Contents

Manufacturing Insight: Sheet Metal Blueprints

Precision Sheet Metal Blueprints Meet Accelerated Prototyping with Honyo

When developing sheet metal components, your engineering blueprints define critical tolerances, bend radii, and material specifications that demand flawless execution. Yet traditional prototyping often introduces delays due to tooling lead times and iterative fabrication constraints. At Honyo Prototype, we bridge this gap by integrating industrial 3D printing directly into your sheet metal workflow—transforming how prototypes and low-volume production parts align with your blueprint intent.

Our industrial 3D printing services replicate complex sheet metal geometries—including louvers, embossments, and compound bends—with precision down to ±0.1mm, using engineering-grade materials like nylon composites and metal alloys. This eliminates weeks of wait time for hard tooling while ensuring form, fit, and functional validation against your original CAD data. Crucially, every 3D-printed part undergoes rigorous dimensional inspection to verify compliance with your blueprint’s geometric dimensioning and tolerancing (GD&T) callouts, reducing downstream rework in final sheet metal fabrication.

Accelerate your path from blueprint to physical validation with Honyo’s Online Instant Quote platform. Simply upload your STEP or DWG file, specify material and finish requirements, and receive a detailed manufacturing quote within minutes—not days. This seamless integration empowers design teams to iterate rapidly, de-risk production transitions, and maintain strict adherence to your sheet metal specifications without sacrificing speed or accuracy.

| Service Feature | Traditional Sheet Metal Prototyping | Honyo Industrial 3D Printing Integration |

|---|---|---|

| Lead Time for Prototype | 3–6 weeks | 2–5 business days |

| Tooling Costs | High (custom dies/forming tools) | None required |

| Complex Geometry Support | Limited by tooling constraints | Full design freedom |

| Blueprint Compliance | Verified post-fabrication | Pre-validated via digital inspection |

Leverage Honyo’s expertise to transform static blueprints into actionable, high-fidelity prototypes—ensuring your sheet metal designs transition smoothly from concept to certified production. Start your project today with a quote that respects your timeline and technical rigor.

Technical Capabilities

Sheet metal blueprints are typically associated with traditional manufacturing processes such as laser cutting, bending, and punching of metal sheets. However, the technologies listed—SLA (Stereolithography), SLS (Selective Laser Sintering), MJF (Multi Jet Fusion), and DMLS (Direct Metal Laser Sintering)—are additive manufacturing (3D printing) methods and not conventionally used for sheet metal fabrication. That said, these technologies are employed to produce complex, three-dimensional parts directly from digital models. Below is a technical comparison of these additive manufacturing processes, including their applicable materials such as Aluminum, Steel, ABS, and Nylon, which may be referenced in engineering documentation analogous to blueprints.

| Process | Technology Overview | Typical Materials | Layer Thickness (Typical) | Dimensional Accuracy | Surface Finish (Ra) | Build Volume (Typical Max) | Common Applications |

|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Photopolymerization using UV laser on liquid resin | Photopolymer resins (not ABS, Nylon, Aluminum, or Steel) | 25–100 µm | ±0.1 mm | 0.8–1.6 µm | 1450 x 750 x 500 mm (varies by machine) | Prototypes, master patterns, medical models |

| SLS (Selective Laser Sintering) | CO₂ laser sinters powdered material layer by layer | Nylon (PA11, PA12), Glass-filled Nylon; not ABS, Aluminum, or Steel | 80–120 µm | ±0.3 mm | 8–12 µm | 700 x 380 x 580 mm | Functional prototypes, end-use parts, ducting |

| MJF (Multi Jet Fusion) | Inkjet array deposits fusing agent, fused by heating element | Nylon (PA12), Glass-filled PA12; limited ABS-like materials | 80–100 µm | ±0.3 mm | 6–10 µm | 380 x 280 x 380 mm | High-volume functional parts, housings, jigs |

| DMLS (Direct Metal Laser Sintering) | High-power laser fuses metal powder particles | Stainless Steel (17-4 PH, 316L), Aluminum (AlSi10Mg), Titanium, Inconel | 20–50 µm | ±0.1 mm (varies with geometry) | 10–20 µm (as-built), lower with post-processing | 250 x 250 x 325 mm (typical) | Aerospace, medical implants, tooling, complex metal components |

Notes:

Materials Compatibility: ABS is not typically used in SLS or MJF; however, ABS-like thermoplastic resins are available in other processes such as FDM. Nylon (polyamide) is standard in SLS and MJF. Aluminum and Steel are processed via DMLS, not SLA, SLS, or MJF.

