Introduction: Navigating the Global Market for roll forming companies

In today’s competitive landscape, sourcing reliable roll forming companies can be a significant challenge for international B2B buyers. As businesses seek cost-effective and high-quality metal components for diverse applications—from construction and automotive to renewable energy—the need for a streamlined procurement process becomes paramount. This guide serves as your essential resource for navigating the global market for roll forming companies, equipping you with the knowledge to identify the right suppliers that meet your specific needs.

Throughout this comprehensive guide, we will explore the various types of roll formed products, their applications across multiple industries, and the critical factors to consider when vetting potential suppliers. From understanding material specifications and production capabilities to evaluating cost structures and delivery timelines, our insights are designed to empower informed purchasing decisions.

By focusing on the unique requirements of international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Saudi Arabia—this guide aims to facilitate effective sourcing strategies that align with your business objectives. With a clear understanding of the roll forming landscape, you can confidently partner with suppliers that not only deliver quality but also enhance your operational efficiency.

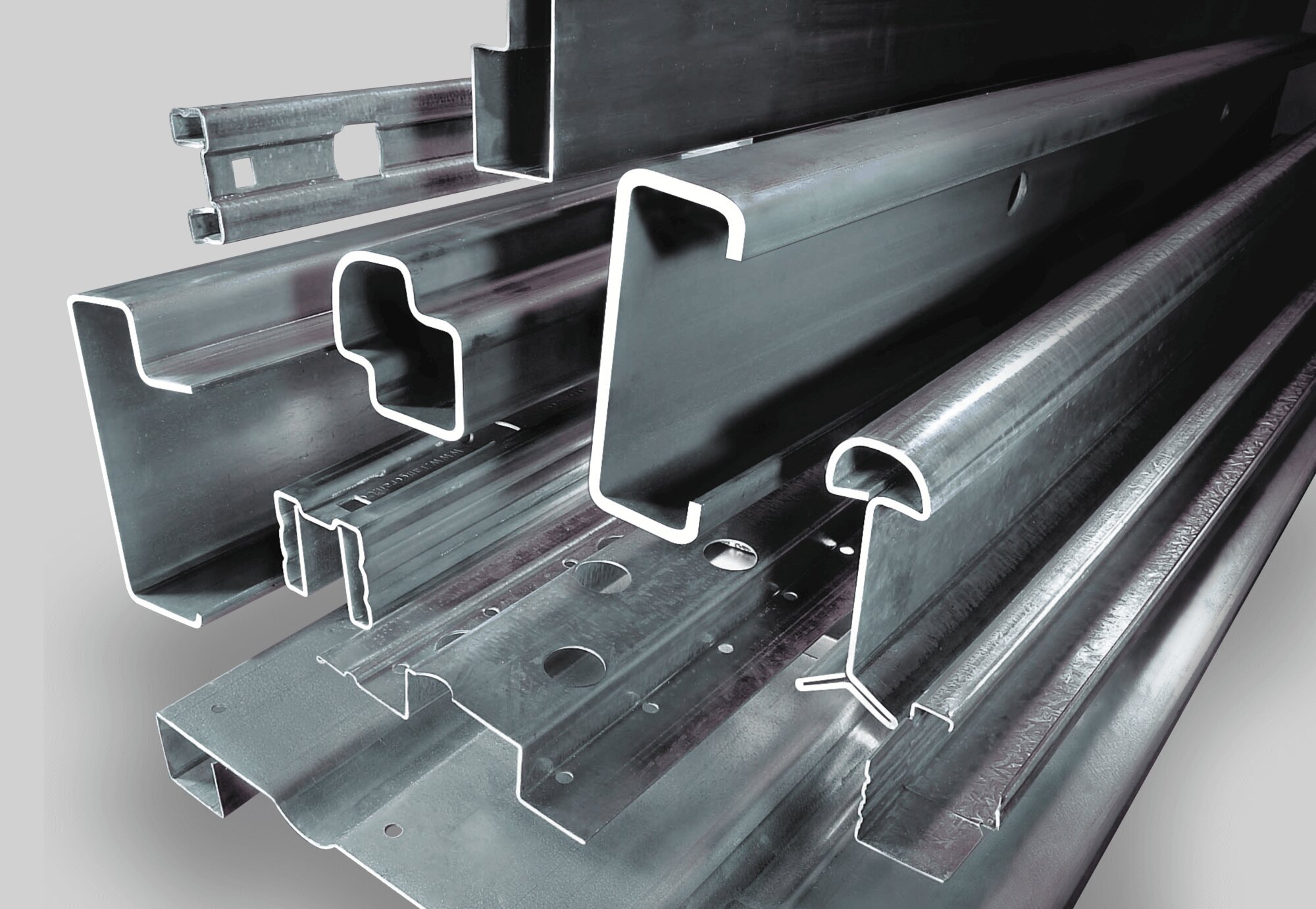

Understanding roll forming companies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Roll Forming | Tailored designs, unique profiles, and specifications | Automotive, Aerospace, Construction | Pros: Highly specialized; meets specific needs. Cons: Longer lead times; potential for higher costs. |

| Standard Roll Forming | Production of common shapes and profiles | HVAC, Building Construction, Furniture | Pros: Quick turnaround; cost-effective. Cons: Limited customization; may not meet niche applications. |

| Heavy Gauge Roll Forming | Capable of handling thick materials | Industrial Equipment, Agriculture | Pros: Durable products; suitable for high-stress applications. Cons: Heavier and less flexible in design. |

| Inline Process Roll Forming | Integration of additional processes (e.g., welding) | Electrical Enclosures, Material Handling | Pros: Streamlines production; reduces handling. Cons: Complexity may increase costs and lead times. |

| Precision Roll Forming | Focus on tight tolerances and high-quality finishes | Aerospace, Medical Devices | Pros: High accuracy; essential for critical applications. Cons: Higher investment; requires advanced machinery. |

What Are the Characteristics of Custom Roll Forming Companies?

