Introduction: Navigating the Global Market for recumbent bike parts

In the ever-evolving landscape of the global market, sourcing high-quality recumbent bike parts presents a unique set of challenges for international B2B buyers. As demand for comfortable and efficient cycling solutions grows, particularly in regions like Africa, South America, the Middle East, and Europe, businesses must navigate a complex web of suppliers, regulations, and product specifications. This comprehensive guide offers invaluable insights into the diverse types of recumbent bike parts available, their applications, and critical considerations for vetting suppliers and understanding pricing structures.

From essential components like pedals and seat cushions to specialized accessories designed for safety and comfort, the guide details the full spectrum of products that can enhance the riding experience. It also addresses logistical aspects, ensuring that buyers are well-equipped to make informed purchasing decisions. By understanding market trends and supplier capabilities, businesses can better align their procurement strategies with customer needs, ultimately driving growth and satisfaction.

Whether you are a distributor looking to expand your product offerings or a manufacturer seeking reliable parts, this guide empowers you with the knowledge necessary to navigate the global market effectively. Equip yourself with the tools to enhance your purchasing strategy and capitalize on the growing interest in recumbent cycling across diverse international markets.

Understanding recumbent bike parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Frames | Lightweight materials, ergonomic design | Manufacturing, assembly, and retail of recumbent bikes | Pros: Durable, customizable; Cons: Higher initial cost, complexity in design variations. |

| Seats | Comfort-focused design, adjustable features | Retail and aftermarket sales for comfort upgrades | Pros: Enhanced rider comfort; Cons: May require additional adjustments for optimal fit. |

| Drivetrain Components | Includes chains, gears, and pedals, optimized for recumbent use | Component suppliers and bike assembly manufacturers | Pros: Improved efficiency and performance; Cons: Requires precise compatibility checks. |

| Accessories | Includes mirrors, lights, and storage solutions | Retail and aftermarket accessory markets | Pros: Enhances safety and functionality; Cons: May add extra weight or complexity. |

| Suspension Systems | Specialized designs for comfort and stability | High-end bike manufacturers and custom builds | Pros: Increased ride comfort; Cons: More components can lead to maintenance challenges. |

What Are the Key Characteristics of Recumbent Bike Frames?

Recumbent bike frames are designed for optimal aerodynamics and rider comfort, often made from lightweight materials such as aluminum or carbon fiber. The frame’s geometry allows for a laid-back riding position, which can reduce strain on the back and neck. For B2B buyers, selecting the right frame involves considering the target market’s preferences, potential for customization, and the balance between weight and durability. Offering a variety of frame types can cater to different riding styles and consumer needs.

How Do Seats Impact the Riding Experience for Recumbent Bikes?

Seats are crucial for enhancing rider comfort and performance. Many recumbent bike seats come with adjustable features and cushioning materials, which can significantly improve the cycling experience. B2B buyers should evaluate seat compatibility with various frame types, ease of installation, and the potential for upgrades. Investing in high-quality seats can lead to increased customer satisfaction and repeat business, making them a valuable product for retailers.

Why Are Drivetrain Components Essential for Recumbent Bikes?

Drivetrain components such as chains, gears, and pedals are vital for the efficient operation of recumbent bikes. These parts must be specifically designed to accommodate the unique geometry of recumbent models, which can differ from traditional bicycles. For B2B buyers, sourcing reliable drivetrain components involves ensuring compatibility with existing products and maintaining high-quality standards to enhance performance. Properly functioning drivetrain systems can significantly impact customer satisfaction and safety.

What Role Do Accessories Play in Enhancing Recumbent Bike Functionality?

Accessories such as mirrors, lights, and storage solutions are designed to improve safety and convenience for recumbent bike users. They are particularly important for long-distance riders who may require additional functionality. B2B buyers should consider the demand for various accessories based on customer preferences and regional trends. Offering a diverse range of accessories can enhance the overall appeal of recumbent bikes and encourage upselling opportunities.

How Can Suspension Systems Improve Rider Comfort on Recumbent Bikes?

Suspension systems in recumbent bikes are engineered to provide a smoother ride by absorbing shocks from uneven terrain. This feature is especially beneficial for long-distance cyclists who prioritize comfort. B2B buyers should assess the complexity and maintenance requirements of different suspension designs when selecting products for their inventory. High-quality suspension systems can differentiate a brand in a competitive market, appealing to customers seeking both performance and comfort.

Key Industrial Applications of recumbent bike parts

| Industry/Sector | Specific Application of recumbent bike parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Rehabilitation programs using recumbent bikes | Enhances patient comfort and recovery outcomes | Quality assurance, ergonomic design, and safety certifications |

| Tourism and Leisure | Rental services for recumbent bikes | Attracts diverse customers seeking unique experiences | Durability, maintenance support, and accessory availability |

| Fitness and Wellness | Fitness centers offering recumbent bike classes | Increases member engagement and satisfaction | Bulk purchasing options, warranty terms, and training resources |

| Transportation | Last-mile delivery solutions with electric recumbent bikes | Reduces emissions and operational costs | Battery life, load capacity, and local regulations |

| Education and Training | Educational institutions promoting cycling programs | Fosters physical health and environmental awareness | Customization options, safety features, and scalability |

How Are Recumbent Bike Parts Utilized in Healthcare Settings?

In healthcare, recumbent bike parts are integrated into rehabilitation programs to support patients recovering from injuries or surgeries. These bikes offer a low-impact alternative to traditional cycling, minimizing strain while promoting cardiovascular fitness. Key considerations for international buyers include ensuring that parts meet safety standards and are ergonomically designed to accommodate patients of varying sizes and abilities. Furthermore, sourcing from suppliers with a proven track record in healthcare equipment can enhance reliability and compliance with local regulations.

What Role Do Recumbent Bikes Play in Tourism and Leisure Industries?

In the tourism sector, recumbent bikes are increasingly used in rental services, providing unique experiences for tourists seeking leisurely exploration. The comfort and stability of these bikes attract a diverse clientele, including families and older adults. Businesses must consider the durability of bike parts and the availability of accessories, such as safety flags and storage options, to enhance the customer experience. Additionally, partnerships with local tourism boards can help promote these services to a broader audience.

