Introduction: Navigating the Global Market for robot custom

Navigating the complexities of sourcing custom robots can be daunting for international B2B buyers, especially when faced with unique challenges in diverse markets such as Africa, South America, the Middle East, and Europe. With the rapid advancement of technology, businesses are increasingly recognizing the need for tailored robotic solutions to enhance operational efficiency and address specific industry demands. This comprehensive guide serves as a vital resource for organizations looking to understand the landscape of robot customization, detailing various types of robots, their applications across multiple sectors, and essential supplier vetting processes.

From ultra-realistic animatronics for entertainment to rugged robots designed for hazardous environments, the scope of custom robotics is vast. Buyers will gain insights into cost considerations, design flexibility, and the latest technological innovations that can be leveraged to meet their operational needs. Additionally, this guide emphasizes the importance of strategic partnerships with reliable suppliers who can deliver high-quality solutions tailored to unique business challenges.

By empowering B2B buyers with the knowledge needed to make informed purchasing decisions, this guide aims to streamline the sourcing process, ultimately fostering the successful integration of custom robotic solutions into their operations. With actionable insights and expert recommendations, organizations can confidently navigate the global market for custom robots and harness their potential to drive growth and innovation.

Understanding robot custom Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Animatronics | Highly realistic, often designed for entertainment | Theme parks, trade shows, marketing events | Pros: Captivating visuals, unique branding. Cons: High initial investment, complex maintenance. |

| Industrial Robots | Designed for specific manufacturing tasks | Assembly lines, logistics, quality control | Pros: Increased efficiency, consistent output. Cons: Requires skilled operators, potential integration challenges. |

| Exploration Robots | Built for hazardous or remote environments | Mining, environmental monitoring, surveillance | Pros: Enhanced safety, access to difficult areas. Cons: High development costs, may require specialized training. |

| Service Robots | Automated solutions for customer interaction | Hospitality, healthcare, retail | Pros: Improved customer experience, labor cost savings. Cons: Limited functionality, ongoing software updates needed. |

| Agricultural Robots | Tailored for farming tasks like planting and harvesting | Precision agriculture, crop monitoring | Pros: Increased yield, reduced labor costs. Cons: High upfront costs, dependency on technology. |

What Are the Key Characteristics of Custom Animatronics?

Custom animatronics are designed to create engaging and lifelike representations, often used in entertainment settings such as theme parks and marketing events. Their primary features include advanced robotics and realistic movements, which can be tailored to fit specific themes or branding needs. Buyers should consider the complexity of maintenance and the initial investment required, as these factors can significantly impact the total cost of ownership.

How Do Industrial Robots Enhance Manufacturing Efficiency?

Industrial robots are engineered for precision and efficiency in manufacturing environments. They are often employed in assembly lines, logistics, and quality control processes. Their key characteristics include high-speed operation and the ability to perform repetitive tasks with minimal errors. While they offer significant productivity boosts, buyers must evaluate the need for skilled operators and the challenges of integrating these robots into existing workflows.

In What Scenarios Are Exploration Robots Most Effective?

Exploration robots are designed to operate in hazardous or hard-to-reach areas, such as mines or disaster sites. They often come equipped with specialized sensors and cameras to monitor environmental conditions and gather data. The primary benefits include enhanced safety for human workers and the ability to access challenging locations. However, buyers should be aware of the high development costs and the necessity for specialized training to operate these robots effectively.

What Benefits Do Service Robots Provide in Various Industries?

Service robots automate customer interactions and can be found in sectors like hospitality, healthcare, and retail. Their main features include user-friendly interfaces and the ability to perform various tasks, such as greeting customers or delivering items. They can significantly enhance customer experience and reduce labor costs. However, potential buyers should consider the limitations in functionality and the need for regular software updates to ensure optimal performance.

How Can Agricultural Robots Transform Farming Practices?

Agricultural robots are customized for tasks such as planting, monitoring, and harvesting crops. They leverage advanced technology to increase yields and reduce labor costs. Key characteristics include precision in operation and the ability to collect data on crop health. While they offer substantial benefits, buyers need to factor in the high upfront investment and the reliance on technology, which may require additional training and maintenance resources.

Key Industrial Applications of robot custom

| Industry/Sector | Specific Application of robot custom | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated Assembly Lines | Increased productivity and reduced labor costs | Compatibility with existing systems and scalability |

| Agriculture | Autonomous Crop Monitoring Robots | Enhanced yield through precise data collection | Terrain adaptability and sensor integration |

| Healthcare | Custom Surgical Robots | Improved surgical precision and reduced recovery times | Compliance with medical regulations and customization options |

| Security | Surveillance and Reconnaissance Robots | Enhanced safety and operational efficiency | Remote operation capabilities and ruggedness |

| Entertainment & Events | Custom Animatronics for Exhibitions and Trade Shows | Unique audience engagement and brand differentiation | Design flexibility and integration with event themes |

How is ‘robot custom’ used in the manufacturing sector, and what problems does it solve?

In the manufacturing sector, custom robots are increasingly employed in automated assembly lines. These robots streamline production processes, reducing the need for manual labor while increasing efficiency. By integrating advanced robotics, companies can minimize human error, enhance product quality, and significantly lower operational costs. International buyers, particularly from regions like Africa and South America, should consider the compatibility of these robots with existing systems and their ability to scale with production demands.

What role do custom robots play in agriculture, and what benefits do they provide?

