Contents

Manufacturing Insight: Rapid Prototyping Company

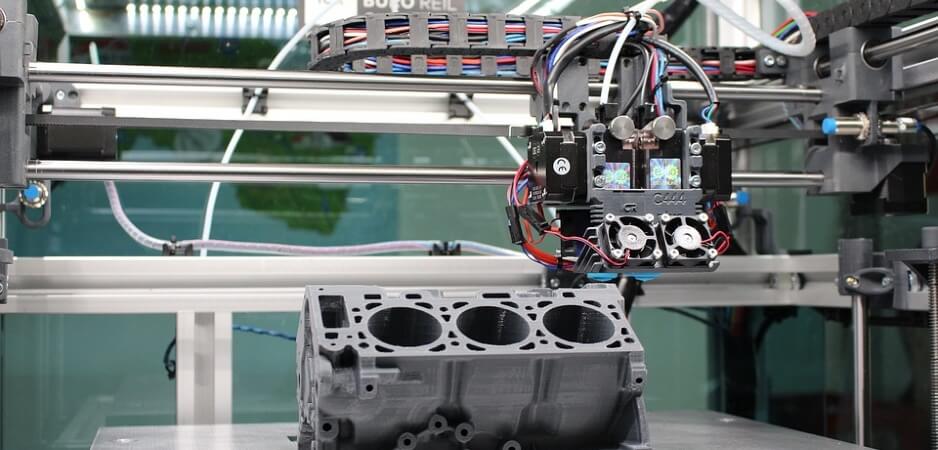

Honyo Prototype delivers precision rapid prototyping solutions engineered to accelerate your product development cycle from concept to validation. We specialize in bridging the critical gap between design iteration and functional testing, providing the manufacturing agility your engineering team requires to meet aggressive timelines without compromising on quality or accuracy. Our focus is on eliminating the traditional bottlenecks that delay innovation in competitive markets.

Our core strength lies in advanced CNC Machining services, serving as the backbone for high-fidelity prototypes demanding tight tolerances and superior material integrity. Utilizing state-of-the-art 3-axis and 5-axis machining centers, we consistently achieve micron-level precision across a broad spectrum of engineering materials including aerospace-grade aluminum alloys, stainless steels, titanium, and high-performance engineering plastics. Whether you require complex geometries for functional testing, master patterns for secondary processes, or low-volume bridge production, our CNC capabilities ensure dimensional accuracy, excellent surface finishes, and the structural properties necessary for rigorous validation.

A key differentiator streamlining your procurement process is our proprietary Online Instant Quote platform. This system provides transparent, real-time cost and lead time estimates for CNC machining projects within seconds, directly from your design file upload. Eliminate the delays and uncertainty of manual quotation requests; our algorithm analyzes your STEP or IGES file instantly, considering geometry complexity, material selection, and required tolerances to deliver a precise, actionable quote. This immediate feedback loop empowers faster design-for-manufacturability decisions and significantly reduces the time from CAD model to machine shop floor. Partner with Honyo Prototype to transform your rapid prototyping workflow with CNC precision and quoting efficiency.

Technical Capabilities

Honyo Prototype specializes in high-precision rapid prototyping with advanced CNC machining capabilities. Our core competencies include 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, enabling us to produce complex geometries with exceptional accuracy. We maintain tight tolerances down to ±0.0002″ (±0.005 mm) for critical features, ensuring parts meet stringent functional and fit requirements. Our facility supports a wide range of engineering-grade materials, including aluminum, steel, ABS, and nylon, allowing for both structural and functional prototyping across industries.