How Do Recumbent Bike Parts Enhance Fitness and Wellness Facilities?

Fitness centers leverage recumbent bike parts to offer specialized classes that cater to a wide range of fitness levels. These bikes are particularly appealing to members who may have mobility challenges or prefer a more comfortable riding position. For B2B buyers in this sector, bulk purchasing options and robust warranty terms are essential to ensure long-term investment viability. Providing training resources for staff on how to maintain and promote these bikes can also improve member engagement and satisfaction.

In What Ways Are Recumbent Bikes Applied in Transportation Solutions?

The transportation industry utilizes electric recumbent bikes for last-mile delivery services, capitalizing on their efficiency and eco-friendliness. These bikes help businesses reduce operational costs and carbon footprints while navigating congested urban areas. Buyers must prioritize battery life and load capacity when sourcing parts, as these factors directly impact delivery efficiency. Understanding local regulations regarding electric vehicles is also crucial for compliance and operational success in various regions, including Africa and the Middle East.

How Are Educational Institutions Incorporating Recumbent Bikes into Their Programs?

Educational institutions are increasingly adopting recumbent bikes to promote physical activity and environmental awareness among students. These bikes can be utilized in cycling programs that teach students about sustainability and healthy lifestyles. Buyers in this sector should look for customization options to cater to different age groups and safety features to ensure student well-being. Additionally, scalability is important for institutions looking to expand their programs as interest grows, making it vital to partner with reliable suppliers who can meet evolving demands.

3 Common User Pain Points for ‘recumbent bike parts’ & Their Solutions

Scenario 1: Ensuring Compatibility with Existing Fleet

The Problem: Many B2B buyers face the challenge of ensuring that new recumbent bike parts are compatible with their existing fleet of bicycles. For instance, a distributor in South America may purchase a bulk order of pedals or seat cushions, only to find that they do not fit with specific models in their inventory. This not only leads to wasted investment but also affects customer satisfaction and operational efficiency.

The Solution: To overcome compatibility issues, B2B buyers should invest in a thorough compatibility assessment before making a purchase. This involves maintaining a detailed inventory list that includes model specifications and part dimensions. When sourcing parts, buyers should reach out to manufacturers for detailed compatibility charts and installation guides. Additionally, establishing a relationship with suppliers who specialize in recumbent bike parts can provide valuable insights and recommendations tailored to your fleet. Regular training for staff on the specifics of various models can also enhance understanding and reduce the risk of mismatches.

Scenario 2: Managing Supply Chain Delays

The Problem: Recumbent bike parts can often be subject to supply chain disruptions, particularly in regions like Africa and the Middle East where logistics can be complex. A buyer may place an order for critical components, only to experience delays that hinder production schedules and leave customers waiting. Such interruptions can damage business relationships and lead to lost revenue.

The Solution: To mitigate the risks associated with supply chain delays, buyers should consider implementing a diversified sourcing strategy. This means not relying on a single supplier for essential parts but rather establishing relationships with multiple vendors across different regions. Creating a buffer inventory for high-demand items can also help maintain operations during unexpected shortages. Additionally, leveraging technology such as supply chain management software can provide real-time updates on order statuses and logistics, allowing for better planning and communication with customers about expected delivery times.

Scenario 3: Addressing Customer Safety Concerns

The Problem: Safety is a paramount concern for B2B buyers in the recumbent bike market, especially those supplying to commercial entities like fitness centers or community programs. Buyers often struggle with ensuring that the parts they purchase, such as mirrors, safety flags, or pedals, meet safety standards and regulations. A lapse in safety can lead to accidents, resulting in liability issues and negative public perception.

The Solution: To address safety concerns effectively, B2B buyers should prioritize sourcing parts from reputable manufacturers that adhere to international safety standards. This involves conducting due diligence on potential suppliers, including reviewing their compliance certifications and quality assurance processes. Additionally, buyers should stay informed about the latest safety regulations in their respective markets and incorporate regular safety audits into their procurement processes. Engaging in customer education about proper usage and maintenance of recumbent bike parts can also reinforce safety practices and foster a culture of safety within their customer base.

Strategic Material Selection Guide for recumbent bike parts

What Are the Key Materials Used in Recumbent Bike Parts?

When selecting materials for recumbent bike parts, various factors such as performance, durability, and cost come into play. Understanding the properties of common materials can help B2B buyers make informed decisions that align with their specific needs and market demands.

Aluminum: The Lightweight Champion

Aluminum is widely used in recumbent bike parts due to its excellent strength-to-weight ratio. It offers good corrosion resistance, making it suitable for outdoor applications. Key properties include a temperature rating of up to 150°C and a pressure rating that varies based on alloy type.

Pros: Aluminum is lightweight, which enhances bike performance and ease of handling. It is also relatively cost-effective and easy to manufacture, allowing for complex shapes and designs.

Cons: While durable, aluminum can be susceptible to fatigue and may not perform well under extreme conditions compared to other materials like steel.

Impact on Application: Aluminum is compatible with various media, including water and lubricants, making it ideal for components like frames, handlebars, and seat supports.

Considerations for International Buyers: Compliance with standards such as ASTM and EN (European Norm) is crucial. Buyers should also consider local preferences for aluminum grades, which may vary by region, particularly in Africa and South America.

Steel: The Stalwart Performer

Steel is another common material, particularly for structural components like frames and axles. It boasts high tensile strength and excellent durability, with a temperature rating often exceeding 200°C.

Pros: Steel is incredibly strong and can handle significant stress, making it ideal for heavy-duty applications. It is also readily available and generally less expensive than high-end materials like titanium.

Cons: The main drawback is its weight, which can negatively impact the overall performance of the bike. Additionally, steel is prone to corrosion if not properly treated or coated.

Impact on Application: Steel’s compatibility with various lubricants and its ability to withstand high pressure make it suitable for critical components like gears and cranksets.