Custom robots in agriculture, such as autonomous crop monitoring systems, facilitate precise data collection on crop health and soil conditions. This technology allows farmers to make informed decisions that enhance yield and resource management. For B2B buyers, especially in developing regions, sourcing considerations include the robot’s adaptability to various terrains and its ability to integrate with existing agricultural technologies, ensuring effective implementation in diverse farming conditions.

How are custom surgical robots transforming the healthcare industry?

In healthcare, custom surgical robots are revolutionizing surgical procedures by providing enhanced precision and control, which leads to better patient outcomes and shorter recovery times. These robots are tailored to specific surgical needs, addressing challenges such as complex procedures and limited access to certain body areas. Buyers in this sector must prioritize compliance with stringent medical regulations and seek customization options that align with their surgical practices.

What benefits do surveillance and reconnaissance robots offer in security applications?

In the security sector, custom robots are deployed for surveillance and reconnaissance tasks, significantly enhancing safety measures. These robots can monitor environments that are hazardous to humans, providing real-time data and situational awareness. For international B2B buyers, key sourcing considerations include the robot’s remote operation capabilities and its durability in various environmental conditions, ensuring reliable performance in critical security applications.

How do custom animatronics enhance engagement in entertainment and events?

Custom animatronics are increasingly used in exhibitions and trade shows to create engaging and memorable experiences for attendees. These robots can be designed to reflect brand themes and capture audience attention, thereby differentiating businesses in competitive markets. For buyers in the entertainment sector, it is crucial to consider design flexibility and the ability to integrate animatronics seamlessly into event concepts, ensuring a cohesive and impactful presentation.

3 Common User Pain Points for ‘robot custom’ & Their Solutions

Scenario 1: Navigating Complex Customization Needs for Robotics

The Problem:

B2B buyers often face the daunting challenge of articulating their specific needs when it comes to custom robotics. Many organizations have unique operational requirements, yet translating these needs into technical specifications can be overwhelming. For instance, a mining company in Africa might need a robot capable of navigating hazardous environments while performing specific tasks, such as remote surveillance or equipment handling. Without a clear understanding of the technical capabilities available, buyers risk investing in solutions that do not fully meet their operational demands.

The Solution:

To effectively source custom robots, buyers should begin by conducting a thorough needs assessment. This involves engaging key stakeholders across departments to identify pain points and desired functionalities. Once the requirements are clearly defined, collaborating with a manufacturer experienced in custom robotics is essential. Buyers should seek partners who offer a comprehensive consultation process, allowing for iterative design discussions. Additionally, utilizing 3D modeling or simulation tools can help visualize the robot’s capabilities before production, ensuring alignment with business needs. By prioritizing clear communication and leveraging technology, buyers can navigate the complexities of custom robotics more effectively.

Scenario 2: Overcoming Budget Constraints in Custom Robotics

The Problem:

Budget limitations are a common pain point for B2B buyers looking to invest in custom robotics. Organizations, particularly small to mid-sized enterprises (SMEs), may struggle to justify the high costs associated with designing and manufacturing bespoke robotic solutions. This concern is particularly prevalent in regions like South America, where economic fluctuations can impact available funding for technology investments.

The Solution:

To overcome budget constraints, buyers should consider a phased approach to robot customization. Instead of attempting to build a fully functional robot in one go, companies can start with a semi-custom solution that addresses immediate needs while leaving room for future enhancements. Engaging with manufacturers who offer flexible pricing models or financing options can also help mitigate upfront costs. Furthermore, buyers should conduct a cost-benefit analysis to evaluate the long-term return on investment (ROI) of implementing custom robots. Highlighting potential savings in labor costs, increased efficiency, and improved safety can provide the necessary justification for the investment, making it easier to secure funding.

Scenario 3: Ensuring Seamless Integration of Custom Robots into Existing Operations

The Problem:

After investing in custom robotics, many B2B buyers struggle with the integration of these new solutions into their existing workflows. This challenge can lead to operational disruptions and reduced productivity, particularly if the robot does not align with current systems or processes. For example, a logistics company may find that a newly acquired robotic sorting system is incompatible with its inventory management software, causing delays and inefficiencies.

The Solution:

To facilitate seamless integration, it is crucial for buyers to work closely with their robotics manufacturer throughout the implementation process. Before finalizing any custom design, buyers should ensure that the manufacturer understands their existing systems and workflows. Conducting a pilot program with the custom robot can help identify integration challenges early on. Additionally, investing in training for staff can significantly enhance the adoption of new technology. Providing comprehensive training sessions on both the technical operation of the robot and its impact on workflow can help employees feel more comfortable and empowered, ultimately leading to a smoother integration process. By prioritizing collaboration and training, buyers can maximize the effectiveness of their custom robotic solutions.

Strategic Material Selection Guide for robot custom

What Are the Key Properties of Common Materials Used in Custom Robotics?

When selecting materials for custom robotics, it is crucial to consider properties such as strength, weight, corrosion resistance, and thermal stability. Here, we analyze four common materials used in robot construction: aluminum, stainless steel, plastics (specifically ABS), and carbon fiber. Each material presents unique advantages and challenges that can significantly impact the performance and suitability of the final product.

How Does Aluminum Contribute to Robotics Applications?

Aluminum is widely favored in robotics due to its excellent strength-to-weight ratio. It typically has a temperature rating of up to 150°C and is resistant to corrosion, making it suitable for various environments.

