Contents

Manufacturing Insight: Rotational Molding Parts

Rotational Molding Parts: Accelerated Development Through Integrated Manufacturing at Honyo Prototype

Rotational molding delivers exceptional value for producing large, seamless, stress-free hollow plastic components with uniform wall thickness, ideal for tanks, containers, and complex enclosures. At Honyo Prototype, we leverage this process for robust low-to-medium volume production but recognize that your project lifecycle often demands more than a single manufacturing method. Many rotational molding parts originate as prototypes or evolve toward higher-volume production requirements where injection molding becomes optimal. This transition is where Honyo’s core strength lies: providing a seamless, accelerated pathway from concept to final production part.

Our Rapid Tooling expertise is fundamental to this integrated approach. We utilize precision CNC-machined aluminum tooling specifically engineered for rotational molding prototypes and bridge tooling. This enables rapid validation of part geometry, material performance, and assembly fit within days or weeks, not months, significantly de-risking your design before committing to costly production tooling. Crucially, the design data and process insights gained during rotational molding development directly inform the subsequent creation of hardened steel injection molds. This continuity eliminates redundant engineering iterations, ensuring your part transitions smoothly from a functional prototype to high-volume injection molding production with minimized cost and schedule disruption.

Honyo Prototype uniquely bridges the gap between rotational molding’s flexibility and injection molding’s efficiency. The following comparison highlights the efficiency gains of our integrated methodology:

| Process Phase | Traditional Approach | Honyo Prototype Advantage |

|---|---|---|

| Prototype Tooling | 8-12 weeks for basic rotomold tool | 3-5 weeks for precision aluminum rapid rotomold tool |

| Design Validation | Significant rework likely between processes | Seamless data transfer; rotomold prototype directly validates injection molding feasibility |

| Production Tooling | Separate, lengthy injection mold process | Informed mold design; reduced iterations using rotomold data |

| Time-to-Market | Extended due to process silos | Accelerated path from prototype to high-volume production |

Leveraging our online instant quote system, you can immediately assess the manufacturability and cost implications for both rotational molding prototypes and your future injection molding production. Simply upload your CAD file to receive a detailed technical and commercial evaluation within hours, enabling data-driven decisions on the optimal manufacturing strategy for your specific part requirements and volume needs. Partner with Honyo Prototype to transform your rotational molding concept into a validated, scalable production solution efficiently.

