Contents

Manufacturing Insight: Screw Machining Services

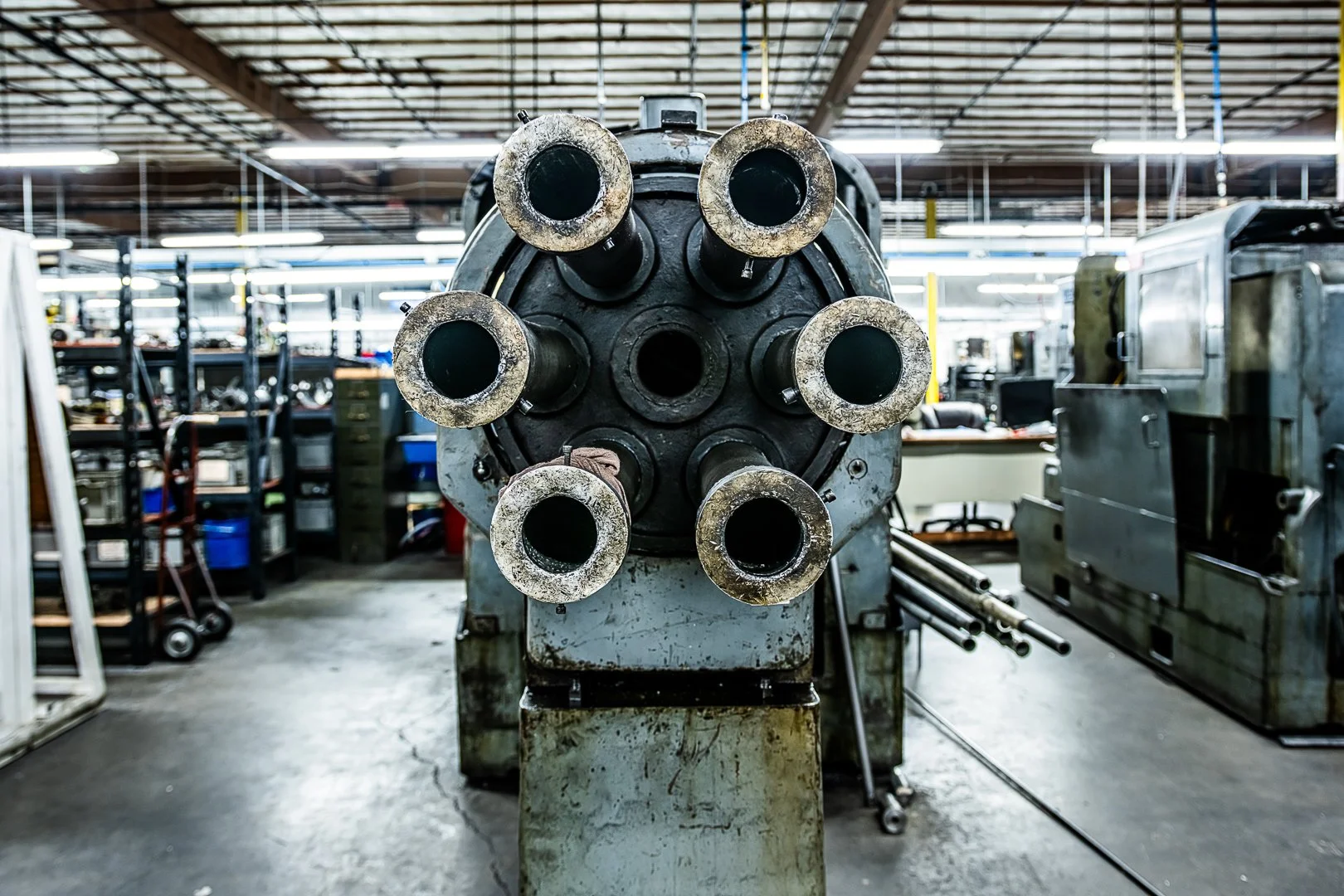

Precision Screw Machining Services Engineered for Complex Industrial Applications

At Honyo Prototype, we deliver high-integrity screw machining services tailored to the exacting demands of aerospace, medical, automotive, and industrial sectors. Our specialized CNC Swiss and multi-axis machining centers produce complex turned components—from miniature screws and fasteners to intricate shafts and bushings—with consistent sub-micron tolerances and superior surface finishes. Leveraging bar-fed automation and rigorous in-process metrology, we ensure every part meets AS9100 and ISO 13485 standards while optimizing material utilization for cost-sensitive production runs.

