Contents

Manufacturing Insight: Semi Solid Metal Casting

Understanding Semi-Solid Metal Casting and Honyo Prototype’s Precision Sheet Metal Capabilities

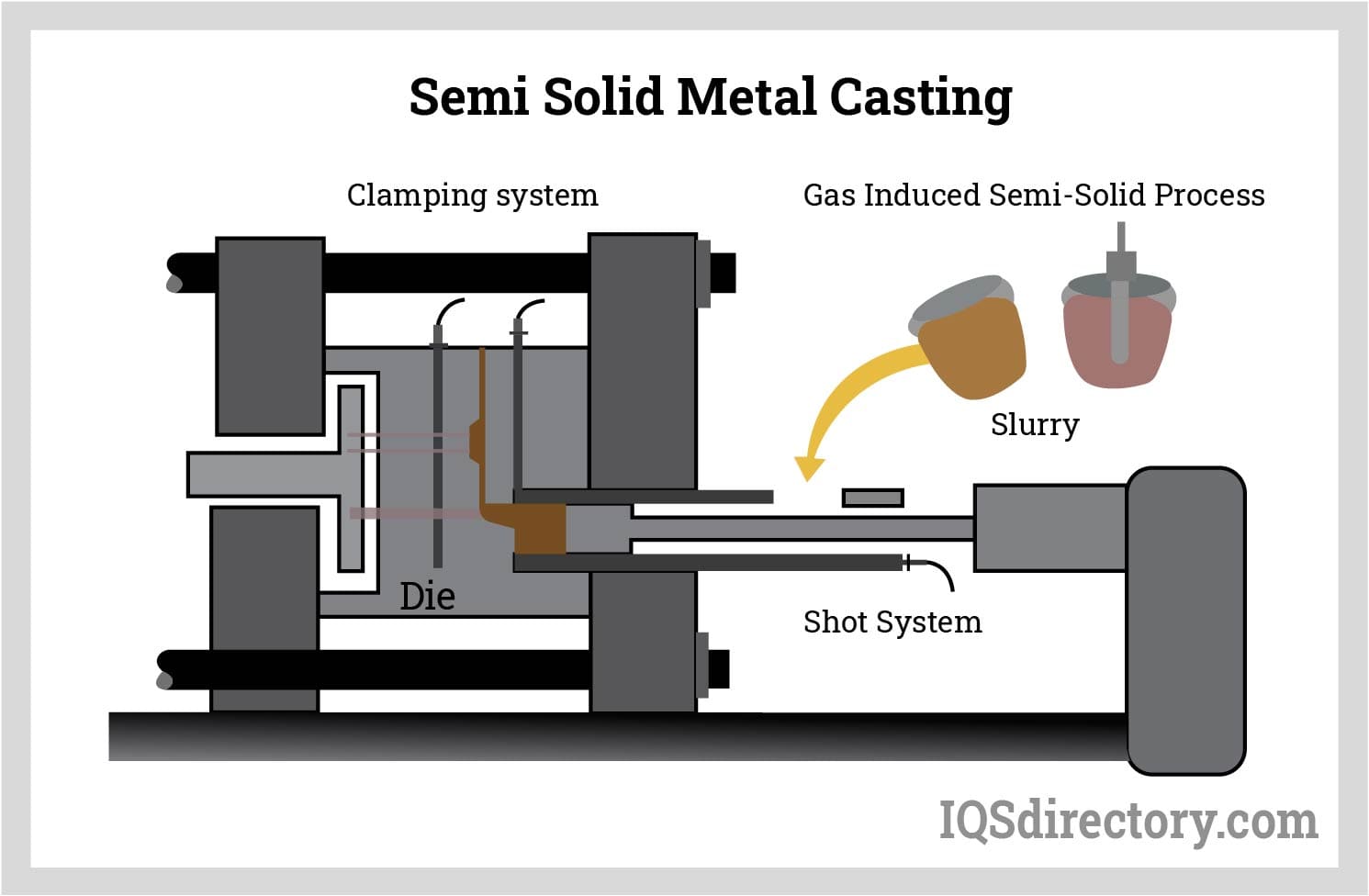

Semi-solid metal casting (SSM) represents an advanced manufacturing technique for producing high-integrity, near-net-shape components with exceptional mechanical properties and reduced porosity. While SSM excels in applications demanding complex geometries and structural performance—such as automotive powertrain or aerospace components—it operates distinctly from solid-state sheet metal fabrication processes. At Honyo Prototype, we specialize in the latter, delivering end-to-end sheet metal solutions that prioritize precision, scalability, and rapid turnaround for both prototyping and low-to-mid volume production.

