Contents

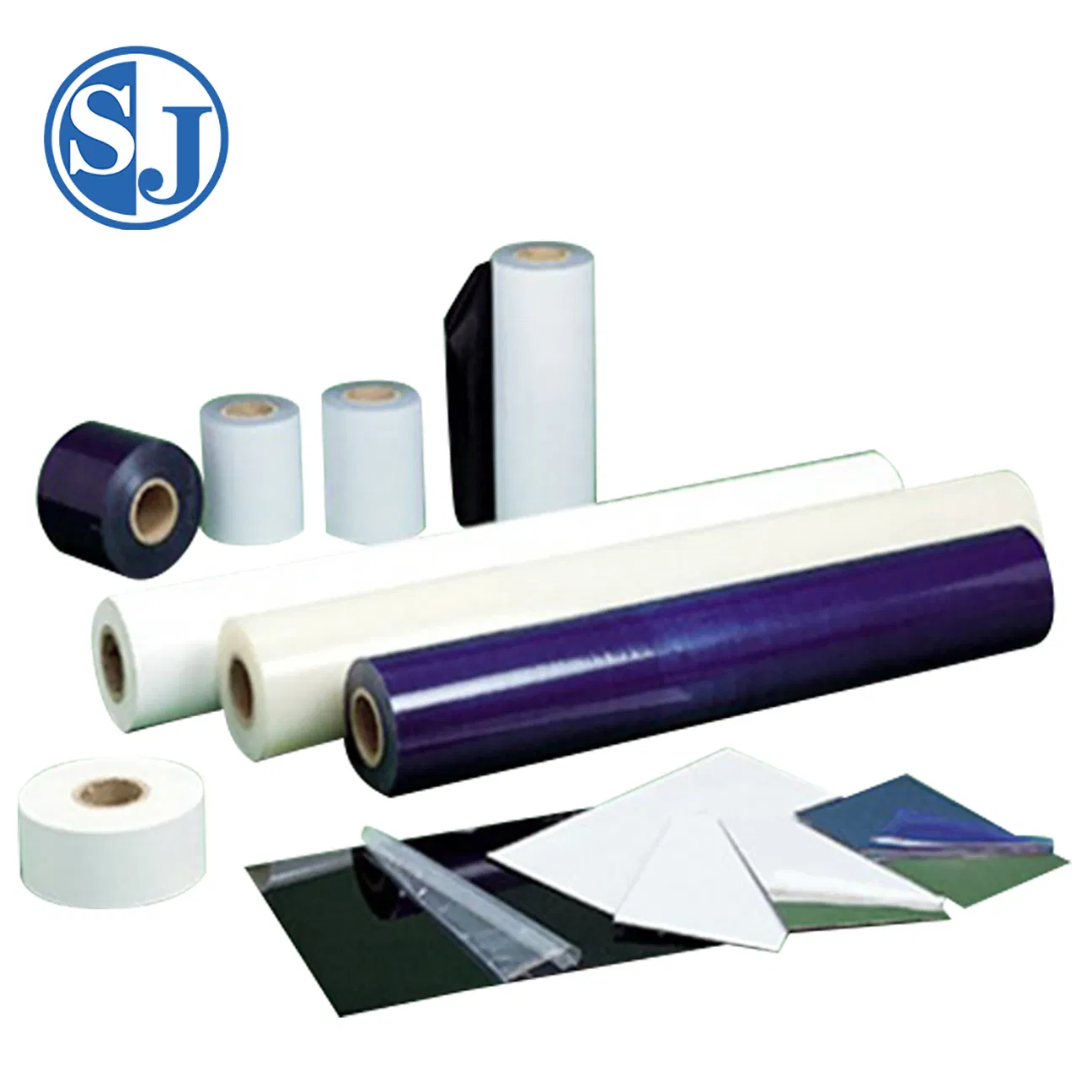

Manufacturing Insight: Self Adhesive Plastic Sheet

Precision Fabrication Solutions for Integrated Metal and Plastic Components

Honyo Prototype delivers industry-leading sheet metal fabrication services engineered for rapid prototyping and low-volume production, with capabilities spanning laser cutting, CNC bending, welding, and finishing for materials including stainless steel, aluminum, and specialty alloys. While our core expertise centers on metal component manufacturing, we recognize that modern assemblies often require seamless integration of complementary materials such as self-adhesive plastic sheets for insulation, labeling, or protective overlays. Our engineering team collaborates with clients to develop cohesive solutions where precision-formed metal enclosures, brackets, or panels interface flawlessly with applied plastic elements, ensuring dimensional accuracy and functional reliability across the entire assembly.