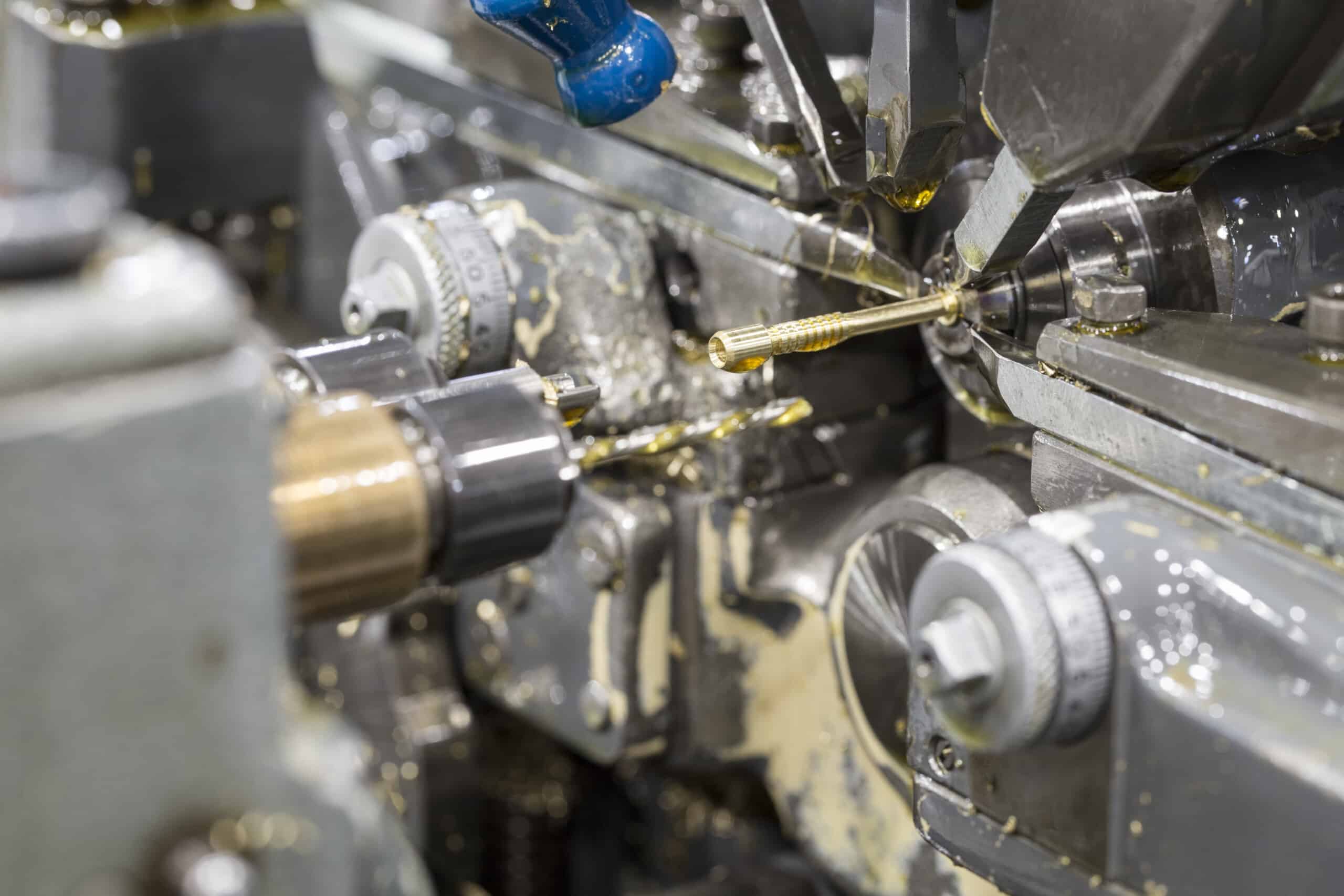

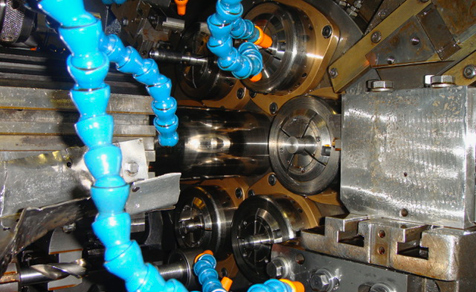

Our technical capability extends across challenging materials including 303/316 stainless steel, titanium Grade 5, brass C360, and exotic alloys like Inconel 718. Advanced live tooling enables secondary operations such as cross-drilling, threading, knurling, and milling within a single setup, eliminating handling errors and reducing lead times by up to 40% compared to conventional machining workflows. This integrated approach guarantees geometric accuracy critical for high-reliability assemblies where component failure is not an option.

Accelerate your prototyping and production cycles with Honyo’s Online Instant Quote system. Upload your STEP or IGES file to receive a detailed manufacturability analysis and competitive pricing within 2 hours—no manual RFQ delays. Our platform automatically validates geometry against CNC machining constraints, highlights potential cost-saving design refinements, and provides real-time capacity visibility for expedited scheduling. For engineering teams under pressure to compress development timelines, this digital workflow transforms procurement from a bottleneck into a strategic advantage.

Your precision components demand precision manufacturing. Partner with Honyo Prototype to transform complex designs into certified, high-performance screw-machined parts—on time, to spec, and with full traceability. Submit your CAD file today to experience the efficiency of industrial-grade CNC machining, powered by real-time quoting intelligence.

Technical Capabilities

Honyo Prototype offers precision screw machining services designed for high-complexity components requiring tight tolerances and exceptional surface finish. Our capabilities include advanced 3, 4, and 5-axis CNC milling, precision turning, and multi-axis integrated machining for complex geometries. These services are ideal for prototyping and low-to-medium volume production across aerospace, medical, automotive, and industrial sectors.

