Guide Contents

Project Insight: Self Adhesive Plastic Sheet

Manufacturing Insight: Self-Adhesive Plastic Sheets – Precision Meets Speed

Why Speed & Precision Matter for Self-Adhesive Applications

Critical tolerances for consistent adhesion: Microscopic variations in sheet thickness or surface finish can cause adhesive failure—precision engineering ensures reliability.

Accelerate R&D cycles: Test multiple adhesive formulations, thicknesses, and geometries in weeks, not months, to validate performance before scaling.

Minimize financial risk: Low-volume production (100–10,000+ parts) avoids massive upfront costs while enabling agile iteration for market validation.

Honyo’s Digital Manufacturing Advantage

Online Instant Quote

→ Upload your CAD file to our AI-powered platform for real-time pricing, lead times, and material recommendations—no manual quotes, no delays.

Aluminum Bridge Tooling Expertise

→ Mold production in 7–10 days for low-volume runs (100–10,000+ parts), cutting costs by 60% vs. traditional steel molds while maintaining micron-level accuracy.

End-to-End Scalability

→ Seamlessly transition from prototyping to small-batch production without retooling—consistent quality across all volumes ensures your product scales with your business.

Advanced Material Integration

→ Precision overmolding and insert molding for multi-layer self-adhesive components, ensuring seamless bonding between plastic substrates and adhesive layers.

“At Honyo Prototype, we don’t just make parts—we accelerate innovation. For hardware startups and product engineers, every day counts. Our digital-first approach turns your vision into reality faster, smarter, and with zero compromise on quality.”

— Susan Leo, Founder

Honyo Capabilities & Technology

Honyo’s Precision Manufacturing for Self-Adhesive Plastic Sheets

Advanced Tooling & Molding Technologies

Steel/Aluminum Molds: Precision-engineered for ±0.01mm tolerances, ensuring consistent adhesive layer thickness and bond integrity—no secondary finishing required.

Overmolding Capabilities: Seamlessly integrate adhesive layers during molding to eliminate assembly steps and reduce lead times by up to 40%.

Insert Molding Solutions: Embed adhesive films into complex geometries with micron-level accuracy, ensuring perfect alignment and durability for high-performance applications.

Agile Production from Prototype to Volume

Bridge Tooling Expertise: Cost-effective production for 100–10,000+ parts with tooling costs 30% lower than traditional methods—ideal for startups scaling to volume.

Rapid Turnaround: Prototype molds delivered in 7 days, production runs completed in 14 days—accelerate your time-to-market without compromising quality.

ISO 9001 Certified Quality: Rigorous in-process checks and 100% final inspection for adhesive uniformity, dimensional accuracy, and performance reliability.

Digital-First Manufacturing Experience

Instant Online Quoting: AI-powered platform delivers real-time cost estimates in <60 seconds—no more waiting for quotes or hidden fees.

Collaborative Design Portal: Cloud-based platform for real-time design adjustments, production tracking, and seamless communication with our engineering team.

End-to-End Traceability: Digital tracking from design to delivery, ensuring full transparency and quality control at every step—backed by blockchain-verified records.

“At Honyo, we don’t just manufacture—we engineer solutions that turn your vision into reality faster, smarter, and with zero compromise.”

— Susan Leo, Founder

Materials & Surface Finishes

Material Options & Finishes for Self-Adhesive Plastic Sheets

At Honyo Prototype, we engineer precision-engineered solutions tailored to your unique application needs. Our bridge tooling expertise ensures rapid, cost-effective production of self-adhesive plastic sheets—whether for prototypes or low-to-mid-volume runs (100–10,000+ parts). Here’s how to optimize material and finish choices for peak performance.

