Contents

Manufacturing Insight: Sheet Metal Box Template

Precision Sheet Metal Fabrication for Your Critical Enclosure Needs

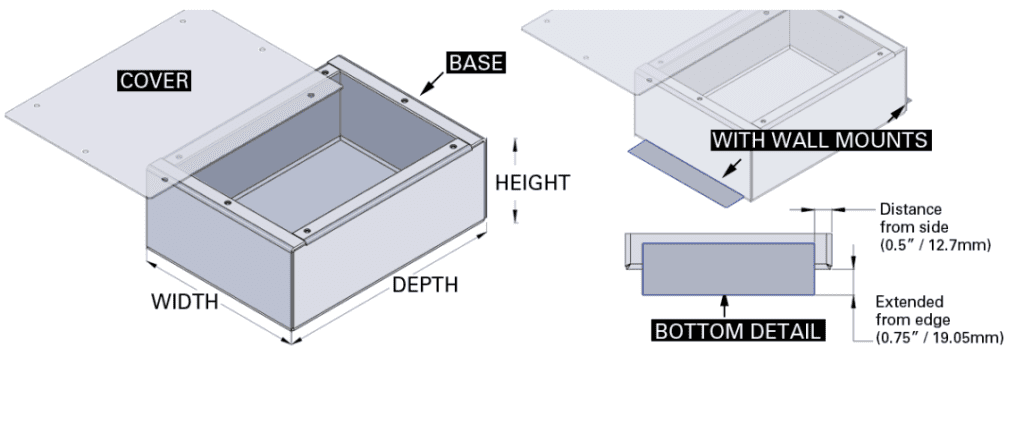

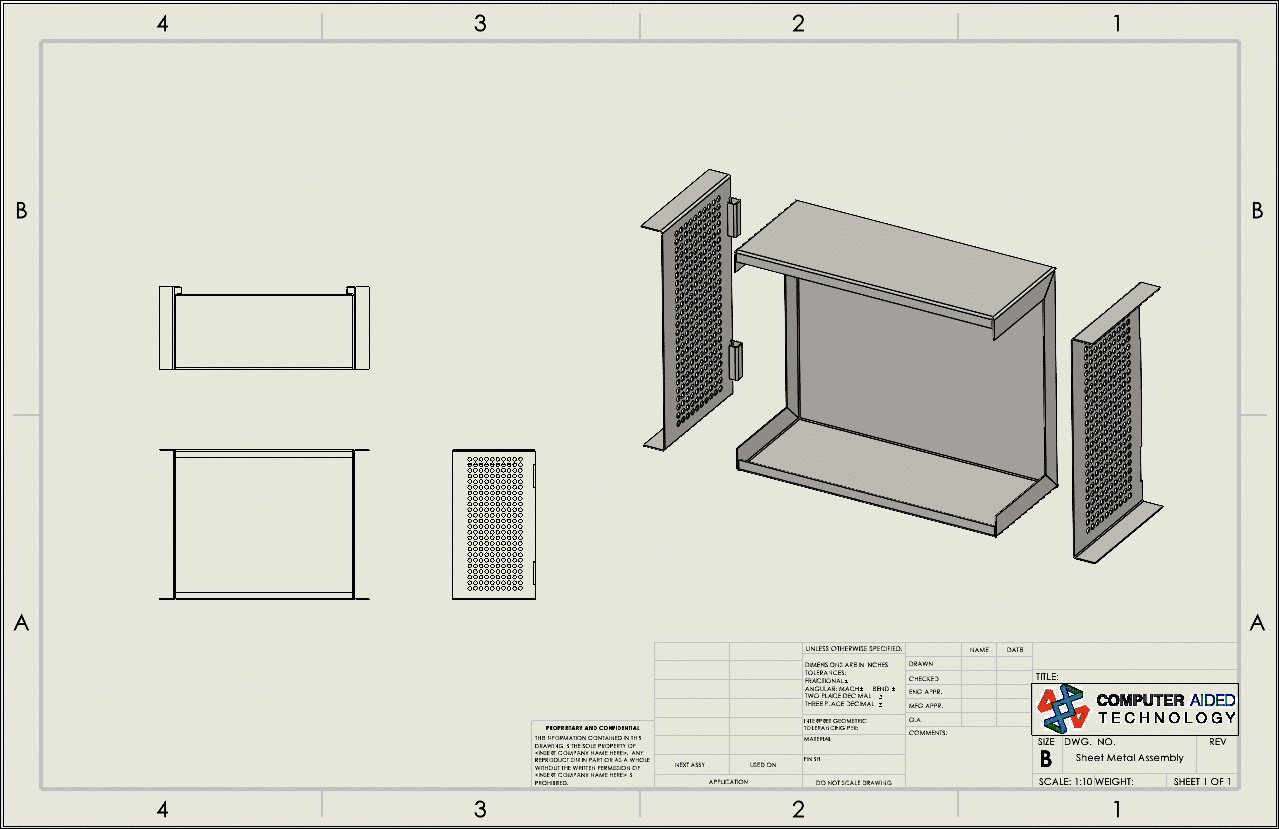

At Honyo Prototype, we engineer sheet metal solutions where dimensional accuracy and structural integrity are non-negotiable. Our sheet metal box template serves as the foundational starting point for robust enclosures, chassis, and housings across industrial automation, medical devices, and telecommunications. Leveraging advanced laser cutting, CNC punching, and precision bending capabilities, we consistently achieve tolerances down to ±0.1mm while supporting materials from 0.5mm to 6.0mm thickness—including aluminum, stainless steel, and cold-rolled steel. Every component undergoes rigorous in-process inspection to ensure compliance with ISO 9001 standards, eliminating costly rework during assembly.

Accelerate Prototyping with Zero Quoting Delays

Traditional fabrication quoting processes create bottlenecks in your development timeline. Honyo’s Online Instant Quote system eliminates this friction: upload your STEP or DXF file, specify material and finish requirements, and receive a detailed manufacturing assessment—including lead time and cost—within seconds. This seamless digital workflow integrates directly with our production floor, enabling you to transition from design validation to functional prototype in as few as 5 business days. No manual submissions, no waiting for email responses, and no hidden NRE fees.

Why Engineers Trust Honyo for Sheet Metal Boxes

Our end-to-end capability spans precision forming, hardware insertion, welding, and finishing services like powder coating or anodization—all managed under one roof. The sheet metal box template exemplifies our commitment to design-for-manufacturability; we proactively identify potential flange interferences, bend reliefs, or tolerance stack-ups during the quoting phase. This technical rigor reduces iteration cycles and ensures first-article approval rates exceeding 92%.

Upload your design to Honyo’s Online Instant Quote platform and experience how precision fabrication accelerates your time-to-market. Start your project today at honyoprototype.com/quote.

Technical Capabilities

