Introduction: Navigating the Global Market for robot vs machine

In today’s rapidly evolving industrial landscape, understanding the distinction between robots and machines is crucial for B2B buyers looking to optimize their operations. As businesses in Africa, South America, the Middle East, and Europe (notably Germany and Brazil) navigate the complexities of automation, the challenge lies in sourcing the right technology that aligns with their specific needs. This guide addresses that challenge by providing an in-depth exploration of the differences between robots and machines, as well as the implications for purchasing decisions.

This comprehensive resource covers various types of robots and machines, their applications across multiple industries, and essential considerations for supplier vetting. Additionally, it delves into cost factors, enabling buyers to assess budgets effectively while maximizing return on investment. By equipping international B2B buyers with the knowledge to differentiate between these technologies, the guide empowers them to make informed purchasing decisions that enhance productivity and efficiency within their operations.

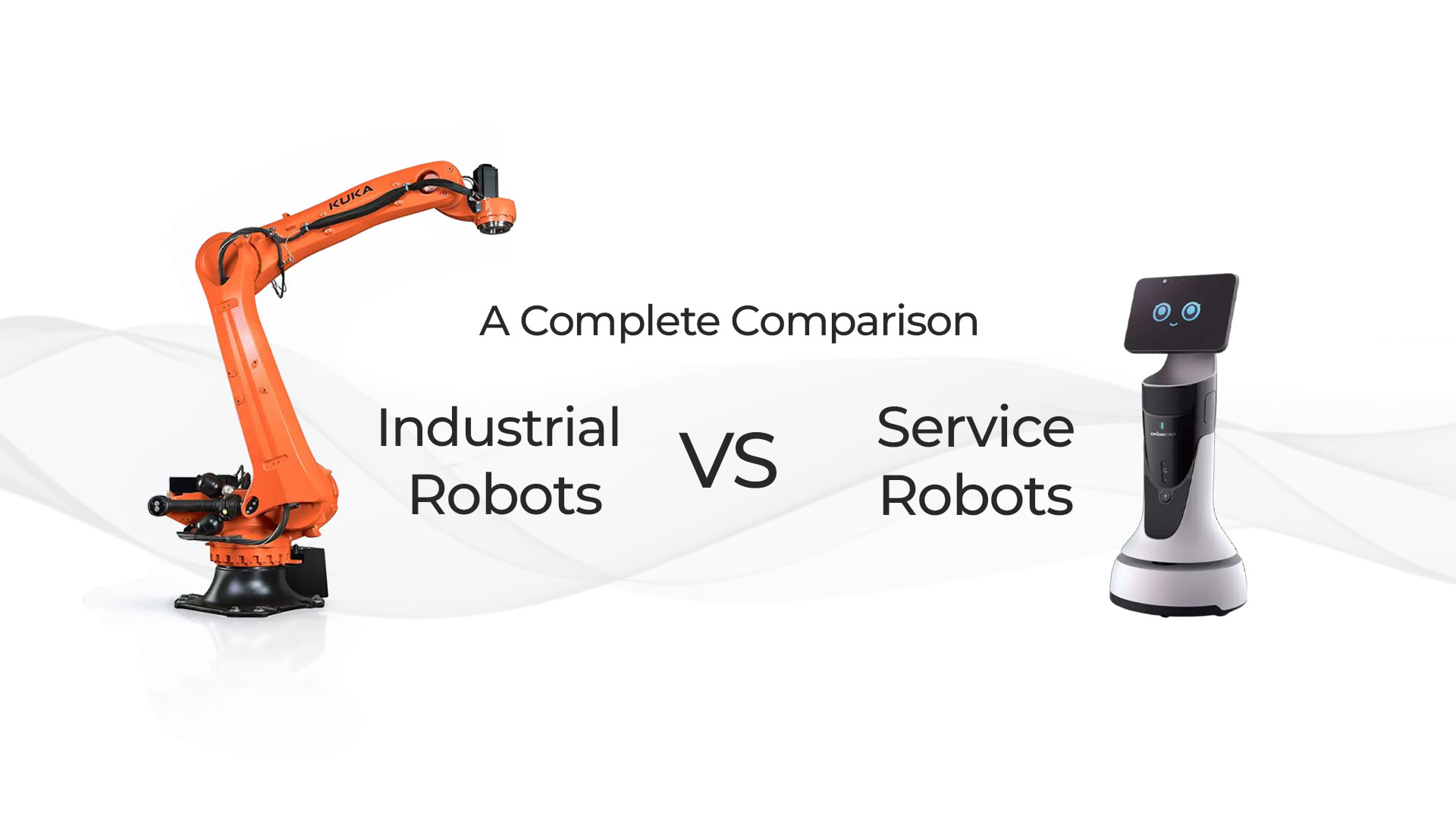

Whether you’re considering the integration of industrial robots for manufacturing or evaluating service robots for customer interaction, this guide serves as a valuable tool in navigating the global market for automation solutions. Understanding these nuances will not only streamline your sourcing process but also position your business for success in an increasingly automated world.

