Introduction: Navigating the Global Market for red powder coat colors

In today’s competitive landscape, sourcing high-quality red powder coat colors presents a significant challenge for international B2B buyers. With diverse applications across various industries—from automotive to architectural design—understanding the nuances of color selection, durability, and finish can be daunting. This guide aims to simplify the decision-making process by offering a comprehensive overview of the different types of red powder coat colors available in the market, their specific applications, and essential factors to consider when selecting suppliers.

B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam, will find actionable insights tailored to their unique needs. We delve into aspects such as supplier vetting, cost considerations, and the importance of testing color samples to ensure consistency and quality. By equipping buyers with the knowledge to make informed purchasing decisions, this guide not only addresses the complexities of sourcing but also empowers businesses to confidently choose the right powder coat solutions for their projects.

Navigating the global market for red powder coat colors does not have to be overwhelming. With the right information at your fingertips, you can streamline your procurement process and enhance the quality of your finished products.

Understanding red powder coat colors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

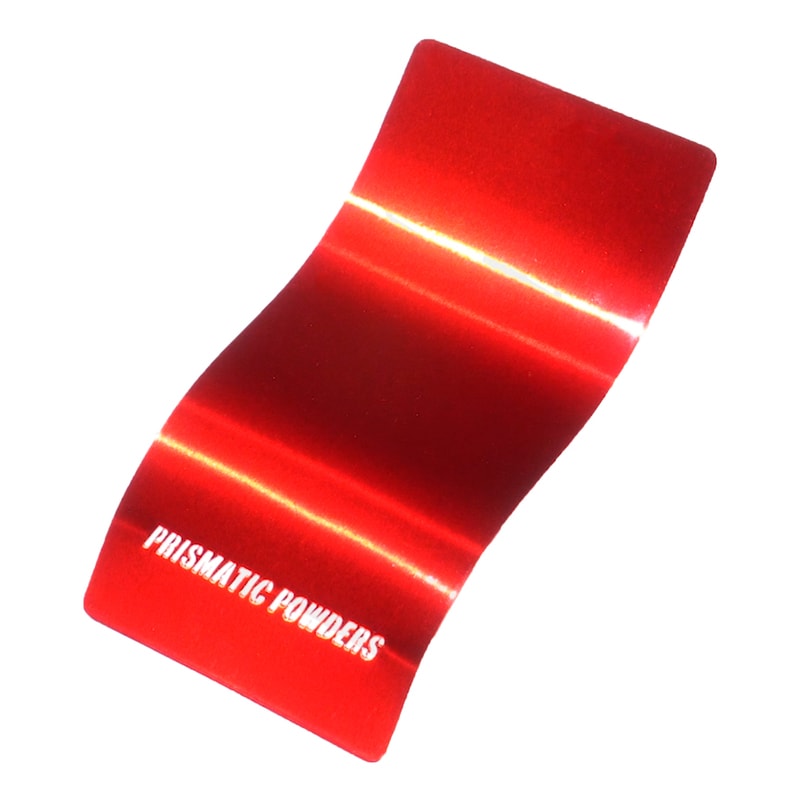

| Anodized Red | Flat transparent finish, satin gloss, polyester top coat | Automotive, Architectural, Industrial | Pros: Elegant appearance, good for reflective substrates. Cons: Requires careful substrate selection for best results. |

| Racing Red | Bright, sparkling finish, high gloss, polyurethane top coat | Automotive, Powersports, Retail Displays | Pros: Eye-catching, durable finish. Cons: Higher cost due to polyurethane composition. |

| Candy Red | Transparent color over a metallic base, deep color depth | Custom Automotive, Furniture, Decorative Items | Pros: Offers unique depth and richness. Cons: More complex application process, requiring a base coat. |

| Matte Red | Non-reflective finish, soft texture, polyester base | Industrial Equipment, Furniture, Retail Fixtures | Pros: Modern aesthetic, hides fingerprints. Cons: Less resistant to scratches compared to glossy finishes. |

| Metallic Red | Shimmering effect due to metallic flakes, high gloss | Automotive, Home Appliances, Electronics | Pros: Attractive, adds value to products. Cons: Requires precise application for even finish. |

What are the characteristics and suitability of Anodized Red powder coat colors?

Anodized Red features a flat transparent finish with a satin gloss, primarily achieved through a polyester top coat. This color is particularly suitable for applications where a subtle yet elegant appearance is desired, such as in automotive parts and architectural elements. B2B buyers should consider the substrate beneath the anodized coat, as the final appearance is influenced by the underlying surface. Ensuring compatibility with reflective materials can enhance the aesthetic appeal.

How does Racing Red compare in terms of application and durability?

Racing Red is characterized by its bright, sparkling hue and high gloss finish, produced with a polyurethane top coat. This type of powder coat is ideal for high-visibility applications in the automotive and powersports industries, where aesthetics are paramount. While it offers exceptional durability, B2B buyers must weigh the higher cost associated with polyurethane against the long-term benefits of a visually striking finish that withstands wear.

What makes Candy Red a popular choice for custom applications?

Candy Red is notable for its transparent color over a metallic base, delivering a rich, deep appearance that is highly sought after in custom automotive and decorative items. This powder coat requires a two-step application process, involving a base coat to achieve the desired depth. B2B buyers should be prepared for a more complex application, but the unique visual impact can justify the investment, particularly for high-end products.

Why might Matte Red be chosen over glossy alternatives?