For projects involving self-adhesive plastic sheets, Honyo provides critical support in material selection, substrate preparation, and application guidance to prevent delamination or adhesion failure—particularly when bonded to fabricated metal surfaces with complex geometries. This holistic approach eliminates supply chain fragmentation, reducing lead times and quality risks associated with multi-vendor sourcing. All services leverage our ISO 9001-certified processes, with tolerances maintained to ±0.1mm for metal components and rigorous validation of plastic adhesion performance under thermal and mechanical stress.

Accelerate your project timeline with Honyo’s Online Instant Quote system, which delivers transparent pricing and manufacturability feedback for sheet metal parts within minutes. Simply upload your STEP or DWG files to receive a detailed quote inclusive of material costs, secondary operations, and lead times—no manual intervention required. For integrated metal-plastic assemblies, our quoting engine identifies interface requirements upfront, ensuring adhesive compatibility and process alignment are addressed at the design stage. Begin streamlining your fabrication workflow today at honyoprototype.com/quote.

Technical Capabilities

The term “self adhesive plastic sheet” typically refers to polymer-based sheets with a pressure-sensitive adhesive layer, often protected by a release liner. While metals such as aluminum and steel are not inherently self-adhesive, they can be laminated with adhesive-backed polymer films. Below is a technical comparison of common materials used in sheet form—Aluminum, Steel, ABS, and Nylon—evaluated for laser cutting, bending, and welding compatibility, including considerations for self-adhesive variants.

| Material | Form Available as Self-Adhesive Sheet | Laser Cutting Suitability | Bending Characteristics | Welding Compatibility | Notes |

|---|---|---|---|---|---|

| Aluminum | Yes (with adhesive-backed film lamination) | Moderate – reflective surface requires high-power, pulsed lasers; risk of melting and edge oxidation | Good – ductile and formable; springback requires overbending | Excellent – compatible with TIG, MIG, and laser welding | Adhesive layer must be protected or removed near weld zones; not weldable through adhesive |

| Steel (Mild) | Yes (adhesive-coated laminates available) | Good – CO₂ lasers effective; produces clean cuts with assist gas | Moderate – higher springback than aluminum; requires precise tooling | Excellent – easily welded via MIG, TIG, spot welding | Adhesive decomposition under heat must be managed; avoid welding through adhesive layer |

| ABS (Acrylonitrile Butadiene Styrene) | Yes – common in adhesive-backed sheets | Excellent – easily laser cut with CO₂ lasers; clean edges with proper settings | Good – thermoplastic; can be heat-formed and bent with proper tooling | Moderate – ultrasonic, solvent, or hot-plate welding possible; not suitable for traditional arc welding | Low melting point (~105°C); ensure adhesive can withstand forming temperatures |

| Nylon (Polyamide) | Yes – available with adhesive backing for industrial use | Good – CO₂ laser cutting feasible; may require ventilation due to fumes | Excellent – high toughness and flexibility; can be cold-formed or heat-bent | Good – compatible with hot gas, ultrasonic, and vibration welding | Hygroscopic – must be dried before laser processing; adhesive selection critical for high-temp resistance |

General Notes:

Self-adhesive variants involve a polymer or metal sheet bonded to a pressure-sensitive adhesive (e.g., acrylic or rubber-based) with a silicone-coated release liner.

During laser cutting, the adhesive layer may emit fumes or char; proper ventilation and optimized laser parameters are essential.