Understanding robot vs machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Industrial Robots | High precision, speed, and ability to perform repetitive tasks autonomously | Manufacturing, assembly lines, automotive, electronics | Pros: Increases productivity and accuracy. Cons: High initial investment and maintenance costs. |

| Service Robots | Designed for interaction with humans, often equipped with sensors for navigation and task execution | Healthcare, hospitality, cleaning services | Pros: Enhances customer experience and efficiency. Cons: Limited by task complexity and environment adaptability. |

| Collaborative Robots (Cobots) | Work alongside humans, designed to assist rather than replace | Manufacturing, warehousing, and assembly tasks | Pros: Safe for human interaction and flexible. Cons: May require human oversight and training. |

| Automated Machines | Pre-programmed to perform specific tasks without human intervention | Food processing, packaging, and logistics | Pros: Reliable for repetitive tasks. Cons: Lack of adaptability to new tasks or environments. |

| Mobile Robots | Capable of navigating and performing tasks in various environments autonomously | Warehousing, agriculture, and logistics | Pros: Increases operational efficiency and reduces labor costs. Cons: Navigation challenges in complex environments. |

What Are the Characteristics and Suitability of Industrial Robots?

Industrial robots are designed for high-volume production environments. They excel in tasks requiring precision and speed, such as welding, painting, and assembly. These robots are ideal for manufacturers looking to enhance productivity and reduce error rates. When considering an industrial robot, B2B buyers should evaluate factors such as the robot’s payload capacity, reach, and compatibility with existing systems, as well as the total cost of ownership, including maintenance and training needs.

How Do Service Robots Enhance Business Operations?

Service robots are engineered to assist and interact with humans, making them invaluable in sectors like healthcare and hospitality. They can perform tasks such as cleaning, food service, and patient assistance, providing consistent service while freeing human workers for more complex duties. When purchasing service robots, businesses should consider the robot’s ability to adapt to different environments, ease of use, and integration capabilities with existing workflows to maximize return on investment.

What Makes Collaborative Robots (Cobots) Unique?

Collaborative robots, or cobots, are designed to work alongside human operators, enhancing productivity without the need for extensive safety measures typical of traditional industrial robots. Cobots are suitable for small to medium-sized enterprises that require flexibility in their operations. Buyers should assess the ease of programming, safety features, and the cobot’s ability to perform a variety of tasks, making them a versatile addition to any production line.

Why Choose Automated Machines for Specific Tasks?

Automated machines are built to perform specific tasks consistently and reliably. They are particularly useful in industries such as food processing and packaging, where uniformity is critical. B2B buyers should evaluate the machine’s output speed, durability, and energy efficiency when considering an automated machine. While they are effective for repetitive tasks, their lack of adaptability can be a drawback in dynamic environments.

How Do Mobile Robots Transform Logistics and Warehousing?

Mobile robots are designed to navigate autonomously through various environments, making them ideal for logistics and warehousing applications. They can transport goods, manage inventory, and assist in order fulfillment. When investing in mobile robots, businesses should consider factors such as navigation technology, load capacity, and the ability to integrate with existing warehouse management systems. While they offer significant labor savings, challenges in navigation and environmental complexity must be addressed.

Key Industrial Applications of robot vs machine

| Industry/Sector | Specific Application of robot vs machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Robotic Assembly Lines | Enhanced precision, reduced labor costs, and increased production speed | Compatibility with existing machinery and software, maintenance support |

| Food and Beverage | Automated Packaging Machines | Improved efficiency and hygiene, reduced waste | Food safety certifications, adaptability to various packaging types |

| Healthcare | Robotic Surgery Systems | Higher accuracy in procedures, reduced recovery times | Regulatory compliance, integration with existing medical systems |

| Logistics and Warehousing | Autonomous Mobile Robots (AMRs) | Increased efficiency in inventory management and reduced operational costs | Navigation technology, battery life, and load capacity |

| Electronics | Robotic Inspection Systems | Improved quality control and defect detection | Calibration standards, compatibility with product lines |

How Are Robots and Machines Used in Automotive Manufacturing?

In the automotive sector, robotic assembly lines are a prime example of how automation enhances production. Robots perform repetitive tasks such as welding and painting, ensuring high precision and consistency. This not only reduces labor costs but also accelerates production cycles, allowing manufacturers to meet increasing demand. For international buyers, sourcing considerations include ensuring compatibility with existing machinery and availability of maintenance support, especially in regions like Europe and South America where manufacturing standards are stringent.

What Role Do Robots Play in Food and Beverage Packaging?

In the food and beverage industry, automated packaging machines utilize robots to streamline the packaging process. These systems enhance operational efficiency while maintaining hygiene standards, critical for food safety. They also minimize waste through precise packaging techniques. Buyers should consider sourcing machines that comply with food safety regulations and can adapt to various packaging types, particularly in regions with diverse consumer preferences like Africa and the Middle East.

How Are Robotic Surgery Systems Transforming Healthcare?

Robotic surgery systems are revolutionizing healthcare by allowing for minimally invasive procedures that enhance precision and reduce recovery times. Surgeons can perform complex operations with greater accuracy, leading to better patient outcomes. For B2B buyers in the healthcare sector, key considerations include ensuring regulatory compliance and the ability to integrate these systems with existing medical technologies, particularly in Europe where healthcare regulations are stringent.

What Advantages Do Autonomous Mobile Robots Offer in Logistics?

In logistics and warehousing, Autonomous Mobile Robots (AMRs) facilitate efficient inventory management by navigating through facilities to transport goods. They significantly reduce operational costs and improve inventory accuracy. For international buyers, sourcing AMRs requires attention to navigation technology, battery life, and load capacity, ensuring they meet the demands of high-volume operations, especially in regions like South America and Africa where logistics infrastructure may vary.

How Do Robotic Inspection Systems Improve Electronics Manufacturing?

Robotic inspection systems in electronics manufacturing provide enhanced quality control by detecting defects in products before they reach consumers. This automation ensures that only high-quality products are shipped, thus reducing returns and increasing customer satisfaction. Buyers should focus on calibration standards and compatibility with their product lines when sourcing these systems, particularly in markets like Germany where precision engineering is paramount.