Custom roll forming companies specialize in creating bespoke metal profiles tailored to the specific needs of their clients. These companies often employ advanced technology and flexible manufacturing processes, allowing them to produce unique shapes that standard manufacturers cannot. For B2B buyers, purchasing from a custom roll forming company is ideal when specific design requirements must be met, particularly in sectors like automotive and aerospace. However, buyers should consider potential longer lead times and higher costs associated with custom projects.

How Do Standard Roll Forming Companies Operate?

Standard roll forming companies focus on producing widely used shapes and profiles, such as channels and angles, that are integral to various industries, including HVAC and construction. These companies typically operate with streamlined processes that allow for quick turnaround times and cost-effective production. B2B buyers looking for readily available components at competitive prices will find standard roll forming companies advantageous. However, the trade-off is limited customization options, which may not suit specialized applications.

What Makes Heavy Gauge Roll Forming Unique?

Heavy gauge roll forming companies are distinguished by their ability to work with thicker materials, producing robust components for demanding applications. Industries such as industrial equipment and agriculture often rely on these companies for products that can withstand high stress and wear. While the durability and strength of heavy gauge products are significant advantages, buyers should be aware that these components may be less flexible in design and potentially heavier, affecting shipping and installation.

Why Choose Inline Process Roll Forming?

Inline process roll forming companies integrate additional manufacturing processes, such as welding or notching, directly into the roll forming line. This capability allows for streamlined production and reduces the handling of parts, making it efficient for applications like electrical enclosures and material handling systems. For B2B buyers, this approach can result in cost savings and faster delivery times. However, the complexity of inline processes may lead to increased costs, so buyers should assess their specific needs carefully.

What Are the Benefits of Precision Roll Forming?

Precision roll forming companies emphasize tight tolerances and high-quality finishes, making them essential for industries like aerospace and medical devices. These manufacturers utilize advanced machinery and techniques to ensure that every component meets strict specifications. B2B buyers in need of high-accuracy parts will benefit from the reliability and quality of precision roll forming. However, the investment required for precision components can be higher, so buyers should weigh the importance of accuracy against their budget constraints.

Key Industrial Applications of roll forming companies

| Industry/Sector | Specific Application of roll forming companies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Building Construction | Structural components for HVAC systems | Enhances energy efficiency and performance of climate control | Material specifications, compliance with local codes |

| Automotive | Lightweight components for vehicle frames | Reduces weight, improving fuel efficiency and performance | Customization capabilities, material strength, and durability |

| Renewable Energy | Racking systems for solar panels | Supports sustainable energy solutions and reduces installation costs | Corrosion resistance, design adaptability, and scalability |

| Material Handling | Racking components for automated warehouses | Increases storage efficiency and operational productivity | Load capacity, customization for specific warehouse layouts |

| Office Furniture | Custom profiles for modular office designs | Enhances aesthetic appeal and functionality of workspaces | Design flexibility, material finish, and ergonomic considerations |

How Are Roll Forming Companies Used in Building Construction?

In the building construction sector, roll forming companies supply structural components for HVAC systems, such as ducts and frames. These components are essential for ensuring optimal airflow and energy efficiency within buildings. Buyers in this sector, particularly from regions like Africa and the Middle East, need to consider local building codes and material specifications to ensure compliance. Additionally, the durability of these components against local environmental conditions, such as humidity or extreme temperatures, is critical.

What Role Do Roll Forming Companies Play in the Automotive Industry?

The automotive industry heavily relies on roll forming for producing lightweight components used in vehicle frames and body panels. This application is vital as it contributes to reducing the overall weight of vehicles, thereby improving fuel efficiency and performance. International buyers, especially from Europe and South America, should prioritize suppliers who can offer high-strength materials and customization options to meet specific design requirements. Ensuring that the suppliers adhere to stringent safety and quality standards is also paramount.

How Are Roll Formed Components Beneficial for Renewable Energy Solutions?

Roll forming companies are pivotal in the renewable energy sector, particularly in manufacturing racking systems for solar panels. These systems need to be robust yet lightweight to support solar installations while minimizing installation costs. Buyers from regions investing in renewable energy, such as South America and Africa, must evaluate the corrosion resistance of materials used in these applications. Additionally, scalability and adaptability of designs to different solar panel sizes and configurations are essential considerations.

Why Are Roll Forming Companies Important for Material Handling?

In material handling, roll forming companies produce racking components designed for automated warehouses and fulfillment centers. These components enhance storage efficiency and operational productivity by allowing for customized layouts that maximize space. B2B buyers in this sector should focus on the load capacity and customization options available from suppliers to meet their specific operational needs. Furthermore, understanding the durability of materials against wear and tear is crucial for long-term performance.

How Do Roll Forming Companies Enhance Office Furniture Design?

Roll forming companies provide custom profiles for modular office furniture, allowing for innovative designs that enhance both aesthetics and functionality. This application is particularly relevant as businesses aim to create flexible and attractive workspaces. Buyers, especially in Europe, should consider the design flexibility and material finishes offered by suppliers to align with modern office trends. Additionally, ergonomic considerations are vital to ensure that the furniture meets the needs of diverse work environments.