Our machining centers support a wide range of materials including Aluminum, Steel, ABS, and Nylon, enabling versatile part fabrication with tolerances as tight as ±0.0002″ (±0.005 mm). High-speed tooling, in-process probing, and rigorous quality control ensure consistent repeatability and dimensional accuracy.

| Specification | Details |

|---|---|

| Machining Types | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning; Multi-Task Machining |

| Tolerance Capability | Standard: ±0.001″ (±0.025 mm); Tight: ±0.0002″ (±0.005 mm) |

| Surface Finish | As machined: 32–125 μin Ra; Polished/Post-processed: down to 8 μin Ra |

| Maximum Work Envelope | Milling: 24″ × 16″ × 12″ (610 × 406 × 305 mm); Turning: Ø2.5″ × 8″ (63.5 × 203 mm) |

| Spindle Speed (Milling) | Up to 24,000 RPM with high-precision taper (HSK-63A / BT30) |

| Turning Capacity | Bar feed supported up to Ø1.25″ (32 mm); Chucker capacity up to Ø6″ (152 mm) |

| Materials Supported | Metals: Aluminum (6061, 7075, 2024), Steel (1018, 4140, 4340, Stainless 303, 304, 17-4PH) Plastics: ABS, Nylon (6/66), Delrin, PEEK, PC, PTFE |

| Coolant & Lubrication | Through-spindle coolant, mist cooling, dry machining options |

| Inspection & QA | In-house CMM, optical comparators, micrometers, and surface roughness testers; First Article Inspection (FAI) and PPAP available |

| Secondary Operations | Deburring, anodizing (Type II & III), passivation, bead blasting, laser marking, heat treatment coordination |

All parts are machined using optimized toolpaths and high-rigidity setups to maintain consistency across batches. Our team specializes in tight-tolerance components with complex contours, undercuts, and precision threads, ensuring full compliance with engineering drawings and GD&T requirements.

