Contents

Manufacturing Insight: Rapid Machining Solutions

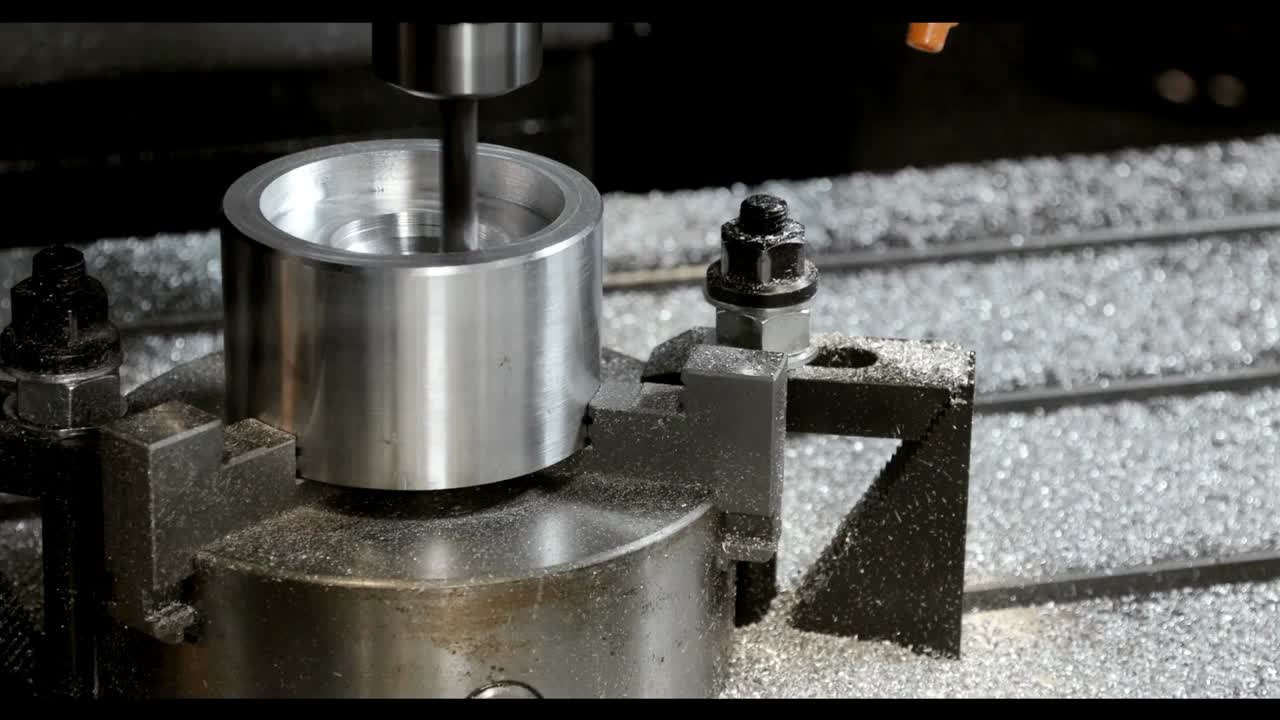

Accelerate Your Product Development with Precision CNC Machining

In today’s competitive manufacturing landscape, speed without compromise is non-negotiable. Honyo Prototype delivers rapid machining solutions engineered for speed, precision, and repeatability, specifically designed to compress your product development timelines while maintaining rigorous quality standards. Our advanced CNC machining capabilities—including 3-, 4-, and 5-axis milling, turning, and multi-axis simultaneous machining—handle complex geometries and tight tolerances across aerospace alloys, medical-grade plastics, engineering composites, and hardened steels. Every process is optimized for rapid iteration, ensuring prototypes and low-volume production parts meet exact specifications on accelerated schedules.

Central to our rapid solution is the Online Instant Quote platform, eliminating traditional procurement delays. Upload your CAD file, specify materials and finishes, and receive a detailed, transparent cost estimate in under 60 seconds—no manual submissions or waiting for engineer review. This seamless integration of engineering expertise and digital efficiency empowers design teams to iterate faster, validate concepts earlier, and transition smoothly from prototype to production.

Honyo Prototype’s end-to-end rapid machining service reduces time-to-market by up to 50% compared to conventional vendors, backed by ISO 9001-certified processes and in-house metrology for guaranteed part accuracy. Partner with us to transform your design intent into high-integrity physical components, consistently and at the speed your innovation demands.

Technical Capabilities

Rapid machining solutions at Honyo Prototype are engineered for high precision, fast turnaround, and repeatability across complex part geometries. Our 3, 4, and 5-axis CNC milling capabilities enable multi-faceted machining in a single setup, minimizing lead time and ensuring dimensional accuracy. High-speed CNC turning is integrated for cylindrical and symmetrical components. All processes are optimized for tight tolerance machining, typically holding ±0.005 mm (±0.0002″) with the ability to achieve ±0.001 mm (±0.00004″) under stringent requirements.

We support a wide range of engineering-grade materials including aluminum, steel, ABS, and nylon, each processed using optimized toolpaths, spindle speeds, and fixturing strategies to maintain surface finish and geometric integrity.