3 Common User Pain Points for ‘roll forming companies’ & Their Solutions

Scenario 1: Difficulty in Achieving Custom Specifications

The Problem: B2B buyers often face challenges when sourcing roll-formed products that meet their unique specifications. Many roll forming companies offer standard shapes, but when a buyer requires a custom profile tailored to specific applications—such as for aerospace components or specialized construction needs—misalignment can occur. This can lead to delays in production timelines, increased costs, and a general frustration when suppliers fail to deliver exactly what is needed. Buyers may find themselves caught between tight deadlines and the limitations of standard offerings.

The Solution: To overcome this challenge, B2B buyers should engage in thorough communication with roll forming companies early in the design phase. Providing detailed drawings, dimensions, and application contexts will help suppliers understand precise needs. Buyers should also inquire about the supplier’s capabilities in custom roll forming, such as their ability to produce complex shapes or utilize advanced materials. It’s beneficial to request samples or prototypes before full production to ensure that the final product meets specifications. Establishing a collaborative relationship with the supplier can lead to more efficient adjustments and faster turnaround times, ultimately enhancing the overall supply chain efficiency.

Scenario 2: Fluctuating Material Costs and Supply Chain Disruptions

The Problem: Another common pain point for B2B buyers in the roll forming industry is the volatility in material costs and the risk of supply chain disruptions. Fluctuating prices for steel, aluminum, and other metals can significantly impact project budgets, while unexpected delays in material delivery can halt production lines. Buyers in regions like Africa or South America may be particularly vulnerable due to varying local market conditions and logistical challenges.

The Solution: To mitigate these risks, buyers should implement a proactive sourcing strategy that includes establishing long-term partnerships with multiple roll forming suppliers. This diversification allows for more flexibility and options if one supplier experiences disruptions. Additionally, buyers should explore fixed-price contracts for materials when possible, which can help stabilize costs. Engaging in regular discussions with suppliers about market trends and forecasts will also keep buyers informed about potential changes in pricing and availability. Finally, buyers should consider investing in inventory management systems that allow them to track usage and optimize ordering processes, ensuring that they can respond quickly to changes in demand without incurring excessive costs.

Scenario 3: Inadequate Post-Purchase Support and Service

The Problem: After a purchase, B2B buyers often encounter insufficient post-purchase support from roll forming companies, which can lead to complications down the line. Issues may arise related to product integration, installation, or performance that require timely assistance. In sectors like construction or automotive manufacturing, where precision and reliability are critical, inadequate support can result in costly rework and delays.

The Solution: To ensure effective post-purchase support, buyers should thoroughly evaluate the service offerings of potential roll forming partners before making a commitment. This includes asking about the availability of technical support, warranty provisions, and the responsiveness of customer service teams. Buyers should also look for companies that offer training or consultation services to assist with product integration into existing systems. Establishing clear communication channels and expectations for post-purchase service can greatly enhance the buyer’s experience. Additionally, buyers should maintain a relationship with their suppliers, providing feedback on product performance, which can foster continuous improvement in service and product offerings. By prioritizing post-purchase support, buyers can ensure smoother project execution and minimize the risk of complications.

Strategic Material Selection Guide for roll forming companies

What Are the Key Properties of Common Materials Used in Roll Forming?

Roll forming companies often utilize various materials based on the specific needs of their applications. Understanding the properties, advantages, and limitations of these materials is crucial for international B2B buyers looking to make informed decisions. Below, we analyze four common materials used in roll forming: Steel, Aluminum, Stainless Steel, and Copper.

How Does Steel Perform in Roll Forming Applications?

Steel is one of the most widely used materials in roll forming due to its excellent strength and versatility. Key properties include high tensile strength and temperature resistance, making it suitable for structural applications. Steel’s corrosion resistance can vary based on the type used (e.g., galvanized or coated).

Pros: Steel is durable and cost-effective, especially for large-scale production. It can be easily formed into complex shapes, making it ideal for a variety of applications, from automotive components to construction materials.

Cons: While steel is strong, it can be susceptible to rust if not properly treated. The manufacturing complexity may increase when additional processes, such as galvanizing, are required.

Impact on Application: Steel is compatible with various media, including water and chemicals, but its performance may degrade in highly corrosive environments.

International Considerations: Buyers from regions like Brazil and Saudi Arabia should ensure compliance with local standards such as ASTM for structural steel. The availability of specific grades may vary, impacting procurement strategies.

What Advantages Does Aluminum Offer in Roll Forming?

Aluminum is another popular choice for roll forming, known for its lightweight and excellent corrosion resistance. Its key properties include a low density and high strength-to-weight ratio, which is advantageous for applications requiring reduced weight without compromising strength.

Pros: Aluminum is easy to work with and can be anodized for enhanced corrosion resistance. Its lightweight nature makes it ideal for transportation applications, such as in the automotive and aerospace sectors.

Cons: While aluminum is generally more expensive than steel, its cost can be justified by its performance benefits. It is also less durable than steel in high-stress applications.

Impact on Application: Aluminum is highly compatible with various environments, including humid or corrosive settings, which makes it suitable for outdoor applications.

International Considerations: Compliance with international standards such as JIS or DIN is essential for buyers in Europe and Asia. Understanding local market preferences for aluminum grades can also influence sourcing decisions.

How Does Stainless Steel Compare in Roll Forming?

Stainless steel is known for its exceptional corrosion resistance and aesthetic appeal, making it a preferred choice for applications where appearance and durability are paramount. Key properties include high strength, heat resistance, and resistance to oxidation.

Pros: Stainless steel’s durability makes it suitable for harsh environments, including food processing and medical applications. Its low maintenance requirement adds to its appeal.

Cons: The cost of stainless steel is generally higher than that of carbon steel and aluminum, which may deter some buyers. Additionally, its forming process can be more complex due to its toughness.