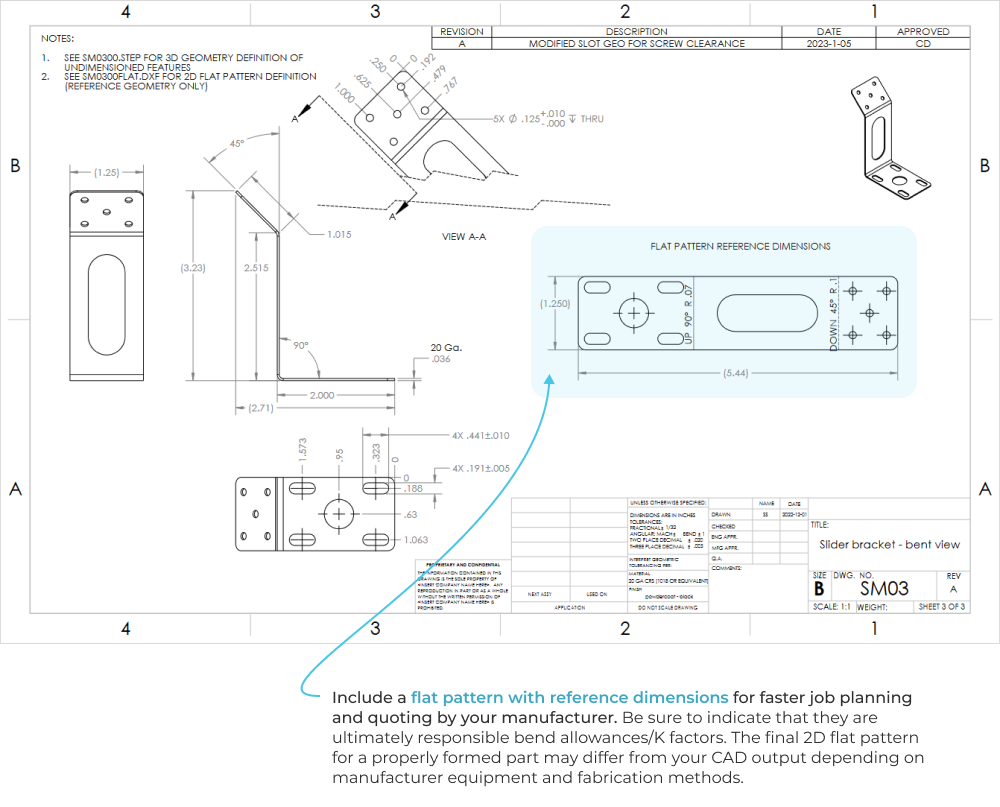

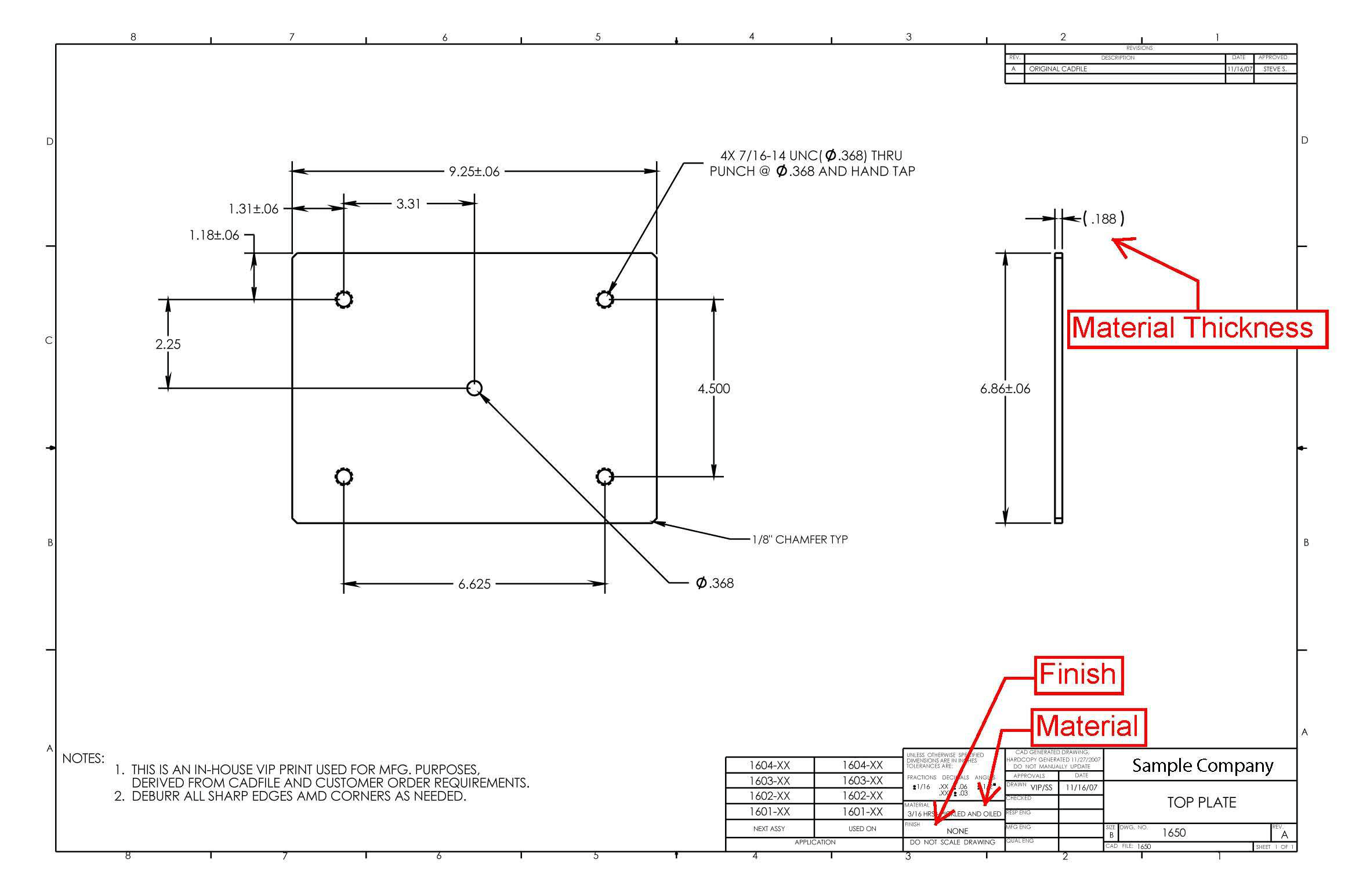

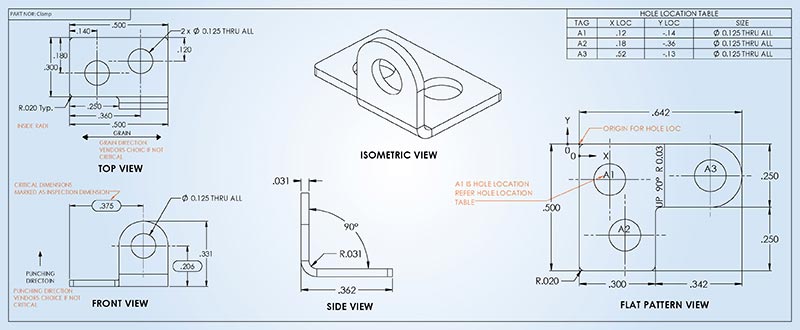

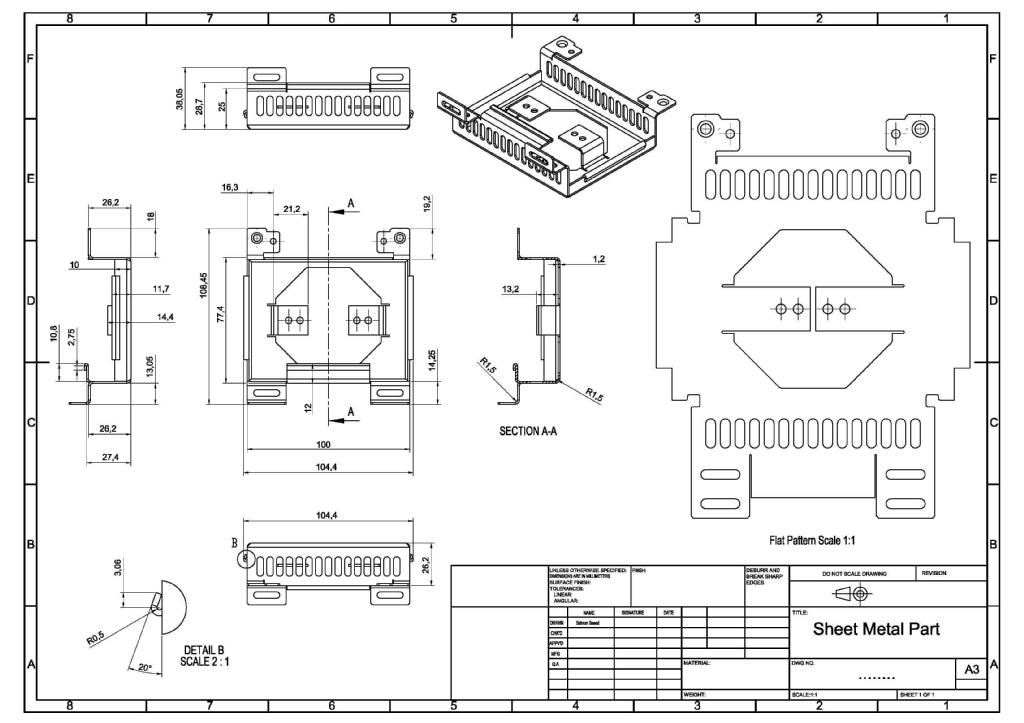

Blueprint Relevance: While traditional sheet metal blueprints define bend lines, flanges, and K-factors, additive manufacturing “blueprints” (3D CAD models with PMI) include information on layer orientation, support structures, and surface finish requirements.

