Contents

Manufacturing Insight: Rapid Sheet Metal Prototyping

Accelerate Product Development with Precision Sheet Metal Prototyping

Honyo Prototype delivers rapid sheet metal prototyping services engineered to compress your development timeline without sacrificing precision. For engineering and procurement teams facing aggressive product launch schedules, our end-to-end fabrication capabilities—including laser cutting, precision bending, CNC punching, and TIG/MIG welding—transform digital designs into fully functional metal prototypes in as few as 3–5 business days. We specialize in low-volume production runs from 1 to 500 units across aluminum, stainless steel, and mild steel gauges ranging from 0.5mm to 3.0mm, ensuring your design intent is validated with production-intent accuracy.

Our process integrates ISO 9001-certified quality controls at every stage, from material sourcing to final inspection, eliminating common prototyping pitfalls like dimensional drift or finish inconsistencies. Unlike traditional vendors requiring manual RFQ reviews, Honyo’s proprietary Online Instant Quote platform provides binding pricing and lead times within 60 seconds—no sales calls or email delays. Simply upload your STEP or DXF file, specify materials and finishes, and receive a manufacturability report alongside your quote, enabling immediate iteration and procurement.

This combination of speed, technical rigor, and digital accessibility positions Honyo as the strategic partner for OEMs and contract manufacturers demanding rapid validation of sheet metal components. Reduce your prototyping cycle from weeks to days while maintaining the dimensional tolerances and structural integrity required for real-world testing.

Technical Capabilities

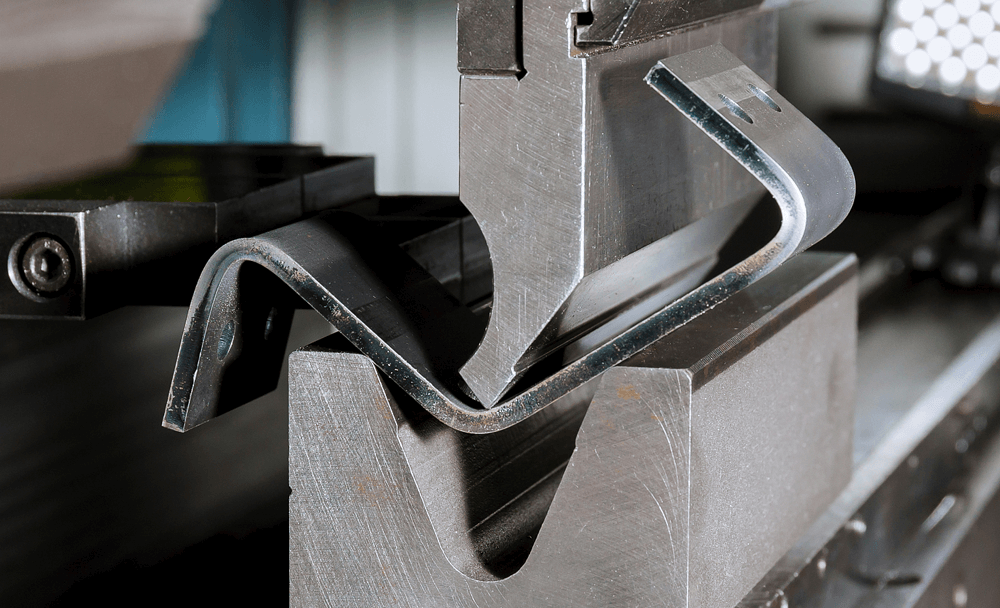

Rapid sheet metal prototyping involves high-speed fabrication processes to quickly produce functional prototypes from sheet materials. Key processes include laser cutting for precise profiling, CNC bending for accurate fold formation, and welding (typically TIG or MIG) for permanent assembly. These processes are optimized for fast turnaround, often within 1–3 days, using automated equipment for repeatability and tight tolerances. Materials commonly used include metals such as aluminum and steel for structural components, and engineering plastics like ABS and nylon for non-load-bearing or insulative parts, though plastics are typically machined or 3D printed rather than bent or welded in traditional sheet metal setups.

| Parameter | Laser Cutting | CNC Bending | Welding (TIG/MIG) |

|---|---|---|---|

| Process Type | Thermal cutting using high-power laser | Mechanical forming using press brake | Fusion joining using electric arc |

| Typical Tolerance | ±0.1 mm | ±0.2° angular, ±0.1 mm linear | ±0.5 mm fit-up, post-weld distortion |

| Material Thickness | 0.5 – 25 mm (metals) | 0.5 – 12 mm | 0.8 – 15 mm (steel/aluminum) |

| Common Materials | Aluminum 5052, 6061; Steel (CRS, SS304) | Aluminum 5052, 6061; Cold Rolled Steel | Aluminum 6061; Mild Steel (A36, CR1018) |