Pros: Aluminum is lightweight, making it ideal for mobile robots where weight is a critical factor. It is also relatively inexpensive and easy to machine, which simplifies the manufacturing process.

Cons: While aluminum is durable, it is less robust than some other metals, such as steel. It can also be prone to fatigue over time, especially in high-stress applications.

Impact on Application: Aluminum is commonly used in structural components and frames where weight savings are essential. However, it may not be suitable for applications requiring high strength under extreme conditions.

Why Choose Stainless Steel for Custom Robotics?

Stainless steel is renowned for its exceptional corrosion resistance and high strength, making it suitable for harsh environments, including marine and industrial settings. It can withstand temperatures up to 800°C depending on the grade used.

Pros: Its durability and resistance to wear and tear make it ideal for long-term applications. Stainless steel also offers good aesthetic qualities, which can be important for consumer-facing robots.

Cons: The primary drawback is its weight, which can hinder mobility in certain robotic designs. Additionally, stainless steel is generally more expensive than aluminum.

Impact on Application: Stainless steel is often used in components that require high strength and corrosion resistance, such as robotic arms and joints, especially in environments exposed to moisture or chemicals.

What Role Do Plastics Like ABS Play in Robotics?

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic that is lightweight and easy to mold, making it suitable for various robotic applications, especially in non-structural components. It typically has a service temperature of around 80°C.

Pros: ABS is cost-effective and can be easily manufactured using techniques like injection molding. It also provides good impact resistance and can be colored easily.

Cons: While ABS is lightweight, it is less durable than metals and can deform under high temperatures or stress. Its chemical resistance is also limited compared to metals.

Impact on Application: ABS is ideal for housings, covers, and non-load-bearing parts of robots, particularly in environments where weight savings are crucial, but extreme durability is not as critical.

How Does Carbon Fiber Enhance Robotics Design?

Carbon fiber is increasingly being used in high-performance robotics due to its exceptional strength and lightweight properties. It can withstand temperatures up to 200°C and offers excellent rigidity.

Pros: Carbon fiber is significantly lighter than metals while providing superior strength. It is also resistant to corrosion and fatigue, making it ideal for high-performance applications.

Cons: The primary limitation is its high cost and complexity in manufacturing. Carbon fiber components often require specialized techniques and equipment, which can increase production time and costs.

Impact on Application: Carbon fiber is perfect for advanced robotics applications that require both strength and weight efficiency, such as drones and high-speed robotic arms.

Summary of Material Properties for Custom Robotics

| Material | Typical Use Case for robot custom | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Structural components | Lightweight and easy to machine | Less robust than steel | Medium |

| Stainless Steel | Robotic arms and joints | High strength and corrosion resistance | Heavier and more expensive than aluminum | High |

| ABS | Housings and covers | Cost-effective and easy to mold | Less durable and limited chemical resistance | Low |

| Carbon Fiber | High-performance applications | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

This analysis provides B2B buyers with actionable insights into material selection for custom robotics, considering performance, cost, and specific application needs. Understanding these factors is essential for making informed decisions that align with project requirements and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for robot custom

What Are the Main Stages of Manufacturing Custom Robots?

The manufacturing process for custom robots involves several critical stages that ensure the final product meets specific client requirements and industry standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves selecting the appropriate materials based on the robot’s intended use. Common materials include metals, plastics, and composites. Advanced manufacturing techniques like 3D printing and CNC milling are often employed to create parts with high precision. The choice of materials can significantly impact the robot’s durability, weight, and functionality.

-

Forming: During this stage, raw materials are shaped into components that will form the robot. Techniques such as laser cutting, injection molding, and bending are frequently used. For example, 3D laser scanning can be utilized to create accurate digital models, which are then transformed into physical components. This process is essential for achieving the desired design specifications.

-

Assembly: Once individual components are formed, the assembly phase begins. This includes integrating mechanical, electrical, and software systems to create a functional robot. Skilled technicians often conduct this work, ensuring all components fit together seamlessly. Each assembly line may focus on different types of robots, from simple designs to complex, multi-functional systems.

-

Finishing: The final manufacturing stage involves applying surface treatments and coatings to enhance aesthetics and protect against environmental factors. This may include painting, anodizing, or applying protective films. Additionally, this stage may include the installation of sensors and other electronic components that will be vital for the robot’s operation.

How Is Quality Assurance Implemented in Custom Robot Manufacturing?

Quality assurance (QA) is crucial in ensuring that custom robots meet stringent performance and safety standards. Various international and industry-specific standards guide this process, with ISO 9001 being one of the most recognized.

-

International Standards: Compliance with ISO 9001 ensures that manufacturers maintain a consistent quality management system. This standard emphasizes continuous improvement and customer satisfaction, crucial for B2B relationships. Additionally, industry-specific certifications such as CE marking for European markets or API standards for robotics used in hazardous environments are often required.

-

Quality Control Checkpoints: The QA process typically involves several checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter the manufacturing process. Suppliers must provide documentation to demonstrate compliance with agreed specifications.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to ensure that each stage meets predefined standards. This can include measuring tolerances and ensuring assembly accuracy.

– Final Quality Control (FQC): After assembly, a comprehensive evaluation is performed. This may involve functional testing, safety assessments, and performance verification to ensure the robot operates as intended. -

Common Testing Methods: Various testing methods are employed to verify the quality of custom robots. These can include:

– Functional Testing: Ensures that the robot performs its intended tasks.

