Contents

Manufacturing Insight: Rapid Sheet Metal Prototypes

Accelerate Your Product Development with Precision Sheet Metal Prototyping

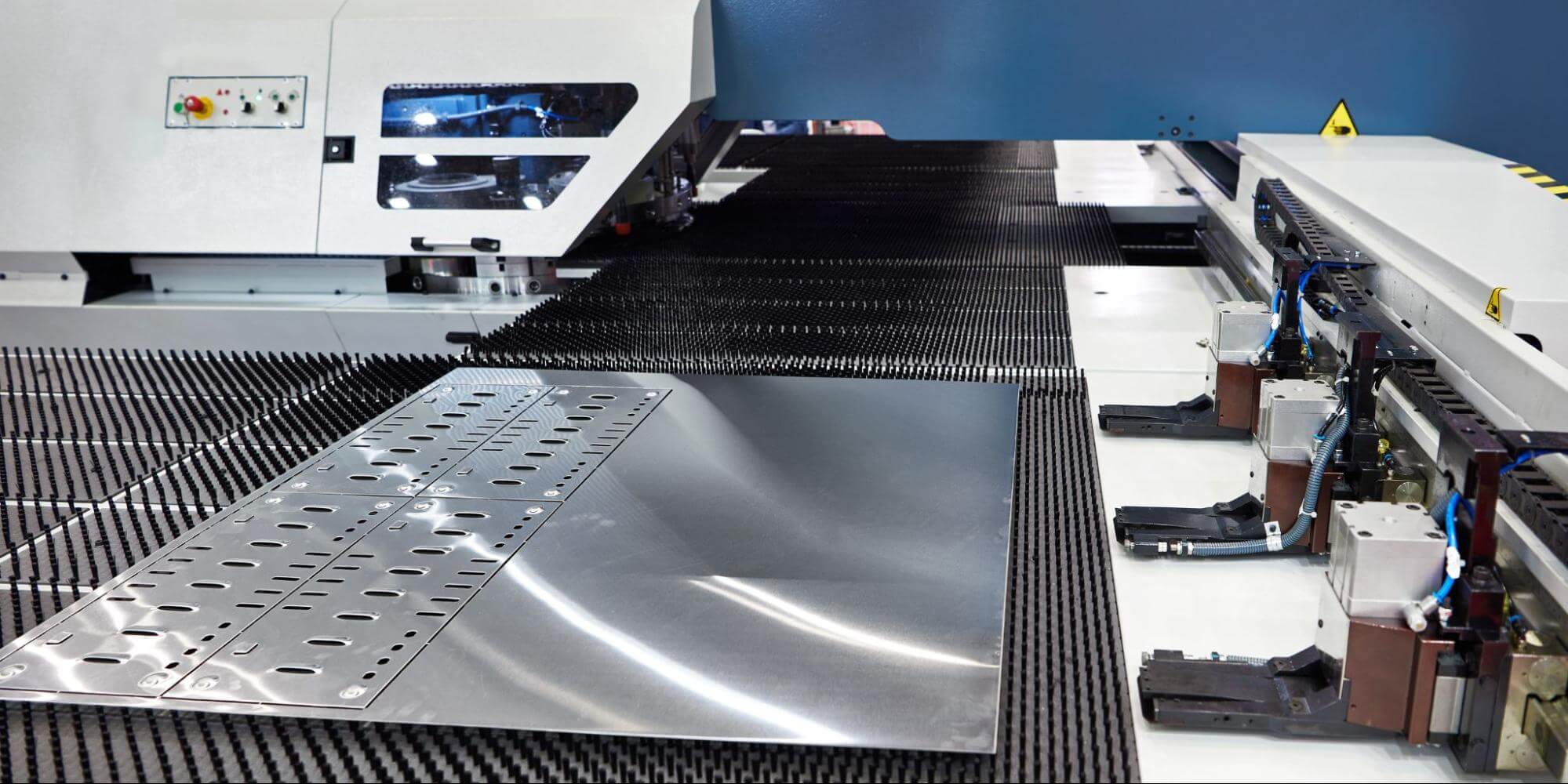

For engineering teams facing compressed development cycles, rapid sheet metal prototyping is not a luxury—it’s a strategic necessity. Honyo Prototype delivers industry-leading speed without compromising on the precision and material integrity critical to functional validation. Our end-to-end sheet metal fabrication services leverage advanced CNC punching, laser cutting, bending, and welding capabilities to transform digital designs into high-fidelity prototypes in as little as 3–5 business days. We support a comprehensive range of materials including aluminum alloys, stainless steel, cold-rolled steel, and brass, with options for critical secondary operations like tapping, hardware insertion, and surface finishing.

Central to our rapid workflow is the Online Instant Quote platform, engineered specifically for engineering professionals. Upload your STEP or DXF file, specify material, thickness, and finish requirements, and receive a detailed, transparent cost breakdown within seconds—not hours or days. This eliminates procurement bottlenecks, allowing your team to iterate designs, validate manufacturability, and secure budget approvals in real time. Unlike traditional RFQ processes, our system provides immediate clarity on lead times, material utilization, and design feedback, ensuring your prototype moves from concept to hands-on testing with unprecedented efficiency.

Honyo Prototype integrates seamless digital workflows with expert engineering oversight, ensuring every rapid sheet metal prototype meets exacting functional and dimensional requirements. Start your next iteration today with a quote that arrives faster than your design files.