| Plastics Compatibility | Limited (ABS, Nylon – thin sheets only, non-structural) | Not recommended for ABS/Nylon (poor formability) | Not applicable (ABS/Nylon cannot be arc welded) |

| Surface Finish | Smooth, minor oxidation on edges | As-raw or coated; bend lines visible | Requires post-weld grinding/polishing |

| Lead Time (Typical) | 1–2 days | 1–3 days (setup-intensive) | 2–3 days (includes fixturing, welding, cleanup) |

| Key Advantages | High precision, fast processing, complex geometries | Repeatable angles, tight bend radii | Strong, permanent joints; suitable for load-bearing |

| Limitations | Kerf width (~0.1–0.3 mm), heat-affected zone | Springback in aluminum, tooling requirements | Distortion, requires skilled operator, post-processing |

Note: While ABS and nylon are occasionally processed using laser cutting for prototyping enclosures or fixtures, they are not compatible with CNC bending (due to low ductility and high springback) or arc welding. Alternative joining methods such as adhesive bonding or mechanical fasteners are used for plastic components.

From CAD to Part: The Process

Honyo Prototype’s rapid sheet metal prototyping process is engineered for speed, precision, and seamless integration with engineering workflows. This end-to-end solution eliminates traditional bottlenecks through digital automation while maintaining rigorous manufacturing standards. Below is a detailed technical breakdown of each phase.

Upload CAD

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, DXF, DWG) via our secure customer portal. Our system performs immediate geometric validation, checking for unit consistency, surface integrity, and file completeness. Invalid submissions trigger real-time feedback specifying required corrections, preventing downstream delays. This phase typically completes within minutes, establishing a structured digital thread for the project.

AI-Powered Quoting Engine

Uploaded geometry is processed by Honyo’s proprietary AI quoting system, which analyzes over 200 manufacturability parameters including material thickness, bend counts, feature density, and tolerance clusters. The engine cross-references live material pricing, machine availability, and shop floor capacity to generate a binding quote within 15 minutes. Unlike manual quoting, this system dynamically accounts for secondary operations like welding or finishing, providing granular cost breakdowns by operation type. Historical data from 50,000+ sheet metal jobs ensures exceptional accuracy in lead time and cost prediction.

Automated DFM Analysis

Following quote acceptance, the CAD model undergoes automated Design for Manufacturability review using rules configured to Honyo’s specific equipment capabilities (e.g., minimum bend radii for our 100-ton Amada press brakes, laser kerf allowances for 4kW Trumpf systems). The system flags non-compliant features such as unfeasible hole-to-bend distances, under-specified tolerances per ISO 2768-mK, or excessive part nesting waste. Engineers receive an interactive report with suggested modifications and manufacturability scores. Critical issues halt progression until resolved; non-critical items generate optional improvement recommendations. This phase reduces traditional DFM iteration cycles from days to under 2 hours.

Lean Production Execution

Approved designs move directly into production via our digital work order system. Key characteristics include:

Material Handling: Laser-cut blanks pulled from climate-controlled inventory with traceable material certs

Process Sequencing: Optimized nesting algorithms maximize yield on 4’x8′ sheets; CNC punch-laser combos handle complex geometries

In-Process Verification: Automated optical inspection after forming checks critical dimensions against CAD; first-article reports generated per AS9102

Secondary Operations: Integrated deburring, tapping, and hardware insertion stations minimize part handling

All production data is logged to our MES for full traceability, with real-time status updates visible to clients through the portal.

Delivery Logistics

Completed prototypes undergo final dimensional validation against the original CAD model using CMM or structured light scanning where specified. Parts ship via pre-negotiated carrier accounts with tracking integration. Standard delivery timelines are maintained as follows:

| Process Phase | Typical Duration | Key Output |

|---|---|---|

| CAD Upload to Quote | < 15 minutes | Validated geometry, binding cost/lead time |

| DFM Analysis | 1-2 hours | Actionable manufacturability report |

| Production | 24-72 hours | FAI documentation, material certs |

| Delivery | +24 hours | Tracked shipment, digital quality records |

This integrated workflow consistently delivers functional sheet metal prototypes in 3-5 business days from CAD upload, with 98.7% first-pass yield based on Q3 2024 production data. The elimination of manual handoffs between quoting, engineering, and production teams is the cornerstone of our rapid turnaround capability, ensuring prototypes meet both functional requirements and production-intent quality standards.

Start Your Project

Looking for rapid sheet metal prototyping with fast turnaround and precision manufacturing? Contact Susan Leo at [email protected] to discuss your project requirements.

Our state-of-the-art factory in Shenzhen offers end-to-end prototyping and low-volume production services, including laser cutting, CNC punching, bending, welding, and surface finishing—all optimized for speed and quality.

Whether you need a single prototype or small batch fabrication, we deliver high-accuracy sheet metal parts with quick lead times, supporting design validation and rapid product development.

Reach out today to accelerate your next project.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.