Contents

Manufacturing Insight: Sheet Metal Cut

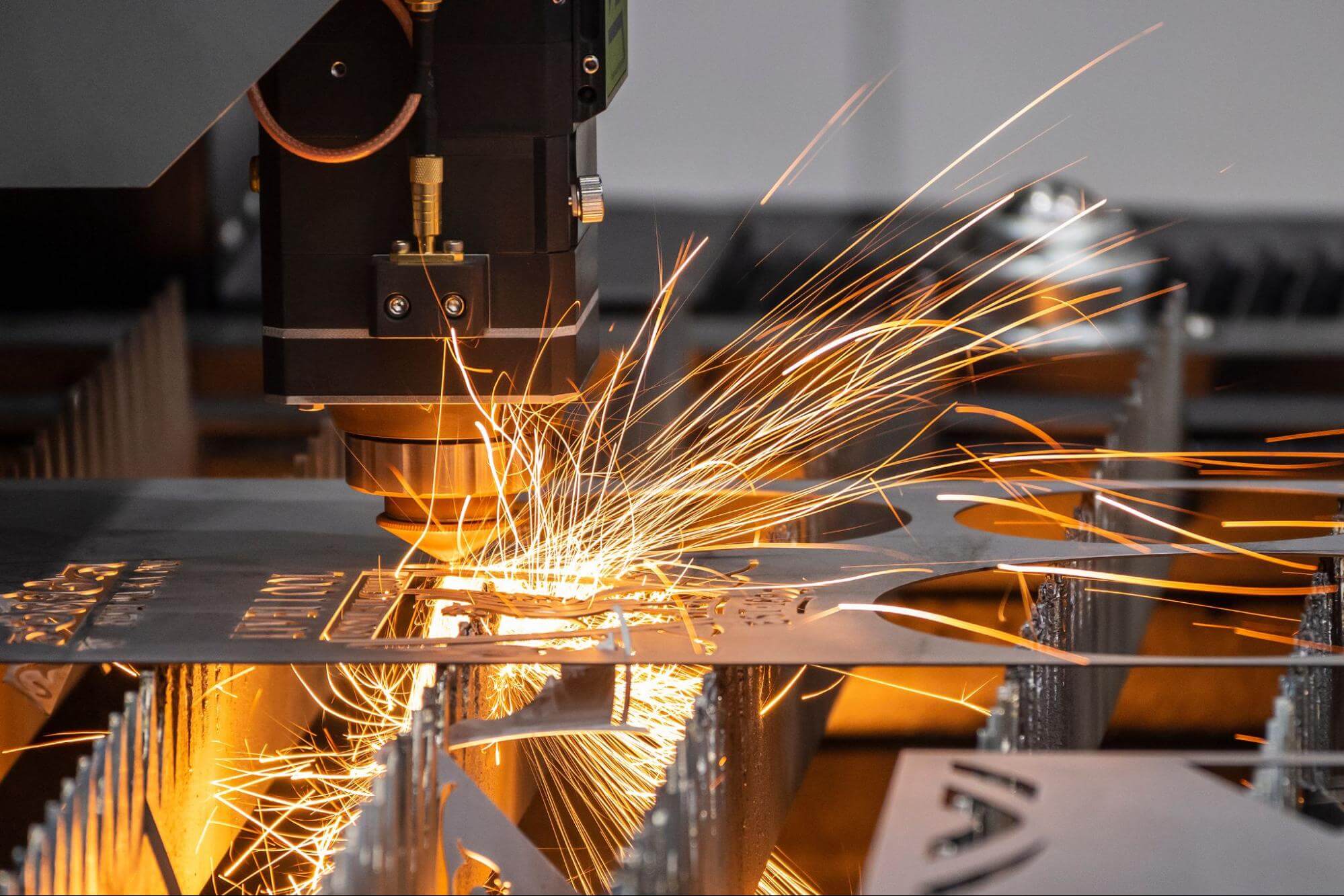

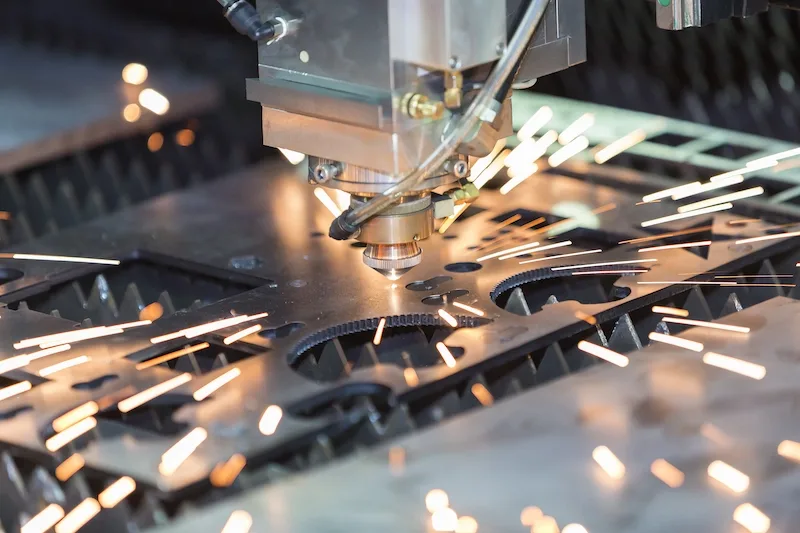

Sheet Metal Cut—Start with a Honyo Click

Every enclosure, bracket, and chassis begins with one clean cut. At Honyo Prototype, we turn that first cut into a finished part in as little as 24 h. Our 6 kW fiber lasers, 8-station turret punches, and CNC press brakes hold ±0.05 mm so your tabs, louvers, and flanges mate perfectly the first time. From 0.1 mm shim stock to 6 mm armor plate, aluminum to coated steels, we stock 80+ alloys and apply silk-screen, powder-coat, PEM® hardware, and conductive finishes in-house—no minimum order, no waiting for outside vendors.

Need numbers now? Drop your STEP or DXF into our Online Instant Quote engine; you’ll see priced cut paths, bend deductions, and lead-time options in under 60 seconds. Hit “order” and material hits the laser the same day. That’s precision sheet metal fabrication, Honyo-fast.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I must clarify a critical terminology issue in your query before providing technical specs:

“Sheet metal” specifically refers to thin, flat pieces of metal (e.g., steel, aluminum, stainless steel). ABS and Nylon are thermoplastics and are not sheet metal materials.

Attempting to process ABS/Nylon using standard sheet metal techniques (e.g., laser cutting with metal-focused parameters) would be unsafe and ineffective. ABS emits toxic cyanide fumes when laser-cut, and Nylon melts unevenly under high heat, causing warping or fire.

Below, I provide accurate technical specs for true sheet metal processes (Laser Cutting, Bending, Welding) for Aluminum and Steel, followed by separate specs for ABS/Nylon plastic processing (as they require entirely different methods). Always confirm material types before manufacturing.