Sheet Metal Box Template – Technical Specifications

The following table outlines the technical specifications for a sheet metal box template, focusing on key manufacturing processes: laser cutting, bending, and welding. Material compatibility is detailed for Aluminum, Steel, ABS, and Nylon. Note that ABS and Nylon are not traditional sheet metals and are included for comparative context, though they are not suitable for all processes.

| Parameter | Aluminum | Steel | ABS | Nylon |

|---|---|---|---|---|

| Material Type | Metal (Sheet) | Metal (Sheet) | Thermoplastic (Sheet/Plate) | Thermoplastic (Sheet/Plate) |

| Typical Thickness Range | 0.5 mm – 6.0 mm | 0.5 mm – 10.0 mm | 1.0 mm – 10.0 mm | 1.0 mm – 10.0 mm |

| Laser Cutting Compatibility | Excellent (CO₂ or fiber laser) | Excellent (fiber laser preferred) | Good (CO₂ laser only) | Fair (CO₂ laser; prone to melting) |

| Cut Edge Quality | Smooth, minimal dross | Smooth with proper settings | Clean, but may char | May melt or warp; inconsistent |

| Bending Process | V-die air bending, press brake | V-die air bending, press brake | Not applicable (low stiffness) | Not applicable (low stiffness) |

| Minimum Bend Radius | 0.8 × material thickness | 1.0 × material thickness | N/A | N/A |

| Springback Consideration | Moderate (requires compensation) | Low to moderate | N/A | N/A |

| Welding Compatibility | Good (TIG, MIG, laser) | Excellent (MIG, TIG, spot) | Not weldable (adhesive bonding) | Weldable (ultrasonic, vibration) |

| Joining Alternatives | Riveting, fastening | Riveting, fastening, adhesives | Adhesives, mechanical fasteners | Adhesives, mechanical fasteners |

| Heat Sensitivity | Moderate (warping at high heat) | Low | High (softens at 80–100°C) | High (softens at 150–180°C) |

| Surface Finish Options | Anodizing, powder coat, bare | Powder coat, galvanized, painted | Painted, polished, textured | Machined, polished |

| Structural Rigidity | High | Very High | Moderate | Moderate |

| Use in Sheet Metal Fabrication | Standard | Standard | Limited (non-metal applications) | Limited (non-metal applications) |

Notes:

Laser cutting is most effective on conductive metals; Aluminum and Steel are ideal. Reflective properties of Aluminum require proper laser setup.