Matte Red features a non-reflective finish that provides a modern aesthetic, making it popular in industrial equipment and retail fixtures. This type of powder coat is effective at hiding fingerprints and minor imperfections, catering to buyers seeking a sleek look. However, it is important to note that Matte Red may be less resistant to scratches compared to glossy finishes, which could influence its suitability for high-traffic applications.

What advantages does Metallic Red offer in product design?

Metallic Red contains metallic flakes that create a shimmering effect, resulting in a high-gloss finish that enhances product appeal. This powder coat is commonly used in automotive and home appliance applications, where visual impact can significantly influence purchasing decisions. B2B buyers should consider the precision required in application to achieve an even finish, as inconsistencies can detract from the final product’s quality.

Key Industrial Applications of red powder coat colors

| Industry/Sector | Specific Application of red powder coat colors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Car body parts and accessories | Enhanced aesthetics and corrosion resistance | Quality certification, compatibility with different substrates, and adherence to local regulations. |

| Construction & Infrastructure | Safety signage and barriers | Improved visibility and durability | UV resistance, compliance with safety standards, and color consistency. |

| Furniture Manufacturing | Outdoor furniture and fixtures | Weather resistance and aesthetic appeal | Custom color matching, durability against environmental factors, and bulk pricing. |

| Electrical Equipment | Housings for electrical devices | Increased product lifespan and safety | Thermal stability, electrical insulation properties, and compliance with international safety standards. |

| Agricultural Equipment | Machinery and implements | Enhanced durability and reduced maintenance | Resistance to chemicals and abrasives, color options for branding, and compatibility with various manufacturing processes. |

How is Red Powder Coat Used in the Automotive Sector?

In the automotive industry, red powder coat colors are commonly used for car body parts, wheels, and accessories. This application not only enhances the aesthetic appeal of vehicles but also provides a protective layer against corrosion and wear. Buyers in this sector must consider factors such as quality certification and compatibility with various substrates to ensure longevity and performance. Additionally, adherence to local regulations regarding vehicle coatings is crucial for international buyers, particularly in regions like Africa and South America, where environmental standards may vary.

What Role Does Red Powder Coat Play in Construction and Infrastructure?

Red powder coat colors are frequently utilized for safety signage, barriers, and fencing in the construction and infrastructure sectors. The vibrant hue ensures high visibility, which is essential for safety in public spaces and construction sites. The durability of powder coatings also protects against harsh weather conditions, making them ideal for outdoor applications. Buyers must focus on sourcing products that offer UV resistance and comply with local safety standards, especially in regions with intense sun exposure, such as the Middle East.

How is Red Powder Coat Beneficial for Furniture Manufacturing?

In furniture manufacturing, red powder coat colors are applied to outdoor furniture and fixtures to provide a vibrant finish that stands up to the elements. This coating not only enhances the visual appeal of the products but also offers excellent weather resistance, reducing the need for frequent maintenance. For international buyers, it is important to ensure that the coatings are durable against environmental factors and that suppliers can provide custom color matching services to meet branding requirements.

What Advantages Does Red Powder Coat Offer for Electrical Equipment?

Red powder coat colors are used extensively for housings of electrical devices, where they contribute to both aesthetic appeal and functional safety. The coating provides an additional layer of protection against corrosion and wear, enhancing the lifespan of electrical components. Buyers should prioritize sourcing materials that exhibit thermal stability and electrical insulation properties, ensuring compliance with international safety standards, especially in regions with stringent regulations.

Why is Red Powder Coat Important for Agricultural Equipment?

In the agricultural sector, red powder coat colors are applied to machinery and implements to improve durability and reduce maintenance needs. The coating protects against chemicals and abrasives commonly found in agricultural environments, extending the life of the equipment. Buyers should consider resistance to environmental factors and the availability of bulk pricing when sourcing these coatings, particularly in regions like Africa and South America, where agricultural machinery is a significant investment.

3 Common User Pain Points for ‘red powder coat colors’ & Their Solutions

Scenario 1: Ensuring Consistent Color Matching for High-Volume Orders

The Problem: A manufacturer in the automotive sector often faces challenges with color matching when ordering red powder coat colors for high-volume production runs. Inconsistent shades can lead to product rejection from clients, resulting in financial losses and reputational damage. The discrepancies may arise from different batches of powder, variations in substrate materials, or improper application techniques.

The Solution: To mitigate color matching issues, B2B buyers should establish a comprehensive color matching protocol. First, request color swatches from suppliers to compare with the desired finish in a controlled lighting environment. Additionally, implement a standardized process for applying the powder coat across all production lines, ensuring that equipment is calibrated and that applicators are trained consistently. Using a color spectrophotometer can further enhance precision by measuring the color of finished products and matching them against the desired red tones. Establishing a close relationship with suppliers who can provide batch consistency guarantees will also significantly reduce risks associated with color mismatching.

Scenario 2: Managing Environmental Regulations and Safety Concerns

The Problem: In regions such as the Middle East and Europe, environmental regulations regarding powder coatings can be stringent. Buyers often find themselves navigating complex compliance requirements related to chemical safety and emissions. The use of certain red powder coat colors may involve hazardous materials that could expose the company to legal penalties or require additional investments in safety equipment.

The Solution: To effectively manage these concerns, B2B buyers should conduct thorough research on local regulations pertaining to powder coatings and chemical usage. Partnering with suppliers who offer eco-friendly or low-VOC red powder coat options can ensure compliance while maintaining product quality. Furthermore, implementing a safety data sheet (SDS) review process for all purchased materials can provide critical information about handling and disposal. Regular training sessions for employees on safety protocols and environmental practices will foster a culture of compliance and responsibility, minimizing risks associated with hazardous materials.