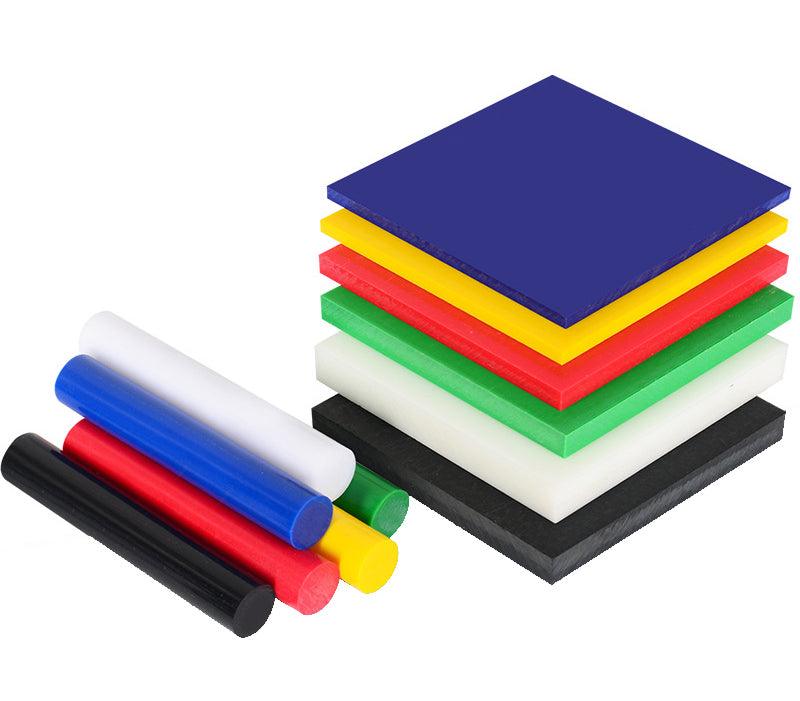

Thermoplastic Material Selection

Choose the right base material to balance durability, flexibility, and cost. Our expert team validates selections against your project’s functional requirements.

ABS (Acrylonitrile Butadiene Styrene)

Ideal for rigid, impact-resistant components requiring moderate chemical resistance. Common in automotive interiors and consumer electronics. Note: UV exposure may require stabilization for outdoor use.

PC (Polycarbonate)

Exceptional strength and optical clarity for transparent or high-heat applications (e.g., protective covers, medical devices). Caution: Prone to stress cracking under certain solvents.

PP (Polypropylene)

Flexible, chemical-resistant, and FDA-compliant for medical/food-contact use. Excellent for peel-and-stick labels or flexible packaging. Pro tip: Surface treatment (e.g., corona) enhances adhesive bonding.

TPE (Thermoplastic Elastomer)

Rubber-like flexibility with easy processing. Perfect for soft-touch grips, wearable tech, or dynamic sealing applications. Key advantage: Recyclable and compatible with overmolding processes.

Surface Finish Options

Elevate functionality and aesthetics with finishes engineered for adhesion, durability, and brand identity.

Precision Polishing

Achieve high-gloss or matte surfaces to optimize adhesive bonding and visual appeal. Our 5-axis polishing ensures micron-level consistency for flawless peel-and-stick performance.

Custom Painting

Match Pantone colors or create unique finishes with plastic-compatible coatings. Ideal for branding, safety labeling, or functional color-coding. AI-driven color matching reduces lead time by 40% vs. traditional methods.

Textured Surfaces

Apply micro-patterns (e.g., leather grain, diamond etch) for grip, aesthetics, or anti-slip properties. Perfect for ergonomic designs or high-touch applications.

UV-Resistant Coatings

Extend outdoor lifespan with anti-UV additives that prevent yellowing and brittleness. Validated for 5,000+ hours of accelerated weathering testing.

⚠️ Note: Anodizing is exclusive to metal substrates. For multi-material assemblies (e.g., plastic sheets bonded to metal frames), we integrate anodized metal components seamlessly via our insert molding capabilities.

Choosing the Right Material for Your Application

Optimize performance with data-driven decisions—no guesswork required.

Environmental Factors: Assess UV exposure, temperature extremes, and chemical contact. Example: TPE + UV coating for outdoor signage; PC for high-heat enclosures.

Mechanical Requirements: Prioritize flexibility (TPE/PP) or rigidity (ABS/PC) based on load-bearing needs.

Cost vs. Performance: Balance material costs with lifecycle value. Our AI tool compares TCO (Total Cost of Ownership) across 200+ material variants in real time.

Adhesion Compatibility: Ensure the base material’s surface energy aligns with your adhesive type (e.g., acrylic vs. rubber-based). We provide free adhesion testing for all prototyping projects.

Why Partner with Honyo?