Considerations for International Buyers: Buyers should ensure compliance with ASTM or JIS standards for steel grades. In regions like the Middle East, where humidity is high, corrosion-resistant coatings are essential.

Carbon Fiber: The Premium Choice

Carbon fiber is increasingly popular for high-performance recumbent bike parts, especially in competitive cycling. It offers exceptional strength while being significantly lighter than aluminum or steel, with a temperature rating that can handle extreme conditions.

Pros: The primary advantage of carbon fiber is its lightweight nature combined with high stiffness, enhancing speed and efficiency. It also has excellent fatigue resistance.

Cons: Carbon fiber is more expensive than other materials and requires specialized manufacturing processes, which can complicate production.

Impact on Application: Its compatibility with various media is excellent, but care must be taken with adhesives and coatings used in assembly.

Considerations for International Buyers: Compliance with international standards like ISO is crucial. Buyers should also be aware of the specific needs for transportation and handling due to the material’s fragility.

Plastic Composites: The Versatile Option

Plastic composites, including nylon and polypropylene, are often used for non-structural components such as seat pads and grips. They offer good temperature resistance and are generally lightweight.

Pros: These materials are cost-effective and can be molded into complex shapes, making them suitable for various applications. They also resist corrosion and are easy to clean.

Cons: While durable, plastic composites may not withstand high stress or extreme temperatures as well as metals or carbon fiber.

Impact on Application: They are compatible with water and other non-corrosive media, making them suitable for accessories like bottle holders and fenders.

Considerations for International Buyers: Compliance with local safety and environmental regulations is vital, especially in regions with stringent standards like Europe.

Summary Table of Material Selection for Recumbent Bike Parts

| Material | Typical Use Case for recumbent bike parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frames, handlebars, seat supports | Lightweight and corrosion-resistant | Susceptible to fatigue | Medium |

| Steel | Frames, axles, gears | High strength and durability | Heavier and prone to corrosion | Low |

| Carbon Fiber | High-performance frames and components | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

| Plastic Composites | Seat pads, grips, non-structural parts | Cost-effective and easy to mold | Limited stress resistance | Low |

By understanding these materials’ properties, advantages, and limitations, B2B buyers can make strategic decisions that enhance their product offerings and meet market demands effectively.

In-depth Look: Manufacturing Processes and Quality Assurance for recumbent bike parts

What Are the Key Manufacturing Processes for Recumbent Bike Parts?

The manufacturing of recumbent bike parts involves several critical stages, each of which is designed to ensure quality, durability, and performance. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Recumbent Bike Parts Manufacturing?

Material preparation is the first step in the manufacturing process. This involves selecting high-quality raw materials, such as aluminum alloys, carbon fiber, and durable plastics, which are essential for producing lightweight yet strong bike components. Suppliers often conduct material tests to verify properties such as tensile strength, corrosion resistance, and weight. For B2B buyers, it is vital to ensure that suppliers provide material certification documents that comply with international standards.

What Forming Techniques Are Used in the Production of Recumbent Bike Parts?

Once the materials are prepared, the next step is forming. This involves various techniques such as CNC machining, extrusion, and molding.

-

CNC Machining: This technique is widely used for precision parts like frames, hubs, and brackets. CNC machines can create complex shapes with high accuracy, ensuring that each part meets specified tolerances.

-

Extrusion: This method is particularly useful for producing long, uniform components such as handlebars and seat rails. The process involves forcing molten material through a die, creating a continuous profile that is then cut to length.

-

Molding: For plastic components, injection molding is commonly used. This process allows for the creation of intricate shapes and is highly efficient for producing large volumes.

B2B buyers should inquire about the specific forming techniques used by suppliers and their capabilities in handling custom designs.