Scenario 3: Overcoming Application Challenges for Specialty Finishes

The Problem: B2B buyers often struggle with achieving the desired finish when using specialty red powder coat colors, such as metallic or transparent variants. These finishes require precise application techniques and substrate preparation to ensure a high-quality outcome. Failure to adhere to these requirements can result in poor adhesion, uneven surfaces, or unwanted imperfections, leading to costly rework.

The Solution: To achieve optimal results with specialty red powder coat colors, it is crucial to invest in proper training and equipment. Buyers should collaborate with suppliers to obtain detailed application guides and technical data sheets that outline the specific requirements for each product. Conducting test runs on sample pieces before full-scale production can help identify potential issues early in the process. Additionally, utilizing advanced application technology, such as electrostatic spray guns, can enhance the quality of the finish. Regular maintenance of application equipment ensures consistent performance, allowing for better control over the application process and ultimately leading to higher-quality finished products.

Strategic Material Selection Guide for red powder coat colors

When selecting red powder coat colors for various applications, the choice of substrate material is crucial. Different materials exhibit unique properties that can significantly influence the performance and longevity of the powder coating. Below, we analyze four common materials used in conjunction with red powder coat colors, focusing on their key properties, advantages, disadvantages, and considerations for international buyers.

What Are the Key Properties of Steel When Used with Red Powder Coat Colors?

Steel is a widely used substrate for powder coating due to its strength and versatility. It typically has a high-temperature rating, making it suitable for applications exposed to heat. Steel also offers excellent corrosion resistance when properly pre-treated and coated.

Pros: Steel is durable and cost-effective, making it an ideal choice for a wide range of applications, from automotive parts to industrial equipment. The powder coating can enhance its aesthetic appeal while providing a protective layer.

Cons: Steel may require additional surface preparation to ensure proper adhesion of the powder coat. It is also susceptible to rust if the coating is compromised.

Impact on Application: Steel’s compatibility with various media, such as automotive fluids and chemicals, makes it suitable for automotive and industrial applications.

International Considerations: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or ISO, to avoid issues with corrosion resistance and durability in harsh environments.

How Does Aluminum Perform with Red Powder Coat Colors?

Aluminum is another popular choice for powder coating, known for its lightweight and corrosion-resistant properties. It has a moderate temperature rating, which is sufficient for many applications.

Pros: Aluminum is easy to work with and offers excellent aesthetic qualities when powder coated. The coating can enhance its natural resistance to corrosion, making it suitable for outdoor applications.

Cons: The cost of aluminum can be higher than steel, and it may require specialized coatings to achieve the desired finish.

Impact on Application: Aluminum is compatible with various media, including moisture and UV exposure, making it ideal for outdoor furniture and architectural applications.

International Considerations: B2B buyers should consider local regulations regarding aluminum use, especially in construction, where specific standards may apply.

What Are the Advantages of Using Plastic with Red Powder Coat Colors?

Plastic substrates, particularly those engineered for high performance, are increasingly popular in powder coating applications. They offer a unique combination of lightweight and flexibility.

Pros: Plastics are resistant to corrosion and can withstand a wide range of chemicals, making them suitable for various applications, including automotive and consumer goods.

Cons: The temperature resistance of plastic is generally lower than that of metals, which may limit its use in high-heat environments. Additionally, the adhesion of powder coatings can be challenging without proper surface treatment.

Impact on Application: Plastics are often used in applications where weight savings are critical, such as in automotive parts and consumer electronics.

International Considerations: Buyers should ensure that the selected plastic meets international standards for safety and environmental impact, particularly in regions with stringent regulations.

How Does Stainless Steel Compare When Using Red Powder Coat Colors?

Stainless steel is renowned for its corrosion resistance and aesthetic appeal. It is often used in applications where hygiene and durability are paramount, such as in food processing and medical equipment.

Pros: The combination of stainless steel and powder coating can provide exceptional durability and resistance to environmental factors, making it suitable for both indoor and outdoor applications.

Cons: Stainless steel is generally more expensive than carbon steel and may require specialized coatings to achieve the desired finish.

Impact on Application: Its compatibility with various media, including acids and alkalis, makes stainless steel ideal for industrial and food-related applications.

International Considerations: Compliance with international standards, such as those set by the FDA or EU regulations, is essential for buyers in the food and medical sectors.

| Material | Typical Use Case for red powder coat colors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive parts, industrial equipment | Durable and cost-effective | Requires surface preparation | Medium |

| Aluminum | Outdoor furniture, architectural elements | Lightweight and corrosion-resistant | Higher cost, specialized coatings needed | High |

| Plastic | Consumer goods, automotive parts | Resistant to corrosion and chemicals | Lower temperature resistance | Medium |

| Stainless Steel | Food processing, medical equipment | Exceptional durability and hygiene | Higher cost and specialized coatings | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties and considerations of various substrates for red powder coat colors. Understanding these factors can lead to better decision-making and enhanced product performance in diverse applications.

In-depth Look: Manufacturing Processes and Quality Assurance for red powder coat colors

What Are the Key Manufacturing Processes for Red Powder Coat Colors?

The manufacturing of red powder coat colors is a multifaceted process that involves several critical stages. Understanding these stages helps B2B buyers ensure they are sourcing high-quality products that meet their specific needs.

How Is Material Prepared in the Powder Coating Process?