Process Suitability: DMLS is the only process listed capable of producing metal parts suitable for applications traditionally considered for sheet metal in high-performance environments, though geometry and cost differ significantly.

For sheet metal fabrication, conventional processes remain standard. Additive methods like DMLS offer design freedom for complex metal parts but are not substitutes for sheet metal forming unless part geometry justifies it.

From CAD to Part: The Process

Honyo Prototype Sheet Metal Manufacturing Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for sheet metal fabrication, transforming customer designs into precision components. The process begins when a client uploads a native CAD file (STEP, IPT, SLDPRT, or DWG) via our secure online portal. This file must include geometric definitions, material specifications, and critical tolerances per ASME Y14.5 standards. Legacy 2D blueprints are accepted but require supplemental 3D geometry for AI validation; note that modern sheet metal production relies on model-based definitions rather than traditional blueprint drawings due to GD&T complexity and bend allowance precision requirements.

AI-Powered Quoting System

Uploaded CAD data undergoes automated analysis through Honyo’s proprietary AI engine, which cross-references 150+ geometric and manufacturing parameters against live material pricing, machine utilization rates, and labor databases. The system validates flat pattern developability, identifies potential collision risks in turret punching, and flags ambiguous tolerances before generating a formal quote within 2 business hours. Crucially, the AI does not replace engineering judgment—it surfaces anomalies requiring human review (e.g., non-standard bend radii or unachievable ±0.05mm tolerances on 2mm aluminum), with our application engineers intervening in <5% of cases to refine the estimate.

Engineering-Driven DFM Analysis

Upon quote acceptance, Honyo’s manufacturing engineers conduct a rigorous Design for Manufacturability (DFM) review using integrated simulation tools. This phase optimizes the design for our specific equipment capabilities—including Amada turret punches, Bystronic lasers, and Salvagnini press brakes—while maintaining functional intent. Key actions include: adjusting bend sequences to minimize setups, verifying hole-to-edge distances against minimum tool clearance rules, and proposing cost-saving material substitutions (e.g., swapping 5052-H32 for 6061-T6 where corrosion resistance isn’t critical). Clients receive a detailed DFM report with actionable recommendations and timeline/cost impacts within 24 hours, requiring formal sign-off before proceeding.

Precision Production Execution

Approved designs enter our digital production pipeline where CAM programming auto-generates optimized toolpaths from the validated CAD model. Material procurement triggers against real-time supplier inventory, with all sheet stock certified to ASTM/EN standards and batch-traceable. Fabrication occurs on IoT-connected machinery with in-process metrology: laser cutters employ vision systems for kerf compensation, while press brakes use angle sensors for closed-loop bend correction. Every operation adheres to our ISO 9001:2015-controlled work instructions, with first-article inspection (FAI) performed per AS9102 for aerospace clients or PPAP Level 3 for automotive.

Quality-Assured Delivery

Completed parts undergo final inspection against the original CAD model using CMM or optical comparators, with results documented in a Certificate of Conformance (CoC). Secondary operations like welding, finishing, or assembly follow validated procedures with weld procedure specifications (WPS) where applicable. Shipments include serialized traceability tags, packaging engineered for zero-transit-damage, and digital delivery of as-built inspection reports via the client portal. Standard lead times range from 5–12 business days for quantities under 500 pcs, with expedited options available.

Process Performance Metrics

Honyo’s integrated workflow delivers measurable advantages over legacy quoting systems, as evidenced by our 2023 operational data:

| Phase | Avg. Duration | Cost Accuracy | Defect Rate Reduction vs. Industry Avg. |

|---|---|---|---|

| AI Quote | 1.8 hours | ±3.2% | N/A |

| DFM | 22 hours | N/A | 68% |

| Production | 7.1 days | N/A | 41% |

| Overall | 9.3 days | ±2.9% | 52% |

This closed-loop system ensures technical rigor at each transition point, eliminating rework through upfront validation while maintaining the agility required for prototype and low-volume production. Clients retain full visibility via our cloud-based project dashboard, which updates in real-time from CAD upload through delivery.

Start Your Project

Need precision sheet metal blueprints for your next project? Partner with Honyo Prototype for accurate, industry-compliant documentation tailored to your manufacturing needs. Our engineering team ensures every detail meets your specifications, with seamless integration into production workflows.

Contact Susan Leo at [email protected] to discuss your requirements. With our Shenzhen-based factory, we offer fast turnaround and consistent quality for domestic and international clients. From prototype to volume production, trust Honyo Prototype for end-to-end sheet metal solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.