Our sheet metal fabrication services leverage state-of-the-art laser cutting, CNC punching, precision bending, and robotic welding technologies to transform raw materials like aluminum, stainless steel, and carbon steel into mission-critical components. With tight tolerances down to ±0.05 mm and the ability to handle thicknesses from 0.5 mm to 6.0 mm, we support industries ranging from medical devices to industrial automation where dimensional accuracy and repeatability are non-negotiable. Unlike SSM, which requires specialized slurry preparation and thermal control, our sheet metal processes offer immediate design flexibility, reduced tooling costs, and seamless integration with secondary operations like finishing and assembly—all under one roof.

To accelerate your path from concept to physical part, Honyo Prototype provides an Online Instant Quote platform. Upload your STEP or DXF files, specify materials and quantities, and receive a detailed, binding quotation in under 60 seconds—bypassing traditional RFQ delays without compromising technical validation. This digital efficiency, combined with our engineering expertise, ensures your sheet metal projects launch faster while meeting rigorous quality standards. Partner with Honyo to transform your designs into high-performance hardware with unmatched speed and precision.

Technical Capabilities

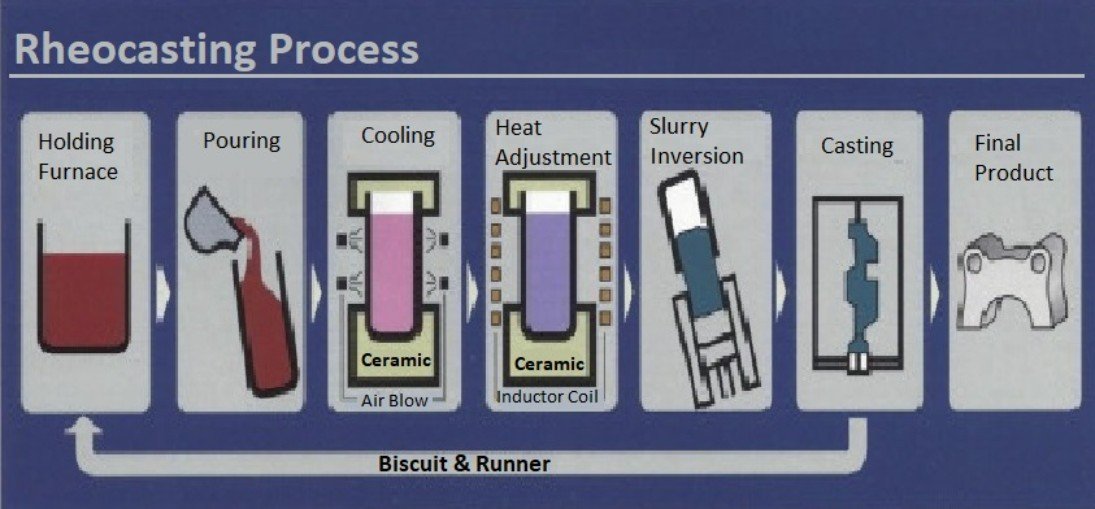

Semi-solid metal casting (SSM) is a precision manufacturing process that involves forming metal alloys in a semi-solid state, where the material exhibits thixotropic behavior—flowing under shear but remaining dimensionally stable when at rest. This process is primarily applicable to metals such as aluminum and certain steels, enabling near-net-shape production with excellent mechanical properties, reduced porosity, and high dimensional accuracy. However, SSM casting is not relevant to thermoplastics like ABS or Nylon, as these materials are processed using techniques such as injection molding or extrusion, not metal casting.

The subsequent operations—laser cutting, bending, and welding—are typically applied post-casting to achieve final component geometry and assembly. Below is a technical overview of how semi-solid cast materials interface with these processes, focusing on aluminum and steel, with notes on ABS and Nylon where relevant.

| Process | Applicable Materials | Technical Specifications & Compatibility with SSM-Cast Components |

|---|---|---|

| Laser Cutting | Aluminum, Steel | SSM-cast aluminum and steel components can be laser-cut with high precision. Aluminum requires fiber or CO₂ lasers with power ranges of 1–4 kW, depending on thickness (typically 1–10 mm). Reflective nature of aluminum demands optimized beam delivery and assist gases (N₂ or O₂). Steel cuts efficiently with oxygen or nitrogen assist; kerf widths range from 0.1–0.3 mm. Not applicable to ABS or Nylon in the context of SSM, though these thermoplastics can be laser-cut separately using CO₂ lasers at lower power (50–150 W). |