– Environmental Testing: Assesses how well the robot withstands various environmental conditions, such as humidity and temperature extremes.

– Safety Testing: Evaluates the robot’s compliance with safety standards to protect users and the environment.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is critical for ensuring reliable partnerships. Here are some actionable insights:

-

Supplier Audits: Conducting on-site audits can provide in-depth insight into a manufacturer’s quality control processes. During an audit, buyers can assess compliance with international standards, review documentation, and observe manufacturing practices firsthand.

-

Quality Reports: Requesting detailed quality reports from suppliers can help buyers understand the effectiveness of their QA processes. These reports should include information on defect rates, compliance with standards, and results from testing phases.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality management practices. These organizations can conduct inspections at various stages of production and provide certifications that enhance trust.

-

Understanding QC Nuances for International Buyers: Different regions may have varying expectations for quality assurance. For example, European buyers may prioritize CE certification, while buyers in the Middle East may focus on compliance with local regulations. Understanding these nuances is essential for establishing effective communication and expectations with suppliers.

What Are the Key Considerations for International B2B Buyers?

When engaging with suppliers for custom robots, international buyers should consider several factors that can affect their procurement process:

-

Cultural and Regulatory Differences: Be aware of the cultural and regulatory landscape in the supplier’s country. This includes understanding local labor laws, environmental regulations, and industry standards, which can impact production timelines and costs.

-

Communication and Language Barriers: Effective communication is vital for successful collaboration. Establishing clear channels for communication can help mitigate misunderstandings that may arise due to language differences.

-

Supply Chain Logistics: Consider the logistics of shipping and handling custom robots. Factors such as import/export regulations, tariffs, and shipping times can influence the overall cost and delivery schedule.

-

Long-term Partnerships: Building long-term relationships with suppliers can lead to better pricing, priority service, and collaboration on future projects. Consider suppliers who demonstrate a commitment to quality and customer satisfaction.

By understanding the manufacturing processes and quality assurance measures in custom robot production, B2B buyers can make informed decisions that align with their business needs and foster successful partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘robot custom’

Introduction

This guide serves as a practical checklist for B2B buyers seeking to procure custom robots tailored to their specific needs. The process of sourcing custom robotics can be complex, involving multiple factors such as technical specifications, supplier capabilities, and compliance standards. By following this checklist, buyers can streamline their procurement process and ensure they select a partner that aligns with their requirements.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your custom robot. This includes its intended use, operational environment, and specific functionalities.

– Why it matters: A well-defined specification helps prevent misunderstandings and ensures that potential suppliers can meet your expectations.

– What to consider: Think about payload capacity, mobility requirements, and any necessary sensors or software capabilities.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers specializing in custom robotics. Look for companies with a proven track record in your industry and similar applications.

– Why it matters: Understanding suppliers’ backgrounds helps gauge their expertise and reliability.

– What to look for: Review case studies, client testimonials, and their portfolio of previous projects to assess their capabilities.

Step 3: Evaluate Supplier Capabilities

Before committing, it’s crucial to vet suppliers thoroughly. Evaluate their manufacturing capabilities, design processes, and technological resources.

– Why it matters: The supplier’s ability to deliver on your specifications relies heavily on their in-house capabilities.

– What to consider: Inquire about their use of advanced technologies such as 3D printing, CNC machining, and software development.

Step 4: Verify Compliance and Certifications

Ensure that the suppliers you are considering comply with industry standards and possess the necessary certifications.

– Why it matters: Compliance with safety and quality standards is essential for minimizing risks and ensuring product reliability.

– What to check: Look for certifications relevant to robotics and any specific regulations in your region or industry.

Step 5: Request Prototypes or Samples

Ask potential suppliers to provide prototypes or samples of their previous work, if available. This allows you to assess the quality and functionality of their designs.

– Why it matters: Physical samples offer insight into the supplier’s craftsmanship and attention to detail.

– What to observe: Pay attention to the materials used, finish quality, and operational performance during demonstrations.

Step 6: Discuss Customization Options

Engage suppliers in discussions about customization capabilities. Understand how flexible they are in adapting designs to meet your specific needs.

– Why it matters: Custom robotics often require unique features; a supplier’s willingness to accommodate changes can significantly impact your project’s success.

– What to explore: Talk about potential design modifications, software adjustments, and additional functionalities that may be important for your application.

Step 7: Negotiate Terms and Review Contracts

Once you have selected a supplier, negotiate the terms of the contract carefully. Ensure that all aspects of the project, including timelines, costs, and warranties, are clearly defined.

– Why it matters: A well-structured contract protects your interests and clarifies expectations for both parties.

– What to include: Be sure to address payment terms, delivery schedules, and any penalties for delays or defects.

By following this checklist, you can enhance your sourcing strategy for custom robots, ensuring a successful partnership that meets your specific operational needs.

Comprehensive Cost and Pricing Analysis for robot custom Sourcing

What Are the Key Cost Components in Custom Robot Sourcing?

When engaging in custom robot sourcing, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Advanced materials such as high-grade plastics, metals, and electronics can increase expenses but often enhance durability and performance. Consideration of environmental factors, especially in regions with extreme conditions, can also influence material selection.

-

Labor: Labor costs encompass both direct and indirect labor. Skilled engineers and technicians are essential for design and assembly, especially for customized solutions. Labor rates can vary widely based on geographical location, with some regions having lower costs, which can affect overall pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help mitigate these costs, making it vital to choose suppliers with optimized production capabilities.