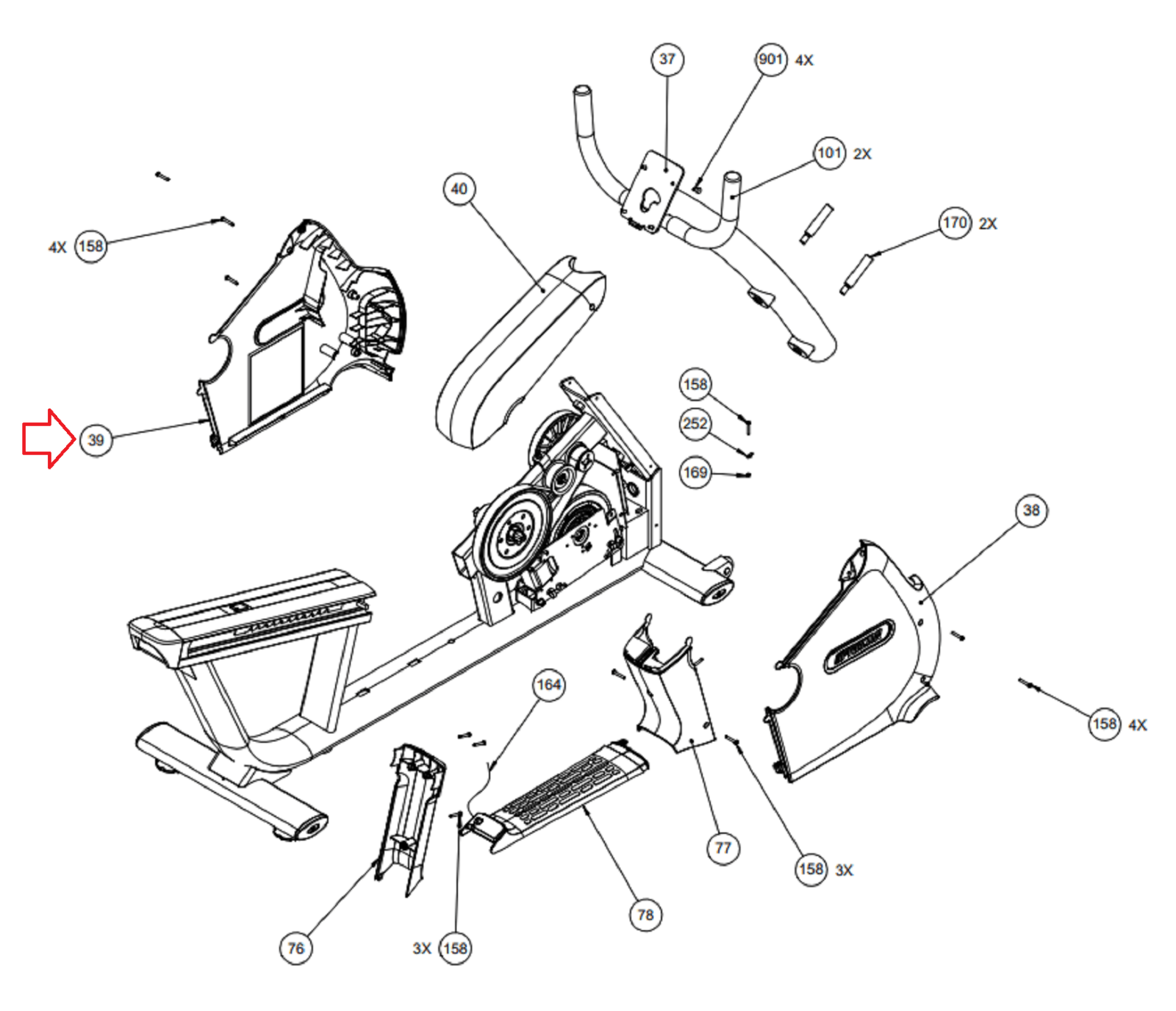

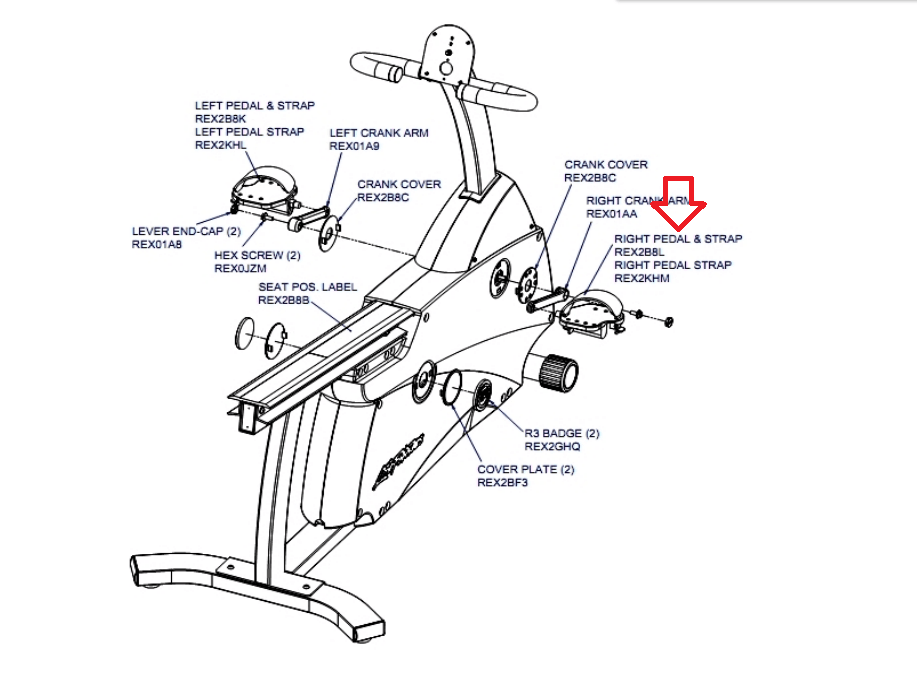

How Are Recumbent Bike Parts Assembled?

The assembly stage involves putting together various components to create the final product. This process can vary significantly based on the complexity of the bike part. For instance, assembling a recumbent bike frame may involve welding or bonding different sections, while the assembly of smaller parts like pedals or seats may require mechanical fastening.

Quality assurance during assembly is critical. Assemblers typically follow detailed work instructions and checklists to ensure that every component is installed correctly. B2B buyers should request information on the assembly processes and the experience of the workforce to ensure consistency and reliability.

What Finishing Techniques Are Applied to Enhance Recumbent Bike Parts?

Finishing processes are essential for improving the aesthetics and durability of recumbent bike parts. Common techniques include anodizing, painting, and powder coating.

-

Anodizing: This electrochemical process enhances corrosion resistance and allows for color customization, which can be an attractive selling point for end-users.

-

Powder Coating: This method provides a durable finish that can withstand the rigors of outdoor use. It also offers a variety of color options and textures.

B2B buyers should verify whether the finishing processes comply with environmental regulations, especially when importing products into regions with strict environmental standards.

What Quality Assurance Standards Are Relevant for Recumbent Bike Parts?

Quality assurance is a critical aspect of the manufacturing process for recumbent bike parts. Suppliers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that a supplier follows established procedures to ensure product quality.

How Do Industry-Specific Standards Apply to Recumbent Bike Parts?

In addition to general quality standards, specific certifications may apply to recumbent bike parts, such as CE marking in Europe and API standards in certain applications. CE marking ensures that products meet EU safety, health, and environmental requirements. For B2B buyers, understanding these certifications can facilitate smoother trade and compliance with local regulations.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to monitor quality. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before processing begins.

-

In-Process Quality Control (IPQC): Ongoing inspections are performed during the manufacturing process to catch defects early. This includes monitoring tolerances during CNC machining and checking assembly accuracy.

-

Final Quality Control (FQC): Before shipment, final inspections ensure that the finished products meet all specifications and quality standards. This may involve functional testing, dimensional checks, and visual inspections.

B2B buyers should request detailed QC reports that outline the methods and frequency of these inspections.

How Can B2B Buyers Verify Supplier Quality Control Processes?

To ensure reliable quality control, B2B buyers should engage in thorough supplier verification. This can include:

-

Audits: Conducting regular audits of suppliers’ facilities to assess their adherence to quality standards and manufacturing processes.