Technical Specifications for Rapid Machining Solutions

| Parameter | Specification |

|---|---|

| Machining Types | 3-Axis, 4-Axis, 5-Axis CNC Milling; CNC Turning (2-axis and multi-axis) |

| Tolerance Capability | Standard: ±0.005 mm (±0.0002″) Precision: ±0.001 mm (±0.00004″) |

| Surface Finish | As-machined: 1.6–3.2 μm Ra Polished/Post-processed: <0.8 μm Ra available |

| Max Work Envelope | Milling: 1200 x 600 x 500 mm Turning: Ø300 mm x 500 mm |

| Spindle Speed (Milling) | Up to 24,000 RPM with high-precision ER collet systems |

| Tooling | Carbide and diamond-coated inserts; automated tool changers (ATC) |

| Control Systems | Fanuc, Siemens, or Heidenhain controls with offline programming support |

| Materials Supported | Aluminum (6061, 7075, 2024) Steel (1018, 4140, Stainless 303, 316) ABS (I400, Natural) Nylon (6, 66, GF-filled) |

| Fixturing | Modular vices, custom soft jaws, rotary tables (4-axis), 5-axis trunnion kits |

| Lead Time | Prototype: 3–7 days Bridge Production: 7–14 days (volume-dependent) |

| Inspection Equipment | CMM, optical comparators, micrometers, bore gauges, surface roughness testers |

These capabilities ensure consistent quality and rapid delivery for functional prototypes, end-use components, and low-volume production parts across aerospace, medical, automotive, and industrial sectors.

From CAD to Part: The Process

Honyo Prototype delivers rapid machining solutions through a streamlined, technology-driven workflow designed for speed, accuracy, and engineering collaboration. Our process eliminates traditional bottlenecks while maintaining rigorous quality standards for B2B clients requiring precision prototypes and low-volume production parts.

CAD Upload and Initial Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, Parasolid, or native formats from SOLIDWORKS, Creo, NX, CATIA) via our secure customer portal. Our system performs immediate automated geometry validation, checking for file integrity, unit consistency, and manufacturability flags such as self-intersecting surfaces or missing radii. This step ensures the design is technically viable before proceeding, reducing downstream delays.

AI-Powered Quoting Engine

Uploaded geometry is processed by our proprietary AI quoting system, which analyzes over 200 geometric and material parameters against real-time production data. The algorithm cross-references current machine availability, material stock levels, tooling requirements, and historical cycle times to generate an accurate cost and lead time estimate within two minutes. The AI factors in secondary operations like tapping, chamfering, or surface finishing specified in the CAD model. Complex geometries triggering uncertainty are automatically routed to our engineering team for manual review, with clients notified within 15 minutes.

Engineer-Led DFM Analysis

Every project undergoes mandatory Design for Manufacturability (DFM) review by our ASME-certified manufacturing engineers. This phase combines automated tolerance stack-up analysis with human expertise to identify optimization opportunities. Engineers evaluate critical aspects including wall thickness feasibility, tool access for internal features, optimal stock size selection, and cost-reduction suggestions such as eliminating unnecessary tight tolerances. Clients receive a detailed DFM report within 4 business hours, highlighting potential redesign recommendations with annotated 3D visuals and time/cost impact analysis. Client approval of the DFM report is required before production commencement.

Precision Production Execution

Approved designs move to our climate-controlled manufacturing floor equipped with 32 CNC machining centers including 5-axis DMG MORI machines, high-speed Haas mills, and Swiss-type lathes. Our integrated MES system automatically schedules jobs based on material availability, machine capabilities, and priority level. Key production features include:

Real-time process monitoring with IoT-enabled machine sensors tracking tool wear and vibration

In-process CMM verification for critical features on runs exceeding 10 parts

Material traceability via laser-etched batch codes on all components

Concurrent quality documentation generation per ISO 9001:2015 standards

Typical lead times vary by complexity and material as shown below:

| Material Category | Typical Lead Time (Business Days) | Max Complexity Level Supported |

|---|---|---|

| Aluminum Alloys (6061, 7075) | 3-5 | High (5-axis features) |

| Engineering Plastics (PEEK, Delrin) | 4-6 | Medium-High |

| Stainless Steel (303, 316) | 5-7 | Medium |

| Titanium Alloys (Grade 5) | 7-10 | Medium |

Quality-Controlled Delivery

All parts undergo final inspection against the original CAD model using calibrated Zeiss CMMs and optical comparators. We provide comprehensive documentation including first-article inspection reports, material certifications, and surface roughness validation. Parts are packaged in ESD-safe containers with custom foam inserts for fragile geometries. Standard delivery includes real-time shipment tracking and a digital quality dossier accessible via our client portal. Expedited shipping options (including same-day air for US clients) are available for urgent requirements, with 72-hour turnaround feasible for qualifying projects.

This integrated approach reduces traditional prototyping cycles by 40-60% while maintaining strict compliance with aerospace (AS9100) and medical device (ISO 13485) requirements. Clients retain full visibility through our production dashboard, which updates at each process milestone from DFM approval through shipment confirmation.

Start Your Project

Looking for rapid machining solutions to accelerate your product development? Honyo Prototype delivers precision, speed, and reliability with in-house manufacturing at our Shenzhen factory. From concept to functional prototype, we support your engineering and production needs with advanced CNC machining and fast turnaround times.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage our Shenzhen-based manufacturing capabilities for agile, high-quality machining solutions tailored to your timeline.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.