-

Tooling: Custom robots often require specialized tooling, which can be a significant initial investment. This cost should be amortized over the expected production volume to assess its impact on unit pricing accurately.

-

Quality Control (QC): Ensuring high-quality standards necessitates rigorous QC processes, which can add to overall costs. Certifications (e.g., ISO) may also be required, particularly for industries with strict compliance standards, influencing supplier selection and pricing.

-

Logistics: Transportation and handling can significantly affect the total cost, especially for international shipments. Factors such as shipping methods, customs duties, and insurance should be factored into the total logistics cost.

-

Margin: Suppliers will typically apply a profit margin to cover their operational risks and investments. This margin can vary based on market competition and the uniqueness of the product.

How Do Price Influencers Affect Custom Robot Sourcing?

Several factors can influence pricing in custom robot sourcing:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit prices due to economies of scale. Establishing long-term relationships with suppliers can also result in better pricing agreements.

-

Specifications and Customization: The complexity and specificity of the robot design directly affect costs. Highly specialized robots or those requiring advanced technology will typically command higher prices.

-

Materials and Quality Certifications: Opting for premium materials and ensuring compliance with quality standards can drive up costs but may offer better performance and longevity, providing a favorable Total Cost of Ownership (TCO) in the long run.

-

Supplier Factors: The reputation, experience, and geographical location of the supplier can significantly affect pricing. Established suppliers may charge a premium for their expertise and reliability, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding the shipping terms agreed upon (e.g., FOB, CIF) is crucial as it influences who bears the risk and cost of transportation, thereby impacting the final price.

What Are the Best Buyer Tips for Negotiating Custom Robot Prices?

-

Negotiate Effectively: Engage suppliers early in the process to discuss pricing structures and explore potential discounts for larger orders or long-term contracts. Leverage quotes from multiple suppliers to strengthen your negotiating position.

-

Focus on Cost-Efficiency: Beyond the initial price, evaluate the TCO. Consider factors such as maintenance, operational efficiency, and potential downtime, which can impact the overall investment value.

-

Understand Pricing Nuances for International Purchases: For buyers in Africa, South America, the Middle East, and Europe, be aware of currency fluctuations, import tariffs, and local regulations that may influence the final cost of acquisition. Establishing a local partnership can mitigate some of these challenges.

-

Request Detailed Quotations: Ensure that quotes include a breakdown of costs, allowing for a clearer understanding of where money is being spent. This transparency can facilitate better comparisons between suppliers.

-

Consider Supplier Support: Evaluate the level of post-sale support and warranty terms offered by suppliers, as these can add significant value and affect overall satisfaction with the purchase.

By comprehensively analyzing these cost components and pricing influencers, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing robot custom With Other Solutions

When considering the integration of robotics solutions in business operations, it is essential to evaluate various alternatives that may offer similar functionalities. This analysis will compare ‘robot custom’ with two viable alternatives: semi-custom robotics and traditional automation systems. By understanding the strengths and weaknesses of each option, B2B buyers can make informed decisions tailored to their specific needs.

| Comparison Aspect | Robot Custom | Semi-Custom Robotics | Traditional Automation Systems |

|---|---|---|---|

| Performance | High adaptability for specific tasks | Moderate adaptability with predefined options | High efficiency for repetitive tasks |

| Cost | Higher upfront investment | Moderate cost due to standard components | Lower initial investment but may require upgrades |

| Ease of Implementation | Requires detailed planning and design | Faster deployment with limited customization | Generally straightforward but can be complex |

| Maintenance | Potentially high due to unique components | Moderate, as parts are standard | Usually lower, with established support |

| Best Use Case | Unique applications needing specific designs | Standard tasks needing some customization | High-volume, repetitive manufacturing tasks |

What Are the Pros and Cons of Robot Custom Solutions?

Robot Custom

The primary advantage of custom robotics lies in its ability to cater to unique operational requirements. Businesses can design robots that fit specific tasks, which can lead to significant performance improvements. However, this customization often comes with a higher cost and longer implementation times, as each solution requires careful planning and design. Maintenance can also be complex due to the uniqueness of the components.

How Do Semi-Custom Robotics Compare?

Semi-Custom Robotics

Semi-custom solutions offer a middle ground between fully custom designs and off-the-shelf products. They allow for some degree of customization, making them suitable for businesses that need tailored functionalities without the extensive investment of a fully custom robot. The implementation is usually faster than fully custom solutions, and costs are more manageable. However, the limitation in customization may hinder performance for specific tasks, as these robots are designed to meet a broader range of applications.

Why Consider Traditional Automation Systems?

Traditional Automation Systems

Traditional automation systems are well-suited for businesses focused on high-volume production or repetitive tasks. Their lower initial investment and straightforward implementation make them attractive for many companies. Additionally, maintenance is generally easier due to the availability of standardized parts and established service networks. However, these systems may lack the flexibility needed for more complex or specialized tasks, limiting their effectiveness in dynamic operational environments.

How Can B2B Buyers Make the Right Choice?

In choosing the right solution, B2B buyers should assess their operational needs, budget constraints, and long-term goals. For organizations requiring specialized tasks and willing to invest time and resources, custom robotics may be the best fit. Conversely, businesses with moderate customization needs might find semi-custom solutions more efficient. For those focused on high-volume, repetitive tasks, traditional automation systems could offer the best return on investment. Ultimately, the decision should align with the specific operational challenges and strategic objectives of the organization.

