Contents

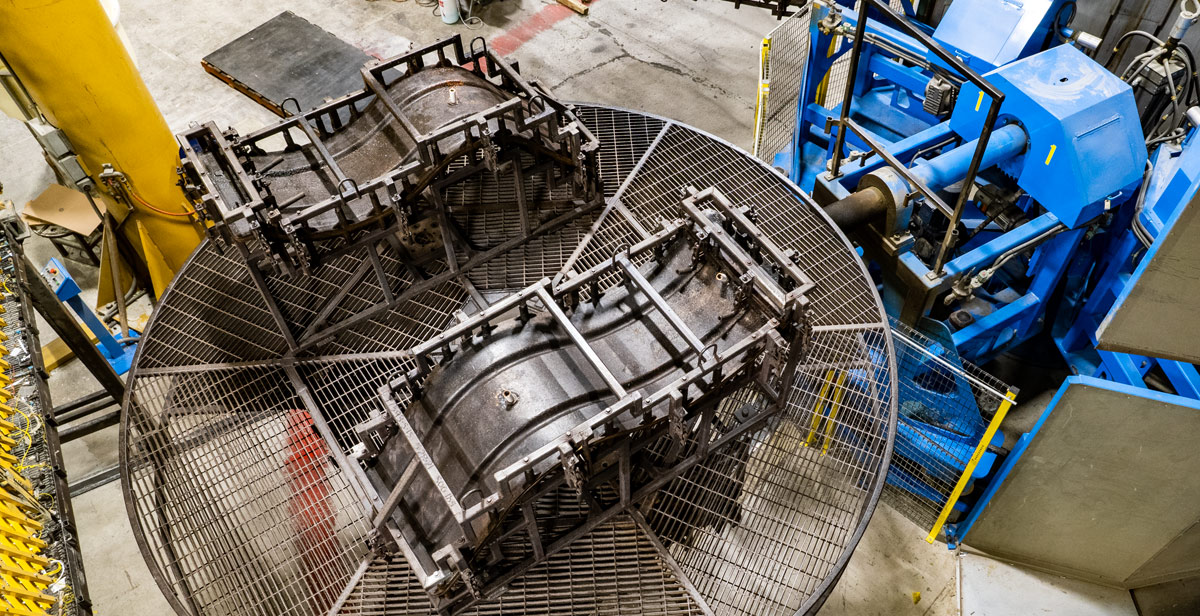

Manufacturing Insight: Roto Molding Machine

Rotational Molding Machine Context and Honyo Prototype’s Precision Manufacturing Solutions

Rotational molding excels in producing large, seamless hollow parts like tanks, kayaks, and playground equipment through its unique low-pressure, biaxial rotation process. While Honyo Prototype specializes in high-precision thermoplastic manufacturing, we recognize roto molding’s role in specific large-part applications. For clients requiring complex geometries, tight tolerances, and rapid production cycles in medium to high volumes, Honyo’s core capabilities in Rapid Tooling and Injection Molding deliver superior speed, repeatability, and material efficiency.

Rapid Tooling for Accelerated Time-to-Market

Our proprietary rapid tooling process leverages advanced CNC machining and 3D printing to create production-ready aluminum or steel molds in as few as 10–15 days. This eliminates traditional bottlenecks, allowing you to validate designs, secure certifications, and launch products up to 50% faster than conventional methods. Each tool undergoes rigorous thermal and stress analysis to ensure durability across 10,000+ cycles without compromising part integrity.

High-Performance Injection Molding

Honyo’s 50–1,200-ton presses support engineering-grade resins—from ABS and polycarbonate to medical-grade PEEK—with micron-level accuracy (±0.05 mm). Our integrated in-house capabilities include insert molding, overmolding, and cleanroom production (ISO Class 8), ensuring end-to-end control from prototype to full-scale manufacturing. Real-time process monitoring guarantees consistent wall thickness, minimal flash, and optimal gate aesthetics for demanding industrial and consumer applications.

Streamline Your Quoting Process

Accelerate your project kickoff with Honyo’s Online Instant Quote platform. Upload CAD files, specify materials and volumes, and receive a detailed cost analysis, lead time estimate, and manufacturability feedback within hours—not days. This industry-first tool reduces procurement cycles by 70%, empowering data-driven decisions without sales team dependencies.

For applications where rotational molding’s limitations in wall consistency or cycle time impact your quality or scalability, partner with Honyo to leverage injection molding’s precision, speed, and cost efficiency. Our engineering team provides free DFM analysis to optimize your design for manufacturability before tooling begins.

| Service | Key Advantage | Typical Lead Time |

|---|---|---|

| Rapid Tooling | Production molds in 10–15 days | 10–15 days |

| Injection Molding | ±0.05 mm tolerance, 50–1,200-ton presses | 2–4 weeks |

| Online Instant Quote | Real-time cost/lead time feedback | < 4 business hours |

Technical Capabilities

Roto molding machines, also known as rotational molding machines, are used to produce hollow plastic parts by heating a mold while rotating it on multiple axes. When utilizing steel or aluminum molds with materials such as ABS or nylon, performance, cycle time, and mold longevity are influenced by the mold material and machine specifications. Honyo Prototype offers rapid T1 sample delivery within 7 days using optimized roto molding systems and precision-engineered molds.

