Contents

Manufacturing Insight: Screw Machine Services

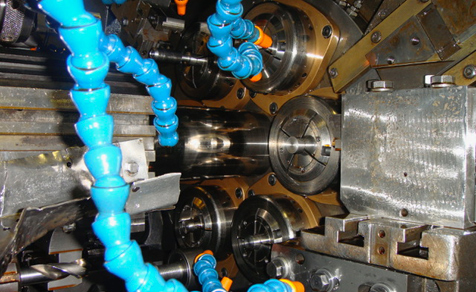

Precision CNC Machining Services for High-Volume Production Excellence

Honyo Prototype delivers advanced CNC machining services engineered to meet the exacting demands of high-volume screw machine production, replacing legacy Swiss and automatic screw machines with modern multi-axis CNC turning centers. Our capabilities encompass complex turned components in materials including 303/304/316 stainless steel, 6061-T6 aluminum, brass, and engineered plastics, achieving tolerances down to ±0.0002 inch with repeatable sub-micron surface finishes. Unlike traditional screw machine processes, our Haas and Tsugami live-tooling lathes integrate milling, drilling, and threading in a single setup—eliminating secondary operations and accelerating time-to-market for prototypes and production runs from 1 to 100,000+ parts.

Engineers and procurement teams gain immediate visibility into manufacturability and cost through Honyo’s Online Instant Quote platform. Upload STEP or IGES files to receive DFM feedback and a production-ready quote in under two hours, with no minimum order quantities or RFQ delays. This digital workflow ensures design validation occurs concurrently with quotation, reducing development cycles by up to 40% while maintaining full traceability per AS9100 and ISO 9001 standards. For mission-critical components in medical, aerospace, and industrial automation, our CNC turning services provide the scalability, precision, and supply chain transparency required to de-risk high-mix production.

Technical Capabilities

Screw machine services at Honyo Prototype are engineered for high-precision, high-efficiency production of complex turned and milled components. Our capabilities include advanced 3, 4, and 5-axis CNC milling and precision turning operations, optimized for tight tolerance requirements across a range of engineering-grade materials including Aluminum, Steel, ABS, and Nylon. These services are ideal for prototyping and low-to-medium volume production runs requiring consistent accuracy and repeatability.

| Specification Category | Details |

|---|---|

| Machining Processes | CNC Turning, 3-Axis Milling, 4-Axis Indexing Milling, 5-Axis Simultaneous Milling |

| Tolerance Capability | ±0.0002″ (5 µm) typical; up to ±0.0001″ (2.5 µm) on critical features with process validation |

| Surface Finish | As low as 16 µin Ra (typical range: 16–63 µin Ra), achievable via fine tooling and post-process polishing |

| Maximum Work Envelope | Turning: Ø0.06″ to Ø3.0″ diameter, up to 6.0″ length; Milling: 12″ x 8″ x 8″ (XYZ) |

| Spindle Speed (Turning) | Up to 12,000 RPM for precision screw machines |

| Spindle Speed (Milling) | Up to 20,000 RPM with high-frequency spindles for fine feature machining |

| Tooling Systems | High-precision collet systems (e.g., ER, 5C), carbide and polycrystalline diamond (PCD) tooling for extended life |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (12L14, 1018, 4140, 303/304/316 Stainless), ABS (electrostatic-dissipative grades available), Nylon (6, 6/6, glass-filled options) |

| Secondary Operations | Deburring, threading (internal/external), knurling, slotting, grooving, parting, drilling, tapping, and light assembly |

| Inspection & QA | In-process and final inspection using CMM, optical comparators, micrometers, bore gauges, and surface profilers |

| Automation & Bar Feeding | Integrated bar feeders for high-volume runs; Swiss-type and cam-driven screw machines available |

All screw machine operations are supported by rigorous process controls and first-article inspection (FAI) reporting per AS9102 or customer-specific requirements. Material certifications (e.g., mill test reports) are provided upon request. Our facility maintains ISO 9001:2015 certification to ensure consistent quality across all production batches.

