Contents

Manufacturing Insight: Rapid Machining Solutions

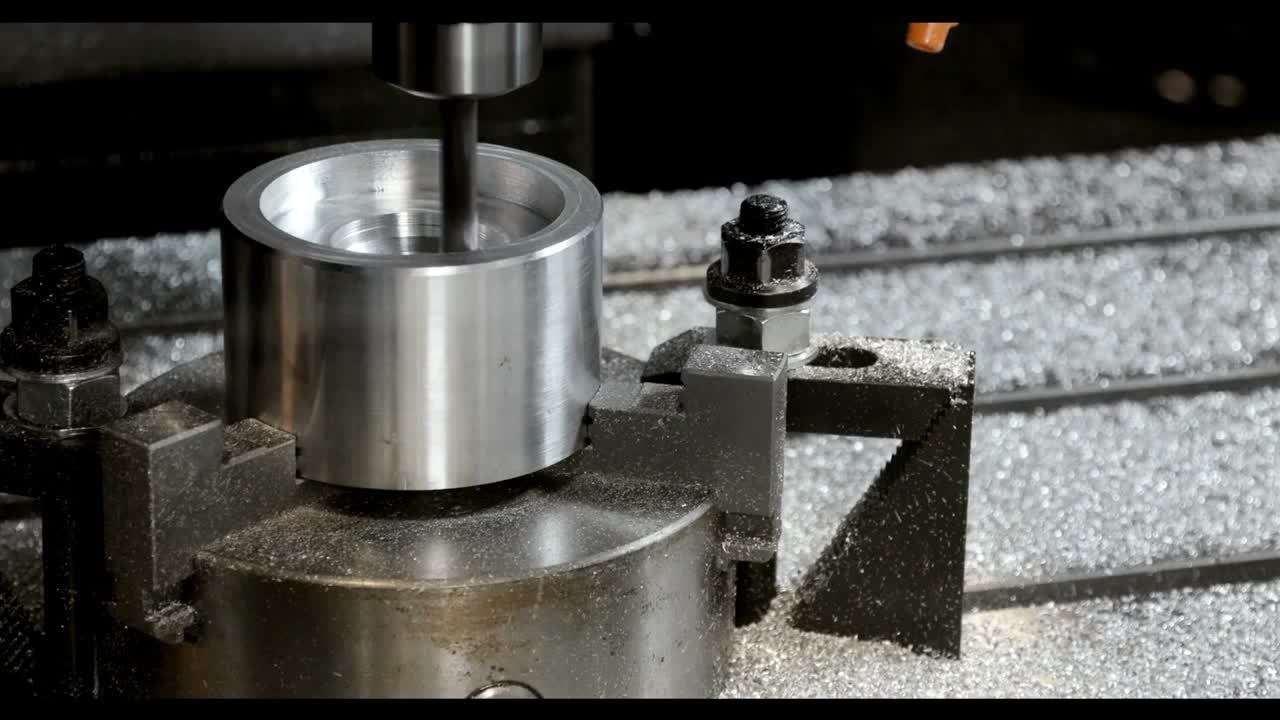

Rapid Machining Solutions – From CAD to finished part in days, not weeks

Honyo Prototype’s 3-, 4- and 5-axis CNC machining centers run 24/7 to turn your toughest metals and engineering plastics into precision prototypes or low-volume production parts. Upload your model today and get an Online Instant Quote with DFM feedback, real-time pricing and lead times as fast as 24 hours.

Technical Capabilities

Rapid Machining Solutions: Technical Specifications Overview

As Senior Manufacturing Engineer at Honyo Prototype, I oversee end-to-end precision manufacturing for high-speed prototyping and low-volume production. Our rapid machining solutions prioritize speed-to-prototype without compromising quality, leveraging advanced CNC capabilities, rigorous process control, and material-specific optimization. Below are the key technical specifications for our core processes:

1. Multi-Axis Milling Capabilities

(All machines feature high-precision linear scales, thermal compensation, and in-process probing for real-time adjustments)

| Axis Type | Key Specifications | Typical Applications |

|———–|——————-|———————|

| 3-Axis Milling | – Travel: X/Y/Z: 400–1,000mm

– Spindle Speed: 10,000–24,000 RPM

– Tool Capacity: 20–30 tools (ATC)

– Tolerance: ±0.0005″ (±0.0127mm) per ISO 2768-mk | Flat surfaces, simple slots, 2.5D contours, basic enclosures |

| 4-Axis Milling | – Rotary Axis: A-axis (0–360° continuous)