The first step in manufacturing red powder coat colors is material preparation. This involves selecting high-quality resins, pigments, and additives that contribute to the desired properties of the final product. For red powder coatings, specific pigments are chosen to achieve the right hue and brightness.

Once selected, these materials are mixed together in precise formulations to create a homogeneous powder. This mixture is then subjected to a grinding process to achieve the desired particle size, which is crucial for ensuring an even application during the coating process. The finer the powder, the smoother the finish will be.

What Forming Techniques Are Used in Red Powder Coating?

After material preparation, the next phase is forming. The powder is typically extruded into strands, cooled, and then ground into a fine powder again. This two-step grinding process ensures consistent particle size, which is vital for achieving uniform coverage and adhesion on substrates.

At this stage, various additives can be introduced to enhance specific characteristics, such as flow properties, curing speed, and UV resistance. It is essential for manufacturers to adhere to strict formulations to ensure that the final product meets industry standards.

How Is the Assembly Process Conducted?

The assembly process in powder coating primarily involves the application of the powder to a substrate. The substrates are pre-treated to remove any contaminants that could affect adhesion. This often involves cleaning, phosphating, or applying a primer coat.

Once prepped, the substrate is electrostatically charged, allowing the powder to adhere uniformly when sprayed. After application, the coated items are cured in an oven, where heat causes the powder to melt and form a durable, cohesive layer. This curing process is critical, as it determines the final mechanical and aesthetic properties of the coating.

What Quality Assurance Measures Are in Place for Red Powder Coating?

Quality assurance (QA) is an integral part of the manufacturing process for red powder coat colors, ensuring that the final product meets international and industry-specific standards.

Which International Standards Are Relevant for Quality Control?

For B2B buyers, it is vital to understand the international standards that govern the quality of powder coatings. One of the most recognized standards is ISO 9001, which outlines the criteria for a quality management system. Compliance with this standard indicates that the manufacturer has established processes for continuous improvement and customer satisfaction.

Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply, depending on the intended use of the powder coating. These certifications ensure that the product meets safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control in powder coating manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This stage assesses the raw materials before they enter the production process. It ensures that all materials meet specified standards and are free from defects.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, samples are taken to evaluate various parameters, such as particle size, color consistency, and flow characteristics. This helps in identifying any deviations early in the process.

-

Final Quality Control (FQC): After the powder has been manufactured, it undergoes final testing to ensure it meets all specifications. This includes assessments of gloss, adhesion, and durability.

What Testing Methods Are Commonly Used in Powder Coating Quality Assurance?

Common testing methods for quality assurance in powder coatings include:

- Adhesion Testing: Evaluates how well the coating adheres to the substrate.

- Impact Resistance Testing: Measures the coating’s ability to withstand impacts without chipping or cracking.

- Weathering Tests: Assesses the coating’s resistance to UV light, moisture, and temperature changes.

- Thickness Measurement: Ensures that the coating thickness is within specified limits for optimal performance.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are some strategies to ensure reliability:

What Role Do Audits and Reports Play in Supplier Verification?

Regular audits of the manufacturing facility can provide insight into the supplier’s adherence to quality standards. Buyers can request third-party audit reports to ensure that the supplier meets both international and industry-specific certifications.

Additionally, suppliers should provide documentation that details their quality control processes, including IQC, IPQC, and FQC. This transparency can help buyers assess the supplier’s commitment to quality.

Why Is Third-Party Inspection Important for B2B Buyers?

Third-party inspection services can serve as an independent verification of the supplier’s quality assurance processes. These inspections can occur at various stages of production, ensuring that the coatings meet the required specifications before shipment.

By leveraging these insights, B2B buyers can make informed decisions when sourcing red powder coat colors, ensuring they receive high-quality products that meet their specific requirements. Understanding the intricacies of manufacturing processes and quality assurance measures not only enhances buyer confidence but also fosters long-term supplier relationships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘red powder coat colors’

The following guide serves as a practical checklist for B2B buyers looking to procure red powder coat colors. This resource is designed to help international buyers navigate the complexities of sourcing these specialized coatings effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before initiating your sourcing process. Consider the desired finish (e.g., gloss, satin, matte), durability requirements, and application methods. These specifications will guide your selection and ensure that the powder coat meets your project needs.

- Finish Types: Decide whether you need a high gloss, satin, or matte finish based on the product’s intended use.

- Durability Standards: Specify any industry standards or certifications, particularly if your product will face harsh environmental conditions.

Step 2: Research Available Color Options

Understanding the variety of red powder coat colors available is crucial. Different suppliers may offer unique shades, including bright reds, anodized reds, or racing reds, each with distinct properties and applications.

- Color Matching: Consider whether you require custom colors or if standard options suffice. Look for suppliers that provide color swatches or digital visualization tools to preview options.

- Transparency and Base Coats: Note if a transparent powder is needed and what base coats may be necessary for achieving the desired appearance.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s vital to conduct thorough evaluations. Request detailed company profiles, product portfolios, and customer references to ensure they meet your quality standards.

- Certifications: Check for industry certifications (e.g., ISO, ASTM) that validate the supplier’s quality control processes.

- Experience: Prefer suppliers with a proven track record in your specific industry, as they are more likely to understand your unique requirements.

Step 4: Request Samples for Testing

Once you narrow down your options, request samples of the red powder coat colors you are considering. Testing these samples in your application environment can provide invaluable insights into their performance and appearance.

- Application Testing: Apply the samples on similar substrates to assess adhesion, color accuracy, and finish.

- Durability Assessment: Evaluate how the samples hold up under typical usage conditions, including exposure to weather, chemicals, or abrasion.