| Bending | Aluminum, Steel | SSM-cast aluminum (e.g., A356, A357) exhibits high ductility and low porosity, making it suitable for precision bending operations post-machining. Bend radii typically ≥1.5× material thickness to avoid cracking. Steel variants used in SSM (e.g., high-carbon or tool steels) require preheating and controlled bending due to higher strength. ABS and Nylon are not SSM materials but can be thermoformed or bent using heat, not applicable to metal-forming equipment. |

| Welding | Aluminum, Steel | SSM-cast aluminum demonstrates excellent weldability via TIG or MIG processes due to low hydrogen porosity and fine microstructure. Pre-weld cleaning and controlled heat input are critical. Steel components from SSM can be welded using MIG, TIG, or laser welding, with post-weld heat treatment often required to maintain mechanical integrity. ABS and Nylon are joined via ultrasonic welding or adhesives, not fusion welding, and are unrelated to SSM casting. |

Note: ABS (Acrylonitrile Butadiene Styrene) and Nylon (Polyamide) are polymer materials and are not compatible with semi-solid metal casting, which is exclusive to metallic alloys. Their processing occurs through entirely different methodologies such as injection molding, extrusion, or additive manufacturing.

From CAD to Part: The Process

Honyo Prototype employs a streamlined semi-solid metal casting (SSM) process optimized for rapid prototyping and low-volume production. Our methodology ensures technical feasibility, cost efficiency, and accelerated time-to-market while maintaining stringent quality standards. Below is a detailed explanation of each phase.

CAD File Requirements and Upload

Clients initiate the process by uploading native 3D CAD files (STEP, IGES, or Parasolid preferred) via our secure customer portal. Non-native formats like STL are accepted but may require additional validation. Critical parameters including material specification (typically A356 or A360 aluminum alloys for SSM), dimensional tolerances per ISO 2768-mK, surface finish requirements, and critical-to-function features must be explicitly defined. Incomplete submissions trigger automated notifications for clarification prior to processing.

AI-Powered Quoting Engine

Uploaded CAD data undergoes automated analysis through our proprietary AI quoting system. This engine evaluates geometric complexity, wall thickness uniformity, draft angles, and undercuts against SSM process constraints. Simultaneously, it calculates material utilization, machine time based on shot weight and cycle parameters, and secondary operation requirements. The output is a detailed technical quote within 4 business hours, including manufacturability risk scoring (rated 1–5), estimated lead time, and cost breakdown. High-risk geometries (e.g., thin walls < 1.5mm) trigger immediate engineering review flags.

Collaborative DFM Optimization

Quotes with moderate-to-high risk scores enter an interactive Design for Manufacturing (DFM) phase. Our engineering team conducts joint virtual reviews with the client, providing specific recommendations such as:

Adjusting radii to minimize stress concentration

Modifying gate locations to prevent flow turbulence

Optimizing ejector pin placement to avoid part distortion

Suggesting tolerance relaxation where functionally permissible

This phase utilizes MAGMAsoft simulation to validate thermal gradients and solidification behavior. Client approval of the final DFM report is mandatory before mold fabrication begins. Average DFM iteration cycle is 2 business days.