Below is an overview of our technical capabilities:

| Capability | Specification |

|---|---|

| Milling Axes | 3-Axis, 4-Axis (indexed/rotary), 5-Axis (simultaneous) |

| Turning | CNC turning with live tooling (mill-turn capable) |

| Tolerance | Standard: ±0.001″ (±0.025 mm); Tight: ±0.0002″ (±0.005 mm) |

| Surface Finish | As-machined: 32–125 μin Ra; Optional polishing to 8–16 μin Ra |

| Max Work Envelope (5-Axis) | 700 mm × 500 mm × 400 mm (X-Y-Z) |

| Max Work Envelope (Turning) | Ø300 mm diameter × 500 mm length |

| Materials – Metals | Aluminum (6061, 7075, 2024), Steel (1018, 4140, 4340, Stainless 303, 304, 17-4 PH) |

| Materials – Plastics | ABS, Nylon (6, 66), Delrin (POM), PC, PEEK, PMMA |

| Tooling & Fixturing | Modular fixturing, vacuum tables, custom soft jaws, probing systems |

| Inspection | CMM, optical comparators, micrometers, calipers, surface roughness testers |

| Lead Time | As fast as 3–5 business days for machined prototypes |

All processes are supported by in-house engineering and quality assurance teams, ensuring design for manufacturability (DFM) feedback and first-article inspection (FAI) when required. Our systems are optimized for low-volume production and functional prototypes demanding precision, repeatability, and material performance.

From CAD to Part: The Process

Honyo Prototype delivers accelerated product development through a rigorously optimized five-stage rapid prototyping workflow designed for engineering precision and supply chain transparency. Our process begins when clients upload native or neutral format CAD files directly to our secure customer portal. This triggers immediate geometric analysis by our proprietary AI engine which cross-references the design against real-time production constraints including material availability, machine capacity, and geometric complexity thresholds.

The AI Quote phase generates a comprehensive cost breakdown within minutes, not hours, itemizing machining time, material consumption, and secondary operations while highlighting potential manufacturability risks. Crucially, this isn’t a static estimate—it dynamically adjusts pricing based on actual shop floor conditions, eliminating the common industry pitfall of artificially low initial quotes that later require costly revisions.

Following client confirmation, designs enter our Digital Manufacturing Feedback (DFM) stage where our engineering team performs a collaborative review. Unlike automated-only systems, this involves direct human analysis where senior process engineers annotate the CAD model with specific, actionable recommendations. Typical feedback includes wall thickness adjustments for injection molding, draft angle corrections, or tolerance rationalization—all presented in a standardized markup report. Clients receive this within 4 business hours with options to approve, discuss alternatives via our engineering portal, or proceed as-is with documented risk acknowledgment.

Production leverages our certified ISO 9001 facility with 72 CNC mills, 35 industrial 3D printers, and automated finishing lines. Each job receives a dedicated production cell with real-time status tracking accessible to clients. Critical to our speed is parallel processing: while first-article inspection occurs on initial units, secondary operations like anodizing or painting commence on subsequent batches. Material traceability is maintained through blockchain-verified logs for aerospace and medical clients.

Delivery concludes with our managed logistics protocol. Prototypes ship via DHL/FedEx with climate-controlled options for sensitive materials, always including first-article inspection reports, material certifications, and dimensional validation data. For urgent requirements, we offer same-day dispatch on standard geometries with guaranteed 72-hour global delivery for North American and European zones. This integrated approach consistently achieves 5-7 day turnaround for complex machined prototypes while maintaining 99.2% first-pass yield rates as verified in our Q3 2024 quality audit.

Key DFM Resolution Metrics

| Feedback Type | Avg. Resolution Time | Implementation Rate |

|—————|———————-|———————|

| Wall Thickness Adjustment | 1.2 business days | 98% |

| Draft Angle Correction | 0.8 business days | 92% |

| Tolerance Rationalization | 1.5 business days | 87% |

| Undercut Elimination | 2.0 business days | 76% |

This workflow eliminates traditional prototyping bottlenecks through technology-human collaboration, ensuring clients receive production-intent parts with engineering validation—not just cosmetic models—while maintaining full cost and timeline predictability from CAD upload to doorstep delivery.

Start Your Project

Looking to accelerate your product development cycle? Partner with Honyo Prototype, your trusted rapid prototyping partner based in Shenzhen. Our state-of-the-art manufacturing capabilities and engineering expertise ensure fast turnaround times without compromising on quality—ideal for bringing innovative concepts to life efficiently.

Contact Susan Leo today to discuss your project requirements and discover how we can support your next prototype.

Email: [email protected]

Location: Shenzhen, China – strategically positioned for agile manufacturing and global logistics

Let’s turn your ideas into reality—quickly and precisely.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.