Step 5: Negotiate Pricing and Terms

Engage in negotiations to ensure you receive the best possible pricing and terms. Be transparent about your volume needs and any potential for long-term partnerships, which can influence pricing structures.

- Bulk Discounts: Inquire about pricing tiers based on order quantities, as larger orders may yield significant savings.

- Payment Terms: Clarify payment options, delivery timelines, and any warranties or return policies associated with the purchase.

Step 6: Confirm Logistics and Delivery Options

Logistics play a crucial role in your sourcing strategy. Ensure that the supplier can meet your delivery timelines and that they have robust shipping options to your location.

- Shipping Costs: Discuss freight costs upfront and consider whether the supplier offers free shipping on larger orders.

- Lead Times: Confirm lead times for both standard and customized orders to avoid project delays.

Step 7: Review Documentation and Compliance

Before finalizing your order, ensure that all necessary documentation is in order. This includes safety data sheets (SDS), technical data sheets (TDS), and compliance certifications relevant to your region.

- Regulatory Compliance: Verify that the powder coatings comply with local regulations, particularly if your products will be sold in regulated markets.

- Safety Considerations: Ensure that suppliers provide comprehensive safety information to protect your workforce during application and handling.

This step-by-step checklist will help streamline your procurement process for red powder coat colors, ensuring you make informed decisions that align with your business needs.

Comprehensive Cost and Pricing Analysis for red powder coat colors Sourcing

What Are the Key Cost Components in Sourcing Red Powder Coat Colors?

When sourcing red powder coat colors, B2B buyers need to understand the various cost components that contribute to the total price. The primary factors include:

-

Materials: The cost of raw materials for powder coating, such as resins and pigments, is a significant portion of the overall expense. The price can fluctuate based on market demand and the quality of materials used. Higher-quality pigments, for instance, may increase costs but offer better durability and finish.

-

Labor: Labor costs encompass the wages paid to workers involved in the manufacturing process. This includes not only direct labor for production but also skilled workers for quality control and application processes.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and equipment depreciation. Efficient operations can help minimize overhead, making it crucial for suppliers to optimize production techniques.

-

Tooling: Tooling costs may arise from the need for specialized equipment or molds for unique color formulations or finishes. Custom tooling can significantly impact the initial investment and should be considered when evaluating suppliers.

-

Quality Control (QC): Ensuring that the powder coat meets industry standards involves QC processes that can add to the cost. Certifications and testing for compliance with environmental and safety regulations are essential, especially for international buyers.

-

Logistics: Shipping and handling costs are critical, particularly for international transactions. Factors such as distance, shipping mode, and customs duties can substantially influence total costs.

-

Margin: Suppliers will typically add a margin to cover their operational costs and profit. This margin varies widely depending on the supplier’s market positioning and service offerings.

How Do Price Influencers Affect the Cost of Red Powder Coat Colors?

Several price influencers can significantly impact the final pricing of red powder coat colors:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer tiered pricing based on order volume, incentivizing bulk purchases.

-

Specifications and Customization: Custom colors or finishes may incur additional costs. Buyers should clearly specify their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher-grade materials and certifications for compliance with international standards can lead to increased costs but may result in better performance and longevity.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with proven track records may charge a premium, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is crucial for international buyers. These terms dictate who is responsible for transportation costs, insurance, and risk during shipping, directly affecting the total cost of ownership.

What Tips Can B2B Buyers Use for Cost-Efficiency in Sourcing?

To navigate the complexities of sourcing red powder coat colors efficiently, buyers can utilize several strategies:

-

Negotiate Terms: Leverage your purchasing power by negotiating terms with suppliers. Don’t hesitate to discuss pricing structures, payment terms, and delivery schedules to find mutually beneficial agreements.

-

Consider Total Cost of Ownership (TCO): Assess the long-term costs associated with powder coat colors, including durability, maintenance, and potential reapplication. This approach helps in understanding the true value of the product beyond the initial purchase price.

-

Research Supplier Options: Explore multiple suppliers and compare their offerings. Look for those who provide transparent pricing and comprehensive service, including logistics and after-sales support.

-

Understand Regional Variations: Pricing can vary significantly based on geographic location. For buyers from regions like Africa and South America, it’s essential to understand local market conditions and potential tariffs that may affect overall costs.

-

Stay Informed on Market Trends: Regularly monitor market trends affecting raw materials and powder coating technologies. Being informed can provide leverage during negotiations and help anticipate future cost changes.

Disclaimer on Indicative Prices

Prices for red powder coat colors can vary based on numerous factors, including market conditions, supplier pricing strategies, and order specifics. The figures mentioned in this analysis are indicative and should be verified with suppliers for accurate and current pricing information.

Alternatives Analysis: Comparing red powder coat colors With Other Solutions

Introduction to Alternative Solutions for Red Powder Coat Colors

When selecting finishes for metal surfaces, red powder coat colors are a popular choice due to their durability and aesthetic appeal. However, various alternative methods and products can also achieve similar results, each with unique advantages and disadvantages. Understanding these alternatives can empower B2B buyers to make informed decisions that align with their specific operational needs and project requirements.