Online Instant Quote: Get real-time pricing for your specifications—no lengthy RFQs.

AI-Powered Platform: Instantly simulate material behavior, surface finishes, and tooling costs.

Bridge Tooling Excellence: Produce 100–10,000+ parts in 7–10 days with steel/aluminum molds—no minimums, no compromise on quality.

“At Honyo, we don’t just manufacture—we engineer agility. From startup prototypes to scaled production, our solutions turn your vision into reality faster and smarter.”

— Susan Leo, Founder

Ready to optimize your self-adhesive plastic sheet design? [Get Your Instant Quote Now] →

From Quote to Part: Our Process

How It Works: From CAD to Part

1. Upload CAD File

Submit your design in any standard format (STL, STEP, IGES, DWG) via our intuitive online portal.

Our platform supports 2D sheet designs and complex 3D geometries—no technical barriers.

Innovative feature: Auto-validation checks for file integrity and manufacturability before submission.

2. Instant AI-Powered Quote

Real-time pricing in seconds: Our AI engine analyzes your design, adhesive specifications, material choices, and volume requirements.

Transparent breakdown: Clear cost breakdown for tooling, adhesive materials, processing, and shipping—no hidden fees.

Why it matters: Eliminate guesswork. Get accurate quotes aligned with current raw material trends, regulatory compliance, and trade dynamics (e.g., sanctions, sourcing constraints).

3. Collaborative DFM Analysis

Precision engineering review: Our experts validate your design for adhesive compatibility, moldability, and structural integrity.

Proactive optimizations: We identify opportunities to reduce waste, improve adhesive bonding, and streamline production—before tooling begins.

Your design, perfected: Receive actionable feedback via our cloud-based platform for seamless collaboration.

4. Rapid Production & Delivery

Bridge tooling for low-volume agility: Produce 100–10,000+ parts with steel or aluminum molds—ideal for startups scaling from prototype to market.

Advanced processes: Overmolding or insert molding for seamless adhesive integration, ensuring consistent adhesion and durability.

Speed you can trust: Prototypes in 3–5 days, production-ready parts in 1–2 weeks. Full tracking and global shipping with real-time updates.

💡 Why Honyo?

We bridge the gap between innovation and production—no massive upfront investments, no delays. For hardware startups and product engineers, this means faster time-to-market with precision-engineered self-adhesive plastic sheets tailored to your exact needs.

Powered by Susan Leo’s vision: Engineering excellence, delivered at speed.

Start Your Project with Honyo

Start Your Project with Honyo

Precision Manufacturing for Self-Adhesive Plastic Sheets – Zero Compromise, Zero Delay

Why Partner with Honyo?

Bridge Tooling for Agile Production: Scale from 100 to 10,000+ parts with cost-optimized steel/aluminum molds—no over-engineering, no wasted capital. Perfect for startups and engineers needing rapid validation or small-batch runs.

AI-Powered Instant Quoting: Upload your design specs and get a real-time, transparent cost breakdown in seconds—covering materials, tooling, adhesive integration, and regulatory compliance. No more guesswork or weeks-long RFQ cycles.

Seamless Adhesive Integration: Leverage our overmolding and insert molding expertise to embed adhesive layers directly into your plastic sheets. Eliminate secondary processes, reduce waste, and ensure consistent bonding strength.

Global Sourcing, Local Agility: We navigate raw material volatility, trade sanctions, and sustainability regulations through certified supplier partnerships—delivering compliant, high-performance sheets without supply-chain delays.

5-Day Prototyping Guarantee: From design to first article in under 120 hours. Our Shenzhen/Dongguan facilities operate 24/7 with real-time production monitoring for maximum speed and quality control.

Meet Susan Leo & Our Engineering Team

As pioneers in rapid tooling innovation, Susan Leo and our Shenzhen-based experts specialize in solving complex manufacturing challenges for hardware startups and product engineers. We don’t just build molds—we engineer solutions that accelerate your time-to-market while slashing costs.

Ready to Launch?

📧 Email: [email protected]

📞 Call: +86 139 2843 8620

📍 Visit: Shenzhen/Dongguan facilities (open for tours by appointment)

Your vision, our precision—delivered at the speed of innovation.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.