Essential Technical Properties and Trade Terminology for robot custom

What Are the Key Technical Properties for Custom Robots?

In the realm of custom robotics, understanding the essential technical properties is crucial for making informed purchasing decisions. Here are some key specifications that buyers should consider:

-

Material Grade

The material used in robot construction can significantly impact durability, weight, and performance. Common materials include aluminum for lightweight designs, stainless steel for strength and corrosion resistance, and high-grade plastics for lightweight applications. Selecting the right material is critical, as it affects not only the robot’s lifespan but also its suitability for specific environments, such as outdoor or hazardous locations. -

Tolerance

Tolerance refers to the allowable deviation from a specified dimension in the robot’s components. High precision is vital for robotic applications where exact movements and interactions are required, such as in assembly lines or surgical procedures. In B2B contexts, tighter tolerances can lead to improved performance and reliability, thereby reducing the likelihood of costly errors or rework. -

Payload Capacity

This specification indicates the maximum weight a robot can handle while operating efficiently. Understanding payload capacity is essential for applications that involve lifting or transporting materials. A robot with insufficient payload capacity can lead to operational failures, while one that is over-engineered for a task may incur unnecessary costs. -

Operational Range

The operational range defines the distance a robot can travel or operate effectively, which is particularly important for mobile robots. This property impacts the robot’s application in various industries, such as agriculture or surveillance. A robot with a limited range may not be suitable for expansive environments, leading to inefficiencies. -

Battery Life and Charging Time

For autonomous robots, battery life is a critical factor that determines how long a robot can operate without needing a recharge. Additionally, the charging time can affect overall productivity, especially in applications requiring continuous operation. Buyers should assess both specifications to ensure that the robot meets their operational demands. -

Control Interface

The control interface refers to the system through which operators interact with the robot. A user-friendly interface can streamline operations and reduce training time for staff. In contrast, a complex control system may lead to increased operational errors and reduced efficiency.

What Are Common Trade Terms in the Custom Robotics Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the custom robotics market. Here are several key terms to know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In robotics, an OEM may provide specific components like sensors or actuators that are integral to the final product. Understanding OEM relationships can help buyers identify reliable suppliers and assess compatibility. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to produce or sell. For B2B buyers, knowing the MOQ is vital for budgeting and inventory management. If the MOQ is too high, it could lead to excess inventory, impacting cash flow. -

RFQ (Request for Quotation)

An RFQ is a formal document that solicits price bids from suppliers for specific products or services. This process helps buyers compare costs and terms among different vendors, facilitating informed purchasing decisions. A well-prepared RFQ can lead to more competitive pricing and better service terms. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for understanding shipping costs, delivery responsibilities, and risk management in cross-border trade. -

Customization

Customization refers to the process of modifying a standard product to meet specific client needs. In robotics, this could involve tailoring hardware or software to suit unique operational requirements. Understanding customization options is essential for buyers looking to optimize robot performance for their particular applications. -

Prototyping

Prototyping is the process of creating a preliminary model of a robot to test concepts and functionalities before mass production. It allows clients to evaluate design and performance, reducing the risk of costly errors in the final product. Engaging in prototyping can provide significant insights into feasibility and cost-effectiveness for custom projects.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of the custom robotics market more effectively, ensuring they make decisions that align with their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the robot custom Sector

What Are the Current Market Dynamics and Key Trends in the Robot Custom Sector?

The global robot custom sector is witnessing significant growth driven by the increasing demand for automation across various industries. Key trends influencing this market include the rise of Industry 4.0, which emphasizes smart manufacturing and IoT integration, and a shift towards more personalized and versatile robotic solutions. B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking custom robots to address unique challenges such as labor shortages, safety concerns in hazardous environments, and the need for enhanced operational efficiency.

Furthermore, advancements in technology, such as 3D printing and AI-driven robotics, are enabling the development of highly specialized and flexible robotic solutions. Companies are now able to prototype and produce robots tailored to specific applications, from agricultural automation in rural settings to advanced surveillance systems in urban environments. This customization can lead to significant cost savings and improved return on investment (ROI) for businesses.

Another emerging trend is the focus on collaborative robots, or cobots, designed to work alongside human workers. This trend is particularly relevant in sectors such as manufacturing and logistics, where the need for human-robot collaboration is growing. The ability to customize these robots for specific tasks enhances their usability and acceptance in the workplace, making them an attractive option for B2B buyers.

How Important Is Sustainability and Ethical Sourcing in the Robot Custom Sector?

Sustainability and ethical sourcing are becoming increasingly important in the robot custom sector, influenced by growing environmental awareness and regulatory pressures. B2B buyers are now prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using eco-friendly materials and minimizing waste in production processes. This shift is not only beneficial for the environment but also enhances a company’s brand reputation among consumers and stakeholders.

The use of “green” certifications and materials is gaining traction as companies look to align with global sustainability goals. For instance, incorporating recyclable components and energy-efficient technologies in robotic designs can significantly reduce the environmental impact of these products. Suppliers that can provide transparency regarding their sourcing and production practices are likely to gain a competitive edge.