Comparison Table of Red Powder Coat Colors and Alternatives

| Comparison Aspect | Red Powder Coat Colors | Anodizing | Liquid Paint |

|---|---|---|---|

| Performance | Excellent durability, resistant to chipping and fading | Very good corrosion resistance, less durable than powder coat | Moderate durability, prone to chipping |

| Cost | Moderate initial cost, cost-effective in bulk | Generally higher cost due to the process | Lower initial cost, but higher long-term maintenance costs |

| Ease of Implementation | Requires specialized equipment for application | Complex process requiring specific equipment | Easier to apply with standard tools |

| Maintenance | Low maintenance, long-lasting | Requires periodic maintenance to maintain appearance | Higher maintenance due to wear and tear |

| Best Use Case | Ideal for automotive, industrial, and outdoor applications | Best for aluminum and high-end applications | Suitable for indoor furniture and decorative items |

Detailed Breakdown of Alternatives

Anodizing

Anodizing is an electrochemical process that enhances the natural oxide layer on metal surfaces, primarily aluminum. This method offers excellent corrosion resistance and can produce vibrant colors, including red. However, anodizing requires specialized equipment and expertise, making it a more complex and costly option compared to powder coating. Additionally, while it provides a good finish, it is generally less durable than powder coating when exposed to harsh environments.

Liquid Paint

Liquid paint is a traditional alternative that is often easier to apply using standard tools. It has a lower initial cost, making it an attractive option for smaller projects or indoor applications. However, liquid paint typically does not provide the same level of durability and resistance as powder coating or anodizing. Over time, it is more prone to chipping and requires more frequent maintenance and touch-ups, leading to higher long-term costs.

Conclusion: How to Choose the Right Solution

For B2B buyers, the choice between red powder coat colors, anodizing, and liquid paint depends on several factors, including the intended application, budget constraints, and performance requirements. If durability and long-term performance are paramount, red powder coat colors may be the best choice. However, for projects requiring a sleek aesthetic finish on aluminum, anodizing might be preferable. Conversely, for budget-sensitive projects with less exposure to wear and tear, liquid paint could be a viable option. By carefully assessing these factors, buyers can select the most suitable finishing solution for their specific operational needs.

Essential Technical Properties and Trade Terminology for red powder coat colors

What Are the Key Technical Properties of Red Powder Coat Colors?

Understanding the technical specifications of red powder coat colors is essential for B2B buyers to ensure they select the right product for their applications. Here are several critical properties to consider:

-

Material Grade

The material grade of a powder coating often refers to its formulation, which can include thermosetting or thermoplastic properties. Thermosetting powders, such as epoxy and polyester, cure through a chemical reaction, providing durability and resistance to heat and chemicals. In contrast, thermoplastic powders can be re-melted and reshaped, offering flexibility in applications. Selecting the appropriate grade can significantly affect the longevity and performance of the coating. -

Gloss Level

Gloss levels are measured in gloss units, indicating the shine of the finish. Common classifications include matte (0-10 gloss units), satin (21-35 gloss units), and high gloss (85+ gloss units). The choice of gloss level influences not only the aesthetic appeal but also the coating’s resistance to dirt and corrosion. Higher gloss finishes tend to be easier to clean, making them suitable for various industrial and commercial applications. -

Color Consistency

Color consistency is critical in ensuring that the finished product meets brand specifications. Variations can occur due to differences in batch production or application techniques. B2B buyers should request color swatches and test panels before placing large orders, as this helps ensure the end product aligns with their expectations and quality standards. -

Weather Resistance

The ability of powder coatings to withstand environmental factors like UV rays, moisture, and temperature fluctuations is vital for outdoor applications. Red powder coats, particularly those formulated with UV inhibitors, can retain their color and gloss longer when exposed to harsh conditions. This property is especially important for industries such as automotive and architectural coatings, where aesthetics and durability are paramount. -

Application Method

Understanding the recommended application method—such as electrostatic spray, fluidized bed, or manual application—is essential for achieving optimal results. Each method has its advantages and can affect the thickness, uniformity, and finish quality of the powder coat. Choosing the right application technique can enhance efficiency and reduce waste during the coating process. -

Cure Temperature and Time

The cure temperature and time are crucial for the proper adhesion and performance of the coating. Most powder coats require baking in an oven at specific temperatures (typically between 350°F to 400°F) for a designated period to ensure complete curing. Buyers must consider the capabilities of their application equipment and the thermal tolerances of the substrates being coated.

What Are Common Trade Terms Related to Red Powder Coat Colors?

Familiarity with industry terminology is essential for effective communication and negotiation in B2B transactions. Here are several common terms to know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the powder coating industry, OEMs often require specific color matches and quality standards for their components, making it crucial to understand their unique requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For red powder coatings, MOQs can vary significantly based on the manufacturer and the specific product. Understanding MOQs helps buyers plan their purchases and manage inventory effectively. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically includes detailed specifications, quantities, and delivery requirements. Submitting a well-structured RFQ can streamline the procurement process and lead to better pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and customs clearance. Knowledge of these terms is essential for B2B buyers to understand their obligations and risks during shipping, especially when importing powder coatings from overseas suppliers. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the powder coating industry, lead times can vary based on production schedules and inventory levels. Understanding lead times is essential for effective project planning and inventory management. -

Color Matching

Color matching is the process of ensuring that a newly produced powder coat matches an existing color standard. This is particularly important for businesses looking to maintain brand consistency across multiple products. Using color matching services can help ensure accuracy and satisfaction with the final product.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their purchasing strategy and align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the red powder coat colors Sector

What Are the Current Market Trends Influencing Red Powder Coat Colors?

The global market for red powder coat colors is experiencing significant growth, driven by the expanding automotive, architectural, and consumer goods industries. As businesses increasingly seek durable and aesthetically pleasing coatings, the demand for high-performance powder coatings continues to rise. Innovations in formulation technology, such as the development of low-VOC (volatile organic compounds) and high-gloss finishes, are gaining traction among B2B buyers. These advancements not only enhance visual appeal but also improve the longevity of products.