Impact on Application: Stainless steel is compatible with a wide range of media, including acids and alkalis, making it versatile for various industries.

International Considerations: Buyers should be aware of the different grades of stainless steel and their compliance with standards such as ASTM and ISO. This is particularly important for markets in the Middle East and Europe.

What Role Does Copper Play in Roll Forming?

Copper is less common in roll forming but is valued for its electrical conductivity and thermal properties. Its key properties include high ductility and resistance to corrosion.

Pros: Copper is an excellent choice for electrical applications due to its superior conductivity. It is also resistant to corrosion, making it suitable for plumbing and roofing applications.

Cons: The cost of copper can be significantly higher than other materials, which may limit its use in large-scale applications. Its softness can also lead to deformation under heavy loads.

Impact on Application: Copper is highly compatible with electrical media and is often used in wiring and electronic components.

International Considerations: Buyers in regions like Africa and South America should consider the availability of copper and its compliance with local electrical standards, which can vary significantly.

Summary Table of Material Selection for Roll Forming

| Material | Typical Use Case for roll forming companies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components in construction | High strength and cost-effective | Susceptible to rust without treatment | Low |

| Aluminum | Automotive and aerospace applications | Lightweight and corrosion-resistant | Higher cost than steel | Medium |

| Stainless Steel | Food processing and medical equipment | Exceptional corrosion resistance | Higher cost and complex forming | High |

| Copper | Electrical wiring and plumbing | Superior conductivity | High cost and softness | High |

This analysis provides a comprehensive overview of the materials commonly used in roll forming, helping international B2B buyers make informed decisions that align with their specific application needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for roll forming companies

What Are the Main Stages of the Roll Forming Manufacturing Process?

The roll forming manufacturing process consists of several key stages that ensure the production of high-quality metal components tailored to specific applications.

Material Preparation

The initial phase involves selecting the right material, typically steel, aluminum, or other metals, depending on the end application. The material is often supplied in coils and must be inspected for thickness, tensile strength, and surface quality. Pre-treatment processes, such as cleaning and degreasing, are performed to remove any contaminants that could affect the final product’s quality.

Forming

Once the material is prepared, it undergoes the roll forming process. This involves passing the metal through a series of rollers, each gradually shaping the metal into the desired profile. The precision of this step is critical, as it directly affects the dimensional accuracy and structural integrity of the final product. Advanced techniques, such as inline punching, notching, and welding, can be integrated into the roll forming line to enhance efficiency and reduce handling.

Assembly

In some cases, components may require assembly. This can involve the joining of multiple roll-formed parts or integrating additional components, such as fasteners or fittings. The assembly process is often automated to ensure consistency and speed.

Finishing

The final stage of manufacturing involves surface finishing treatments, which can include painting, coating, or galvanizing. These treatments not only improve the aesthetic appeal of the product but also enhance its durability and resistance to corrosion.

What Quality Assurance Standards Should B2B Buyers Look for in Roll Forming Companies?

For international B2B buyers, understanding the quality assurance measures employed by roll forming companies is essential. Many manufacturers adhere to internationally recognized standards such as ISO 9001, which outlines a framework for quality management systems. This certification ensures that companies maintain consistent quality in their processes and products.

Industry-Specific Certifications

In addition to ISO standards, various industry-specific certifications may be relevant. For example, the CE marking is crucial for products sold in the European Union, indicating compliance with health, safety, and environmental protection standards. In the oil and gas sector, certifications like API (American Petroleum Institute) are vital for ensuring that products meet stringent performance criteria.

How Is Quality Control Implemented During the Roll Forming Process?

Quality control (QC) is integrated at multiple checkpoints throughout the roll forming process to ensure that products meet specified standards.

Incoming Quality Control (IQC)

This initial checkpoint involves inspecting raw materials upon arrival. Key attributes such as material thickness, chemical composition, and surface finish are assessed. Any materials failing to meet specifications are rejected or returned to the supplier.

In-Process Quality Control (IPQC)

During the manufacturing phase, IPQC involves regular monitoring of the production process. Operators check for dimensional accuracy and the overall quality of the formed parts at various stages. This proactive approach helps identify and rectify issues before they escalate, ensuring that defects are minimized.

Final Quality Control (FQC)

Once production is complete, FQC involves a thorough inspection of the finished products. This may include dimensional checks, visual inspections, and functional testing, depending on the product’s application. Any non-conforming items are either reworked or discarded.

What Common Testing Methods Are Used in Quality Control for Roll Formed Products?

Various testing methods are employed to verify the quality and performance of roll-formed products.

Mechanical Testing

Mechanical tests, such as tensile and yield strength tests, evaluate the material’s performance under stress. These tests are crucial for applications requiring high structural integrity, such as in the automotive or aerospace industries.

Dimensional Inspection

Using precision measuring tools, dimensional inspections ensure that the products meet specified tolerances. This is particularly important for components that must fit precisely within larger assemblies.

Surface Quality Checks

Visual inspections and surface testing methods, such as gloss measurement or roughness testing, assess the finish of the product. A quality surface finish is vital for aesthetic purposes and functional applications, such as corrosion resistance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must conduct due diligence to ensure that their suppliers maintain high-quality standards.

Supplier Audits

Regular audits of potential suppliers can provide insights into their quality control processes and adherence to industry standards. These audits should assess both manufacturing capabilities and quality management systems.

Requesting Documentation

Buyers should request documentation demonstrating compliance with quality standards. Certificates of conformity, inspection reports, and quality management system certifications can serve as evidence of a supplier’s commitment to quality.

Third-Party Inspections

Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These services can conduct audits, sample inspections, and tests to verify that products meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, must be aware of specific nuances in quality control.

