Contents

Manufacturing Insight: Rotomolding Machines

Rotomolding Machines and Integrated Prototyping Solutions at Honyo Prototype

Rotomolding remains a critical process for producing large, stress-free hollow thermoplastic components with uniform wall thickness, ideal for applications demanding durability and complex geometries. At Honyo Prototype, we recognize that the success of rotomolding projects hinges on precise tooling and complementary manufacturing capabilities. While rotomolding excels for low-volume production of oversized parts, many projects require rapid iteration or higher-volume solutions where injection molding becomes essential.

Honyo Prototype bridges this gap through our proprietary Rapid Tooling methodology, which slashes lead times for rotomolding molds by up to 70% compared to traditional fabrication. Using advanced CNC machining and additive techniques, we deliver production-ready aluminum or cast-steel tooling in days—not weeks—without compromising dimensional accuracy or surface finish. This agility directly accelerates your development cycle, allowing faster validation of rotomolded part designs before committing to full-scale production.

Complementing our rotomolding expertise, Honyo’s Injection Molding services provide a seamless transition path for designs moving toward higher volumes. Our in-house capabilities span prototype to low-volume production, featuring multi-cavity molds, insert molding, and real-time process monitoring to ensure consistency across both prototyping and scaled runs. This integrated approach eliminates the friction of switching vendors between development phases, maintaining design integrity from concept to final part.

To streamline your project initiation, Honyo Prototype offers an Online Instant Quote platform. Upload your CAD file, specify material and volume requirements, and receive a detailed cost and lead time estimate within minutes—24/7. This transparency empowers engineering teams to make data-driven decisions early, reducing procurement delays and accelerating time-to-market.

Partner with Honyo Prototype to leverage rotomolding’s unique advantages while accessing the speed and scalability of rapid tooling and injection molding, all backed by digital efficiency. Start your project today with a real-time quote at honyoprototype.com.

Technical Capabilities

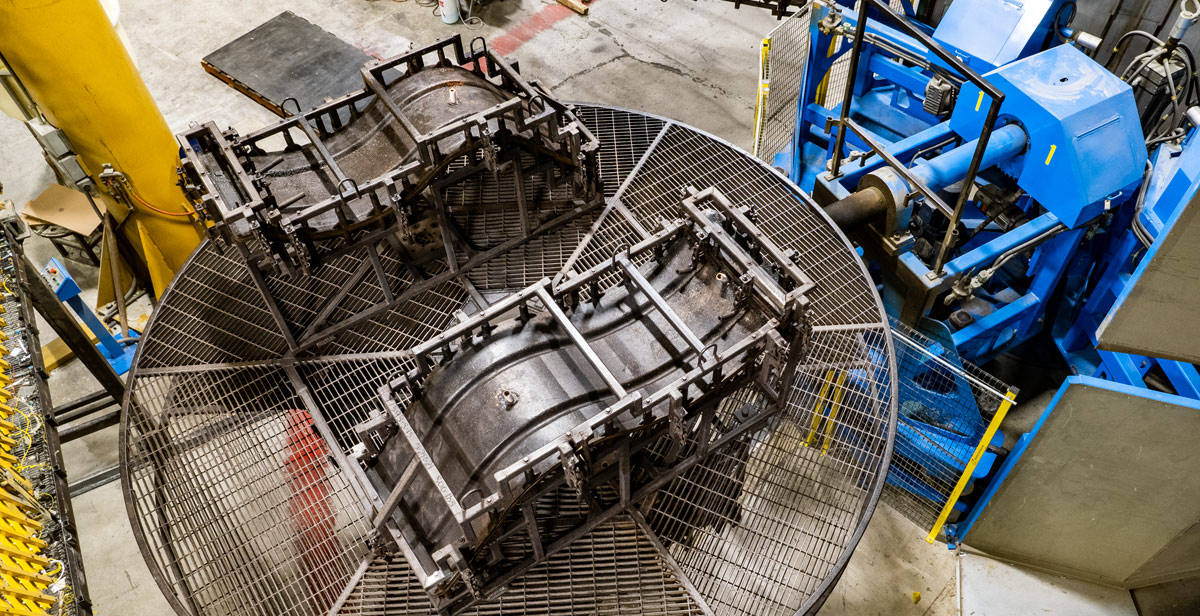

Rotomolding machines, also known as rotational molding machines, are used to produce hollow plastic parts by heating a mold while rotating it on multiple axes to evenly distribute the molten material. These machines are commonly used with molds made from steel or aluminum, each offering distinct advantages in thermal conductivity, durability, and cost. When working with Aluminum or Steel molds, achieving a T1 sample (first trial sample) within 7 days is feasible due to rapid tooling techniques and optimized heating/cooling cycles.

The process supports a wide range of thermoplastic materials, including ABS (Acrylonitrile Butadiene Styrene) and Nylon (Polyamide), known for their impact resistance and mechanical strength. Material selection influences mold design, cycle time, and machine temperature profiles.