3 Common User Pain Points for ‘robot vs machine’ & Their Solutions

Scenario 1: Navigating the Complexity of Automation Solutions

The Problem: Many B2B buyers are overwhelmed by the plethora of automation solutions available in the market, especially when distinguishing between robots and traditional machines. This confusion can lead to misinvestments, where companies may purchase a simple machine thinking it can replace a more complex robot, or vice versa. For instance, a manufacturer may invest in a conventional conveyor system expecting it to handle tasks that require the adaptability and decision-making capabilities of a robotic solution, resulting in operational inefficiencies and unmet production targets.

The Solution: To address this challenge, B2B buyers should conduct a thorough needs assessment before making any purchases. Begin by mapping out the specific tasks that need automation, focusing on the complexity, required adaptability, and the level of autonomy necessary for those tasks. Engage with solution providers to gain insights into the capabilities of both robots and machines. For example, if tasks require real-time decision-making, investing in robotic solutions with advanced sensors and AI capabilities is essential. Additionally, consider adopting a phased approach where you pilot a robotic solution in a limited scope before full-scale implementation. This way, you can evaluate performance metrics and ensure it meets your operational needs before committing to a larger investment.

Scenario 2: Balancing Cost with Technological Advancement

The Problem: Budget constraints often plague B2B buyers when deciding between investing in robots or machines. Many organizations are hesitant to adopt advanced robotics due to perceived high upfront costs, believing that traditional machines can deliver the same results at a lower price. However, this short-term thinking can lead to long-term operational inefficiencies and higher costs due to maintenance, labor, and lost production opportunities.

The Solution: B2B buyers should focus on the total cost of ownership (TCO) rather than just initial purchase prices. Conduct a detailed cost-benefit analysis that includes not only the purchase price but also maintenance, training, and potential downtime costs associated with traditional machines. Furthermore, consider the return on investment (ROI) from increased productivity, reduced labor costs, and improved quality control that robots can provide. Manufacturers can also explore financing options or leasing agreements for robotic systems, which can alleviate budget pressures while still allowing access to cutting-edge technology. Engaging with a consultant who specializes in automation can also provide tailored insights to optimize investment decisions based on specific industry needs.

Scenario 3: Understanding Integration Challenges in Existing Systems

The Problem: Integrating new robotic solutions into existing manufacturing processes can be a daunting task for B2B buyers. Many companies struggle with compatibility issues between new robotic technologies and legacy systems, leading to significant downtime and disruptions in operations. This challenge is particularly pronounced in sectors where machines have been in place for decades, creating apprehension about the potential for operational chaos during the transition period.

The Solution: To mitigate integration challenges, B2B buyers should prioritize working with vendors that offer comprehensive support during the implementation process. Before purchasing, ensure that the robotic solutions are compatible with current systems through detailed discussions with suppliers about integration capabilities. Opt for modular robotic systems that can be gradually introduced into existing workflows, allowing for testing and adjustments without halting production. Additionally, investing in training for staff on both the new technology and integration processes will foster a smoother transition. Collaborating with technology partners who specialize in automation integration can also provide valuable insights and resources to ensure a successful implementation, reducing the risk of operational disruptions.

Strategic Material Selection Guide for robot vs machine

When selecting materials for robots and machines, it’s crucial to understand the unique requirements of each application. The choice of material can significantly influence performance, durability, and cost-effectiveness. Below, we analyze four common materials used in the manufacturing of robots and machines, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Aluminum in Robots and Machines?

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio and corrosion resistance. It typically has a temperature rating of up to 600°C, making it suitable for various applications. Its low density allows for easier handling and mobility in robotic systems.

Pros: Aluminum is durable, resistant to corrosion, and easy to machine, which makes it ideal for complex designs. It is also relatively cost-effective compared to other metals.

Cons: While aluminum is strong, it can be less durable than steel under heavy loads. It is also more susceptible to deformation under high pressure.

Impact on Application: Aluminum is widely used in the frames of robots and machines, especially in applications requiring mobility and lightweight components.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers should also consider local availability and the cost implications of importing aluminum components.

How Does Steel Compare for Use in Robots and Machines?

Steel is renowned for its strength and durability, making it a popular choice for heavy-duty applications. It can withstand high temperatures and pressures, with some alloys rated for extreme environments.

Pros: Steel is highly durable and can handle significant stress, making it suitable for both structural and functional components in machines and robots.

Cons: Steel is heavier than aluminum, which can affect the mobility of robotic systems. It is also more prone to corrosion unless treated.

Impact on Application: Steel is often used in the construction of machine frames, gears, and other components that require high strength and reliability.

Considerations for International Buyers: Buyers should ensure that steel components meet local regulations and standards. Corrosion resistance treatments may be necessary depending on the application environment, particularly in humid regions.

What Are the Benefits of Using Plastic in Robotics and Machinery?

Plastics, particularly engineering plastics like nylon and polycarbonate, are increasingly used in robotics and machines due to their lightweight and versatile properties. They can withstand moderate temperatures and offer good chemical resistance.

Pros: Plastics are lightweight, cost-effective, and can be molded into complex shapes, making them ideal for intricate designs in robots.

Cons: Plastics generally have lower strength and thermal resistance compared to metals, which can limit their use in high-stress applications.

Impact on Application: Plastics are often used for non-structural components, such as housings and covers, where weight savings are critical.

Considerations for International Buyers: Buyers should verify that the plastics used comply with international safety and environmental standards, especially in regions with strict regulations.

Why is Composite Material Gaining Popularity in Robotics?