Understanding Local Standards

Quality standards can vary significantly by region. Buyers should familiarize themselves with local regulations and standards applicable to their specific industry to ensure compliance.

Communication and Documentation

Clear communication with suppliers about quality expectations is essential. Buyers should ensure that suppliers provide documentation in a language and format that is easy to understand and verify.

Cultural Considerations

Cultural differences may influence business practices, including quality control. B2B buyers should be prepared to navigate these differences and establish clear expectations to foster strong partnerships.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is essential for B2B buyers in the roll forming industry. By focusing on these critical areas, buyers can make informed decisions, ensuring they partner with suppliers who deliver high-quality products tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘roll forming companies’

Introduction

In the competitive landscape of manufacturing, sourcing the right roll forming company is crucial for ensuring quality, efficiency, and cost-effectiveness. This guide provides a structured checklist to help B2B buyers navigate the procurement process, ensuring that they select a supplier that meets their specific needs and standards.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in sourcing roll forming services. This includes specifying the types of materials you need (e.g., steel, aluminum), the thickness of the materials, and the dimensions of the parts. By having precise specifications, you can communicate effectively with potential suppliers and ensure they can meet your production needs.

Step 2: Research and Shortlist Potential Suppliers

Take time to conduct thorough research to identify potential roll forming companies that align with your requirements. Look for suppliers with experience in your industry and check their website for product offerings and case studies. A well-established supplier with a solid reputation will likely have the capacity and expertise to fulfill your orders reliably.

Step 3: Evaluate Supplier Certifications

Certifications such as ISO 9001:2015 can indicate a supplier’s commitment to quality management and continuous improvement. Verify that potential suppliers possess relevant certifications, as these can be critical in ensuring compliance with industry standards. This step not only helps mitigate risks but also assures you of the supplier’s dedication to quality and safety.

Step 4: Request Samples and Prototypes

Once you have shortlisted suppliers, request samples or prototypes of their work. This will allow you to assess the quality of their roll-formed products and determine if they meet your specifications. Evaluate the samples for consistency in dimensions, surface finish, and structural integrity to ensure they align with your standards.

Step 5: Discuss Lead Times and Production Capacity

Engage potential suppliers in discussions about their production capabilities and lead times. Understanding their capacity to handle your orders—especially during peak times—can prevent potential delays in your supply chain. Ask about their flexibility in scaling production up or down based on your needs, as this can be crucial for managing inventory effectively.

Step 6: Inquire About Secondary Operations

Many roll forming suppliers offer additional services such as welding, punching, and coating. Inquire about these secondary operations to determine if they can provide a comprehensive solution for your project. Utilizing a supplier that can handle multiple aspects of production can streamline your processes and reduce the need for multiple vendors.

Step 7: Check References and Customer Reviews

Finally, it’s essential to gather feedback from previous customers. Request references from suppliers and reach out to these contacts to gauge their satisfaction with the supplier’s performance. Pay attention to reviews regarding product quality, reliability, and customer service, as these factors can significantly impact your partnership.

By following this checklist, B2B buyers can navigate the sourcing process effectively, ensuring they select a roll forming company that meets their technical and operational needs.

Comprehensive Cost and Pricing Analysis for roll forming companies Sourcing

What Are the Key Cost Components in Roll Forming?

When evaluating the cost structure of roll forming companies, it’s essential to break down the various components that contribute to the final pricing of products. The primary cost elements include:

-

Materials: The type and quality of raw materials—such as steel, aluminum, and specialized alloys—significantly affect costs. Prices for these materials can fluctuate based on market conditions, supplier contracts, and transportation costs.

-

Labor: Skilled labor is required for operating machinery and ensuring quality control. Labor costs can vary by region and often include not just wages but also training and benefits.

-

Manufacturing Overhead: This encompasses the costs related to facility maintenance, equipment depreciation, utilities, and administrative expenses. Efficient operations can help mitigate these costs.

-

Tooling: Custom tooling can be a substantial upfront investment. The design and fabrication of specialized tools to create unique profiles add to initial costs but can be amortized over larger production runs.

-

Quality Control (QC): Implementing rigorous QC processes ensures that products meet industry standards and client specifications. This involves testing materials and finished products, which can add to the overall cost.

-

Logistics: Shipping and handling costs can vary significantly based on the destination and volume. International shipping often involves customs duties and tariffs that must be factored into the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing to ensure business sustainability. This margin can vary widely among suppliers based on their market positioning and operational efficiencies.

How Do Pricing Influencers Impact Roll Forming Costs?

Several factors can influence the pricing strategies of roll forming companies, making it critical for buyers to understand these dynamics:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often result in lower per-unit costs due to economies of scale. Understanding a supplier’s MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Custom profiles and specifications can lead to higher costs. The complexity of the design and the need for specialized tooling can increase both labor and material expenses.

-

Materials: The choice between standard and premium materials can greatly impact pricing. For instance, high-strength or corrosion-resistant materials may incur additional costs.

-

Quality and Certifications: Products that require specific certifications (like ISO or ASTM) may be priced higher due to the additional processes involved in achieving compliance.

-

Supplier Factors: Different suppliers may have varying cost structures based on their operational efficiency, location, and market strategy. Building relationships with suppliers can lead to better pricing and terms.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, affecting the overall cost of acquisition.

What Buyer Tips Can Help Optimize Costs in Roll Forming Procurement?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiation: Always be prepared to negotiate pricing, especially if you can commit to larger volumes or longer-term contracts. Building rapport with suppliers can facilitate better terms.

-

Total Cost of Ownership (TCO): Consider not just the upfront costs but the long-term implications of your purchase. Factors like durability, maintenance, and logistics can significantly affect TCO.