Moreover, ethical supply chains are essential in today’s global market, where buyers are increasingly scrutinizing the labor practices of their suppliers. Ensuring that materials are sourced responsibly and that workers are treated fairly is crucial for maintaining trust and compliance with international labor standards. Companies that prioritize ethical practices are not only contributing to social responsibility but also appealing to a broader base of conscientious buyers.

What Is the Evolution of the Robot Custom Sector?

The evolution of the robot custom sector can be traced back to the early days of industrial robotics in the mid-20th century, where robots were primarily used for repetitive tasks in manufacturing. As technology advanced, the introduction of programmable robots opened new avenues for customization, allowing businesses to tailor robotic solutions to meet specific operational needs.

In the 1980s and 1990s, the emergence of computer-aided design (CAD) and rapid prototyping further revolutionized the sector. These technologies enabled faster and more efficient design processes, making it feasible for companies to produce custom robots with greater precision and reduced lead times. The turn of the century saw the rise of automation and robotics in various sectors beyond manufacturing, including healthcare, agriculture, and logistics.

Today, the focus on smart robotics and AI integration marks the latest phase in this evolution. Custom robots are now being designed not just for functionality but also for adaptability, enabling them to learn and evolve based on their environments and tasks. This trend is set to continue as businesses increasingly recognize the value of personalized robotic solutions in enhancing operational efficiency and addressing complex challenges in an ever-changing market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of robot custom

-

How do I solve challenges with sourcing custom robots for my business?

To address sourcing challenges, start by clearly defining your requirements, including specifications, functionality, and budget. Research potential suppliers with proven experience in creating custom robots for your industry. Utilize online platforms, trade shows, and industry networks to identify reputable manufacturers. Engage in initial discussions to gauge their capabilities and willingness to customize solutions. Don’t hesitate to ask for case studies or references to ensure they can meet your unique needs effectively. -

What is the best approach to vet suppliers for custom robotics?

When vetting suppliers, evaluate their industry experience, technical capabilities, and past projects. Request a portfolio showcasing their previous custom robot designs and client testimonials. Check for certifications and compliance with international quality standards. It’s also beneficial to conduct site visits or video tours of their facilities. Finally, consider their responsiveness and communication style, as a reliable partner should be attentive and transparent throughout the process. -

What are the typical minimum order quantities (MOQ) for custom robots?

Minimum order quantities for custom robots can vary significantly based on the complexity of the design and the supplier’s production capabilities. Generally, MOQs can range from a single prototype to several units, especially for more complex designs that require specialized materials or technology. Discussing your specific needs with potential suppliers can help clarify their MOQ policies, as some may offer flexibility for first-time clients or smaller projects. -

How can I ensure quality assurance in custom robot manufacturing?

To ensure quality assurance, request detailed information about the supplier’s quality control processes. This includes inspections at various stages of production, testing protocols, and compliance with international quality standards such as ISO. Ask for documentation of quality assurance measures and consider arranging for third-party inspections if necessary. Establish clear communication regarding expectations and deliverables to avoid any misunderstandings during the manufacturing process. -

What payment terms should I expect when sourcing custom robots internationally?

Payment terms can vary widely among suppliers, but common practices include upfront deposits, milestone payments during production, and final payments upon delivery. It’s crucial to clarify terms in advance and consider using secure payment methods like letters of credit to protect your investment. Additionally, factor in any currency exchange risks and potential tariffs that may affect the overall cost of the transaction. -

What logistics considerations should I keep in mind for importing custom robots?

When importing custom robots, consider shipping methods, customs regulations, and potential tariffs in your destination country. Work closely with your supplier to understand their shipping practices and any available options for expedited delivery. Ensure that all documentation, including invoices and customs declarations, is complete and accurate to avoid delays. Additionally, assess the supplier’s experience with international logistics to ensure a smooth shipping process. -

How can I customize a robot to fit specific operational needs?

Customization starts with a detailed assessment of your operational needs and challenges. Engage with your supplier early in the design process to discuss potential features, attachments, and software requirements that can enhance the robot’s functionality. Be open about your goals and provide examples of similar solutions if possible. The best suppliers will collaborate with you to design and create a robot tailored to your specifications while offering valuable insights based on their expertise. -

What are the common applications for custom robots across various industries?

Custom robots are utilized in diverse applications, including manufacturing automation, healthcare assistance, agricultural tasks, and hazardous environment exploration. In industrial settings, they can enhance efficiency through automated assembly lines or material handling. In healthcare, robots can assist in surgery or patient care. Additionally, sectors such as mining and construction leverage robots for inspection and safety monitoring. Identifying the specific needs of your industry will help you determine the most suitable robotic solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Robot Custom Manufacturers & Suppliers List

1. Animatronic Robotics – Custom Entertainment Solutions

Domain: animatronicrobotics.com

Registered: 2010 (15 years)

Introduction: Custom Entertainment Solutions specializes in creating personalized animatronics, robotics, and special effects solutions since 2005. Key offerings include ultra-realistic animatronics, custom animatronics for tradeshows, and advanced robotic designs. Notable products include Ultra Realistic Artificial Hands, Mecha Hitsu Gen2, Alien Mecha TE ADV Robot Hand, Limited Edition Android Doppleganger Rep…