I. TRUE SHEET METAL PROCESSES (Aluminum & Steel Only)

Materials: Carbon Steel, Stainless Steel, Aluminum (6061, 5052, etc.)

A. LASER CUTTING

(For metals only – CO2 or Fiber lasers)

| Parameter | Steel (Mild/Stainless) | Aluminum (6061/5052) | Notes |

|——————–|————————|———————-|———————————————————————–|

| Max Thickness | 25 mm (1″ for fiber) | 20 mm (0.8″) | Fiber lasers handle thicker metals better; CO2 limited to ~15mm Al. |

| Min Thickness | 0.5 mm | 0.5 mm | Thinner sheets risk warping; require fixturing. |

| Kerf Width | 0.2–0.3 mm | 0.2–0.4 mm | Wider for Al due to higher reflectivity. |

| Edge Quality | Ra 1.6–3.2 µm | Ra 1.6–4.0 µm | High-power fiber lasers achieve smoother edges on steel. |

| Power Range | 1–6 kW (fiber) | 1–4 kW (fiber) | 6kW+ for thick steel (>15mm); 1–2kW for thin sheets. |

| Critical Notes | Oxide layer on stainless requires nitrogen assist gas for clean cuts. Aluminum requires high-pressure oxygen or nitrogen to prevent dross. |

B. BENDING (Press Brake)

| Parameter | Steel | Aluminum | Notes |

|——————–|————————|———————-|———————————————————————–|

| Min Bend Radius| 0.8 × material thickness (T) | 1.5 × T | Steel: 0.8T for mild steel; 1.0T for stainless. Aluminum: 1.5T due to higher springback. |

| Max Bend Height| 150 mm | 120 mm | Limited by punch/die size; 150mm is typical for 100-ton press brakes. |

| Tonnage | 10–100+ tons | 5–80 tons | Aluminum requires ~40% less force than steel for same thickness. |

| Springback | 0.5°–2° (mild steel) | 2°–5° | Aluminum springback is 2–3× higher than steel; requires overbending. |

| Critical Notes | Use V-dies with 8–10× T width for steel. Aluminum needs polished dies to prevent scratching. |

