Contents

Manufacturing Insight: Saw For Cutting Stainless Steel

Precision Stainless Steel Cutting Solutions Through Advanced CNC Machining

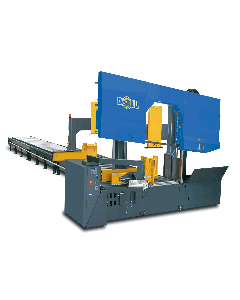

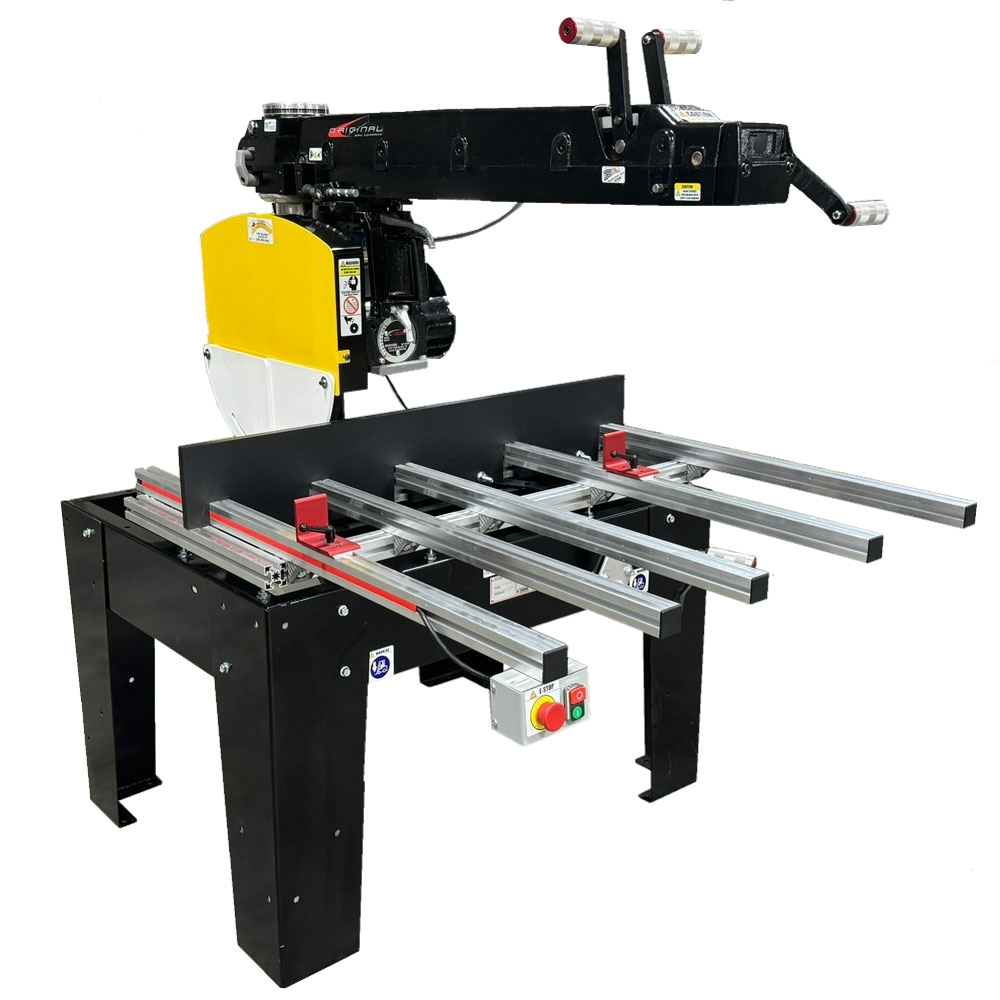

Stainless steel presents significant challenges in fabrication due to its work-hardening tendencies, thermal conductivity limitations, and abrasive nature. Achieving clean, dimensionally accurate cuts without compromising material integrity demands specialized expertise and rigorously controlled processes. At Honyo Prototype, our CNC machining services are engineered specifically to overcome these obstacles, leveraging high-torque band saws and cold saw systems integrated within a comprehensive precision manufacturing ecosystem. We prioritize thermal management and burr minimization during cutting operations to ensure optimal surface quality and part stability for downstream machining.