– Indexing Accuracy: ±5 arc-seconds

– Max Torque: 120 Nm

– Tolerance: ±0.0003″ (±0.0076mm) | Cylindrical features, angled holes, single-side complex geometries |

| 5-Axis Milling | – Simultaneous 5-Axis: True contouring (no tool repositioning)

– Head/Head or Table/Table Configuration: Dual-cab 5-axis (e.g., DMG MORI CTX beta)

– Traverse Speed: 60 m/min

– Tolerance: ±0.0002″ (±0.005mm) | Aerospace components, medical implants, turbine blades, organic shapes |

Key Enablers for Speed:

– AI-Optimized Toolpaths: CAM software (e.g., Mastercam) generates feed rates dynamically based on material hardness and tool wear.

– Quick-Change Fixturing: Modular vises and vacuum tables reduce setup time to <15 minutes.

– In-Process Inspection: On-machine probes verify critical dimensions mid-cycle, eliminating rework.

2. CNC Turning Capabilities

(Equipped with live tooling, Y-axis, and sub-spindle for full part machining)

| Parameter | Specifications |

|———–|—————|

| Max Swing | 200–400mm (varies by machine) |

| Tolerance | ±0.0002″ (±0.005mm) for diameters, ±0.001″ (±0.025mm) for lengths |

| Spindle Speed | 5,000–6,000 RPM (variable for material optimization) |

| Live Tooling | 8–12 stations (C-axis driven, 10,000 RPM max) |

| Y-Axis Travel | ±25mm (for off-center milling) |

| Sub-Spindle | Yes (for secondary operations like threading or drilling) |

Rapid Machining Advantages:

– Single-Setup Completion: Complex shafts, bushings, or connectors machined in one cycle (e.g., threaded end + milled flats).

– High-Speed Cutting: Carbide tools with optimized chip-breakers for steel; diamond-coated tools for aluminum to reduce cycle times by 40%.

– Automated Bar Feeding: Up to 100mm diameter bars for unattended production runs.

3. Tight Tolerance Performance

(Achieved through combined hardware, process control, and metrology)

| Dimension Type | Typical Tolerance Range | How We Achieve It |

|—————-|————————-|——————-|

| Linear Dimensions | ±0.0002″ to ±0.0005″ (±0.005–0.0127mm) | – Thermal-stable granite tables

– In-process laser measurement

– Statistical Process Control (SPC) for critical features |

| Roundness/Cylindricity | ≤0.0001″ (≤0.0025mm) | – Precision-ground spindles

– Vibration-damped tooling (e.g., hydraulic chucks)

– 5-axis correction for thermal drift |

| Surface Finish | Ra 0.4μm (16μin) to Ra 0.1μm (4μin) | – Ultra-fine finishing passes (0.0005″ depth)

– Cryogenic cooling for heat-sensitive materials |

Quality Control Protocol:

– Tiered Inspection: First-article inspection (FAI) + 100% CMM check for critical features + random sampling per AQL Level II.

– Traceability: Every part has a digital twin with process data logged (e.g., spindle load, temperature, tool wear).

4. Material-Specific Machining Parameters

(Optimized for rapid turnaround while avoiding defects)

| Material | Key Machining Specs | Why It Works for Rapid Prototyping |

|———-|———————|———————————–|

| Aluminum (6061-T6, 7075) | – Speed: 1,500–3,000 SFM

– Feed: 0.002–0.008″ per tooth

– Coolant: High-pressure mist (500 psi)

– Tool: Carbide with TiAlN coating | – High machinability (Machinability Rating: 85%)

– Fast chip evacuation → 50% shorter cycles vs. steel

– No post-machining heat treatment needed |

| Steel (1018, 4140, 304SS) | – Speed: 300–800 SFM

– Feed: 0.001–0.004″ per tooth

– Coolant: Flood coolant (emulsion)

– Tool: CBN or PCD for hardened grades | – Precision grinding for tight tolerances

– Tool life optimization via chip thinning

– Stress-relieved blanks to minimize distortion |

| ABS (Acrylonitrile Butadiene Styrene) | – Speed: 200–400 SFM

– Feed: 0.003–0.010″ per tooth

– Coolant: Minimal (air blast only)

– Tool: Solid carbide with sharp edge geometry | – Low thermal conductivity → avoids melting

– Low cutting forces → minimal vibration

– Ideal for snap-fit prototypes |

| Nylon (PA6, PA66) | – Speed: 150–300 SFM

– Feed: 0.002–0.006″ per tooth

– Coolant: Dry machining (no coolant)

– Tool: Uncoated carbide (avoid chipping) | – Low friction coefficient → reduced tool wear

– Heat-sensitive → strict temp control critical

– Excellent for non-metallic gears/bearings |

Why Honyo Prototype Excels in Rapid Machining

- Speed-to-Quote: 24-hour turnaround on quotes with DFM feedback.