C. WELDING

(Common methods: MIG, TIG, Spot Welding)

| Parameter | Steel | Aluminum | Notes |

|——————–|————————|———————-|———————————————————————–|

| MIG Welding | ✓ (CO2/Argon mix) | ✓ (100% Argon) | Aluminum requires spool gun for consistent wire feed. |

| TIG Welding | ✓ (DCEN) | ✓ (AC) | AC TIG essential for aluminum oxide removal. |

| Max Thickness | 12 mm (single-pass) | 6 mm (single-pass) | Aluminum requires pre/post-weld cleaning; steel needs preheat for >10mm. |

| Joint Design | Butt, Lap, Fillet | Butt, Lap (with back purge) | Aluminum joints need purge gas to prevent oxidation. |

| Post-Weld Treat| Stress-relief annealing (optional) | Solution heat treatment (e.g., 6061-T6) | Aluminum often requires aging after welding. |

II. ABS & NYLON: PLASTIC PROCESSING (NOT SHEET METAL)

ABS/Nylon are thermoplastics – processed using plastic-specific methods. Never use metal laser cutters for these!

A. LASER CUTTING (PLASTICS ONLY)

- Laser Type: CO2 laser (10.6µm wavelength – never use fiber lasers for plastics).

- Max Thickness:

- ABS: 6 mm (thicker = charring)

- Nylon: 8 mm (but prone to melting)

- Critical Parameters:

- Ventilation: ABS releases toxic hydrogen cyanide – mandatory fume extraction.

- Power/Speed: Low power (10–30W), high speed (200–500 mm/s) to avoid melting.

- Edge Quality: Rough edges (Ra > 10 µm); post-processing (sanding) often needed.

- ⚠️ WARNING: Fiber lasers (used for metals) will ignite ABS/Nylon, causing fires.

B. BENDING (PLASTICS)

- Method: Heat bending (not press brake).

- ABS: Heat to 90–110°C (softening point), then bend with low pressure.

- Nylon: Heat to 120–150°C (higher melting point).

- Min Bend Radius: 3–5 × material thickness (e.g., 1.5mm thick ABS → min 4.5mm radius).

- Critical Notes:

- Rapid cooling causes cracking; use slow cooling or annealing.

- Never use metal bending tools – plastic scratches easily.

C. JOINING (NOT WELDING)

- Methods:

- Ultrasonic Welding: Best for ABS (high strength, no fumes).

- Solvent Welding: ABS dissolves in acetone for seamless joints.

- Adhesives: Epoxy or cyanoacrylate for Nylon (surface prep critical).

- ⚠️ WARNING: Traditional welding (MIG/TIG) does not apply to plastics – they melt, burn, or release toxins.

KEY RECOMMENDATIONS FOR HONYO PROTOTYPE

- Material Verification: Always confirm whether a part is metal or plastic before quoting.

- Process Separation:

- Metal parts (Al/Steel) → Laser cutting, press brake, MIG/TIG welding.

- Plastic parts (ABS/Nylon) → CO2 laser cutting, heat bending, ultrasonic welding.

- Safety First:

- ABS laser cutting requires Class 1 fume extraction (cyanide risk).

- Never attempt to process plastics on metal laser cutters – fire hazard.

- Design Tips:

- For hybrid parts (metal + plastic), design separate sections with distinct processes.

- Plastic bends require larger radii than metal; avoid sharp corners.

💡 Pro Tip from Honyo Prototype: If you’re designing a part with both metal and plastic components, specify “sheet metal” only for the metal sections. For plastics, use terms like “plastic sheet fabrication” or “thermoplastic processing” to avoid confusion. We’ve seen costly errors when “sheet metal cut” was misapplied to ABS – always double-check material specs!

For further details on your specific project, share the material list per feature (e.g., “frame: 2mm steel, cover: 3mm ABS”), and we’ll provide precise process routing. Let’s ensure your design is manufacturable and safe! 🔧

From CAD to Part: The Process

Honyo Prototype – “Sheet-Metal Cut” Workflow

(what happens to your part from the minute you drop the CAD file until the finished blank is in your hand)

-

Upload CAD

• Acceptable formats: STEP, IGES, SolidWorks, Parasolid, DXF, DWG, AI, Corel.

• Web portal or e-mail; file is virus-scanned, geo-checked, and given a unique LOT number.