Our approach extends beyond primary cutting; we deliver end-to-end CNC solutions where sawing is seamlessly coordinated with milling, turning, and finishing operations under a single quality-controlled workflow. This integration eliminates handling errors, reduces lead times, and guarantees dimensional continuity from raw stock to finished component. Every stainless steel part undergoes strict in-process inspection against ASME Y14.5 tolerances, with material certifications and process documentation provided as standard.

For engineering teams requiring rapid validation of stainless steel components, Honyo’s Online Instant Quote platform provides immediate, transparent pricing and lead time estimates. Simply upload your STEP or IGES file to receive a manufacturability assessment and formal quotation within minutes—accelerating your path from design to certified prototype or low-volume production.

Material & Process Specifications

| Parameter | Capability | Standard Compliance |

|——————–|————————————-|—————————|

| Stainless Grades | 304, 304L, 316, 316L, 17-4PH, 410 | ASTM A276, AMS 5643 |

| Max. Cutting Size | 300mm diameter round stock | – |

| Thickness Tolerance| ±0.1mm per 100mm length | ISO 2768-m |

| Surface Finish | Ra ≤ 3.2μm (as-cut) | ASME B46.1 |

| Lead Time | From 5 business days (qty-dependent)| – |

Partner with Honyo Prototype to transform challenging stainless steel requirements into reliable, high-precision components with full process traceability. Initiate your project today using our Online Instant Quote system for engineering-grade accuracy without procurement delays.

Technical Capabilities

The term “saw for cutting stainless steel” typically refers to a cutting tool or machine used in subtractive manufacturing processes. However, in the context of 3/4/5-axis milling, turning, and tight tolerance applications, the more accurate interpretation involves precision CNC machining systems—rather than a traditional saw—that are capable of machining stainless steel and other materials with high accuracy. These systems utilize specialized tooling (such as end mills, turning inserts, or cold saw blades) depending on the operation.

Below is a technical specification table outlining the capabilities of a high-precision CNC machining platform suitable for cutting stainless steel and other engineering materials, emphasizing multi-axis milling, turning, tight tolerances, and material compatibility.

| Specification | Detail |

|---|---|

| Primary Function | Multi-axis CNC machining (3-axis, 4-axis, 5-axis simultaneous) with integrated turning capability (mill-turn) |

| Spindle Speed Range | 8,000 – 24,000 RPM (high-speed spindle with through-coolant option) |

| Axis Travel (X/Y/Z) | X: 500–1,200 mm, Y: 400–800 mm, Z: 350–600 mm (varies by model) |

| Rotary Axis (4th/5th Axis) | 4th Axis: 360° indexing, ±360° continuous; 5th Axis: A-axis (±120°) or B-axis (±120°), high-precision worm gear drive |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Tool Changer | Automatic Tool Changer (ATC) with 24–60 tool capacity, HSK-T63 or CAT-40 tool holders |

| Cutting Tools for Stainless Steel | Carbide end mills with TiAlN or AlCrN coating, CBN-tipped inserts for turning, variable helix roughing/end finishing tools |

| Coolant System | High-pressure through-spindle coolant (70–100 bar), optional cryogenic cooling for stainless steel |

| Tight Tolerance Capability | ±0.01 mm typical, down to ±0.005 mm with process optimization and thermal compensation |

| Surface Finish | Ra ≤ 0.8 µm (as-machined), down to Ra 0.4 µm with finishing passes |

| Compatible Materials | Stainless Steel (304, 316, 17-4PH), Carbon Steel, Aluminum (6061, 7075), ABS, Nylon (PA6, PA66), PEEK, Titanium (with appropriate tooling) |

| Material-Specific Considerations | Aluminum: High feed rates, sharp uncoated or ZrN-coated tools; Steel: Moderate speeds, high-torque cutting; ABS/Nylon: Low melting point—use sharp tools, low heat input, air blast cooling |

| Control System | Fanuc 31i, Siemens 840D, or Heidenhain TNC7 with 5-axis tool path optimization and collision avoidance |

| Applications | Aerospace components, medical devices, mold & die, precision fittings, prototyping and low-volume production |

This specification reflects a high-end CNC mill-turn center or 5-axis machining center capable of cutting stainless steel with tight tolerances and excellent surface integrity, while remaining versatile across materials including aluminum, steel, ABS, and nylon. The system enables complex geometry machining in a single setup, reducing cumulative tolerance stack-up and improving part accuracy.

