Contents

Manufacturing Insight: Self-Adhesive Plastic Sheet

Introducing Precision Surface Solutions: Self-Adhesive Plastic Sheets for Enhanced Sheet Metal Fabrication

At Honyo Prototype, we engineer integrated manufacturing solutions that address the full spectrum of prototyping and low-volume production challenges. While our core expertise lies in high-precision sheet metal fabrication—including laser cutting, CNC bending, and welding—we recognize that optimal part performance often extends beyond the metal substrate itself. This is where our complementary self-adhesive plastic sheet offerings deliver critical value.

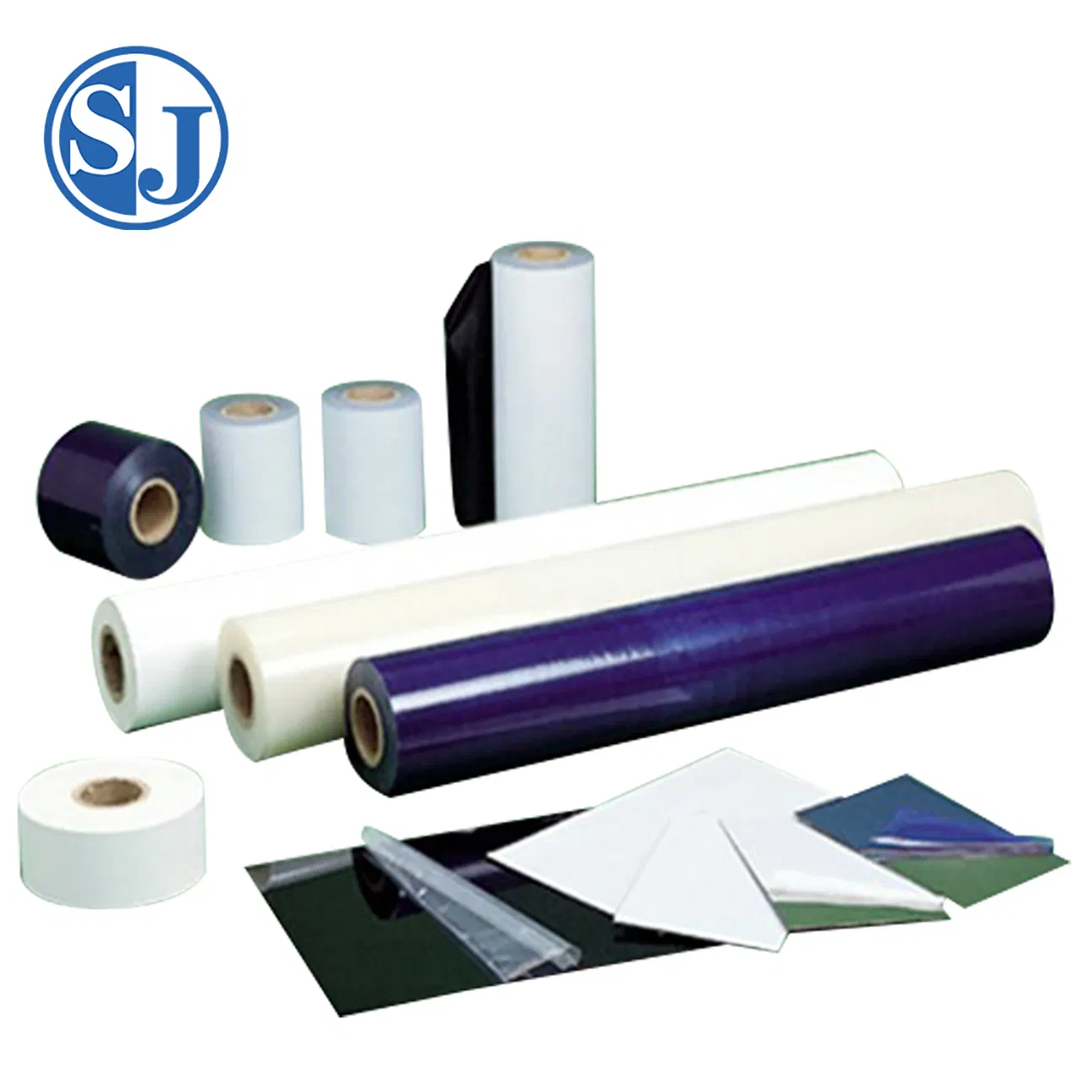

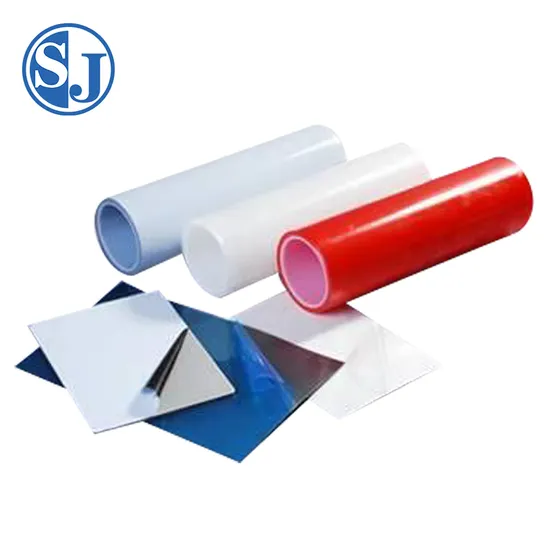

Self-adhesive plastic sheets serve as engineered protective and functional layers for fabricated metal components, providing solutions for corrosion resistance, electrical insulation, aesthetic finishes, or temporary masking during secondary processes. Unlike generic alternatives, Honyo sources and processes these materials to stringent tolerances, ensuring compatibility with demanding industrial applications. Our technical team collaborates with you to select the ideal plastic variant—be it PET, PVC, or polycarbonate—based on thermal stability, chemical exposure, adhesion strength, and longevity requirements.

This capability seamlessly integrates with our end-to-end sheet metal fabrication services. When your design necessitates protective overlays, branding elements, or specialized surface treatments, Honyo eliminates supply chain fragmentation. We handle metal fabrication, plastic sheet application, and final assembly under one roof, maintaining micron-level accuracy from digital file to finished component. This unified workflow reduces lead times, minimizes handling errors, and ensures cohesive quality control across both material systems.

Accelerate your project timeline with Honyo’s Online Instant Quote platform. Upload your sheet metal fabrication drawings alongside plastic sheet specifications to receive a comprehensive, real-time cost analysis within minutes. Our system evaluates material synergies—such as adhesive compatibility with post-fabrication finishes or thermal expansion coefficients—providing actionable insights before production begins. This transparency empowers data-driven decisions without compromising on engineering rigor.

For engineered solutions where metal and polymer systems converge, trust Honyo Prototype to deliver precision, integration, and speed. Initiate your next fabrication project with confidence through our instant quoting system and experience the efficiency of a single-source manufacturing partner.

Technical Capabilities