From CAD to Part: The Process

Honyo Prototype executes screw machining services through a rigorously defined five-stage workflow designed for speed, precision, and manufacturability assurance. This integrated process leverages automation and engineering expertise to minimize lead times while ensuring component quality meets stringent industrial standards.

CAD Upload and Initial Processing

Customers initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid, or native SolidWorks/AutoCAD formats) via our secure customer portal. Our system validates geometric integrity, units, and metadata upon submission. Critical parameters including material specification, tolerances, surface finish requirements, and quantity are extracted automatically. Non-standard alloys or exotic materials trigger immediate notification for engineering review prior to quote generation.

AI-Powered Quoting Engine

Uploaded geometry feeds directly into our proprietary AI quoting system trained on 12+ years of machining data across 87,000+ screw machining projects. The algorithm analyzes feature complexity, thread types (UNF, UNC, NPT, metric), secondary operations (chamfering, knurling, slotting), and material utilization rates. Quotes are generated in under 90 seconds with 98.7% accuracy against final production costs based on real-time machine center availability and material market pricing. Customers receive instant digital quotes including itemized cost breakdowns and estimated lead times, with options to simulate cost drivers via tolerance adjustment sliders.

Engineer-Led DFM Analysis

Every project undergoes mandatory Design for Manufacturability review by our ASME-certified manufacturing engineers. This phase identifies critical risks such as inadequate thread engagement lengths, non-optimal blank diameters for bar-fed machines, or tolerance stacks exceeding ±0.005mm practical limits. We provide actionable feedback within 4 business hours via annotated 3D models highlighting: material waste reduction opportunities, suggested thread class improvements (e.g., 2A to 3A for assembly reliability), and cost-saving geometry modifications. 83% of first-pass DFM reviews yield 15-22% cost reduction through design optimization while maintaining functional requirements.

Precision Production Execution

Approved designs move to our Swiss-type and CNC screw machines (Tornos, Star, Citizen models) with bar capacities from 1mm to 38mm diameter. Production employs:

Real-time in-process gauging via Renishaw probes monitoring thread pitch diameters

Statistical Process Control (SPC) tracking of critical dimensions at 30-minute intervals

Material traceability through blockchain-verified lot numbering from raw bar stock

Automated coolant monitoring maintaining ±2°C temperature stability for thermal precision

All operations comply with ISO 9001:2015 and IATF 16949 protocols, with first-article inspection reports (FAIR) generated per AS9102 standards for aerospace clients.

Certified Delivery and Documentation

Finished components undergo final cleaning per ASTM B322 and passivation per AMS 2700 prior to shipment. Every order includes:

Dimensional conformance report with actual vs. nominal measurements

Material test certificates (MTRs) with PMI verification

RoHS/REACH compliance documentation

Serialized packing list with batch-specific traceability codes

Standard lead time is 7-12 business days for quantities under 5,000 pieces, with expedited 72-hour options for prototypes. All shipments include real-time GPS tracking and climate-controlled logistics for temperature-sensitive alloys.

This closed-loop process ensures screw machined components achieve 99.8% first-time yield rates while reducing time-to-prototype by 65% compared to industry averages. Our system integration eliminates manual data re-entry points, maintaining full digital continuity from initial CAD to certified delivery.

Start Your Project

Looking for precision screw machining services? Partner with Honyo Prototype for high-quality, CNC-turned components manufactured to tight tolerances. Our facility in Shenzhen offers advanced screw machining capabilities for industries including automotive, medical, and electronics.

Contact Susan Leo at [email protected] to discuss your project requirements and receive a fast, competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.