Composite materials, such as carbon fiber reinforced polymers, offer a unique combination of lightweight and high strength. They can withstand a wide range of temperatures and are resistant to corrosion.

Pros: Composites are incredibly strong yet lightweight, making them ideal for advanced robotic applications where performance is critical.

Cons: The manufacturing process for composites can be complex and costly, which may not be feasible for all applications.

Impact on Application: Composites are increasingly used in high-performance robotics, such as drones and aerospace applications, where weight and strength are paramount.

Considerations for International Buyers: Buyers should consider the availability of composite materials in their region and ensure compliance with relevant industry standards.

Summary Table of Material Selection for Robots vs. Machines

| Material | Typical Use Case for robot vs machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Robot frames, lightweight components | Excellent strength-to-weight ratio | Less durable under heavy loads | Medium |

| Steel | Structural components, gears | Highly durable and strong | Heavier, prone to corrosion | Medium |

| Plastic | Housings, non-structural parts | Lightweight and cost-effective | Lower strength than metals | Low |

| Composite | High-performance robotics | Strong and lightweight | Complex and costly manufacturing | High |

This strategic material selection guide provides essential insights for B2B buyers in Africa, South America, the Middle East, and Europe, helping them make informed decisions based on performance, cost, and compliance.

In-depth Look: Manufacturing Processes and Quality Assurance for robot vs machine

What Are the Key Manufacturing Processes for Robots and Machines?

Understanding the manufacturing processes for robots and machines is crucial for B2B buyers, especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe. The manufacturing of both robots and machines involves several main stages: material preparation, forming, assembly, and finishing.

What Are the Main Stages of Manufacturing for Robots and Machines?

-

Material Preparation:

– Robots: The manufacturing process begins with selecting appropriate materials, which may include metals, plastics, and composites. Material properties are crucial, as they affect durability and functionality. For instance, lightweight alloys may be used in robotic arms to enhance mobility while maintaining strength.

– Machines: Similar to robots, machines require careful material selection. However, the focus may be on heavier materials that can withstand repetitive stress, such as steel or cast iron for industrial machines. -

Forming:

– Robots: This stage may involve advanced techniques such as CNC machining, laser cutting, or additive manufacturing (3D printing). Precision is key, as components like gears and joints must fit together seamlessly.

– Machines: Forming techniques often include forging and stamping, particularly for components that require higher strength and durability. The choice of technique can significantly influence the overall quality and performance of the final product. -

Assembly:

– Robots: Assembly of robots is often automated, utilizing robotic arms for tasks such as welding and screwing. This enhances precision and reduces labor costs. Cobots (collaborative robots) may also be integrated into the assembly line to work alongside human workers, ensuring efficiency without compromising safety.

– Machines: The assembly of traditional machines may still involve significant manual labor, particularly in sectors where customization is essential. However, automation is increasingly being adopted to streamline this process. -

Finishing:

– Robots: The finishing process for robots may involve surface treatments such as painting, coating, or anodizing to improve aesthetics and corrosion resistance. Quality in this stage is essential for both functionality and market appeal.

– Machines: Machines may undergo similar finishing processes, but they often require additional steps like balancing and testing to ensure they operate smoothly under load.

How Is Quality Assurance Implemented in the Manufacturing of Robots and Machines?

Quality assurance (QA) is paramount in the manufacturing of both robots and machines, ensuring that products meet international standards and customer expectations. This involves adhering to various quality control (QC) checkpoints and standards.

What Are the Relevant International Standards for Quality Assurance?

-

ISO 9001: This standard focuses on quality management systems and is applicable to both robots and machines. Companies seeking certification must demonstrate a commitment to quality through continual improvement and customer satisfaction.

-

CE Marking: Particularly relevant for European markets, CE marking indicates compliance with health, safety, and environmental protection standards. It is essential for manufacturers of machines and robots aiming to sell in Europe.

-

API Standards: For industries such as oil and gas, the American Petroleum Institute (API) sets standards that are vital for the quality assurance of machines used in these sectors. Compliance ensures reliability and safety.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control involves several checkpoints to ensure products meet the required standards throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses raw materials before production begins. It is critical for identifying defects early in the process, thus preventing costly rework later on.

-

In-Process Quality Control (IPQC): Continuous monitoring during production helps identify defects or deviations from specifications. Techniques such as statistical process control (SPC) can be used to maintain quality throughout the manufacturing stages.

-

Final Quality Control (FQC): This stage involves comprehensive testing of the final product against established criteria. For robots, this may include functionality tests and performance evaluations, while machines might undergo stress testing to ensure reliability under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure that products meet their specific needs. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits of suppliers can provide valuable insights into their quality assurance processes. This allows buyers to assess compliance with international standards and identify areas for improvement.

-

Quality Control Reports: Requesting detailed QC reports can help buyers understand the testing methods used, results obtained, and any corrective actions taken. This transparency is crucial for building trust.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing and quality assurance processes. This is particularly important for buyers in regions with varying standards of quality assurance.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, must navigate various certification requirements and quality standards. It is essential to be aware of the following:

-

Regional Variations: Different regions may have specific regulations or standards that impact product compliance. For instance, buyers in the European Union must pay particular attention to CE marking, while those in North America may focus on ANSI and UL standards.

-

Cultural Considerations: Understanding cultural differences in business practices can help facilitate smoother negotiations and partnerships. Buyers should be aware of the varying levels of rigor in quality assurance across different countries.

-

Documentation and Traceability: Ensuring that suppliers maintain comprehensive documentation of their quality control processes can help buyers trace any issues back to their source, facilitating more effective resolutions.