Self-adhesive plastic sheets are composite or monolayer materials with a pressure-sensitive adhesive backing, often protected by a removable liner. While the adhesive layer facilitates bonding to substrates such as aluminum, steel, ABS, or nylon, the base sheet material determines compatibility with secondary fabrication processes such as laser cutting, bending, and welding.

Below is a technical comparison of common plastic sheet materials used in self-adhesive formats, evaluated for their performance in laser cutting, bending, and welding operations. Note that the adhesive layer may influence processing outcomes and should be considered during fabrication.

| Material | Laser Cutting Compatibility | Bending Characteristics | Welding Feasibility | Notes on Use with Substrates (Aluminum, Steel, ABS, Nylon) |

|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Good – cleanly cut with CO₂ lasers; minimal charring with proper settings | Excellent – high ductility allows tight bend radii without cracking | Good – compatible with ultrasonic, solvent, and hot plate welding | Adheres well to aluminum, steel, ABS, and nylon; commonly used for trim and interior panels |

| Nylon (Polyamide, PA6/PA66) | Fair – tends to melt and discolor; requires precise laser control | Good – flexible and tough, but may require preheating for sharp bends | Excellent – suitable for vibration, hot gas, and laser welding | Strong adhesion to metals and engineering plastics; hygroscopic nature requires conditioning |

| Polycarbonate (PC) | Good – clean cuts with CO₂ laser; may require assist gas to reduce edge melting | Excellent – high impact and formability; cold forming possible | Poor – not typically weldable; adhesive or mechanical joining preferred | Bonds well to aluminum and steel; used in protective overlays and displays |

| Polyethylene (PE) | Poor – low melting point and high thermal expansion cause poor edge quality | Good – flexible and chemically resistant; limited by low stiffness | Good – compatible with hot plate and extrusion welding | Adhesion to metals requires surface treatment; better on primed aluminum or steel |

| Polypropylene (PP) | Poor – similar to PE; prone to melting and inconsistent cuts | Good – resilient and fatigue-resistant; suitable for living hinges | Good – weldable via hot gas, ultrasonic, and spin methods | Requires surface activation for reliable adhesion to metals and engineering plastics |

| PET (Polyethylene Terephthalate) | Very Good – clean, precise cuts with minimal residue | Fair – stiffer than PE/PP; may crack if bent too sharply | Poor – not commonly welded; typically joined via adhesive | Strong bond to aluminum and steel; used in electronic and labeling applications |

