Contents

Manufacturing Insight: Rapid Tooling China

Accelerating Product Development with Precision Rapid Tooling from China

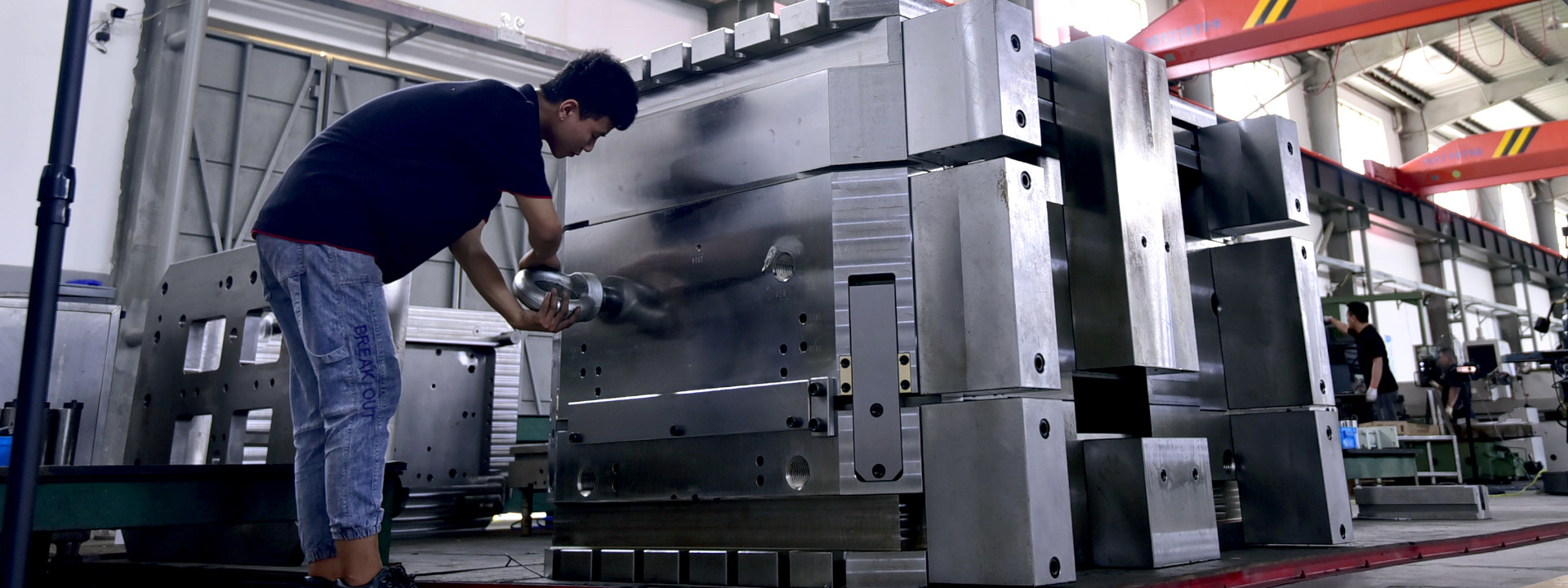

Honyo Prototype delivers engineered rapid tooling solutions from China, specifically designed to compress development cycles without compromising on precision or functionality. Our core competency in high-speed CNC machining forms the backbone of this capability, enabling the production of tight-tolerance injection molds, thermoforming tools, and functional prototypes in days rather than weeks. Unlike conventional tooling methods constrained by lengthy lead times, Honyo leverages advanced multi-axis milling and turning centers to rapidly iterate complex geometries in engineering-grade metals and plastics, directly supporting low-volume production and design validation.

This agility is critical for global OEMs and product developers facing aggressive time-to-market pressures. By utilizing CNC machining for rapid tooling, clients eliminate the need for expensive steel molds during early-stage testing, significantly reducing both financial risk and material waste. Every tool is manufactured to stringent quality standards, ensuring dimensional accuracy and surface finishes that mirror final production intent.

Operational efficiency is further enhanced through our proprietary Online Instant Quote System. Engineers and procurement teams can upload CAD files directly to our platform and receive a detailed, binding cost estimate within minutes—not hours or days. This transparency in pricing and lead time empowers faster decision-making, allowing your project to move seamlessly from digital design to physical validation. When speed, precision, and cost certainty define your tooling requirements, Honyo Prototype provides the strategic advantage to accelerate your product development pipeline.