In conclusion, understanding the manufacturing processes and quality assurance measures for robots and machines is vital for B2B buyers. By focusing on key manufacturing stages, international standards, QC checkpoints, and verification methods, buyers can make informed decisions that enhance their operational efficiency and product quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘robot vs machine’

To effectively navigate the procurement process for robots and machines, this checklist serves as a comprehensive guide for B2B buyers. Understanding the distinctions between these technologies is crucial for making informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Clearly outline the specific tasks you need the robot or machine to perform. This step is vital because the functionality of robots and machines varies significantly. For instance, if you require a robot for automated assembly, you’ll need to specify load capacities, precision levels, and operational environments.

- Consider the application: Identify whether you need an industrial robot for repetitive tasks or a service robot for direct human interaction.

- Assess compatibility: Ensure that your technical specifications align with existing systems in your facility to maximize efficiency.

Step 2: Determine Your Budget

Establish a clear budget for your procurement process. This step is important as it helps narrow down options and avoids overspending. Consider not just the purchase price but also maintenance costs, training, and potential upgrades.

- Include all costs: Factor in installation and operational costs to gain a comprehensive view of the financial commitment.

- Seek ROI: Estimate the return on investment by evaluating potential efficiency gains or labor cost savings.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough vetting is essential. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. This ensures the supplier has a proven track record of reliability and quality.

- Check certifications: Ensure suppliers hold relevant industry certifications that guarantee compliance with safety and performance standards.

- Assess support services: Inquire about after-sales support, warranty terms, and training programs to ensure a smooth implementation.

Step 4: Review Technology and Features

Investigate the technological capabilities of the robots or machines you are considering. Understanding the features available will help you select a solution that meets your needs.

- Autonomy and adaptability: Look for robots with advanced sensors and AI capabilities that can learn and adapt to new tasks.

- Scalability: Choose technology that can grow with your business, allowing for future upgrades or expansions.

Step 5: Conduct a Risk Assessment

Evaluate potential risks associated with integrating new robots or machines into your operations. Identifying these risks early can prevent costly setbacks later.

- Safety considerations: Analyze how the new technology will impact workplace safety and compliance with local regulations.

- Operational disruptions: Consider potential downtime during the transition period and plan accordingly to minimize disruptions.

Step 6: Request Demonstrations and Trials

Arrange for product demonstrations or trial periods with shortlisted suppliers. This hands-on experience is critical for assessing whether the technology meets your operational requirements.

- Real-world testing: Observe the performance of the robot or machine in conditions that mimic your operational environment.

- Evaluate ease of use: Ensure that the technology is user-friendly and does not require extensive retraining of staff.

Step 7: Finalize Contracts and Agreements

Once you’ve selected a supplier, ensure that all terms and conditions are clearly documented in a contract. This protects both parties and clarifies expectations.

- Negotiate terms: Discuss payment schedules, delivery timelines, and service agreements to ensure mutual understanding.

- Include performance metrics: Establish clear performance indicators to evaluate the success of the robot or machine post-implementation.

By following this checklist, B2B buyers can make informed decisions when procuring robots and machines, ensuring that their investments align with their operational goals and business strategies.

Comprehensive Cost and Pricing Analysis for robot vs machine Sourcing

What Are the Key Cost Components in Robot vs. Machine Sourcing?

When considering the procurement of robots versus traditional machines, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The type of materials used significantly influences costs. Robots typically require advanced materials, such as specialized alloys and electronics, which can be more expensive than the materials used in traditional machines. Understanding the material specifications can help buyers gauge potential cost differences.

-

Labor: Labor costs can vary based on the complexity of assembly and maintenance. Robots often necessitate skilled technicians for installation and programming, which can increase initial costs. In contrast, machines may require less specialized labor, impacting overall expenses differently.

-

Manufacturing Overhead: Overhead costs include expenses related to facilities, utilities, and administrative costs. The production of robots may involve higher overhead due to the complexity of the manufacturing processes and the need for more sophisticated technology.

-

Tooling: The tooling costs for robots can be higher, especially if custom parts are required for specific applications. Traditional machines might have lower tooling costs due to their standardized designs.

-

Quality Control (QC): QC processes are crucial for both robots and machines, but robots may require more rigorous testing due to their autonomous capabilities. This can add to the overall cost but ensures reliability and performance.

-

Logistics: The logistics of transporting robots can be more complex and costly, especially when considering their size and sensitivity. Additionally, international shipping regulations may impact costs, particularly for advanced technology.

-

Margin: Supplier margins can vary significantly based on the product’s complexity and market demand. Robots, being more specialized, may attract higher margins compared to standard machines.

What Influences Pricing for Robots and Machines?

Several factors can influence pricing, including volume or minimum order quantities (MOQ), specifications and customization, material quality, certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Higher order volumes can lead to reduced per-unit costs. Negotiating larger orders can be a strategic way to lower costs, especially for B2B buyers operating at scale.

-

Specifications and Customization: Customized solutions often come at a premium. Buyers should assess whether standard models can meet their needs to avoid unnecessary expenses.

-

Materials: The choice of materials impacts not only the initial cost but also the longevity and maintenance expenses of the equipment. Investing in higher-quality materials can reduce long-term costs.

-

Quality/Certifications: Products with recognized certifications may carry higher upfront costs but can lead to lower operational risks and higher efficiency, making them cost-effective in the long run.

-

Supplier Factors: The supplier’s reputation, reliability, and service offerings can affect pricing. Established suppliers may offer better support and warranty options, which can justify a higher price point.