-

Understand Pricing Nuances: Be aware that pricing may vary based on geographic factors, currency fluctuations, and local economic conditions. This is particularly relevant when sourcing from suppliers in different countries.

-

Leverage Technology: Utilize supply chain management software to track orders, optimize inventory, and analyze costs, enabling better decision-making and forecasting.

-

Request Detailed Quotes: Always ask for itemized quotes that break down costs. This transparency can help you identify areas for negotiation and better understand the pricing structure.

In conclusion, a comprehensive understanding of the cost components and pricing influencers in roll forming can significantly enhance the sourcing strategies of international buyers. By applying these insights, companies can make informed decisions that lead to cost-effective procurement and successful partnerships.

Alternatives Analysis: Comparing roll forming companies With Other Solutions

Understanding Alternatives to Roll Forming Companies

In the manufacturing landscape, businesses often seek the most efficient and cost-effective methods for producing metal components. While roll forming companies are a popular choice for creating custom metal profiles, there are alternative solutions that may better suit specific project requirements. This section explores these alternatives, providing a comparative analysis to aid international B2B buyers in making informed decisions.

| Comparison Aspect | Roll Forming Companies | Extrusion Technology | Stamping Technology |

|---|---|---|---|

| Performance | High precision for complex shapes | Excellent for continuous profiles | High-speed production for flat parts |

| Cost | Moderate initial setup, low per-unit cost | Higher initial investment, competitive per unit | Low initial investment, but higher per unit cost for complex shapes |

| Ease of Implementation | Requires specialized machinery and tooling | Needs specific dies and molds | Relatively easy to set up for simple shapes |

| Maintenance | Regular maintenance required on machinery | Moderate maintenance depending on mold wear | Lower maintenance, but tool replacement can be costly |

| Best Use Case | Custom profiles for construction and automotive | Continuous profiles for architectural applications | High-volume production of flat or simple parts |

Extrusion Technology: Pros and Cons

Extrusion technology involves forcing material through a shaped die to create continuous profiles. This method excels in producing uniform shapes such as pipes and channels. The main advantages of extrusion are its efficiency in high-volume production and its ability to create complex cross-sections. However, the initial investment in dies can be substantial, which may deter smaller projects. Additionally, the process is less versatile compared to roll forming, which can handle more intricate designs.

Stamping Technology: Pros and Cons

Stamping involves pressing material into a die to create parts, making it ideal for high-speed production of flat components like brackets and panels. The major benefits of stamping are its cost-effectiveness for mass production and relatively low initial setup costs. However, it is less suitable for producing complex shapes compared to roll forming. Stamping also requires significant tooling, which can lead to higher costs if the design is intricate or requires frequent changes.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between roll forming companies and alternative manufacturing methods, B2B buyers should evaluate their specific project requirements, including the complexity of the desired shapes, production volume, and budget constraints. Roll forming stands out for its versatility and efficiency in producing custom profiles, making it a strong choice for construction and automotive applications. Conversely, extrusion and stamping may be more appropriate for projects requiring high-volume production of simpler components. Ultimately, understanding the strengths and limitations of each method will enable buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for roll forming companies

When navigating the complexities of sourcing roll formed products, understanding essential technical properties and industry terminology is crucial for making informed purchasing decisions. This section highlights key specifications and jargon frequently encountered in the roll forming industry, tailored for international B2B buyers.

What Are the Key Technical Properties of Roll Forming Products?

1. Material Grade

Material grade refers to the specific type of metal used in manufacturing roll formed products, such as stainless steel, aluminum, or high-strength low-alloy (HSLA) steel. Different grades offer varying mechanical properties, such as strength, ductility, and corrosion resistance. For B2B buyers, selecting the appropriate material grade is vital for ensuring the durability and performance of the final product in its intended application.

2. Tolerance

Tolerance is the allowable deviation from a specified dimension in the manufacturing process. It is expressed in terms of plus or minus values (e.g., ±0.005 inches). High tolerance levels are essential for ensuring that parts fit together correctly, which is particularly important in industries like automotive and aerospace, where precision is critical. Understanding tolerance requirements helps buyers ensure that their components will meet assembly and operational standards.

3. Gauge

Gauge refers to the thickness of the metal sheet used in roll forming, typically measured in American Wire Gauge (AWG) or millimeters. The gauge affects the strength, weight, and flexibility of the final product. Buyers must consider the gauge of materials based on the structural requirements of their projects to avoid issues related to under- or over-engineering components.

4. Strip Width

Strip width is the width of the metal strip entering the roll forming machine and can vary significantly based on the design specifications. It influences the type of profiles that can be produced. Understanding strip width is critical for buyers to ensure compatibility with their production processes and to optimize material usage.

5. Secondary Operations

Secondary operations include additional processes performed on roll formed parts, such as punching, notching, welding, and coating. These operations can enhance the functionality and aesthetics of the final product. Buyers should clarify their needs for secondary operations to streamline production and avoid unnecessary delays.

What Are Common Trade Terms Used in the Roll Forming Industry?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces components that are used in another company’s end product. In roll forming, OEMs often require specific profiles and customizations to meet their unique design specifications. Understanding the OEM relationship helps buyers identify reliable suppliers who can provide tailored solutions.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to know, as it affects inventory management and cost efficiency. Understanding MOQs can help buyers negotiate better terms and avoid over-committing to large orders that may not align with their production needs.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. Submitting an RFQ is an essential step in the procurement process, as it allows buyers to compare offers from multiple suppliers and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international contracts to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand their obligations, costs, and risks involved in international transactions.