-

Reports: Requesting comprehensive quality reports that outline testing methods, results, and corrective actions taken in case of non-compliance.

-

Third-Party Inspection: Engaging third-party inspection services can provide an unbiased assessment of product quality and compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, may encounter specific challenges regarding quality control. These challenges may include:

-

Language Barriers: Miscommunication can lead to misunderstandings regarding specifications and quality expectations. It’s essential to establish clear communication channels.

-

Regulatory Compliance: Different countries have varying regulations concerning product safety and quality. Buyers must ensure that suppliers are compliant with local laws to avoid penalties or product recalls.

-

Cultural Differences: Understanding cultural nuances in business practices can aid in establishing more effective partnerships.

By focusing on these key aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing recumbent bike parts, ensuring that they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘recumbent bike parts’

Introduction

This practical sourcing guide provides B2B buyers with a systematic approach to procure high-quality recumbent bike parts. The global market for these components is growing, particularly in regions like Africa, South America, the Middle East, and Europe. By following this checklist, you can ensure that your sourcing process is efficient, cost-effective, and aligned with your business needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of successful procurement. Specify the type of recumbent bike parts you need, such as frames, wheels, or accessories, and detail the materials, dimensions, and performance characteristics required. This clarity will help you communicate effectively with suppliers and avoid costly mistakes later in the process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers in the recumbent bike parts industry. Utilize online directories, trade shows, and industry publications to gather a list of potential candidates. Pay attention to their market presence, product range, and customer reviews, which can provide insights into their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with international quality standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management. This step ensures that the parts you procure meet safety and quality benchmarks, reducing the risk of defects and returns.

Step 4: Request Samples and Product Specifications

Request samples of the recumbent bike parts you intend to purchase to assess their quality firsthand. Additionally, obtain detailed product specifications and warranty information. Analyzing samples can help you evaluate the durability and functionality of the parts, ensuring they meet your operational requirements.

Step 5: Negotiate Pricing and Terms

Engage in negotiations with potential suppliers to secure favorable pricing and payment terms. Discuss bulk purchase discounts, shipping costs, and payment methods. Establishing clear terms upfront can enhance your budgeting process and prevent unexpected expenses down the line.

Step 6: Assess Logistics and Delivery Options

Evaluate the logistics capabilities of your chosen suppliers to ensure timely delivery of your orders. Consider factors such as shipping methods, delivery times, and costs associated with international shipping. Understanding these elements will help you plan your inventory and avoid disruptions in your supply chain.

Step 7: Establish a Communication Plan

Set up a clear communication plan with your suppliers to facilitate ongoing collaboration. Determine the preferred methods of communication, frequency of updates, and key contacts on both sides. Effective communication is essential for addressing issues promptly and maintaining a strong supplier relationship.

By following this step-by-step checklist, B2B buyers can enhance their procurement processes for recumbent bike parts, ensuring they source high-quality components that meet their business needs.

Comprehensive Cost and Pricing Analysis for recumbent bike parts Sourcing

What Are the Key Cost Components in Sourcing Recumbent Bike Parts?

When sourcing recumbent bike parts, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The type of materials used—such as aluminum, carbon fiber, and high-quality plastics—significantly impacts costs. Premium materials often lead to higher durability and performance but come at a higher price.

-

Labor: Labor costs can vary based on the region and the complexity of manufacturing processes. Countries with lower labor costs may provide a competitive edge, but quality control can become a concern.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and equipment maintenance. Efficient production facilities can lower overhead costs, impacting the final pricing of parts.

-

Tooling: Initial tooling costs for custom parts can be substantial. However, these costs can be amortized over larger production runs, reducing the per-unit cost.

-

Quality Control (QC): Implementing rigorous QC measures ensures that parts meet safety and performance standards. While this adds to the cost, it can prevent costly returns and reputational damage.

-

Logistics: Shipping costs, especially for international orders, can vary widely depending on distance, shipping method, and customs duties. Incorporating these costs into your total analysis is vital for understanding the true expense of sourced parts.

-

Margin: Suppliers typically apply a margin to cover their costs and ensure profitability. Understanding the margin expectations of different suppliers can help buyers negotiate better deals.

How Do Price Influencers Affect Recumbent Bike Parts?

Several factors can influence the pricing of recumbent bike parts, including:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often result in lower per-unit costs due to economies of scale. Buyers should negotiate for better pricing based on their expected purchase volumes.

-

Specifications and Customization: Custom parts tailored to specific needs may incur additional costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials: The choice of materials not only affects the cost but also influences performance and longevity. Buyers should consider the long-term value of higher-quality materials.

-

Quality and Certifications: Parts that meet international safety and quality certifications may command higher prices. However, these certifications can assure buyers of the product’s reliability and safety.

-

Supplier Factors: The reputation and reliability of suppliers can significantly influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They dictate who is responsible for shipping costs, insurance, and tariffs, influencing the total landed cost of the parts.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Wisely: Leverage your position as a buyer by negotiating not just on price but also on terms such as payment conditions, delivery timelines, and after-sales support.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the initial purchase price but also factors such as maintenance, durability, and potential repair costs. A lower upfront cost may not always lead to better overall value.

-

Understand Pricing Nuances: Familiarize yourself with regional pricing differences and potential tariffs that may affect costs. Engaging with local suppliers can sometimes mitigate these expenses.

-

Build Relationships with Suppliers: Establishing long-term partnerships with suppliers can lead to better pricing and priority service. Suppliers are often more willing to negotiate with trusted clients.

-

Stay Informed on Market Trends: Keeping abreast of industry trends, such as material advancements and shifts in consumer preferences, can help buyers make informed purchasing decisions that align with market demands.

Disclaimer on Indicative Prices

Prices for recumbent bike parts can fluctuate based on market conditions, raw material costs, and supply chain dynamics. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing recumbent bike parts With Other Solutions

Exploring Alternatives to Recumbent Bike Parts

In the world of cycling, especially for recumbent bike enthusiasts, the choice of parts and accessories is crucial for optimizing performance, comfort, and safety. However, buyers may encounter various alternatives that can serve similar purposes. Understanding these alternatives can help international B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe, make informed purchasing decisions.

