best, while thermoplastics require careful thermal management. Welding is structurally viable for metals; thermoplastics use alternative joining methods due to non-metallic bonding mechanisms.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined sheet metal cutting process designed to maximize accuracy, efficiency, and manufacturability while minimizing client risk. Our integrated workflow seamlessly connects digital design validation with physical production, ensuring optimal outcomes from initial concept to final delivery.

CAD File Upload and Initial Processing

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, DXF, DWG) via our secure customer portal. Our system performs immediate automated validation checks for file integrity, unit consistency, and geometric completeness. This initial screening prevents downstream delays caused by corrupted or incompatible files, establishing a reliable foundation for subsequent stages.

AI-Powered Quoting and Preliminary Feasibility Assessment

Uploaded geometry undergoes real-time analysis by our proprietary AI engine, which simultaneously generates a competitive commercial quote and a preliminary manufacturability assessment. This dual-output system evaluates critical factors including material utilization efficiency, machine capability alignment, geometric complexity scoring, and potential cost drivers. The AI provides an estimated cost range alongside a manufacturability index (0-100 scale), enabling clients to make informed decisions before formal commitment. This step typically completes within 2 business hours.

Formal Design for Manufacturability (DFM) Review

Upon quote acceptance, our engineering team conducts an in-depth DFM analysis. This is not an automated step but leverages AI insights to guide expert human evaluation. Key parameters scrutinized include:

| Parameter Category | Specific Checks | Industry Standard Tolerance | Honyo Target Tolerance |

|---|---|---|---|

| Geometric Features | Bend radii, hole diameter-to-thickness ratios, slot widths, feature spacing | ±0.1mm | ±0.05mm |

| Material Constraints | Minimum/maximum sheet thickness per alloy, grain direction implications | ASTM/ISO standards | Tighter process control bands |

| Process Capabilities | Minimum internal corner radii, maximum part size per machine, tooling accessibility | Machine OEM specifications | Optimized for reduced secondary ops |

The DFM report details actionable recommendations for design optimization, potential cost-saving modifications, and clear identification of non-manufacturable features. Client collaboration is mandatory at this stage; we require formal sign-off on the DFM report before proceeding to production, ensuring alignment on any necessary design adjustments.

Precision Production Execution

Approved designs advance to our CNC-controlled production floor. Sheet metal cutting utilizes state-of-the-art AMADA LC series laser cutters and turret punches with automatic material handling systems. Key production protocols include:

Material certification verification against client specifications occurs prior to machine loading. Parts undergo in-process inspection at critical stages using calibrated CMMs and optical comparators. Our proprietary nesting software dynamically optimizes material yield while maintaining strict thermal management protocols to prevent warpage during laser processing. Secondary operations such as deburring, tapping, and forming occur within the same controlled workflow to minimize handling errors.

Quality-Controlled Delivery

All completed parts undergo final inspection per AS9102 aerospace standards (or client-specified requirements), including first-article reporting when required. Dimensional reports, material certs, and process documentation are compiled into a comprehensive delivery package. Parts ship via client-preferred logistics partners with real-time tracking, typically within 5-7 business days post-DFM approval for standard orders. Rush services with 72-hour turnaround are available for qualified geometries. We maintain a documented chain of custody from material receipt through final shipment, ensuring full traceability for critical applications.

This structured process eliminates common industry pitfalls through enforced DFM collaboration and AI-enhanced validation. By requiring client sign-off at the DFM stage, we achieve first-pass yield rates exceeding 92% on complex sheet metal components, directly reducing time-to-market and non-conformance costs for our partners. Delivery timelines remain predictable due to our capacity to validate manufacturability before production commitment.

Start Your Project

Looking for precision sheet metal cutting services? Contact Susan Leo at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and dedicated facility in Shenzhen, Honyo Prototype delivers high-quality, fast-turnaround sheet metal fabrication for prototyping and low-volume production. Trust our engineering team to support you from design to delivery.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.