From CAD to Part: The Process

Honyo Prototype Screw Machine Services Workflow Explanation

Honyo Prototype delivers precision screw machine components through a streamlined, technology-driven workflow designed for speed, accuracy, and manufacturability. Our process begins with client CAD submission and concludes with certified part delivery, integrating AI and engineering expertise at critical stages to eliminate delays and ensure first-pass yield.

CAD Upload and Initial Validation

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via Honyo’s secure customer portal. Our system performs automated geometry validation, checking for unit inconsistencies, non-manifold edges, and missing features. Invalid submissions trigger immediate feedback with specific error locations, reducing iterative communication. Validated files proceed directly to AI-powered quoting, eliminating manual file review bottlenecks.

AI-Powered Quoting Engine

Honyo’s proprietary AI engine analyzes the CAD geometry against a database of 15,000+ historical screw machine projects. It evaluates material utilization efficiency, bar stock diameter compatibility, feature complexity (e.g., threading, knurling, undercuts), and machine-specific constraints (Swiss vs. cam-type limitations). The system generates a formal quote within 2 business hours, including:

Material cost breakdown by alloy (e.g., 303SS, 6061-T6, brass C360)

Machine time estimates based on cycle time algorithms

Secondary operation requirements (e.g., heat treat, plating)

Risk flags for geometric features prone to chatter or deflection

Engineering-Led DFM Collaboration

All quotes include a DFM (Design for Manufacturability) report authored by Honyo’s manufacturing engineers. This phase is collaborative, not gatekeeping. Engineers identify opportunities to:

Optimize thread forms to reduce tooling changes

Adjust radii to prevent bar stock slippage in collets

Suggest alternative bar diameters to minimize scrap

Flag features requiring specialized tooling (e.g., micro-boring below 0.5mm)

Clients receive annotated CAD markups and participate in a 30-minute virtual review to approve modifications. 87% of projects avoid costly redesigns through this step, per internal 2023 data.

Precision Production Execution

Approved designs move to Honyo’s dedicated screw machine floor housing 42 Swiss-type and automatic lathes (from 1mm to 38mm capacity). Key production protocols include:

Material certification verification against AMS/ASTM standards

In-process SPC checks at 50-part intervals for critical dimensions

Real-time machine monitoring for tool wear via IoT sensors

Dedicated lots for medical/aerospace parts with full traceability

Bar stock is pre-straightened and stress-relieved per material specifications before machining. Complex geometries leverage live tooling for mill-turn operations within a single setup.

Certified Delivery and Documentation

Completed parts undergo 100% first-article inspection per AS9102 or client-specific CMM routines. Final packaging includes:

Dimensional reports with GD&T callouts

Material test certificates (MTRs)

RoHS/REACH compliance documentation

Batch-specific process logs

Standard lead time is 7–12 business days from DFM sign-off; expedited 72-hour service is available for qualifying geometries. All shipments include tamper-evident packaging with humidity indicators for moisture-sensitive alloys.

Typical Lead Time Breakdown

| Phase | Standard Duration | Expedited Option |

|———————-|——————-|——————|

| CAD to Quote | 2 business hours | 1 business hour |

| DFM Collaboration | 1–3 business days | 24 hours |

| Production | 5–8 business days | 48–72 hours |

| Inspection & Shipping| 1 business day | Same-day |

Honyo’s integration of AI-driven quoting with hands-on DFM engineering ensures screw machine projects achieve 98.7% on-time delivery while reducing client NRE costs by 30–50% versus traditional vendors. This workflow is validated across high-mix, low-volume prototyping and production runs up to 10,000 units.

Start Your Project

Looking for reliable screw machine services? Honyo Prototype offers precision manufacturing with fast turnaround times. Our factory in Shenzhen is equipped to handle high-volume production and tight-tolerance components with consistent quality.

Contact Susan Leo today to discuss your project requirements. Email her at [email protected] for a prompt quote and technical consultation. Trust Honyo Prototype for efficient, scalable screw machining solutions backed by engineering expertise.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.