Emerging B2B tech trends like digital color matching and visualization tools are revolutionizing the sourcing process. For instance, platforms that allow buyers to visualize powder coat finishes in 3D prior to purchase enable better decision-making. This is particularly beneficial for international buyers from regions such as Africa and South America, where logistics can complicate the supply chain. Furthermore, the integration of e-commerce solutions and automated ordering systems is streamlining procurement processes, making it easier for businesses to source the right products quickly.

How Is Sustainability Shaping the Sourcing of Red Powder Coat Colors?

Sustainability is becoming a critical factor in sourcing red powder coat colors, with increasing pressure on manufacturers to adopt eco-friendly practices. The environmental impact of traditional coatings, which often contain harmful solvents, is prompting a shift towards powder coatings that are not only free from solvents but also recyclable. B2B buyers are now prioritizing suppliers that demonstrate a commitment to sustainability through certifications such as ISO 14001 and the use of green materials.

Ethical sourcing is also gaining importance, especially in regions where supply chain transparency is crucial. Buyers are increasingly interested in the origin of materials and the manufacturing processes used, seeking suppliers who adhere to fair labor practices and environmentally responsible methods. This trend is especially relevant for international buyers in regions like the Middle East and Europe, where regulatory frameworks on environmental compliance are more stringent.

What Is the Historical Context Behind Red Powder Coat Colors?

The use of powder coating technology dates back to the 1950s, primarily gaining traction in the automotive industry due to its durability and resistance to corrosion. Red powder coat colors, specifically, have evolved from basic shades to a wide array of finishes, including matte, gloss, and metallic options. This evolution has been fueled by advancements in chemistry and application techniques, allowing for more vibrant and lasting colors.

Over the decades, the market has seen a diversification of applications beyond automotive to include furniture, appliances, and architectural elements. This broader adoption has made red powder coat colors a staple in various industries, emphasizing the need for suppliers to continually innovate and adapt to changing consumer preferences and market dynamics. Today, the focus is not just on aesthetics but also on performance and sustainability, reflecting the shifting priorities of B2B buyers globally.

Frequently Asked Questions (FAQs) for B2B Buyers of red powder coat colors

-

How do I choose the right red powder coat color for my project?

Selecting the appropriate red powder coat color depends on several factors, including the intended application, desired aesthetic, and substrate material. Consider the gloss level, as different finishes (matte, satin, high gloss) can significantly affect the final appearance. Additionally, evaluate the environmental conditions the coated item will face, such as UV exposure or chemical contact, to ensure durability. Request swatches from suppliers to visually compare colors and finishes against your project requirements before making a decision. -

What is the best way to ensure color consistency in red powder coating?

To achieve color consistency, it’s crucial to source your red powder coat colors from a single supplier for the entire batch. Variations can occur between different manufacturers or even different production runs. Always request a sample or swatch before placing a large order and conduct a test application to confirm that the color meets your specifications. Implement a quality control process to assess the color before and after application to identify any discrepancies. -

What are the minimum order quantities (MOQ) for red powder coat colors?

Minimum order quantities for red powder coat colors can vary significantly by supplier and region. Typically, MOQs range from 5 kg to 50 kg, depending on the product type and color. When sourcing internationally, consider the impact of shipping costs on smaller orders. Some suppliers may offer flexibility in MOQs for repeat customers or bulk orders, so it’s advisable to discuss your specific needs directly with the supplier. -

What should I consider regarding payment terms when sourcing red powder coat colors?

When negotiating payment terms, consider factors such as payment methods, deposit requirements, and credit terms. Many suppliers may require a partial upfront payment (typically 30-50%) with the balance due before shipment. For international transactions, ensure that the payment method is secure and offers buyer protection. Also, inquire about currency fluctuations and potential fees associated with international wire transfers or credit card payments to avoid unexpected costs. -

How can I vet suppliers of red powder coat colors for quality and reliability?

To vet suppliers effectively, start by researching their reputation in the industry through customer reviews and testimonials. Request references from previous clients, particularly those within your region, to gauge their experiences. Evaluate the supplier’s certifications, such as ISO or compliance with local regulations, to ensure they meet industry standards. Additionally, consider conducting a site visit or utilizing third-party inspection services for larger orders to verify their production capabilities and quality control processes. -

What logistics considerations should I keep in mind when importing red powder coat colors?

Logistics plays a critical role in sourcing red powder coat colors internationally. Understand the shipping options available, including air freight for faster delivery or sea freight for cost savings on larger orders. Be aware of import duties, taxes, and customs regulations specific to your country, as these can impact overall costs and delivery timelines. Collaborate with a reliable logistics partner who can navigate these complexities and ensure compliance with international shipping standards. -

Are there customization options available for red powder coat colors?

Many suppliers offer customization options for red powder coat colors, allowing you to tailor the hue, finish, and texture to your specific needs. Custom formulations can be developed to match specific color codes or achieve unique aesthetics. Be sure to discuss your requirements with potential suppliers early in the negotiation process, as custom orders may have different lead times and MOQs compared to standard colors. -

How do I ensure quality assurance for my red powder coat orders?