Comparison Table

| Comparison Aspect | Recumbent Bike Parts | Electric Bikes | Traditional Upright Bikes |

|---|---|---|---|

| Performance | High efficiency and comfort for long rides | Enhanced speed and less physical effort | Versatile but can be less comfortable on long journeys |

| Cost | Moderate to high, depending on customization | Higher upfront cost, plus battery replacements | Generally lower initial investment |

| Ease of Implementation | Requires specific knowledge for assembly | User-friendly with minimal setup | Simple assembly, widely available parts |

| Maintenance | Moderate; requires regular checks and part replacements | Low to moderate; battery and electrical components need monitoring | Low; easy access to parts and repairs |

| Best Use Case | Long-distance touring, comfort-focused rides | Urban commuting, recreational riding | Daily commuting, fitness |

Detailed Breakdown of Alternatives

Electric Bikes

Electric bikes (e-bikes) have gained significant popularity due to their ability to enhance performance and reduce physical strain. They offer features like pedal-assist technology, which can make uphill rides and longer distances more manageable. However, e-bikes come with a higher initial cost, and the necessity of battery management can complicate maintenance. For buyers in regions with varied terrain or longer commuting distances, e-bikes can be an effective alternative, though they may sacrifice some of the comfort and ergonomics that recumbent bikes provide.

Traditional Upright Bikes

Traditional upright bicycles are widely recognized for their versatility and accessibility. They are generally less expensive than both recumbent bikes and e-bikes, making them an attractive option for budget-conscious buyers. However, they may not provide the same level of comfort for long rides, especially for those with back or joint issues. Traditional bikes are also easier to maintain, with a vast market for parts and repair services. For B2B buyers looking for a cost-effective and widely accepted solution for short-distance travel or fitness, traditional bikes could be a suitable choice.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between recumbent bike parts and alternative cycling solutions, it’s essential to consider the specific needs of your target market. Factors such as performance expectations, budget constraints, ease of maintenance, and the intended use case should guide your decision. Recumbent bikes excel in comfort and long-distance efficiency, while electric bikes and traditional upright bicycles may offer advantages in cost and ease of use. By carefully evaluating these alternatives, B2B buyers can ensure they make the most informed choices for their customers, ultimately leading to greater satisfaction and loyalty in the competitive cycling market.

Essential Technical Properties and Trade Terminology for recumbent bike parts

What Are the Essential Technical Properties of Recumbent Bike Parts?

When considering the procurement of recumbent bike parts, understanding the technical properties is crucial for ensuring quality, safety, and performance. Here are some key specifications to consider:

1. Material Grade

Material grade refers to the quality and composition of the materials used in manufacturing bike parts, such as aluminum, carbon fiber, or steel. Higher-grade materials typically offer better durability, weight savings, and resistance to corrosion. For B2B buyers, selecting parts made from superior materials can lead to longer product lifespans and reduced maintenance costs.

2. Tolerance

Tolerance is the permissible limit or limits of variation in a physical dimension or measured value. For example, the tolerance on a crank arm length may affect how smoothly the bike operates. In a B2B context, understanding tolerance levels helps ensure compatibility between components and can prevent costly errors during assembly or usage.

3. Weight Capacity

Weight capacity indicates the maximum load a component can safely support. For recumbent bikes, this is especially important for parts like seats, frames, and wheels. B2B buyers should prioritize weight capacity to ensure the safety and comfort of end-users, especially in markets with diverse rider profiles.

4. Finish

The finish of a component refers to its surface treatment, which can include anodizing, powder coating, or painting. A quality finish not only enhances aesthetics but also improves resistance to wear and environmental factors. For B2B transactions, understanding finish specifications can be vital for branding and ensuring product longevity.

5. Compatibility

Compatibility pertains to how well different parts work together within a bike system. This is crucial when sourcing components from various manufacturers. B2B buyers need to assess compatibility to avoid issues in assembly and performance, ensuring that all parts meet the specific requirements of the bike model.

What Are Common Trade Terms Used in the Recumbent Bike Parts Industry?

Familiarizing yourself with industry jargon can enhance communication and streamline transactions. Here are some important terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM produces parts that are used in the manufacturing of another company’s products. In the recumbent bike industry, OEM parts are often preferred for their guaranteed fit and quality. B2B buyers should ensure they understand whether they are sourcing OEM or aftermarket parts, as this can impact warranty and performance.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers to manage inventory costs effectively. It can also dictate the overall investment required for initial purchases.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific quantities of products. For B2B buyers, issuing RFQs can facilitate competitive pricing and help in comparing different suppliers, ensuring the best value for their procurement needs.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international shipping terms that define the responsibilities of buyers and sellers in a transaction. Familiarity with these terms helps B2B buyers understand shipping costs, risk transfers, and delivery obligations, which are critical for international trade.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the goods. In the recumbent bike parts industry, lead time can vary significantly based on the supplier’s location and production capabilities. B2B buyers must consider lead time when planning inventory and sales strategies.

By understanding these technical properties and trade terminology, B2B buyers can make informed decisions, ensuring that they procure the right recumbent bike parts that meet their business needs and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the recumbent bike parts Sector

What Are the Key Trends Shaping the Recumbent Bike Parts Market?

The recumbent bike parts market is witnessing robust growth, propelled by several global drivers. The increasing popularity of cycling as a sustainable mode of transportation, coupled with rising health consciousness, has spurred demand for recumbent bikes, particularly in urban settings across Africa, South America, the Middle East, and Europe. Emerging markets are seeing a rise in recreational cycling, influenced by government initiatives promoting eco-friendly transport solutions.

B2B tech trends are significantly impacting sourcing strategies. Digital platforms are streamlining procurement processes, enabling international buyers to access a diverse range of products from global suppliers. E-commerce solutions and online marketplaces are becoming essential tools for buyers seeking competitive pricing and unique offerings. Furthermore, advancements in supply chain technologies, such as blockchain, are enhancing transparency and traceability, allowing buyers to verify the origins and quality of parts.