-

Incoterms: Understanding the delivery terms is vital. Different Incoterms can affect shipping costs and responsibilities, impacting the total landed cost.

What Are the Best Negotiation Tips for International Buyers?

When negotiating pricing for robots or machines, B2B buyers from regions like Africa, South America, the Middle East, and Europe should consider the following tips:

-

Research and Benchmarking: Conduct thorough market research to understand prevailing prices and benchmark against competitors. This information can empower negotiation.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but the TCO, which includes maintenance, operational costs, and potential downtime. Highlighting TCO benefits can strengthen your negotiation position.

-

Leverage Volume Discounts: If your business model allows for it, consider placing larger orders or developing long-term partnerships to leverage volume-based pricing.

-

Explore Financing Options: Some suppliers may offer financing or leasing options. Discussing these can lead to lower upfront costs and better cash flow management.

-

Be Mindful of Cultural Nuances: Understanding cultural differences in negotiation styles can enhance communication and lead to more favorable outcomes.

Disclaimer on Indicative Prices

Pricing for robots and machines can fluctuate based on market conditions, technological advancements, and supplier negotiations. Buyers should consider these factors and consult with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing robot vs machine With Other Solutions

Exploring Alternatives to Robots and Machines in Industrial Applications

When considering automation solutions for industrial processes, understanding the alternatives to traditional robots and machines is crucial for B2B buyers. While robots and machines offer unique advantages, alternative technologies may better suit specific operational needs. In this analysis, we will compare the ‘Robot vs Machine’ concept against two viable alternatives: Automated Guided Vehicles (AGVs) and Manual Labor.

Comparison Table

| Comparison Aspect | Robot Vs Machine | Automated Guided Vehicles (AGVs) | Manual Labor |

|---|---|---|---|

| Performance | High efficiency and precision | Moderate efficiency; limited by path constraints | Variable efficiency; dependent on human skill |

| Cost | Higher initial investment | Moderate upfront costs; lower long-term costs | Low initial costs; high long-term labor costs |

| Ease of Implementation | Requires significant integration | Easier to implement; minimal infrastructure changes needed | Simple to deploy; training needed |

| Maintenance | Regular software updates and repairs | Low maintenance; routine checks needed | High variability; human resource management |

| Best Use Case | Complex tasks requiring precision | Material handling in structured environments | Tasks needing flexibility and human judgment |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Automated Guided Vehicles (AGVs)?

Automated Guided Vehicles (AGVs) are mobile robots used for transporting materials within a facility. They navigate predefined paths using various technologies such as magnets, lasers, or cameras.

Pros: AGVs are particularly effective in environments where material transport is routine and predictable, such as warehouses and manufacturing plants. They can improve operational efficiency by reducing the time spent on manual transportation tasks.

Cons: However, AGVs have limitations in flexibility. They require a structured environment with established paths, making them less suitable for dynamic settings where paths may frequently change. Additionally, while initial costs may be moderate, integrating AGVs into existing systems can still be a significant investment.

How Does Manual Labor Compare to Robots and Machines?

Manual labor involves human workers performing tasks that may range from simple to complex. It has been the traditional approach to many industrial operations.

Pros: The primary advantage of manual labor is its flexibility; human workers can adapt to changing tasks and conditions. This adaptability is particularly beneficial in industries where tasks are not repetitive or where quick changes are necessary.

Cons: However, manual labor comes with challenges, such as variability in performance and the potential for human error. Moreover, as labor costs rise and the demand for efficiency increases, relying solely on human workers can lead to higher long-term operational costs.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When selecting the right solution for automation needs, B2B buyers should carefully assess their specific operational requirements, budget constraints, and long-term goals. Robots and machines excel in environments requiring precision and automation of repetitive tasks, while AGVs provide efficient material handling in structured settings. Manual labor remains a viable option for tasks that demand flexibility and human judgment. Ultimately, the decision should be driven by a thorough analysis of each alternative’s strengths and weaknesses in relation to the unique context of the buyer’s operations.

Essential Technical Properties and Trade Terminology for robot vs machine

What Are the Key Technical Properties That Differentiate Robots from Machines?

When evaluating robots and machines for industrial applications, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

-

Autonomy Level

– Definition: This property measures the extent to which a machine or robot can operate without human intervention. Robots can be fully autonomous, semi-autonomous, or teleoperated.

– B2B Importance: High autonomy levels reduce labor costs and increase operational efficiency, making robots more attractive for businesses looking to streamline processes. -

Payload Capacity

– Definition: This refers to the maximum weight a robot can handle while performing its tasks. It is typically measured in kilograms or pounds.

– B2B Importance: Understanding payload capacity is critical for applications such as material handling and assembly. Choosing a robot with an appropriate payload ensures operational safety and efficiency. -

Precision and Tolerance

– Definition: Precision refers to the accuracy with which a robot can perform tasks, while tolerance indicates the acceptable deviation from a specified dimension or position.

– B2B Importance: High precision and low tolerance are vital in industries like aerospace and automotive, where even minor errors can lead to significant quality issues or safety hazards. -

Operating Environment

– Definition: This describes the conditions under which a robot or machine can operate, including temperature, humidity, and exposure to chemicals or dust.

– B2B Importance: Selecting machines and robots that can withstand specific environmental conditions is essential for durability and reliability, especially in industries like manufacturing and food processing. -

Programming Flexibility

– Definition: This property refers to how easily a robot can be programmed or reprogrammed to perform different tasks.

– B2B Importance: A robot with high programming flexibility can adapt to changing production needs, making it a long-term investment for businesses looking to scale operations. -

Energy Consumption

– Definition: This indicates the amount of energy a robot or machine requires to operate, often measured in kilowatts per hour (kWh).

