Contents

Manufacturing Insight: Screw Machining Automotive Parts

Precision Screw Machining for Demanding Automotive Applications

Automotive innovation demands components that meet exacting standards for performance, reliability, and safety. At Honyo Prototype, our specialized CNC screw machining services deliver high-precision, small-diameter automotive parts—from fuel system fittings and sensor housings to transmission components—with micron-level accuracy and exceptional repeatability. Leveraging advanced Swiss-type and multi-axis CNC lathes, we machine complex geometries in challenging materials including aluminum alloys, stainless steels, and brass, adhering strictly to automotive industry specifications such as IATF 16949.

Our engineered approach ensures optimal material utilization, reduced cycle times, and seamless scalability from rapid prototyping through low-to-mid volume production. Every part undergoes rigorous in-process and final inspection using calibrated CMMs and vision systems to guarantee dimensional integrity and surface finish compliance. For engineering teams accelerating development cycles, Honyo’s Online Instant Quote platform provides real-time pricing and lead time estimates within minutes, enabling faster decision-making without compromising technical rigor. Partner with us to transform precision automotive component challenges into competitive advantages.

Technical Capabilities

Technical Specifications for Screw Machining Automotive Parts

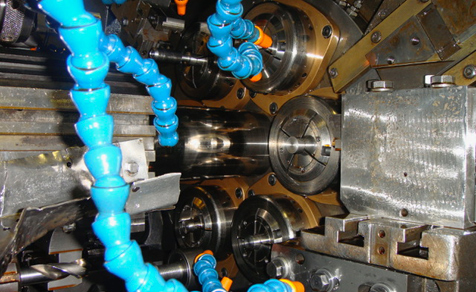

Screw machining of automotive components typically involves high-precision CNC equipment capable of producing complex geometries with tight tolerances. The process leverages 3, 4, and 5-axis milling and turning centers to achieve multi-faceted features and rotational symmetry in a single setup. These machines are optimized for high repeatability and surface finish, critical for automotive applications such as fuel system components, sensors, transmission parts, and engine connectors.

The following table outlines key technical specifications relevant to screw machining automotive parts using multi-axis CNC equipment:

| Parameter | Specification Details |

|---|---|

| Machining Process | CNC Screw Machining with integrated 3-axis, 4-axis, and 5-axis milling and turning capabilities |

| Axis Configuration | 3-Axis: XYZ linear motion 4-Axis: XYZ + A (rotary) 5-Axis: XYZ + AB or AC rotary axes for full contouring |

| Tolerance Capability | ±0.005 mm (±0.0002″) typical; down to ±0.001 mm (±0.00004″) for critical features with tight process control |

| Surface Finish | Ra 0.8 µm (32 µin) standard; Ra 0.4 µm (16 µin) achievable with fine finishing passes |

| Spindle Speed | Up to 12,000 RPM (milling); up to 6,000 RPM (turning), depending on machine and material |

| Feed Rate | Up to 10,000 mm/min (394 ipm) for high-speed milling operations |

| Tooling Interface | HSK-63 or CAT-40 for milling; live tooling with ER collets or hydraulic chucks for turning |

| Materials Processed | Aluminum (6061, 7075), Steel (12L14, 1018, 4140), ABS, Nylon (6, 66) |

| Aluminum Machinability | High; low cutting forces, excellent chip evacuation; ideal for high-speed machining |

| Steel Machinability | Moderate to low; requires rigid setups, coated carbide tooling, and controlled feeds/speeds |

| ABS & Nylon Handling | Low melting point; requires sharp tools, low heat buildup, and reduced feed pressure to avoid deformation |

| Coolant/Lubrication | Through-spindle coolant for steels and aluminum; air blast or minimal lubrication for plastics |

| Part Size Range | Diameter: 2 mm to 76 mm (0.08″ to 3.0″) Length: Up to 150 mm (6.0″) depending on bar feed |

| Automation Compatibility | Bar feeders, gantry loaders, and inspection integration for high-volume production |

| Quality Standards | ISO 2768 (medium accuracy), ISO 1302 (surface finish), customer-specific GD&T requirements |

This combination of multi-axis flexibility, precision control, and material adaptability enables screw machining to meet the stringent performance and reliability demands of modern automotive systems.