In terms of market dynamics, buyers should be aware of fluctuating material costs and supply chain disruptions, often influenced by geopolitical factors and environmental regulations. Establishing strong relationships with manufacturers and suppliers can mitigate these risks, ensuring a steady supply of quality parts. Buyers are increasingly prioritizing suppliers who demonstrate agility and innovation in adapting to market changes, thereby enhancing their competitive edge.

How Is Sustainability and Ethical Sourcing Reshaping the Recumbent Bike Parts Sector?

Sustainability is becoming a cornerstone of the recumbent bike parts sector, driven by both consumer demand and regulatory pressure. Environmental impacts associated with manufacturing processes, such as carbon emissions and waste generation, are prompting companies to adopt greener practices. Buyers are increasingly seeking suppliers that prioritize sustainable sourcing of materials and environmentally friendly production methods.

Ethical supply chains are equally important. Buyers are encouraged to engage with manufacturers who adhere to fair labor practices and have transparent sourcing policies. Certifications like ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices. These certifications not only enhance brand reputation but also meet the growing consumer demand for responsible products.

Investing in ‘green’ materials, such as recycled aluminum and biodegradable components, is becoming a strategic advantage. Suppliers who can offer eco-friendly options are likely to attract discerning B2B buyers looking to align their procurement strategies with corporate social responsibility (CSR) goals. By prioritizing sustainability, companies can not only reduce their environmental footprint but also drive innovation within the recumbent bike parts market.

What Is the Evolution of the Recumbent Bike Parts Market?

The evolution of the recumbent bike parts market has been marked by significant technological advancements and shifts in consumer preferences. Initially, recumbent bikes were niche products primarily used by enthusiasts. However, over the past few decades, the market has expanded as manufacturers have improved designs, making them more accessible and appealing to a broader audience.

The introduction of innovative materials and manufacturing techniques has enhanced the performance and comfort of recumbent bikes, leading to increased adoption. Additionally, as urban areas become more congested, the demand for alternative transportation methods has surged, further propelling the growth of the recumbent bike market.

Today, international B2B buyers are well-positioned to leverage this evolution, as the market continues to mature with a focus on quality, sustainability, and innovation. As the sector grows, staying informed about technological developments and market dynamics will be crucial for making strategic sourcing decisions that align with long-term business goals.

Frequently Asked Questions (FAQs) for B2B Buyers of recumbent bike parts

-

1. How do I solve supply chain delays for recumbent bike parts?

Supply chain delays can often arise from international shipping issues, customs regulations, or supplier reliability. To mitigate these challenges, establish clear communication with your suppliers and inquire about their logistics capabilities. Additionally, consider diversifying your supplier base to avoid dependency on a single source. Implementing inventory management practices, such as safety stock and just-in-time ordering, can also help maintain product availability despite potential delays. -

2. What is the best type of recumbent bike part for long-distance riding?

For long-distance riding, prioritize comfort and durability when selecting recumbent bike parts. High-quality seats, such as those with ergonomic design and ventilation, are crucial for comfort over extended periods. Additionally, opt for reliable drivetrain components that can withstand long rides without frequent maintenance. Accessories like hydration systems and adjustable handlebars also enhance the riding experience, making them essential for long-distance journeys. -

3. How can I vet suppliers for recumbent bike parts effectively?

To vet suppliers, start by researching their reputation within the industry. Look for reviews, testimonials, and case studies from other B2B buyers. Request samples of their products to assess quality firsthand. Additionally, verify their certifications and compliance with international standards. Engaging in direct communication can also provide insight into their responsiveness and customer service, which are crucial for a successful partnership. -

4. What are the minimum order quantities (MOQs) for recumbent bike parts?

Minimum order quantities (MOQs) can vary significantly between suppliers and products. Many manufacturers set MOQs based on production costs, inventory management, and market demand. When negotiating, inquire about flexible MOQs, especially if you are a new buyer or testing a market. Some suppliers may offer lower MOQs for specific items or during promotional periods, so it’s beneficial to discuss your requirements openly. -

5. What payment terms should I expect when sourcing recumbent bike parts internationally?

Payment terms can differ widely among suppliers, but common practices include upfront deposits, net 30, or 60-day payment terms. Always clarify the payment structure before finalizing orders to avoid misunderstandings. Consider using secure payment methods such as letters of credit or escrow services, especially for larger transactions, to ensure both parties are protected. Discussing payment options upfront can foster a stronger relationship with your supplier. -

6. How can I customize recumbent bike parts to meet specific market needs?

Customization of recumbent bike parts is often possible through direct communication with manufacturers. Discuss your specific requirements regarding size, color, materials, and features. Many suppliers are willing to collaborate on design modifications, especially for bulk orders. Be prepared to provide detailed specifications and, if necessary, engage in prototype development to ensure the final product aligns with your market needs. -

7. What quality assurance practices should I look for in suppliers of recumbent bike parts?

When sourcing recumbent bike parts, inquire about the supplier’s quality assurance practices. Look for certifications such as ISO 9001, which indicates a commitment to quality management. Ask about their inspection processes, testing methods, and whether they have a dedicated quality control team. Suppliers that provide transparency regarding their QA processes are more likely to deliver consistent and reliable products. -

8. What logistics considerations are important when importing recumbent bike parts?

Logistics plays a crucial role in the successful importation of recumbent bike parts. Assess shipping methods, lead times, and costs associated with international transport. Familiarize yourself with customs regulations and tariffs in your country to avoid unexpected delays. Partnering with a reliable freight forwarder can streamline the process and provide insights into the best practices for shipping, ensuring timely delivery of your products.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Recumbent Bike Parts Manufacturers & Suppliers List

1. Hostelshoppe – Bike & Recumbent Parts

Domain: hostelshoppe.com

Registered: 1996 (29 years)

Introduction: Parts collection includes a wide range of bike and recumbent parts for repair and maintenance. Key categories include Adaptive Cycling, Bearings, Bottom Brackets, Brakes (including Cables, Calipers, Levers, and Pads), Chain Management, Cranks, Derailleurs, Electric Assist components, Forks, Frame Parts, Grips, Handlebars, Headsets, Hubs, Pedals, Saddles, Seatposts, Shifters, Stems, Suspension, Tir…

2. Laidback Cycles – SportCrafters Roller & Recumbent Trike Ramps

Domain: laidbackcycles.com

Registered: 2011 (14 years)

Introduction: SportCrafters Roller – Trike Trainer: Sale price $234.99, 11 reviews, designed specifically for recumbent trikes, easy to use, lightweight, portable, no assembly or maintenance required.