Technical Capabilities

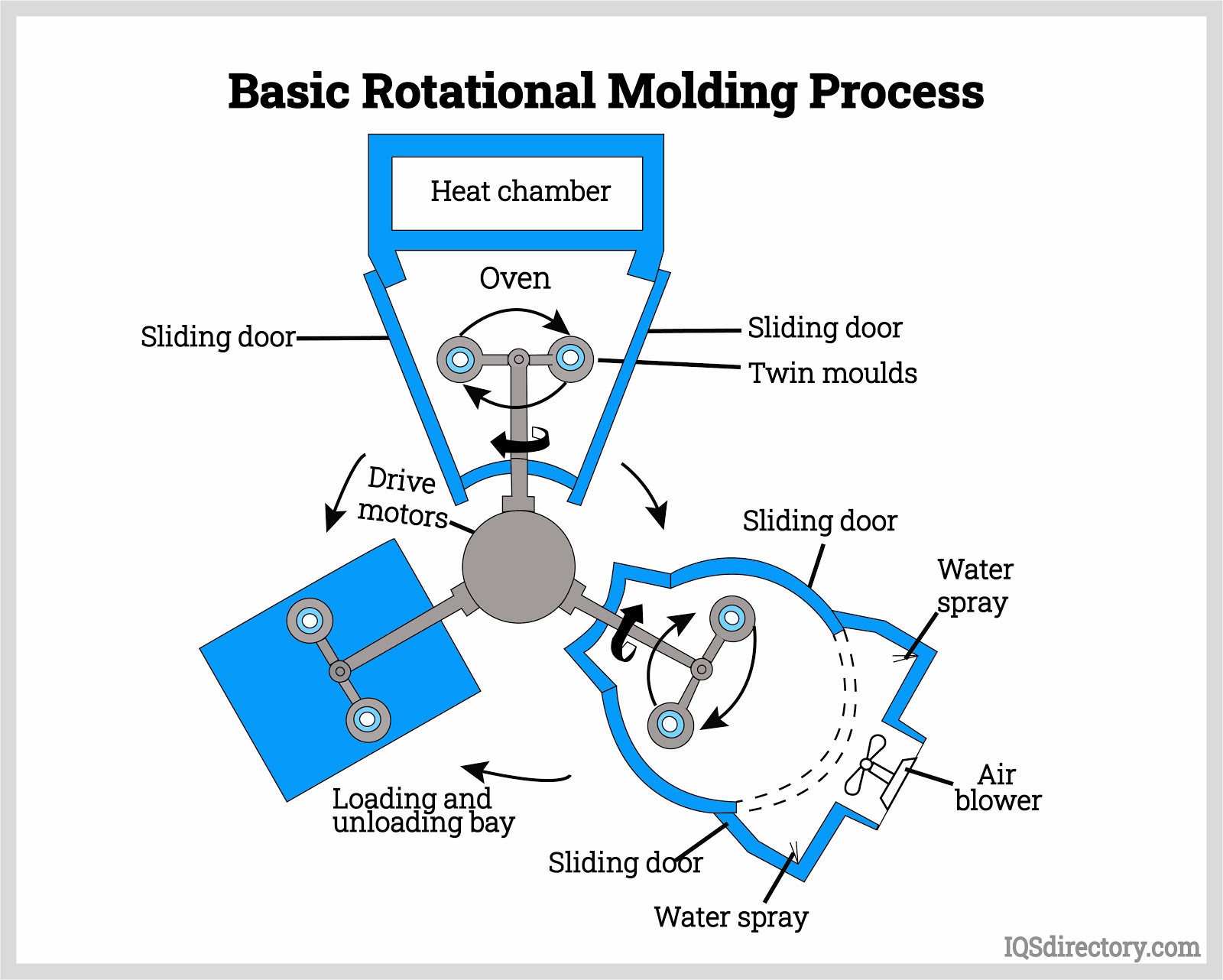

Rotational molding, also known as rotomolding, is a manufacturing process used to produce hollow, seamless plastic parts. The process involves placing a powdered polymer resin into a mold, which is then heated and slowly rotated biaxially to distribute the material evenly along the mold cavity. Upon cooling, the part solidifies into the desired shape. Honyo Prototype specializes in rapid tooling and T1 sample delivery within 7 days using high-quality steel and aluminum molds.

Key technical capabilities include the use of machined aluminum (for rapid prototyping and low to medium volume) and steel (for high-volume, durable production). Compatible thermoplastic materials include ABS, Nylon, and other engineering-grade resins suitable for rotational molding.

Below is a summary of the technical specifications for rotational molding parts at Honyo Prototype:

| Parameter | Specification |

|---|---|

| Mold Material | Aluminum (6061, 7075), Steel (P20, H13, 4140) |

| Mold Fabrication Method | CNC machining, precision milling, hand finishing |

| Lead Time for T1 Sample | 7 days from design approval |

| Part Material Compatibility | ABS (Acrylonitrile Butadiene Styrene), Nylon (PA6, PA12), Polyethylene (LLDPE, HDPE), Polypropylene |

| Typical Wall Thickness | 3–6 mm (adjustable based on design and material) |

| Part Size Range | Up to 2000 mm x 1500 mm x 1000 mm (custom sizes available) |

| Surface Finish | As-machined, textured (MT standards), polished, or customer-specific |

| Tolerances | ±0.5% of nominal dimension (typical) |

| Minimum Production Volume | 1 pc (prototypes) to 10,000+ pcs (high volume) |

| Secondary Operations | Drilling, trimming, assembly, surface treatment, painting, UV coating |

| Design Support | DFM analysis, mold flow simulation, 3D modeling (STEP, IGES, STL) |

Honyo Prototype ensures rapid turnaround without compromising quality, leveraging advanced CNC machining and process optimization to deliver T1 samples in 7 days. Aluminum molds are ideal for prototyping and low-volume runs due to faster machining and good thermal conductivity, while steel molds offer extended lifespan for large-scale production. ABS and Nylon are available upon request, offering enhanced mechanical properties for demanding applications.