5. JIT (Just-In-Time)

JIT is a production strategy that aims to reduce inventory costs by receiving goods only as they are needed in the production process. This approach can lead to cost savings and increased efficiency for buyers, making it essential to discuss JIT capabilities with suppliers.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, foster effective supplier relationships, and ensure that the roll formed products meet their operational requirements.

Navigating Market Dynamics and Sourcing Trends in the roll forming companies Sector

What Are the Key Market Dynamics and Trends Impacting Roll Forming Companies?

The global roll forming market is witnessing significant evolution, driven by various factors that impact B2B buyers across different regions. Key drivers include the growing demand for lightweight materials in the automotive and aerospace sectors, which necessitates the use of roll-formed parts that offer both strength and reduced weight. Additionally, the construction industry is increasingly adopting roll-formed components for structural applications, spurred by rapid urbanization and infrastructural development in emerging markets, particularly in Africa and South America.

Emerging technologies such as automation and Industry 4.0 are reshaping the sourcing landscape for roll forming companies. Advanced manufacturing techniques, including robotics and artificial intelligence, are improving production efficiency and reducing lead times. Moreover, the integration of supply chain management software is enabling companies to optimize inventory and streamline procurement processes. For international buyers, this translates into more reliable sourcing options, enhanced customization capabilities, and improved product quality.

Another trend is the increasing focus on local sourcing and supply chain resilience, especially following disruptions caused by global events like the pandemic. Buyers are now more inclined to engage with regional roll forming companies to mitigate risks associated with long-distance logistics. This shift not only supports local economies but also enhances the sustainability of operations, making it a win-win for both suppliers and buyers.

How Important Are Sustainability and Ethical Sourcing in Roll Forming?

Sustainability and ethical sourcing have become paramount in the roll forming industry. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt greener practices. This includes utilizing recycled materials and implementing energy-efficient manufacturing techniques. For B2B buyers, partnering with roll forming companies that prioritize sustainability can enhance their corporate social responsibility (CSR) profiles and appeal to environmentally conscious customers.

Moreover, the significance of ethical supply chains is gaining traction. Buyers are increasingly seeking suppliers who demonstrate transparency and accountability in their sourcing practices. Certifications such as ISO 14001 for environmental management and the use of green materials can serve as indicators of a company’s commitment to sustainable practices. This focus on ethical sourcing is not only about compliance but also about building trust and long-term relationships with suppliers.

In addition to compliance with environmental regulations, roll forming companies are also exploring innovative materials that reduce waste and energy consumption. For instance, advancements in materials science are leading to the development of high-strength alloys that require less material without compromising performance, thereby contributing to a more sustainable manufacturing process.

What Is the Historical Context of Roll Forming for B2B Buyers?

The history of roll forming dates back to ancient times, with its origins rooted in metal shaping techniques first documented around 600 B.C. The process has evolved significantly, from primitive rolling mills in South Asia to the sophisticated machinery used today. The introduction of the slitting mill in England in the late 16th century marked a pivotal moment in the evolution of roll forming, allowing for the mass production of metal strips that could be further shaped into various profiles.

Throughout the centuries, roll forming technology has been refined and adapted to meet the changing demands of industries such as construction, automotive, and aerospace. The versatility and efficiency of roll forming processes have made them a preferred choice for producing complex metal components at scale. As roll forming continues to advance, B2B buyers can benefit from a rich legacy of innovation, ensuring they have access to high-quality, cost-effective solutions tailored to their specific needs.

Frequently Asked Questions (FAQs) for B2B Buyers of roll forming companies

-

How do I choose the right roll forming supplier for my business needs?

Selecting the right roll forming supplier involves evaluating several key factors. Start by assessing their experience in your specific industry and their capacity to handle your required volume. Look for certifications like ISO 9001 to ensure quality standards. Request samples of their work to gauge the quality of their products. Additionally, consider their ability to provide customization, lead times, and their customer service responsiveness. Engaging in discussions about your unique needs will help you determine if they are a suitable partner. -

What are the typical lead times for roll forming projects?

Lead times for roll forming projects can vary significantly based on complexity, order size, and the supplier’s current workload. Generally, lead times range from a few weeks to several months. For custom designs, expect longer timelines as they may require additional engineering and tooling. It is advisable to communicate your project timelines upfront, allowing the supplier to provide a more accurate estimate. Establishing a solid relationship with your supplier can also lead to improved lead times for future orders. -

What customization options are available in roll forming?

Roll forming is highly versatile and can be customized to create various shapes, sizes, and profiles. Common customization options include material selection (steel, aluminum, etc.), thickness, width, and specific design features such as slots or notches. Suppliers often provide engineering assistance to help you refine your designs. Be sure to discuss your specific requirements and any secondary operations needed, such as welding or painting, to ensure the final product meets your expectations. -

What are the minimum order quantities (MOQs) for roll formed products?

Minimum order quantities (MOQs) for roll formed products can differ between suppliers and are influenced by factors like material type, complexity of the design, and production processes. Typically, MOQs can range from a few hundred to several thousand units. Discussing your needs with potential suppliers is essential, as some may offer flexibility for smaller orders, especially for custom products. Understanding the MOQ can help you manage inventory and cost effectively. -

What payment terms should I expect when working with roll forming companies?

Payment terms with roll forming companies can vary widely based on the supplier’s policies and your business relationship. Common terms include partial payment upfront with the balance due upon delivery or net 30/60 days after invoice. For international transactions, additional considerations such as currency exchange, shipping costs, and tariffs may apply. It is crucial to clarify payment terms early in negotiations to avoid misunderstandings and ensure a smooth transaction process. -

How do roll forming companies ensure quality control in their production processes?