Semi-Solid Production Execution

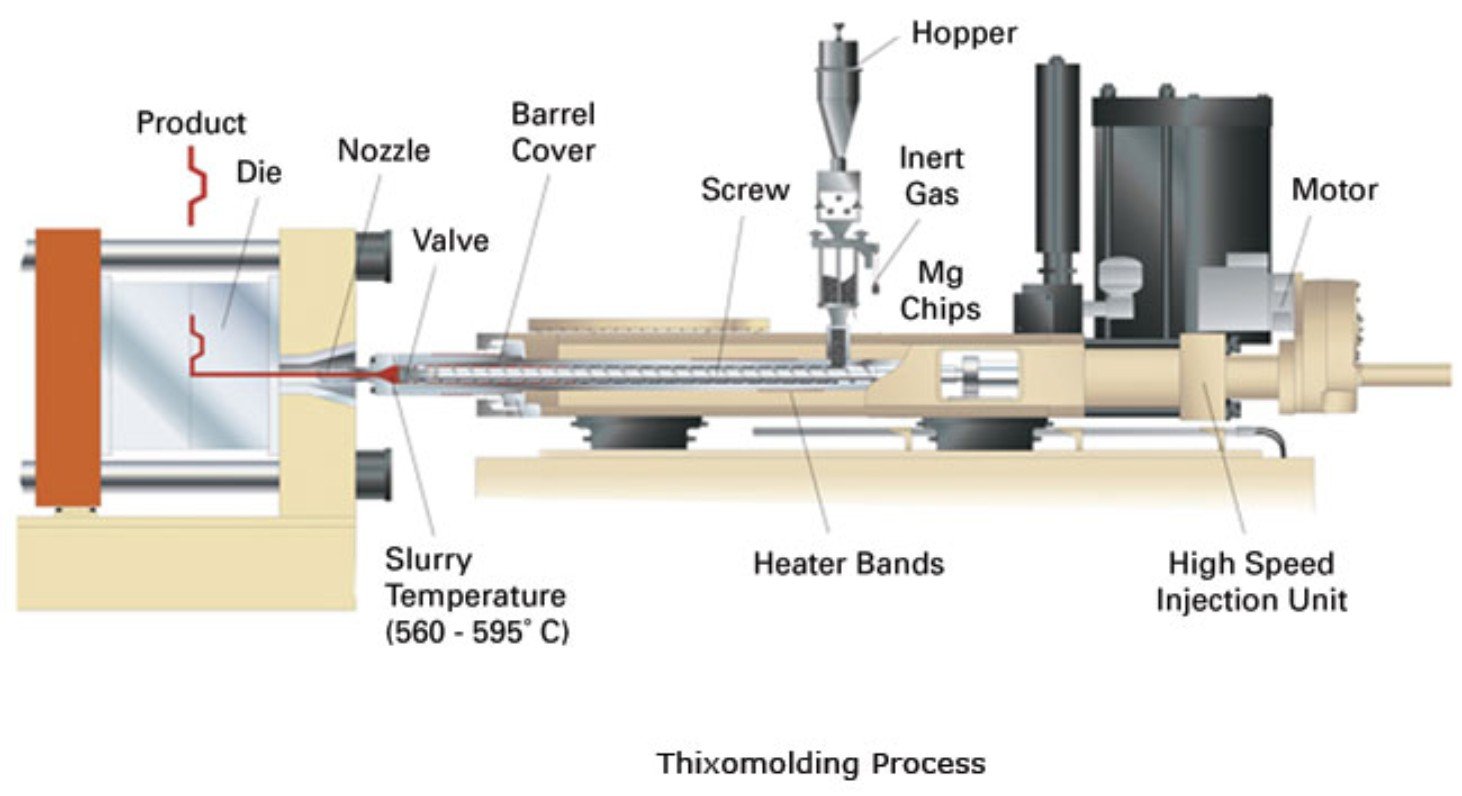

Approved designs proceed to production using thixocasting technology. Billets are induction-heated to the semi-solid state (585–600°C for A356), sheared into slugs, and injected into steel molds at controlled speeds (0.5–2 m/s) to maintain globular microstructure. Key production controls include:

Real-time monitoring of die temperature (180–220°C)

Shot speed profiling to minimize turbulence

In-process CMM verification of critical dimensions after first-article approval

Full material traceability with batch-specific chemical and mechanical test reports

Quality-Controlled Delivery

All parts undergo rigorous inspection per AS9102 First Article requirements. Dimensional reports, porosity analysis via X-ray (per ASTM E1578), and tensile test results (including elongation verification to confirm SSM’s superior ductility) are compiled. Standard lead time from DFM sign-off is 15–20 business days for mold fabrication and initial production. Final shipments include:

PPAP Level 3 documentation

ISO 9001:2015 certified material test reports

Digital inspection data package (PDF + Excel)

Protective packaging meeting ISTA 3A standards for transit

| Process Phase | Key Deliverable | Typical Duration | Quality Gate |

|---|---|---|---|

| CAD Upload | Validated geometry package | 1 business day | Format compliance check |

| AI Quote | Technical quote with risk score | ≤4 business hours | Risk score ≤3 for auto-approval |

| DFM | Approved manufacturing drawing | 2–5 business days | Client sign-off required |

| Production | First-article parts | 15–20 business days | FAI approval (AS9102) |

| Delivery | Shipment with full documentation | 2 business days post-FAI | Final dimensional report |

This integrated workflow reduces traditional SSM development cycles by 40% while ensuring metallurgical integrity and dimensional accuracy. We maintain strict adherence to NADCA standards for semi-solid processes, with all engineers certified in die casting best practices. Clients receive proactive milestone updates through our project management portal, including real-time production tracking.

Start Your Project

Discover the future of precision manufacturing with semi solid metal casting from Honyo Prototype. Our advanced process delivers high-intensity, near-net-shape components with exceptional mechanical properties and minimal porosity—ideal for automotive, aerospace, and industrial applications.

With our state-of-the-art facility located in Shenzhen, we offer fast turnaround, tight tolerances, and full technical support from prototype to production.

Contact Susan Leo today to discuss your project requirements and learn how our semi solid metal casting solutions can enhance your product performance and manufacturing efficiency.

Email: [email protected]

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.