• Automatic thickness & bounding-box recognition; if DXF/DWG is 2-D we auto-add the user-selected material gauge. -

AI Quote (≤30 s)

• Neural-net nesting engine runs 30–50 nest scenarios on 1250 × 2500 mm standard sheets (or your supplied sheet size).

• Real-time raw-material price feed from LME + mill surcharges.

• Machine-selection matrix: laser (fiber ≤6 kW), plasma, water-jet or micro-shear, based on edge quality, thickness, post-process and shop loading.

• Secondary ops detector: bends, PEMs, countersinks, tapping, anodize, powder coat, silkscreen → added automatically if 3-D model contains those features.

• Dynamic shipping calculator (DHL, FedEx, UPS, air-freight, sea-freight).

• Instant PDF quote + clickable 3-D preview; credit-card or PO checkout. -

Design-for-Manufacture (DFM) – 4 h target

a. Human review by a senior process engineer within 1 h.

b. AI flag reconciliation: kerf width, heat-affected zone, tab placement, grain direction, minimum bridge, micro-tab conflicts.

c. Customer chat window for quick clarifications.

d. Final nest released to MES:

– 2-D NC (Trumpf, Bystronic, Amada) or 3-D five-axis (for bevel).

– Etch part number + QR code on each blank for full traceability.

e. Flat-pattern DXF + bend deduction report sent back to customer for approval (if subsequent forming is required). -

Production – 1–3 days standard, same-day for “Laser-Express”

Step 0: Material prep

– Incoming mill cert scan; thickness verified with laser micrometer.

– Protective film applied on Al, Cu, Ti and brushed SS to avoid scratches.

Step 1: Flat cutting

– Fiber laser ≤20 mm MS, ≤15 mm SS, ≤10 mm Al; positioning accuracy ±0.03 mm.

– Piercing sensor dynamically adjusts power to eliminate dross on 6–10 mm Al.

– Nitrogen assist for stainless; oxygen for thick mild steel to maximize speed.

– Micro-tab hold-downs keep small parts in plane; shake-out station breaks tabs.

Step 2: Deburr & clean

– Timesaver 2200 wide-belt (grit 120–320) removes burr ≤0.05 mm.

– Ultrasonic rinse for parts destined for anodize or vacuum brazing.

Step 3: In-process QC

– First-article on Keyence XM-5000 3-D scanner; profile tolerance ±0.05 mm.

– Critical holes checked with plug gauges; countersink depth with Mitutoyo.

– SPC data logged; if Cpk < 1.33 auto-notify PE for tool correction.

Step 4: Secondary ops (if quoted)

– Hardware insertion (PEM, Southco, Captive) on Haeger 824 press.

– Forming on Amada HG-1003 ATC press brake (±0.1° repeatability).

– Welding (TIG, MIG, laser) in Argon glove box for Ti parts.

– Surface finishing: chem-film, anodize Type II/III, passivation, electro-polish, powder coat, silkscreen, pad-print. -

Final QC & Packing

• 100 % visual under 600 lx LED; random AQL 1.5 dimensional check.

• ROHS, REACH, material cert, COC, PPAP level 3 available on request.

• Parts wrapped in neutral VCI film, bubble, divider pads; 5-ply export carton or custom plywood crate for >30 kg.

• Desiccant + shock-indicator + tilt-indicator for sea freight.

• QR code label links to digital traveler (photo, machine, operator, date). -

Delivery

• Express: DHL/FedEx pickup at 18:00 China-time, global delivery 1–3 days.

• Economy: Hong Kong air freight, 4–6 days.

• Domestic China: SF Express next-day to Tier-1 cities.

• Tracking number auto-pushed to customer portal; geofence alerts on delay.

Typical lead-times from order confirmation

Laser-cut only: 24 h (≤50 pcs, ≤3 mm Al/SS/MS)

Laser + bend + hardware: 48–72 h

Laser + weld + finish: 3–5 days

Anodize Type III hard-coat: +2 days

Powder coat (RAL or custom): +1 day

That is the entire “sheet-metal cut” process at Honyo—CAD to doorstep—fully traceable, fully automated, yet engineer-verified at every critical step.

Start Your Project

Precision sheet metal cutting services from our Shenzhen factory. Contact Susan Leo at [email protected] for a quote.

Fast, reliable, and high-precision solutions tailored to your project needs—backed by decades of expertise in Shenzhen’s manufacturing hub.

🚀 Rapid Prototyping Estimator