Implementing a robust quality assurance process is vital to ensure your red powder coat orders meet your specifications. Request a detailed product data sheet and safety data sheet (SDS) for each color you order. Establish clear inspection protocols upon delivery to check for color consistency, finish quality, and packaging integrity. If possible, conduct random sampling during production runs and consider third-party quality inspections to mitigate risks associated with large orders.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Red Powder Coat Colors Manufacturers & Suppliers List

1. The Powder Coat Store – High Gloss Red Powder Coat

Domain: thepowdercoatstore.com

Registered: 2013 (12 years)

Introduction: [{‘name’: ‘High Gloss Red Powder Coat Powder Paint’, ‘weight’: ‘1 LB’, ‘price’: ‘From $7.99’, ‘rating’: ‘5.0’, ‘reviews’: ‘1’}, {‘name’: ‘Transparent Candy Red Powder Coating Paint’, ‘weight’: ‘1 LB’, ‘price’: ‘From $11.49’, ‘rating’: ‘5.0’, ‘reviews’: ’14’}, {‘name’: ‘Super Durable High Gloss Red Powder Coat Powder Paint’, ‘weight’: ‘1 LB’, ‘price’: ‘From $7.99’, ‘rating’: ”, ‘reviews’: ”}, {‘n…

2. PPG – Red Powder Coating

Domain: powdercoatings.ppg.com

Registered: 1990 (35 years)

Introduction: Red Powder Coating by PPG offers a variety of RAL, Pantone, and AAMA red colors. It is available for free standard shipping.

3. Eastwood – Powder Coating Powders

Domain: eastwood.com

Registered: 1995 (30 years)

Introduction: Eastwood offers a variety of powder coating powders suitable for different applications. The powders are available in various colors and finishes, including gloss, satin, and matte. They are designed for durability, providing resistance to chipping, scratching, and fading. The products are easy to apply and cure at specific temperatures, ensuring a strong bond to the substrate. Eastwood’s powder c…

4. TIGER Coatings – Powder Coating Colors & Finishes

Domain: tiger-coatings.com

Registered: 2000 (25 years)

Introduction: Shop Powder Coating Colors Online | Over 1,000+ Finishes, TIGER Drylac® applications, Metallics & Special Effects, TIGER Trend Colors & Finishes 2025, BattleCoats by TIGER & HyperShock, TIGER Drylac® metallics, 3D Metallics, Pearl, Antique/Vein, Dusk, Horizon, Arctic Steel, Aqua Marine Metallic, Amber, Ruby, Flame, Tangerine, Yellow, TIGITAL Inks, Tattoo, Revolutionary 3D Powder Coating Visualizat…

5. All Powder Paints – Coating Colors for Automotive and Specialty Applications

Domain: allpowderpaints.com

Registered: 2011 (14 years)

Introduction: All Powder Coating Colors include a wide range of categories such as Automotive, Agricultural, Construction, and Specialty Coatings. Key offerings include:

– **Automotive Colors**: Specific colors for brands like Chevy, Dodge, Ford, Harley Davidson, and more.

– **Specialty Coatings**: Antimicrobial, Architectural Grade, High Temp Powders, and more.

– **Color Options**: Includes Candy & Transpar…

6. Wright Coating – Custom RAL Powder Coating

Domain: wrightcoating.com

Registered: 1998 (27 years)

Introduction: RAL Powder Coat Color Chart – Custom Powder Colors | Wright Coating Technologies offers a wide selection of custom and RAL colors including black, blue, yellow, red, silver, orange, white, and more. Customers can choose from hundreds of RAL colors and shades. If a specific color is not listed, customers can contact Wright Coating to find the desired color from various suppliers. The company provid…

7. Smith Powder Coating – Bangel Red Powder Coating

Domain: smithpowdercoating.com

Registered: 2016 (9 years)

Introduction: Bangel Red Powder Coating is a rich red powder coating color that creates a scarlet shade on metal surfaces. It is twice the thickness of most paint and much more durable.

8. SendCutSend – Powder Coating Solutions

Domain: sendcutsend.com

Registered: 2015 (10 years)

Introduction: We currently offer powder coating in the following colors: Matte Black (Axalta Black Magic BK120, 0-9% Gloss), Gloss Black (Cardinal BK12, RAL 9011, 90% Gloss), Wrinkle Black (Cardinal BK176, 10% Gloss), Metallic Gray (59/95726, 75% Gloss), Gloss Gray (138/70046, RAL 7040, 87% Gloss), Gloss White (Tiger Bengal White 149/11111, RAL 9003, 90% Gloss), Gloss Red (Cardinal RD03, RAL 3002, 90% Gloss), G…

Strategic Sourcing Conclusion and Outlook for red powder coat colors

In conclusion, the strategic sourcing of red powder coat colors presents a unique opportunity for B2B buyers across diverse markets, particularly in Africa, South America, the Middle East, and Europe. The vibrant and varied options, such as Anodized Red and Racing Red, not only enhance product aesthetics but also offer durability and versatility for various applications—from automotive to architectural projects. Understanding the nuances of each color, including required base and top coats, ensures that buyers can achieve optimal results while meeting their specific project needs.

Emphasizing the importance of strategic sourcing, companies can leverage supplier relationships to secure high-quality materials at competitive prices, ensuring consistency in production and a strong market presence. As global demand for high-performance coatings continues to rise, now is the ideal time for international buyers to explore innovative color solutions that can elevate their offerings.

Looking ahead, the landscape of powder coating is evolving with new formulations and technologies. We encourage buyers to engage with suppliers, utilize digital tools for color visualization, and remain informed about market trends to stay ahead. By strategically sourcing red powder coat colors, businesses can enhance their product lines and drive growth in an increasingly competitive environment.