Below are the key technical specifications for a high-performance roto molding machine tailored for use with steel and aluminum molds, supporting materials like ABS and nylon:

| Parameter | Specification |

|---|---|

| Machine Type | Biaxial Rotational Molding Machine (Arm-Type) |

| Max Mold Size (L × W × H) | 2000 mm × 1200 mm × 1200 mm |

| Max Part Weight | Up to 150 kg |

| Rotation Speed (Main Arm) | 0–20 RPM (adjustable, independent for X and Y axes) |

| Drive System | Servo-controlled dual-axis rotation with independent speed and ratio control |

| Oven Type | Convection or Infrared, Gas-Electric Hybrid |

| Max Oven Temperature | 400°C (752°F) – suitable for nylon and ABS processing |

| Cooling Chamber | Forced air and optional water mist cooling |

| Cooling Time (Typical) | 15–30 minutes (dependent on part thickness and material) |

| Cycle Time Range | 20–60 minutes per cycle (material and wall thickness dependent) |

| Control System | PLC with HMI touchscreen interface, recipe storage, data logging |

| Mold Mounting System | Universal fixture with quick-clamp mechanism for rapid mold changes |

| Mold Materials Supported | Aluminum (7075-T6, 6061), Tool Steel (P20, H13) |

| Compatible Resins | ABS, Nylon (PA6, PA12), Polyethylene (LLDPE, HDPE), Polypropylene |

| Layer Thickness Range | 2–20 mm (adjustable via powder volume and cycle settings) |

| Tooling Lead Time (Standard) | 5–7 days for aluminum molds; 10–14 days for steel molds |

| T1 Sample Delivery | Within 7 days from mold completion (using aluminum molds and standard part geometry) |

Aluminum molds are preferred for rapid prototyping due to faster machining and improved thermal conductivity, enabling quicker cycle times and faster T1 sample realization. Steel molds are used for high-volume production due to superior durability and wear resistance. ABS and nylon require precise temperature control during sintering and cooling to prevent warpage and ensure consistent wall thickness.

Honyo Prototype leverages high-precision CNC-machined aluminum molds and optimized roto molding parameters to guarantee T1 sample delivery in as fast as 7 days, supporting accelerated product development cycles for clients in automotive, industrial, and consumer sectors.

From CAD to Part: The Process

Honyo Prototype executes rotational molding projects through a rigorously defined workflow optimized for precision, speed, and manufacturability. Our process begins with the client uploading a 3D CAD model of the desired part to our secure portal. This initiates our proprietary digital pipeline, ensuring all geometry and material specifications are captured for downstream analysis.

The uploaded CAD model triggers our AI-powered quoting engine, which performs initial dimensional and geometric analysis against rotomolding process constraints. This system rapidly generates a preliminary cost estimate and lead time projection by evaluating factors such as part volume, surface complexity, and material requirements. Crucially, this AI output undergoes mandatory validation by our senior manufacturing engineering team to ensure technical accuracy and feasibility before client submission.

Following client acceptance of the quote, the project enters the Design for Manufacturability (DFM) phase. Our engineers conduct a comprehensive rotomolding-specific DFM review, focusing on critical parameters including uniform wall thickness distribution, draft angles, parting line optimization, and structural rib design. We identify potential issues like excessive thin sections or inadequate radii that could cause thermal stress or warpage during the slow cooling cycle inherent to rotomolding. Clients receive a detailed DFM report with actionable recommendations, often including CAD markups for geometric adjustments to enhance part integrity and reduce cycle time.

Approved designs advance to production, where our rotomolding process utilizes computer-controlled ovens and biaxial rotation arms. Material preparation involves precise resin grinding and charging into the mold cavity. The mold undergoes a precisely sequenced thermal cycle: heating phases ensure complete polymer sintering and coalescence, while controlled cooling prevents internal stresses. Throughout this stage, real-time monitoring of temperature profiles and rotation speeds ensures conformance to material specifications. Post-molding, parts undergo trimming, deflashing, and rigorous dimensional validation against the original CAD model using calibrated CMM equipment.

Final delivery encompasses comprehensive documentation including first-article inspection reports, material certifications, and process parameter logs. Parts are packaged to prevent deformation during transit, with serialized traceability linking each unit to its specific production run data. Our standard lead time from CAD upload to delivery for prototyping rotomolded parts typically ranges from 10–15 business days, contingent on design complexity and material selection.

This integrated workflow ensures technical rigor at each transition point while leveraging digital tools to minimize manual handoffs, directly addressing common rotomolding challenges such as inconsistent wall thickness and extended cycle times through proactive engineering intervention.

Start Your Project

Interested in high-performance roto molding machines engineered for precision and durability? Contact Susan Leo today at [email protected] to discuss your production needs. Our manufacturing facility is located in Shenzhen, ensuring fast lead times and reliable quality control for global clients. Let Honyo Prototype be your trusted partner in rotational molding solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.