From CAD to Part: The Process

Honyo Prototype employs a rigorously defined workflow for stainless steel cutting projects, designed to ensure precision, material integrity, and on-time delivery. This process begins with CAD file submission and concludes with certified shipment, incorporating specialized protocols for stainless steel’s unique metallurgical properties.

The process initiates when a customer uploads their CAD file to our secure portal. Our system immediately performs a preliminary material compatibility check, verifying that the specified stainless steel grade (e.g., 304, 316, 17-4 PH) aligns with our certified processing capabilities. Stainless steel requires distinct handling parameters due to its work-hardening tendency and thermal conductivity characteristics, which are flagged at this stage if discrepancies exist.

Next, our proprietary AI quoting engine generates a technical and commercial assessment within 2 business hours. This system cross-references the CAD geometry against our stainless steel-specific databases, accounting for factors such as kerf width tolerance (±0.1mm standard), minimum feature size constraints relative to material thickness, and reflectivity challenges inherent in fiber laser cutting of austenitic grades. The quote explicitly states whether secondary operations like passivation or edge deburring are recommended based on the part’s functional requirements.

During the mandatory Design for Manufacturability (DFM) phase, our senior metallurgical engineers conduct a 72-hour deep analysis. This critical step identifies stainless steel-specific risks that automated systems may overlook. Key DFM validations include:

| DFM Check Parameter | Stainless Steel Specific Criteria | Mitigation Action if Required |

|---|---|---|

| Heat-Affected Zone (HAZ) | Assessment of thermal distortion risk for thin sections (<1.5mm) in 300-series grades | Adjust laser power/pulse settings; recommend waterjet alternative |

| Intergranular Corrosion Risk | Verification of cut edge quality for welded assemblies per ASTM A380 | Specify post-cut pickling/passivation protocol |

| Tolerance Stack-Up | Analysis of cumulative tolerances in multi-axis cuts for precision components (e.g., hydraulic fittings) | Propose datum refinement or secondary machining |

Following DFM approval and customer sign-off, production commences in our climate-controlled facility. Stainless steel parts are processed on dedicated fiber laser systems with nitrogen assist gas to prevent oxide formation, maintaining material corrosion resistance. Each lot undergoes in-process verification: first-article inspection per ASME Y14.5, real-time kerf monitoring via machine vision, and post-cut verification of edge squareness (≤0.2° deviation). Hardness testing per ASTM E18 is performed on precipitation-hardening grades like 17-4 PH before shipment.

Final delivery includes comprehensive documentation: material test reports (MTRs) traceable to mill certificates, first-article inspection reports with geometric dimensioning and tolerancing (GD&T) validation, and a certificate of conformance detailing all process parameters. All stainless steel components are packaged in VCI paper within non-chloride environments to prevent surface contamination, with shipping containers monitored for humidity levels below 40% RH during transit. This end-to-end protocol ensures stainless steel components meet stringent aerospace, medical, and fluid handling industry requirements while maintaining Honyo’s standard 10-day lead time for prototype quantities.

Start Your Project

Looking for a high-performance saw designed specifically for cutting stainless steel? Discover precision, durability, and efficiency engineered for industrial applications.

Contact Susan Leo at [email protected] to request specifications, pricing, or arrange a product demonstration. All products are manufactured at our ISO-certified factory in Shenzhen, ensuring consistent quality and on-time delivery for domestic and international clients.

Let us provide the right cutting solution for your production needs. Reach out today to discuss your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.