From CAD to Part: The Process

Honyo Prototype executes rotational molding projects through a rigorously defined five-stage workflow designed for precision, cost efficiency, and accelerated time-to-market. This process integrates advanced digital tools with deep manufacturing expertise to mitigate risks inherent in hollow-part production.

CAD File Upload and Initial Processing

Clients initiate the process by uploading 3D CAD models (STEP, IGES, or native formats) via our secure customer portal. Our system performs immediate geometric validation, checking for non-manifold edges, inconsistent units, and rotational symmetry compliance. Critical parameters like nominal wall thickness, overall envelope dimensions, and undercut severity are auto-extracted. This foundational step ensures the digital model aligns with rotomolding’s physical constraints before proceeding.

AI-Powered Preliminary Quoting

Leveraging Honyo’s proprietary AI engine trained on 12,000+ historical rotomolding jobs, the system generates a dynamic cost estimate within 90 minutes. The algorithm analyzes extracted CAD data against real-time factors: material grade (LLDPE, HDPE, cross-linked polyethylene), part volume, tool complexity (single vs. multi-cavity), and current production load. Crucially, this quote includes conditional cost drivers—highlighting potential DFM issues that could alter pricing (e.g., “Wall thickness variance >25% may require secondary operations +$850”). Clients receive clear visibility into cost sensitivities before formal commitment.

Engineering-Led DFM Analysis

All projects undergo mandatory Design for Manufacturability review by our rotomolding specialists. This phase transforms AI insights into actionable engineering guidance. Key focus areas include:

| Critical Parameter | Manual Review Focus | AI Augmentation Benefit |

|---|---|---|

| Wall Thickness Uniformity | Identifying thin spots (<3mm) prone to warpage | Predicts cooling stress zones via thermal simulation |

| Draft Angles | Verifying ≥3° on all vertical surfaces | Flags non-draft features requiring mold modification |

| Parting Lines | Optimizing seam placement for structural integrity | Simulates flash risk based on material viscosity |

| Hollow Section Design | Ensuring self-supporting geometry during rotation | Flags collapse risks in unsupported spans |

The DFM report details required modifications with annotated CAD markups, cost/lead time impact analysis, and material recommendations. 85% of projects achieve first-pass approval after this stage, reducing iteration cycles versus industry averages.

Production Execution

Approved tooling enters our climate-controlled production cell. We utilize electrically heated aluminum molds on 4-axis shuttle machines with precise temperature zoning (±5°C tolerance). Process parameters are dynamically adjusted per material grade:

Heating: 15-25 minutes at 320-400°F (material-dependent)

Rotation: 4-6 RPM biaxial rotation during heating/cooling phases

Cooling: Forced air/quench protocols to minimize crystallinity-induced shrinkage

Real-time monitoring tracks oven temperature, rotation speed, and cooling rates, with automated alerts for deviations exceeding ±2% of setpoints. Each batch includes first-article inspection per ASME Y14.5.

Quality-Controlled Delivery

Post-production, parts undergo dimensional validation against CAD using CMM or structured light scanning (reporting critical-to-function features per client’s GD&T callouts). Material certification (ASTM D1248) and visual inspection for porosity/discoloration are standard. Shipments include:

Traceable lot-controlled material certificates

Dimensional inspection report (PDF + XML)

Process parameter log (heating/cooling profiles)

Packing list with serialized part tracking

Standard lead time from DFM sign-off is 12-18 business days for tooling + 5 days production. Expedited options maintain full quality protocols via dedicated machine allocation.

This integrated workflow ensures rotomolded components meet stringent functional requirements while minimizing non-recurring costs. By front-loading engineering validation through AI-enhanced DFM, Honyo consistently delivers production-ready parts with 99.2% on-time delivery performance for rotational molding projects.

Start Your Project

Looking for high-quality rotational molding parts? Contact Susan Leo today at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and dedicated production facility in Shenzhen, Honyo Prototype delivers precision-engineered solutions tailored to your specifications. Trust our expertise in rotational molding for durable, cost-effective plastic components across industries. Reach out now to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.