From CAD to Part: The Process

Honyo Prototype Screw Machining Process for Automotive Parts

Our end-to-end process for precision screw machining of automotive components integrates digital engineering with lean manufacturing principles to ensure compliance with IATF 16949 standards. The workflow begins with secure CAD data ingestion and concludes with certified delivery, optimized for tight-tolerance parts such as fuel injector nozzles, transmission shafts, and sensor housings.

Upload CAD

Clients submit 3D CAD models (STEP, IGES, or native formats) via our encrypted portal. All files undergo automated validation for geometric completeness and unit consistency. For automotive applications, we specifically verify datum structures, GD&T callouts per ASME Y14.5, and material specifications against OEM requirements (e.g., AISI 4140, 303 stainless steel). This phase includes metadata tagging for traceability, linking the part to the client’s internal part number and revision level.

AI Quote

Our proprietary AI engine analyzes the CAD geometry to generate instant, data-driven quotations within 2 business hours. The system evaluates critical automotive-specific parameters:

| Parameter | Evaluation Criteria | Impact on Quote |

|——————–|——————————————————|——————————-|

| Feature Complexity | Number of operations, thread types, undercuts | Machine time multiplier |

| Tolerance Severity | ±0.005mm vs. ±0.05mm on critical diameters | Scrap risk surcharge |

| Material Grade | Machinability index (e.g., 12L14 vs. 17-4PH stainless)| Tool wear adjustment |

| Volume Tier | Prototype (1–50 pcs) vs. bridge production (500+ pcs) | Setup cost amortization |

The output includes a preliminary lead time estimate, NRE costs for custom tooling, and material waste calculations. Clients receive a downloadable PDF report with interactive 3D model markup for clarification requests.

DFM (Design for Manufacturability)

Engineering teams conduct a rigorous DFM review focused on automotive durability and assembly requirements. We identify risks such as:

Wall thickness inconsistencies that could cause distortion during heat treatment

Non-optimal thread engagement lengths violating OEM assembly specs

Surface finish mismatches (e.g., Ra 0.8µm specified where Ra 1.6µm suffices)

This phase involves collaborative iteration with the client via secure video conference, with revised CAD suggestions submitted within 48 hours. For critical safety components, we mandate FMEA documentation aligned with AIAG/VDA standards prior to tooling release.

Production

Parts are manufactured on CNC Swiss-type lathes (e.g., Star SG-207, Citizen L20) with sub-micron repeatability. Key production protocols include:

In-process gauging at 30-minute intervals using laser micrometers for critical diameters

Coolant management with oil-mist suppression to meet automotive cleanroom standards

Real-time SPC data logging for all dimensions, accessible via client dashboard

All automotive lots undergo 100% first-article inspection per AS9102 and batch-level CMM validation. Secondary operations (e.g., heat treating, passivation) are performed by IATF-certified partners with full material traceability from ingot to finished part.

Delivery

Finished parts ship in ESD-safe, anti-corrosion packaging with serialized labels for lot tracking. Each shipment includes:

IATF 16949-compliant COC (Certificate of Conformance) with material certs

Full FAIR (First Article Inspection Report) data package

Dimensional run charts from production

Automotive clients receive JIT delivery scheduling with ASN (Advanced Shipping Notice) integration into their ERP systems. Typical lead time from CAD approval to delivery is 2–4 weeks, with expedited options for urgent tooling trials. All components are staged in our Detroit warehouse for North American OEMs, ensuring 48-hour emergency resupply capability.

Start Your Project

Looking for precision screw machining for automotive parts? Honyo Prototype delivers high-quality, tight-tolerance components tailored to the demands of the automotive industry. With our advanced CNC screw machining capabilities and strict quality control, we ensure reliable performance and fast turnaround.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Our manufacturing facility is located in Shenzhen, China, providing efficient production and global shipping capabilities.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.