Bending of adhesive-backed sheets requires attention to the adhesive’s elongation and tack properties to prevent delamination.

Welding is generally not performed directly on the adhesive; it must be masked, removed, or avoided in joint areas. For plastics, welding refers to joining techniques specific to thermoplastics.

From CAD to Part: The Process

Honyo Prototype Self-Adhesive Plastic Sheet Manufacturing Process

Honyo Prototype executes a streamlined, technology-driven workflow for self-adhesive plastic sheet production, ensuring precision, efficiency, and adherence to client specifications. The process begins with CAD Upload & Validation, where clients submit detailed 2D/3D design files via our secure portal. Our system immediately performs automated geometry checks for file integrity, unit consistency, and layer alignment. Critical parameters such as sheet thickness tolerance (±0.05mm standard), adhesive backing thickness, and die-cut contour complexity are validated against Honyo’s material capabilities. Invalid submissions trigger real-time feedback loops for client correction, minimizing downstream delays.

Following validation, the AI-Powered Quoting Engine (ProtoQuote AI) generates a comprehensive commercial proposal within 2 business hours. This system cross-references uploaded CAD data against Honyo’s proprietary database of 15,000+ material formulations—including PVC, PETG, and polycarbonate variants with acrylic or rubber-based adhesives—to calculate material yield, waste factors, and process-specific variables. The quote explicitly itemizes costs for adhesive layer protection (e.g., silicone-coated liner selection), UV-curing requirements, and environmental controls for low-odor adhesive processing. Clients receive dynamic pricing based on volume tiers and expedited lead time options, with all assumptions documented for transparency.

The Design for Manufacturability (DFM) Review phase is a collaborative, iterative engineering checkpoint. Honyo’s manufacturing engineers conduct material-specific analyses focused on adhesive integrity, including:

| DFM Parameter | Standard Checkpoint | Adhesive-Specific Focus |

|---|---|---|

| Thermal Stability | Glass transition temperature (Tg) validation | Adhesive bleed risk at processing temperatures |

| Tolerance Stackup | ±0.1mm critical feature verification | Liner removal force consistency across sheet area |

| Tooling Feasibility | Die-cut blade angle/pressure simulation | Preventing adhesive “ooze” during kiss-cutting |

| Environmental Compliance | RoHS/REACH certification alignment | VOC emissions control during lamination |

Clients receive annotated DFM reports with actionable recommendations—such as adjusting corner radii to prevent adhesive delamination during forming—within 4–8 business hours. Formal client sign-off is required before proceeding.

Production Execution occurs in Honyo’s climate-controlled facility (22±1°C, 45% RH) to maintain adhesive tack stability. Key stages include: precision roll-to-roll lamination under laminar flow hoods to eliminate particulate contamination, CNC-turret die-cutting with adhesive-specific blade geometries to minimize burrs, and automated liner application with tension control systems ensuring 99.8% edge adhesion integrity. In-process quality checks verify peel strength (per ASTM D3330), optical clarity, and dimensional accuracy at defined batch intervals. All adhesive layers undergo 100% visual inspection for micro-bubbles or coating defects using high-resolution automated optical inspection (AOI) systems.

Delivery & Documentation concludes the workflow with climate-controlled logistics partners to prevent temperature excursions during transit. Shipments include: certified material traceability reports (including adhesive lot numbers), peel/adhesion test data from the production batch, and cleanroom-packaged components with humidity indicators. Standard lead time is 7–10 business days post-DFM approval, with real-time production tracking accessible via the client portal. Critical for medical or electronics applications, Honyo provides ISO 13485-compliant documentation packages upon request, ensuring full regulatory alignment for adhesive performance in end-use environments.

Start Your Project

Looking for high-quality self-adhesive plastic sheets for your next project? Contact Susan Leo today at [email protected] to request samples, pricing, or technical specifications.

With our manufacturing facility based in Shenzhen, we ensure fast production, consistent quality control, and reliable delivery for both prototyping and volume orders.

Reach out now to discuss your requirements and discover how our adhesive plastic sheet solutions can enhance your manufacturing efficiency.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.