Important Considerations:

Laser cutting of self-adhesive sheets requires careful parameter tuning to avoid degrading the adhesive layer, which may outgas or leave residue on the substrate. Post-cutting cleaning may be necessary, especially when the adhesive is exposed at the edges.

Bending operations should account for the added compliance of the adhesive layer, which may affect springback and dimensional accuracy. For high-precision forming, lamination after bending is preferred.

Welding is generally not performed directly on the adhesive side. When joining dissimilar materials (e.g., plastic sheet to nylon or ABS housing), structural integrity should rely on mechanical or ultrasonic welding of the base plastic, with the adhesive serving only for secondary bonding or sealing.

For metal substrates (aluminum, steel), ensure surfaces are clean, dry, and free of oils or oxides to maximize adhesive performance. Surface treatments such as abrasion or primer application can significantly improve bond durability.

From CAD to Part: The Process

Honyo Prototype Self-Adhesive Plastic Sheet Manufacturing Process

Upon client submission of a CAD file for a self-adhesive plastic sheet component, Honyo initiates a streamlined digital workflow designed for precision and efficiency. The process begins with secure CAD file ingestion through our encrypted client portal, where geometry, material specifications, and adhesive requirements are validated for completeness. This triggers an immediate AI-powered quoting engine that cross-references real-time material costs, substrate-adhesive compatibility databases, and historical production metrics to generate a preliminary cost estimate within 2 hours. The AI system specifically evaluates adhesive type (e.g., acrylic, rubber-based), liner requirements, and surface energy compatibility with the target substrate to avoid bonding failures.

Following client acceptance of the AI-generated quote, the project enters mandatory Design for Manufacturability (DFM) analysis. Our engineering team conducts a rigorous review focusing on adhesive-specific parameters: minimum feature tolerances to prevent adhesive bleed, liner stability during die-cutting, and thermal expansion coefficients between the plastic sheet and adhesive layer. Critical checks include validating peel strength requirements against material thickness, assessing edge sealing integrity for environmental resistance, and confirming compatibility with the client’s intended application method (e.g., automated dispensing vs. manual application). Any design conflicts—such as insufficient land areas for adhesive anchoring or improper venting in vacuum-formed parts—are documented with actionable revision recommendations, typically resolved within 24–48 hours through direct engineer-client collaboration.

Approved designs advance to production where Honyo employs roll-to-roll processing under controlled ISO Class 8 cleanroom conditions. Precision digital die-cutting or laser contouring is executed with micron-level accuracy, while adhesive application utilizes gravure or slot-die coating systems calibrated for uniform thickness (±5µm). Each sheet undergoes inline optical inspection for coating defects and automated peel/adhesion testing per ASTM D3330 standards. For multi-layer constructions, lamination occurs under precisely controlled pressure and temperature to eliminate air entrapment. All adhesive-facing surfaces are protected with silicone-coated release liners matched to the adhesive’s rheology.

Final quality verification includes batch-specific peel strength reports, dimensional certification against the original CAD, and environmental aging tests if specified. Completed sheets are vacuum-sealed with desiccant, labeled with traceable QR codes linking to full production data, and shipped via client-preferred logistics. Standard lead time from DFM approval to delivery is 5–7 business days for prototypes and 10–12 days for small batches, with real-time shipment tracking provided through our client dashboard. All deliveries include material compliance documentation (e.g., RoHS, REACH) and adhesive performance certificates.

Start Your Project

Looking for high-quality self-adhesive plastic sheets for your next project? Contact Susan Leo today at [email protected] to discuss your requirements and get expert support from our manufacturing team.

Our production facility is based in Shenzhen, ensuring fast turnaround, strict quality control, and scalable solutions for prototyping and low-volume production.

Reach out now to request samples, pricing, or technical specifications. Let’s bring your application to the next level with reliable, precision-manufactured materials.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.