Technical Capabilities

Rapid sheet metal prototyping involves high-precision fabrication processes including laser cutting, bending, and welding to quickly produce functional prototypes from sheet materials. These processes are optimized for speed, accuracy, and repeatability, supporting iterative design validation and low-volume production. Below are the technical specifications relevant to each process, with supported materials including aluminum, steel, and select thermoplastics such as ABS and nylon—though note that thermoplastics are typically processed using alternative methods like CNC routing or 3D printing rather than traditional sheet metal techniques.

| Process | Technology Type | Material Compatibility | Thickness Range | Tolerance (Typical) | Tooling Requirements | Notes |

|---|---|---|---|---|---|---|

| Laser Cutting | Fiber Laser / CO₂ Laser | Aluminum, Steel, ABS (CO₂ only), Nylon (CO₂ only) | 0.5 mm – 25 mm | ±0.1 mm | None | Fiber laser preferred for metals; CO₂ laser used for plastics. High edge quality. |

| Bending | CNC Press Brake | Aluminum, Steel | 0.8 mm – 12 mm | ±0.2° angular, ±0.2 mm linear | Custom tooling (punch/die) per bend profile | Minimum flange length: ~3× material thickness. Bend radius typically ≥ material thickness. |

| Welding | TIG, MIG, or Spot Welding | Aluminum, Steel | 0.8 mm – 10 mm | ±0.5 mm positional | Electrodes (spot), filler wire (MIG/TIG) | TIG preferred for precision and clean welds on prototypes. Not applicable to ABS or nylon. |

Notes:

ABS and nylon are not conventional sheet metal materials and are incompatible with bending and welding as applied in metal fabrication. These thermoplastics may be laser cut using CO₂ systems but require post-processing and are generally fabricated using non-metallic methods. Rapid prototyping services may combine metal and plastic components in an assembly but process them separately using appropriate techniques.

From CAD to Part: The Process

Honyo Prototype Rapid Sheet Metal Prototyping Process

Honyo Prototype delivers rapid sheet metal prototypes through a streamlined, technology-driven workflow designed for speed, accuracy, and engineering integrity. Our process eliminates traditional bottlenecks while maintaining rigorous quality standards for B2B clients.

Upload CAD

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, DWG, DXF) via our secure customer portal. The system performs immediate validation checks for file integrity, unit consistency, and geometric completeness. All data is protected under NDA-compliant infrastructure, ensuring IP security from the first interaction. Invalid files trigger automated feedback specifying required corrections, minimizing submission delays.

AI Quote Generation

Validated CAD data enters our proprietary AI quoting engine, which analyzes geometric complexity, material requirements, tolerances, and secondary operations. The engine cross-references real-time material costs, machine availability, and labor rates against Honyo’s historical production database. Within 2 business hours, clients receive a detailed quote including precise lead time (typically 3–7 days), cost breakdown, and material sourcing options. The AI flags high-risk geometries for engineering review but provides immediate baseline pricing without human intervention.

DFM Analysis

Every design undergoes automated and engineer-validated Design for Manufacturability (DFM) review. Our system checks critical parameters against sheet metal fabrication best practices, identifying potential failures before cutting begins. Common issues addressed include:

| DFM Parameter | Critical Threshold | Resolution Approach |

|---|---|---|

| Bend-to-Feature Spacing | < 2.5× material thickness | Suggest feature relocation or relief cuts |

| Hole Diameter | < Material thickness | Recommend laser etching or alternative |

| Internal Radii | < 0.6× material thickness | Propose radius adjustment or kerf compensation |

| Flat Pattern Overlap | Any intersection | Auto-generate corrected flat pattern |

Engineers provide actionable feedback within 4 business hours, offering tactical adjustments to maintain functionality while optimizing manufacturability. Clients approve revisions digitally before production release.

Production Execution

Approved designs move to Honyo’s dedicated rapid prototyping cell featuring:

Fiber laser cutters (0.5–6mm stainless steel, aluminum, mild steel) with < ±0.1mm positional accuracy

CNC press brakes with adaptive tooling for complex bends up to 3m length

In-line inspection using calibrated CMMs at 20% production intervals

Dedicated material stock for common grades (304/316 SS, 5052/6061 Al, SPCC) ensuring no sourcing delays

All processes follow AS9100-aligned documentation protocols, with real-time job tracking accessible via client portal. Secondary operations (welding, tapping, finishing) are sequenced in parallel where feasible to compress lead times.

Delivery & Validation

Completed prototypes undergo final dimensional verification against original CAD per ASME Y14.5 standards. Each shipment includes:

First-article inspection report with critical dimension callouts

Material certification (MTR) and RoHS compliance documentation

Packaging engineered for fragile feature protection during transit

Digital delivery confirmation with tracking and quality metrics

Typical delivery occurs within 5 business days from CAD approval for standard prototypes. Rush services (72-hour turnaround) are available for qualified geometries. This integrated approach ensures clients receive functionally validated parts with full traceability, enabling faster design validation cycles and reduced time-to-market.

Start Your Project

Need rapid sheet metal prototypes? Turn your designs into high-quality parts fast with Honyo Prototype. Our Shenzhen-based factory delivers precision sheet metal fabrication with quick turnaround times, ideal for prototyping and low-volume production.

Contact Susan Leo at [email protected] to request a quote or discuss your project. We support DFM feedback, laser cutting, CNC punching, bending, welding, and finishing—all under one roof for seamless execution.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.