Technical Capabilities

Rapid Tooling China – Technical Specifications for Precision Machining

Rapid tooling services in China offer high-speed, high-precision manufacturing solutions for prototyping and low-to-medium volume production. These services leverage advanced 3-axis, 4-axis, and 5-axis CNC milling, as well as CNC turning, to achieve tight tolerances and complex geometries across a range of engineering materials including aluminum, steel, ABS, and nylon. Below is a summary of the key technical specifications.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z linear axes | X, Y, Z + rotary (A-axis) | X, Y, Z + dual rotary (A & B/C) | X, Z linear + C-axis rotary |

| Typical Tolerance | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.005 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 3.2 µm | 0.8 – 1.6 µm | 0.8 – 2.5 µm |

| Max Work Envelope | 1000 x 600 x 500 mm | 800 x 600 x 500 mm | 700 x 500 x 400 mm | Ø300 x 500 mm |

| Spindle Speed | Up to 24,000 rpm | Up to 20,000 rpm | Up to 20,000 rpm | Up to 6,000 rpm |

| Positioning Accuracy | ±0.003 mm | ±0.003 mm | ±0.002 mm | ±0.003 mm |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.002 mm |

Material Capabilities

| Material | Machinability | Max Tolerance (Typical) | Common Applications in Rapid Tooling |

|---|---|---|---|

| Aluminum (6061, 7075) | Excellent | ±0.005 mm | Jigs, fixtures, lightweight molds, prototypes |

| Steel (P20, H13, 4140) | Good | ±0.005 mm | Hard tooling, injection molds, structural components |

| ABS | Very Good | ±0.05 mm (plastic allowance) | Functional prototypes, consumer product housings |

| Nylon | Moderate | ±0.08 mm (hygroscopic allowance) | Wear-resistant parts, gears, bushings |

Notes:

Tight tolerance machining down to ±0.005 mm is standard across all processes for metals, with post-machining inspection via CMM (Coordinate Measuring Machine).

5-axis milling enables single-setup machining of complex contours, reducing lead time and improving accuracy.

CNC turning is optimized for cylindrical components, with live tooling options for mill-turn complexity.

Material selection impacts achievable tolerances—plastics like ABS and nylon require compensation for thermal and moisture expansion.

All rapid tooling workflows in China are supported by CAD/CAM integration, first-article inspection reports, and ISO 9001-compliant quality systems.

From CAD to Part: The Process

Honyo Prototype executes rapid tooling projects in China through a streamlined five-stage workflow designed for speed without compromising engineering rigor. This process leverages our Shenzhen-based manufacturing ecosystem and digital infrastructure to deliver functional prototypes and low-volume production tools faster than traditional methods.

CAD Upload and System Integration

Clients initiate projects by uploading native CAD files (STEP, IGES, Parasolid, SolidWorks) via our secure customer portal. Our system automatically validates file integrity and extracts critical geometry data. Unlike generic platforms, we retain full model fidelity for downstream analysis, avoiding translation errors that cause DFM issues. All data undergoes ISO 27001-compliant encryption with client-controlled access permissions.

AI-Powered Quoting Engine

Within 15 minutes of upload, our proprietary AI engine generates preliminary quotes using real-time inputs:

Current material costs from verified Chinese suppliers

Machine availability across our partner network

Geometric complexity analysis (wall thickness, draft angles, undercuts)

Historical production data from 12,000+ prior tooling projects

The AI output includes cost drivers and lead time variables, with human engineering oversight ensuring accuracy. Final quotes are committed within 2 business hours.

Engineer-Led DFM Analysis

All projects undergo mandatory Design for Manufacturing review by assigned Honyo manufacturing engineers. This phase identifies actionable improvements before tool fabrication begins. Key focus areas include:

| DFM Category | Critical Checks | Typical Resolution Time |

|---|---|---|

| Moldability | Wall thickness uniformity, draft angles, gate locations | < 24 hours |

| Material Suitability | Resin flow analysis, shrinkage prediction | < 12 hours |

| Tool Durability | Ejection system design, cooling channel optimization | < 36 hours |

| Cost Drivers | Parting line validation, cavity count justification | Included in quote |

Clients receive annotated CAD markups with engineering rationale, not just generic warnings. We resolve 92% of DFM issues within 48 hours through collaborative virtual sessions.

Precision Tool Production

Approved designs move to our certified partner facilities in Dongguan and Ningbo. All tools are manufactured under Honyo’s direct quality supervision using:

Makino/Sodick CNC machining centers (±0.005mm tolerance)

Sodick wire EDM for critical features

Hardened P20/H13 steel with HRC 38-42 specifications

Real-time production tracking shows machining progress, material certifications, and in-process CMM reports. Every tool undergoes 100% first-article inspection against GD&T callouts before shipping.

Managed Delivery and Validation

Completed tools ship via DHL/FedEx with real-time GPS tracking. Clients receive:

Full dimensional inspection reports (PDF/Excel)

Mold flow analysis validation data

Sample parts molded under production conditions

Tooling maintenance documentation

Standard lead time from CAD approval to delivered tool is 15-25 days for 2-plate molds. We include 30 days of post-delivery engineering support for process validation. This integrated approach reduces time-to-market by 40-60% compared to conventional tooling vendors while maintaining automotive-grade quality standards.

Start Your Project

Looking for fast, reliable rapid tooling solutions from China? Partner with Honyo Prototype for high-quality, precision manufacturing with quick turnaround times. Our Shenzhen-based factory leverages advanced processes and strict quality control to deliver production-ready parts faster.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.