Recumbent Trike Ramps: 7′ Adjustable Telescoping: Sale price $269.00, Regular price $299.99, 15 reviews, made for ease of loading into SUVs and Trucks.

‘I Ride Laid Back’ T-Shirt: Sale price From $24.99, 1 revie…

3. Cruzbike – Bottle Cage

Domain: cruzbike.com

Registered: 2004 (21 years)

Introduction: {“Cruzbike Bottle Cage”:{“price”:”$20.00″,”weight”:”47 grams”,”description”:”Light weight, anodized alloy side and top-pull cage that works for either left or right. Includes required installation hardware. Fits standard-sized water bottles like the Camelbak Podium. Installs on the seat back of the V20c, S40, T50 and Q45 and on the Headrest Cage Mount Kit for the S40 and V20.”,”installation_guide”…

4. T-Cycle – Recumbent Parts & Accessories

Domain: t-cycle.com

Registered: 2010 (15 years)

Introduction: T-Cycle offers a variety of exquisite recumbent parts and accessories, including: Accessory Mounts, Assist Accessories, Bags & Hydration Packs, Battery Mounts, Bike Polo, Chain in Bulk, Chain Idlers, Chain Idler Kits, Chain Management Accessories, Fairings, Flags, GlideFlex Stems, LAMA Mounts, Neckrests, Pannier Racks, SeatSide Mount System, Stainless Bolt Kits, Workstands, and Xtras, Blems & Disc…

5. Bicycleman – Recumbent Bikes and Accessories

Domain: store.bicycleman.com

Registered: 1998 (27 years)

Introduction: Bicycleman Online offers a variety of recumbent bike parts and accessories. Key product categories include:

– Recumbent Bikes and Trikes

– Recumbent Parts by Brand (e.g., Avenue Trikes, Azub, Bacchetta, Burley, Catrike, etc.)

– Parts and Accessories (e.g., Clothing and Mech Accessories, Adaptive Car Racks, DIY Corner, Drivetrain Parts, Exercise Fairings, Fenders, Luggage Racks, Safety Seats, Tires…

6. Catrike – E-Cat Electric Motor Upgrade

Domain: basicallybicycles.com

Registered: 1999 (26 years)

Introduction: [{“name”:”Catrike E-Cat electric motor upgrade”,”price”:”$3,550.00″,”description”:”Adding an electric assist to your Catrike recumbent trike is easy with the e-Cat electric motor kit upgrade. Compatible with Catrike models Dumont, 5.5.9, Expedition, Trail, Pocket, or Villager. Features Bosch Active Line Plus system with four levels of assistance and a 400 Wh battery pack with a maximum range of 62…

7. Bacchetta – Replacement Parts

Domain: bacchettabikes.com

Registered: 2001 (24 years)

Introduction: Bacchetta replacement parts include: Bacchetta Idler (from $20.00), Bacchetta Idler Assembly (from $39.00), Bacchetta Hardshell Seat Mounting Hardware ($40.00), Bacchetta Idler Bolt ($3.00, sold out), Bacchetta Grips and Plugs ($15.00, sold out), Bacchetta Idler Spacer ($6.00), Bacchetta Chainkeeper ($10.00), Bacchetta Giro A20 Frameset ($975.00), T-Cycle Bacchetta 23t Sport Idler Kit ($159.00, so…

8. Ligfiets – Trike Work Stand

Domain: ligfiets.shop

Introduction: Trike work stand: €375,00; Table top trike work stand: €225,00; Shelf trike work stand: €19,95; Plier holder trike work stand: €19,95; Screwdriver holder trike work stand: €16,95; Walking stick holder: €39,95; Optima Lowracer bag: €39,95; Shimano Deore Xt pedal PD-T8000: €84,95; Third Eye eyeglasses mirror: €16,95; Cassette 9-speed 11-34: €34,95 SRP / €29,95; Cassette 9-speed 11-36: €34,95 SRP / €…

9. Startrac – Recumbent Bike Parts

Domain: gympart.com

Registered: 1997 (28 years)

Introduction: Startrac Recumbent Bike Parts available at Gympart.com. Popular parts include drive belts, seats, crank assemblies, and cosmetic parts like pedal straps. Compatible with Model S and StairMaster technology. Replacement procedures and diagnostics available. Serial number check recommended for accurate part matching.

Strategic Sourcing Conclusion and Outlook for recumbent bike parts

In the evolving landscape of recumbent bike parts, strategic sourcing emerges as a crucial element for international B2B buyers seeking to optimize their supply chains. By prioritizing quality and reliability, buyers can ensure they provide their customers with superior products, from essential bike components to accessories that enhance the riding experience. Key takeaways include the importance of understanding regional market demands, leveraging local suppliers, and maintaining robust relationships with manufacturers to facilitate timely deliveries and innovative product offerings.

As markets across Africa, South America, the Middle East, and Europe continue to expand, the demand for high-quality recumbent bike parts is set to rise. Buyers should actively engage with suppliers that offer comprehensive product ranges and flexible shipping options to navigate the complexities of international trade.

Looking ahead, embracing a proactive sourcing strategy will not only enhance competitive advantage but also foster long-term partnerships that can adapt to market shifts. Now is the time for B2B buyers to evaluate their sourcing strategies and align with suppliers that prioritize sustainability, innovation, and customer satisfaction. The future of recumbent biking is bright, and your sourcing decisions today will shape the ride of tomorrow.