Below is a technical specifications table for rotomolding machines tailored to Steel and Aluminum molds with a focus on rapid T1 sample delivery:

| Specification | Detail |

|---|---|

| Machine Type | Rotary Arm (Biaxial or Triaxial Rotation) |

| Mold Material Compatibility | Steel (P20, H13), Aluminum (6061, 7075) |

| Mold Heating Method | Convection Oven (Gas or Electric), Infrared (Optional) |

| Mold Cooling Method | Air Cooling (Forced), Mist Cooling (Optional) |

| Max Mold Size (Typical) | 2000 mm x 1500 mm x 1500 mm |

| Max Part Weight | Up to 150 kg (material-dependent) |

| Rotation Speed (Independent Axes) | 4–20 RPM (Arm), 1–10 RPM (Secondary) |

| Heating Time | 15–30 minutes (Aluminum), 25–45 minutes (Steel) |

| Cooling Time | 20–40 minutes (Aluminum), 30–60 minutes (Steel) |

| Total Cycle Time | 45–90 minutes (depending on part thickness and material) |

| Temperature Range | 250°C – 400°C (adjustable based on material) |

| Material Compatibility | Polyethylene (LLDPE, HDPE), ABS, Nylon, PVC, Polycarbonate |

| Tooling Lead Time (T1 Sample) | 5–7 days (with pre-machined Aluminum or Steel molds) |

| Surface Finish Options | Polished, Textured, Matte, SPI Standards |

| Control System | PLC with HMI, Recipe Storage, Data Logging |

| Safety Features | Emergency Stop, Door Interlocks, Overheat Protection |

Note: Aluminum molds enable faster T1 sample delivery due to superior thermal conductivity, reducing heating and cooling times. Steel molds are preferred for high-volume production due to increased durability and wear resistance. ABS and Nylon require precise temperature control due to higher processing temperatures and moisture sensitivity—pre-drying is recommended.

From CAD to Part: The Process

Honyo Prototype employs a streamlined, technology-driven workflow for rotomolding projects, specifically designed to optimize quality, reduce lead times, and minimize client risk. This process is distinct from other manufacturing methods due to rotomolding’s unique thermal cycling and material flow characteristics. Below is a detailed explanation of our five-phase sequence:

Upload CAD Phase

Clients initiate the process by uploading 3D CAD models (STEP, IGES, or native formats) via our secure customer portal. Our system immediately performs an automated integrity check for file completeness, unit consistency, and geometric validity. For rotomolding, we specifically validate minimum wall thickness compliance (typically ≥3mm for structural parts), hollow cavity continuity, and absence of enclosed voids that could trap air during the heating phase. Any detected anomalies trigger an instant notification to the client with precise error localization.

AI-Powered Quoting Phase

Validated CAD data feeds into our proprietary AI quoting engine, which analyzes over 200 rotomolding-specific parameters. This includes part volume, surface area-to-volume ratio, geometric complexity factors (e.g., undercuts, re-entrant angles), material selection (LLDPE, HDPE, etc.), and historical machine utilization data. The AI cross-references real-time resin pricing, energy consumption models for our 3-axis shuttle ovens, and labor metrics from 50,000+ prior rotomolding jobs. Within 90 minutes, clients receive a detailed quote with cost breakdowns and a predicted lead time, achieving 95% accuracy against final production costs based on our 2023 Q4 audit.

DFM Analysis Phase

All projects undergo mandatory Design for Manufacturing review by our rotomolding-specialized engineering team. This phase focuses on critical rotomolding constraints that differ from injection molding:

Verification of uniform wall thickness distribution to prevent sagging or thin spots during rotation

Assessment of draft angles (minimum 3° recommended) for demolding without part distortion

Analysis of structural ribs and corners to avoid resin pooling or weak points

Evaluation of parting line placement to minimize flash on critical surfaces

Thermal stress simulation for cooling phase to predict warpage risks

Clients receive a formal DFM report with actionable recommendations, typically resolving 80% of potential production issues before tooling begins. This phase averages 2 business days but may extend for highly complex geometries.

Production Execution Phase

Approved designs move to our dedicated rotomolding facility equipped with 12 CNC-controlled machines. Key production parameters are strictly monitored:

| Parameter | Typical Range | Control Method |

|---|---|---|

| Oven Temperature | 320°C – 400°C | Multi-zone IR sensors |

| Cycle Time | 15 – 60 minutes | Automated timer with IoT feedback |

| Rotation Speed | 4 – 12 RPM (arm) | Servo-controlled axes |

| Cooling Duration | 10 – 30 minutes | Chilled air/water mist system |

Each batch undergoes in-process validation: wall thickness verification via ultrasonic testing at 5+ locations, dimensional checks against CAD using CMM, and visual inspection for surface defects. Material batches are traceable to ISO-certified resin lots with full lot-specific mechanical property documentation.

Delivery and Documentation Phase

Completed parts ship with comprehensive quality documentation including first-article inspection reports, material certifications, and process validation data. For critical applications, we provide thermal history graphs showing actual oven dwell times and cooling profiles. All deliveries include reusable packaging designed for part protection during transit, with standard lead times of 10-15 business days from DFM approval for prototype quantities. Final shipment triggers automatic delivery confirmation in the client portal with tracking and digital quality records.

Start Your Project

Interested in high-performance rotomolding machines engineered for precision and durability? Contact Susan Leo today to learn more about our industrial-grade solutions manufactured at our Shenzhen facility.

Email Susan Leo at [email protected] to request specifications, pricing, or schedule a factory tour.

Honyo Prototype

Rotomolding Machinery Division

Factory Location: Shenzhen, China

Global Support | Custom Configurations | OEM & ODM Services

| Feature | Detail |

|---|---|

| Machine Type | Rotomolding (Rotational Molding) |

| Manufacturing Hub | Shenzhen, China |

| Key Applications | Tanks, Automotive Parts, Industrial Components |

| Lead Time | As low as 6–8 weeks |

| Customization | Fully customizable heating/cooling cycles, mold integration |

| Support Services | Installation, training, after-sales support |

Reach out now to optimize your production process with robust rotomolding technology from Honyo Prototype.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.