– B2B Importance: Lower energy consumption translates to reduced operational costs, which is a significant factor for businesses focused on sustainability and cost efficiency.

What Are the Common Trade Terms Used in Robotics and Machinery?

In the world of robotics and machinery, specific jargon is frequently used that can be critical for effective communication and negotiation. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is essential for businesses seeking quality components and ensuring compatibility within their operational systems. -

MOQ (Minimum Order Quantity)

– Definition: This is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps businesses manage inventory costs and negotiate better terms with suppliers, especially when scaling operations. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document issued by a buyer to solicit price bids from suppliers for specific products or services.

– Importance: Using RFQs effectively can help businesses compare supplier offerings and negotiate favorable terms, ensuring they get the best value for their investments. -

Incoterms (International Commercial Terms)

– Definition: These are a series of pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms is crucial for international trade, as they dictate shipping responsibilities, risks, and costs, aiding in smoother transactions. -

Lead Time

– Definition: This term refers to the amount of time from the initiation of a process until its completion, often used in manufacturing and supply chain contexts.

– Importance: Understanding lead times is essential for project planning and inventory management, helping businesses align production schedules with demand. -

Cobot (Collaborative Robot)

– Definition: A cobot is a robot designed to work alongside humans in a shared workspace, enhancing productivity without the need for safety cages.

– Importance: Cobots are increasingly popular in various industries for their versatility and ability to augment human labor, making them a cost-effective solution for many businesses.

By grasping these technical properties and trade terms, B2B buyers can make better-informed decisions when investing in robots and machines, ultimately enhancing their operational efficiency and competitiveness in the global market.

Navigating Market Dynamics and Sourcing Trends in the robot vs machine Sector

What Are the Current Market Dynamics and Key Trends Affecting the Robot vs Machine Sector?

The global robotics and machinery market is witnessing transformative changes driven by technological advancements and evolving consumer demands. For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing decisions. Key drivers include the increasing automation of industries, the push for efficiency and productivity, and the rise of Industry 4.0, which integrates IoT, AI, and big data into manufacturing processes.

Emerging trends indicate a growing interest in collaborative robots (cobots) that work alongside humans, enhancing productivity without replacing the workforce. Additionally, the demand for service robots is on the rise, particularly in sectors such as healthcare and hospitality, where they provide essential support. B2B buyers should also be aware of the shift towards modular and customizable solutions, allowing businesses to tailor robots and machines to specific operational needs. This flexibility not only improves efficiency but also aids in reducing costs.

In regions like Germany and Brazil, regulatory frameworks and government incentives are fostering innovation in automation technologies. The emphasis on digital transformation presents opportunities for international B2B buyers to invest in state-of-the-art robotic solutions that can enhance operational capabilities and competitiveness.

How Does Sustainability and Ethical Sourcing Influence the Robot vs Machine Sector?

Sustainability is becoming a critical consideration for B2B buyers in the robot and machine sector. The environmental impact of manufacturing processes and product lifecycle management is under scrutiny, prompting businesses to adopt greener practices. This includes sourcing materials that are environmentally friendly and ensuring that the manufacturing process minimizes waste and carbon emissions.

Ethical sourcing is also paramount. B2B buyers are increasingly prioritizing suppliers that adhere to ethical labor practices and demonstrate a commitment to social responsibility. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming essential in supplier assessments. Buyers should seek partners that are transparent about their supply chains and can provide evidence of sustainable practices, such as the use of recycled materials or energy-efficient production methods.

Incorporating sustainability and ethical sourcing into procurement strategies not only enhances brand reputation but can also lead to cost savings and improved operational efficiencies. As global consumers become more environmentally conscious, companies that align with these values are likely to see enhanced customer loyalty and market positioning.

What Is the Historical Context Behind the Robot vs Machine Sector?

The evolution of robots and machines dates back to the Industrial Revolution, which laid the groundwork for mechanization and automation. Early machines were primarily mechanical, designed to enhance productivity in manufacturing settings. As technology progressed, the introduction of electronics and computers led to the development of more sophisticated machines capable of automation.

The late 20th century saw the rise of industrial robots, which revolutionized manufacturing by performing repetitive tasks with precision and speed. This shift was further accelerated by advancements in artificial intelligence and machine learning, giving rise to robots that can learn from their environments and adapt their actions accordingly. Today, the robot vs machine sector is at the forefront of innovation, driven by a blend of traditional engineering principles and cutting-edge technology, making it an exciting area for international B2B buyers to explore and invest in.

Frequently Asked Questions (FAQs) for B2B Buyers of robot vs machine

1. How do I determine whether to invest in robots or traditional machines for my business?

To make an informed decision between robots and traditional machines, assess your operational needs, production volume, and desired flexibility. Robots are ideal for complex tasks requiring precision and adaptability, while traditional machines excel in repetitive, straightforward tasks. Consider factors like the initial investment cost, long-term ROI, and the potential for automation to enhance efficiency. Additionally, evaluate your workforce’s capacity to manage and maintain robotic systems, as this can influence overall productivity.

2. What types of robots are most suitable for manufacturing processes?

The most suitable robots for manufacturing typically fall into two categories: industrial robots and collaborative robots (cobots). Industrial robots are designed for high-volume tasks such as welding, painting, and assembly, providing speed and accuracy. Cobots, on the other hand, work alongside human operators, enhancing productivity without the need for extensive safety measures. Assess your specific manufacturing requirements to determine which type aligns best with your operational goals.