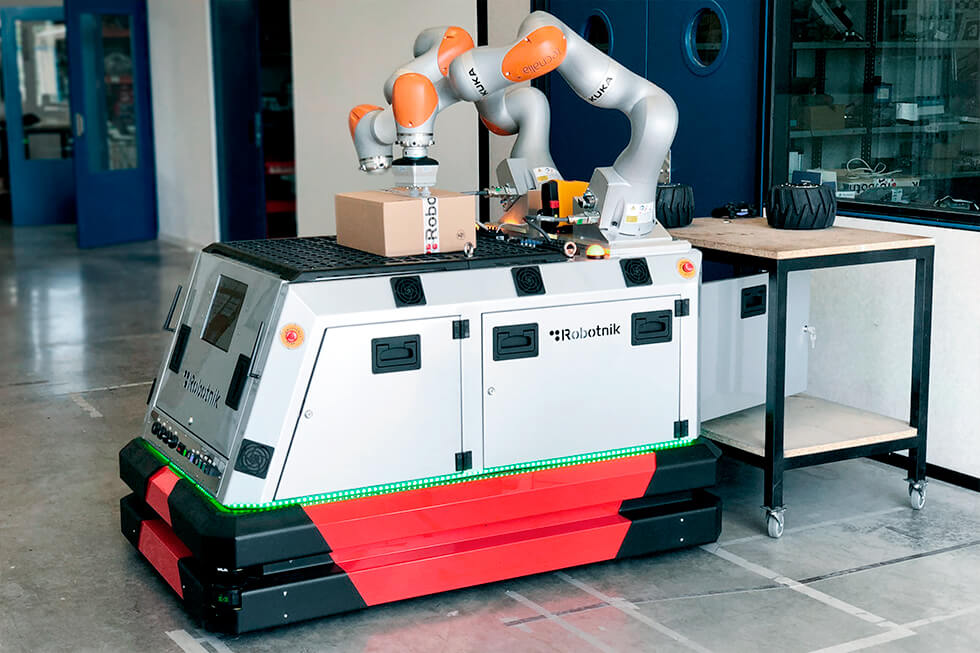

2. SuperDroid Robots – Custom Robotic Solutions

Domain: superdroidrobots.com

Registered: 2002 (23 years)

Introduction: Custom and semi-custom robots designed to solve real-world business challenges across various industries. Applications include exploration, monitoring, and accessing hard-to-reach locations. Features include:

– 360° Pan Camera with 20x Zoom

– 6-Axis Arm capable of lifting 20 pounds

– Weather-resistant chassis with tracks for outdoor terrain

– Split-screen camera display

– Parallel Finger Gripper w…

3. ManiSkill – Robot Simulation Framework

Domain: maniskill.readthedocs.io

Introduction: ManiSkill supports importing robots and assets via URDF and MJCF definitions. Key features include: 1. Flexibility to change mounted sensors, controllers, and robot embodiments. 2. Requirements for usability: creating a robot class with a uid, defining keyframes, defining robot controllers, and modeling materials for functionality. 3. Supports importing URDF and MJCF files, with automatic creation…

4. Oz Robotics – Robotics & Drones

Domain: ozrobotics.com

Registered: 2004 (21 years)

Introduction: This company, Oz Robotics – Robotics & Drones, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Walmart – 6 Rubber Robot

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – 6 Rubber Robot, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. ZeroPopArt – Custom Robots

Domain: zeropopart.com

Registered: 2020 (5 years)

Introduction: {“collection”:”Custom Robots”,”products”:[{“name”:”Custom Small Robot”,”regular_price”:”$110.00″,”sale_price”:”$110.00″,”availability”:”In stock”},{“name”:”Custom Medium Robot”,”regular_price”:”$140.00″,”sale_price”:”$140.00″,”availability”:”In stock”},{“name”:”Custom Large Robot”,”regular_price”:”$180.00″,”sale_price”:”$180.00″,”availability”:”In stock”}]}

7. Pollen Robotics – Reachy Mini

Domain: pollen-robotics.com

Registered: 2016 (9 years)

Introduction: Reachy Mini is the first open-source desktop robot designed for human-robot interaction and creative applications. It is priced at $299 and sold as a kit for self-assembly, with shipping expected by the end of summer 2025. The robot enables rapid prototyping of AI applications with full open-source hardware and software integration. It features pre-installed apps and a growing library of community…

Strategic Sourcing Conclusion and Outlook for robot custom

What Are the Key Benefits of Strategic Sourcing in Custom Robotics?

As the demand for custom robotic solutions continues to grow, strategic sourcing emerges as a critical factor for international B2B buyers. By collaborating with experienced manufacturers, businesses can leverage advanced technologies such as 3D printing, CNC milling, and robotics design expertise to create tailored solutions that meet their unique operational challenges. This approach not only enhances product quality but also reduces lead times and minimizes costs, thereby maximizing return on investment.

How Can Businesses in Emerging Markets Leverage Custom Robotics?

For buyers in Africa, South America, the Middle East, and Europe, the potential applications of custom robotics are vast and varied. From agricultural automation to advanced surveillance systems, the adaptability of these solutions can significantly improve efficiency and safety across multiple sectors. Engaging with suppliers who understand local market needs and regulatory frameworks is essential for successful implementation and long-term partnership.

What’s Next for Buyers Considering Custom Robotics?

As we look to the future, the integration of robotics into everyday business processes is set to accelerate. Companies are encouraged to explore partnerships that foster innovation and flexibility. By prioritizing strategic sourcing in custom robotics, businesses not only position themselves at the forefront of technological advancement but also ensure they are equipped to meet evolving market demands. Now is the time to take action—connect with experts in the field and start envisioning how custom robotics can transform your operations.