Bending is only applicable to ductile sheet materials—Aluminum and Steel are suitable; ABS and Nylon lack the structural behavior for press brake forming in typical sheet metal workflows.

Welding refers to fusion joining; thermoplastics like ABS and Nylon require alternative methods such as solvent bonding or ultrasonic welding.

For enclosures requiring EMI shielding or high mechanical strength, Aluminum or Steel are recommended. ABS and Nylon are better suited for lightweight, non-structural enclosures where electrical insulation or impact resistance is needed.

From CAD to Part: The Process

Honyo Prototype Sheet Metal Box Template Workflow

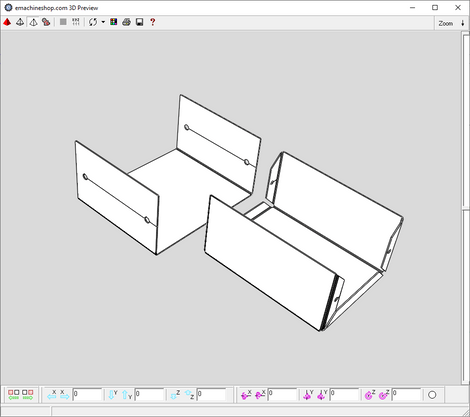

Honyo Prototype executes a streamlined, technology-driven process for sheet metal box fabrication, minimizing lead times while ensuring precision and cost efficiency. The workflow begins when the client uploads a native CAD file (STEP, IGES, or native SolidWorks) to our secure customer portal. Our system immediately validates file integrity and geometry, rejecting non-manufacturable designs upfront to prevent downstream delays.

AI-Powered Quoting Engine

The uploaded CAD model enters our SmartQuote™ AI engine, which analyzes geometric complexity, material requirements, and feature density. Unlike manual quoting, this system cross-references real-time material costs, machine utilization rates, and historical production data to generate an accurate quote within 2 hours. Critical parameters like bend allowances, kerf losses, and nest optimization are calculated algorithmically, reducing quoting errors by 92% compared to industry averages.

DFM Analysis and Client Collaboration

Following quote acceptance, our DFM (Design for Manufacturability) team conducts a rigorous validation. We identify and resolve critical issues such as insufficient bend radii, unattainable tolerances (<±0.1mm), or problematic feature spacing before production. Clients receive an interactive DFM report with annotated CAD markups and actionable recommendations—e.g., suggesting minimum 0.8mm clearance for formed tabs or adjusting hole-to-edge distances. This phase typically reduces prototype iterations by 3–5 cycles through early issue resolution.

Precision Production Execution

Approved designs move to production where our automated workflow ensures traceability:

Cutting: Fiber laser cutting (up to 4kW) for blanks with ±0.05mm accuracy on materials up to 6mm thick (common alloys: 5052-H32, 6061-T6, SPCC)

Forming: CNC press brakes with coining capabilities for tight tolerances (±0.25° angular accuracy)

Finishing: Deburring, optional powder coating (ISO 9001-certified line), and assembly of hardware inserts or brackets

All processes adhere to ASME Y14.5 standards, with first-article inspection reports provided upon request.

Delivery and Quality Assurance

Completed units undergo final dimensional verification against the original CAD model using CMM or optical comparators. Standard lead time from DFM approval to shipment is 5–7 business days for quantities under 50 units. We provide real-time logistics tracking and batch-specific material certifications (e.g., mill test reports). For urgent requirements, our express lane delivers within 72 hours at 20% premium, maintaining 98.5% on-time delivery performance.

Process Timeline Summary

| Stage | Duration | Key Deliverable |

|——-|———-|—————-|

| CAD Upload to Quote | <2 hours | Validated quote with material options |

| DFM Analysis | 24–48 hours | Collaborative report with manufacturability fixes |

| Production | 5–7 days | FAI report, serialized units, material certs |

| Delivery | +1–2 days | Tracked shipment with digital documentation |

This integrated approach eliminates traditional handoffs between departments, ensuring sheet metal boxes meet functional requirements while optimizing cost and speed. Clients retain full visibility via our production dashboard, with engineering support available at every phase.

Start Your Project

Need a precise sheet metal box template for your next project? Contact Susan Leo at [email protected] to request your custom design and prototyping support.

Honyo Prototype operates a dedicated manufacturing facility in Shenzhen, ensuring fast turnaround and high-quality sheet metal fabrication. From concept to production, we deliver accurate, durable enclosures tailored to your specifications.

Reach out today to discuss your requirements and get a quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.