3. What are the key considerations when vetting suppliers for robotic solutions?

When vetting suppliers for robotic solutions, consider their experience, reputation, and track record in your industry. Evaluate their product range, support services, and customization options to ensure they can meet your specific needs. Request case studies or references from previous clients to gauge their reliability. Additionally, assess their technological expertise, warranty terms, and after-sales support to ensure you receive comprehensive service throughout the partnership.

4. How can I customize robotic solutions to fit my specific business needs?

Customization of robotic solutions can be achieved by collaborating with your supplier to define your operational requirements. Discuss your production processes, desired functionalities, and any specific constraints. Many suppliers offer modular designs, allowing you to integrate components or software tailored to your workflows. Ensure that the supplier is open to adjustments and can provide ongoing support for future modifications as your business evolves.

5. What is the typical minimum order quantity (MOQ) for robots and machines?

Minimum order quantities (MOQs) for robots and machines vary by supplier and product type. Some manufacturers may have MOQs as low as one unit for standard robots, while specialized machines may require larger orders. It’s essential to discuss your needs with potential suppliers to understand their MOQ policies. Additionally, consider bulk purchasing options if you plan to scale operations, as this can lead to cost savings and favorable payment terms.

6. What payment terms should I expect when purchasing robots or machines internationally?

Payment terms for international purchases of robots and machines can vary widely. Common practices include upfront deposits (typically 30-50%) followed by the balance upon delivery or installation. Some suppliers may offer financing options or extended payment plans, especially for larger orders. It’s crucial to clarify these terms before finalizing the agreement and to ensure that they align with your cash flow management.

7. How do I ensure quality assurance (QA) for robots and machines sourced internationally?

To ensure quality assurance for internationally sourced robots and machines, request detailed specifications and certifications from suppliers. Implement a rigorous inspection process during manufacturing and prior to shipment. Consider third-party quality inspections or audits to verify compliance with industry standards. Additionally, establish clear communication regarding warranty terms and support services, enabling you to address any issues promptly after delivery.

8. What logistics considerations should I keep in mind when importing robots or machines?

When importing robots or machines, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Engage with experienced freight forwarders familiar with your industry to navigate international shipping challenges. Assess the total landed cost, including tariffs, insurance, and handling fees. Additionally, ensure that your supplier provides adequate packaging and documentation to prevent delays during customs clearance and to protect equipment during transit.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Robot Vs Machine Manufacturers & Suppliers List

1. Reddit – Autonomous Robots

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: A robot is a machine that can perform tasks with more autonomy, resembling human-like abilities. It can make rudimentary decisions and operate without constant human intervention, while a machine typically requires human input to function. Examples include a robot that can flip burgers autonomously versus a machine that needs someone to operate it.

2. Medium – Understanding Robots vs. Machines

Domain: medium.com

Registered: 1998 (27 years)

Introduction: Robots are intelligent machines that can perform tasks autonomously, while machines are devices designed for specific tasks. Key differences include: 1. Autonomy: Robots can make decisions and act independently; machines require constant user control. 2. Senses and Perception: Robots have sensors (cameras, microphones, touch sensors) to interact with their environment; machines follow preset instr…

3. RobotShop – Community Insights

Domain: community.robotshop.com

Registered: 2004 (21 years)

Introduction: This company, RobotShop – Community Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Otomasyon AVM – Robotics Solutions

Domain: otomasyonavm.com

Registered: 2012 (13 years)

Introduction: This company, Otomasyon AVM – Robotics Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. UiPath – Robot Management

Domain: forum.uipath.com

Registered: 2011 (14 years)

Introduction: Machine: A physical or virtual computer host. Robot: A service that runs on the machine, executing processes designed in UiPath Studio. In Orchestrator, the robot object represents the UiPath Robot and defines its capabilities and access to Orchestrator resources. When creating a Robot record in Orchestrator, it requires assigning a Machine and user credentials to define the profile under which th…

6. EVSINT – Intelligent Robotic Solutions

Domain: evsint.com

Registered: 2020 (5 years)

Introduction: Mobile Intelligent Vision, Welding / Cutting Robot, Robotic Tunnel, Rebar Intelligent Production Line, Robotic Welding Station, Laser Welding System for Pillow Plates, Collaborative Robot, Industrial Robot, 4-Axis Robot, 6-Axis Robot, Robot Positioner, Welding Positioner/Turntable, SCARA Robot, Robot Track, Charging Robot, Coffee Robot, Bartending Robot, Automatic Screwing Robotic Machine, Welding…

7. Robotiq – Robotics vs. AI Explained

Domain: blog.robotiq.com

Registered: 2006 (19 years)

Introduction: This company, Robotiq – Robotics vs. AI Explained, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for robot vs machine

The distinction between robots and machines is crucial for international B2B buyers aiming to enhance operational efficiency and productivity. Understanding that robots operate autonomously and can adapt to their environment, while machines require human intervention for task execution, provides a strategic advantage in sourcing decisions. Companies that invest in robotic automation can streamline their processes, reduce labor costs, and improve precision in manufacturing and service delivery.

For businesses in Africa, South America, the Middle East, and Europe, strategic sourcing of robots and machines can be transformative. As industries globally pivot towards automation, leveraging the capabilities of robots can position organizations ahead of competitors who may still rely on traditional machines.

In conclusion, the future of automation is bright, and the opportunity for growth through strategic sourcing of advanced robotic solutions is significant. Companies are encouraged to explore partnerships with robotics providers and invest in technology that aligns with their operational goals. By embracing these innovations, businesses can not only enhance their productivity but also contribute to a more sustainable and efficient industrial landscape.