Quality control in roll forming involves a series of checks and measures throughout the production process. Most reputable suppliers adhere to industry standards and implement rigorous inspection processes, including raw material quality checks, in-process monitoring, and final product evaluations. They may also utilize advanced technologies like automated measurement systems and statistical process control (SPC) to maintain consistency. Requesting details about a supplier’s quality assurance practices can provide confidence in their ability to meet your standards. -

What logistics considerations should I be aware of when sourcing roll formed products internationally?

When sourcing roll formed products internationally, consider logistics factors such as shipping methods, customs regulations, and lead times. Understanding the supplier’s shipping capabilities and the associated costs is crucial. Additionally, ensure compliance with import/export regulations in your country, which may involve tariffs and documentation requirements. Working with a supplier experienced in international trade can help streamline the process, minimizing delays and ensuring timely delivery of your products. -

What industries benefit most from roll forming technology?

Roll forming technology serves a wide array of industries due to its versatility and cost-effectiveness. Key sectors include construction (for structural components), automotive (for lightweight parts), HVAC (for ductwork), and renewable energy (for solar panel mounts). Other applications span agriculture, office furniture, and material handling. Understanding the specific needs of your industry can help you better communicate with suppliers and leverage their expertise in producing tailored solutions for your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Roll Forming Companies Manufacturers & Suppliers List

1. Bradbury Group – Custom Roll Forming Services

Domain: bradburygroup.com

Registered: 2001 (24 years)

Introduction: Custom roll forming services for light and heavy gauge applications. Manufacturing space of 51,000 square feet with ten rollforming lines. Capabilities include material thickness from 30 ga to 1/2″ thick, using materials such as CRS, HRS, HSLA, Aluminum, Copper, and various stainless steel grades. Strip widths up to 24″ wide. Inline capabilities for punching, notching, welding, curving, and bendin…

2. Roll Formed Parts – Metal Shaping Solutions

Domain: rollformedparts.com

Registered: 2000 (25 years)

Introduction: Roll formed parts are metal products shaped by a series of rollers during the roll forming process. Common products include angle irons, aluminum and steel angles, metal channels (U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels), trims, wall panels, and circular metal rings. These products are used across various industries such as building construction…

3. RF Corp – Custom Roll Formed Solutions

Domain: rfcorp.com

Registered: 1996 (29 years)

Introduction: voestalpine Roll Forming Corporation supplies custom roll formed metal components into several industries including Aerospace, Building Construction, Enclosures, Material Handling & Fulfillment, Office Furniture, Solar & Renewables, Transportation, and Off-Highway. Key services and solutions include dedicated support, custom profile solutions, engineering expertise, finite element analysis, in-hou…

4. Roll Former – Custom Machinery Solutions

Domain: rollformerllc.com

Registered: 2021 (4 years)

Introduction: Roll Former offers a variety of custom machinery products including: Roof Panel Machines and Panformers, Power Seamers, Cap/Curver Machines, Wall Panel/Soffit Machines, Hemming Machines, Coil Processing Machines, Perforators, Decoilers and Coil Cradles, Drip Edge Machines, Trim Machines, Metal Folders, and Shears. The company specializes in designing and developing machinery tailored to specific a…

5. Johnson Roll Forming – Roll Formed Products

Domain: johnsonrollforming.com

Registered: 2004 (21 years)

Introduction: Roll Forming & Roll Formed Products: Channels (U-Channels, J-Channels, C-Channels, Box Channels, Hat Channels, Strut Channels), Metal Framing, Busduct & Supports, Z-Channels, Channel Profiles, Profiles, Mouldings, Special Shapes & Sections, Stainless Steel Mouldings, Angles (Angle Irons, L-Shapes, V-Shapes), Specialty Tubing (Shelf Support Tubing, Open Seam, Open Buttseam, Tubing with Gap Lock Sea…

6. Samson Roll Form – Custom Roll Formed Products

Domain: samsonrollform.com

Registered: 1998 (27 years)

Introduction: Samson Roll Form offers a variety of roll formed products including Angles, Butt Seam Tube, C Channels, Hat Channels, Lock Seam Round Tube, Lock Seam Square Tube, Open Seam Tube, U Channels, and J Channels. They provide custom roll formed solutions tailored to customer specifications and have an extensive catalog of over 2,000 shapes ranging from simple to complex designs.

7. IQS Directory – Roll Forming Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Roll forming is a highly efficient metal forming process that shapes metal through a sequence of rollers without relying on heat. Key product details include:

– Capable of producing various profiles such as U-Channels, C-Channels, J-Channels, Hat Channels, Box Channels, Zee Channels, Strut Channels, moldings, angles, rings, frames, and tubing.

– Unique profiles can be run in gauges from 0.005″ to…

Strategic Sourcing Conclusion and Outlook for roll forming companies

In conclusion, strategic sourcing in the roll forming sector provides significant advantages for B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By partnering with reputable roll forming companies, buyers can access high-quality, customized metal products tailored to diverse applications, from construction and automotive to renewable energy. The versatility of roll forming technology enables the production of complex shapes efficiently, ensuring that businesses can meet the evolving demands of their industries while maintaining cost-effectiveness.

Furthermore, understanding the capabilities of suppliers—such as their experience, certifications, and technological advancements—can enhance procurement strategies and foster long-term partnerships. As global supply chains continue to evolve, it is imperative for international buyers to prioritize strategic sourcing to ensure the reliability and quality of their metal components.

Looking ahead, the roll forming industry is poised for growth, driven by advancements in manufacturing technologies and increasing demand for sustainable solutions. B2B buyers are encouraged to explore partnerships with leading roll forming companies to stay competitive and innovate in their respective markets. Embrace the opportunities that strategic sourcing can offer and position your business for future success.