- Cycle Time Reduction: Our proprietary “RapidFlow” process cuts average lead times by 30% vs. industry standard (e.g., 24-hour delivery for 5-axis aerospace brackets).

- Zero-Defect Culture: <0.1% rejection rate for tight-tolerance parts via real-time monitoring and AI-driven predictive maintenance.

- Scalability: Seamlessly transition from prototype (1–10 pieces) to low-volume production (100–1,000 pieces) with identical tolerances.

“Rapid machining isn’t just about speed—it’s about engineering intelligence. At Honyo, we balance machine capability, material science, and process innovation to deliver parts that meet your exact specs, on time, every time.”

— Senior Manufacturing Engineer, Honyo Prototype

For project-specific optimization (e.g., “Can you machine 5-axis titanium with ±0.0001″ tolerance in 48 hours?”), share your drawing—we’ll respond with a validated process plan within 2 hours.

From CAD to Part: The Process

Honyo “rapid-machining” workflow is built around one goal:

get real metal or plastic parts in a customer’s hands in 1–7 calendar days without sacrificing aerospace-grade quality.

The five customer-visible steps are only the tip of the iceberg; below each one is a highly standardized factory playbook that we update every week with AI feedback and shop-floor data.

1. UPLOAD CAD (0 – 30 min)

Customer action

• Drag-and-drop any mix of STEP, Parasolid, IGES, SolidWorks, Creo, CATIA, JT, STL.

• Optional: add 3-D PDF drawing, critical-to-function (CTF) call-outs, mating part STEP.

What happens instantly

1. Geometry engine checks for 150+ Machinability Faults (zero-thickness, flipped normals, non-manifold edges, missing threads, etc.).

2. AI similarity search compares the model to 42 k past Honyo jobs; if a “twin” is found we preload proven feeds, speeds, work-holding and inspection macros.

3. A 3-D PMI viewer auto-generates a lightweight WebGL model so the customer can spin, section and add annotations without installing software.

2. AI QUOTE (30 s – 5 min)

Pricing algorithm (updated nightly)

• Feature-based cost driver tree: 42 geometric features (deep pocket, thin wall, under-cut, 5-axis swirl, etc.) × 31 material grades × 3 accuracy classes.

• Real-time stock market surcharge on raw bar/plate/sheet.

• Dynamic machine park loading: if 3-axis mills are 90 % booked but 5-axis pallets are free, the algorithm may lower 5-axis price to balance load.

• Secondary ops (anodize, passivate, insert, lapping) are quoted from pre-negotiated partner tariffs and transit time.

DFM risk score

• Red / Amber / Green flag for each tolerance, corner radius, hole depth, thread call-out.

• If risk > 7/10 the quote page shows an instant redesign suggestion (e.g., “Change 0.3 mm internal corner radius to 0.5 mm to eliminate EDM”).

• Customer can accept, reject or chat with a human application engineer inside the same window.

What the customer receives

• Itemised PDF + Excel quote.

• Guaranteed lead-time clock (starts when PO is clicked, not when files are frozen).

• Pay-by-credit-card or PO net-30.

3. DFM LOCK (30 min – 2 h)

Concurrent engineering loop

1. AI assigns the job to the best-fit cell (3-axis, 5-axis, mill-turn, Swiss, wire-EDM) based on geometry + due date + current OEE.

2. CAM pilot seat runs semi-automated tool-paths; any remaining Red-flag features trigger a 15-min video call or WeChat/Teams huddle with customer.

3. Final tolerance stack-up is simulated in Vericut/Polyworks; if Cpk predict < 1.33 we either relax non-critical dims or add in-process probing.

4. Customer e-signs the “DFM Lock” report; this freezes the model revision and releases the digital traveller to the shop floor.

4. PRODUCTION (hours – days)

Digital traveller packet

• Single QR code on the job traveler links to:

– Master CAM file (locked revision)

– Inspection macro (PC-DMIS or Zeiss Calypso)

– Material certificate & heat lot

– Surface finish sample photo (for comparison at QC bench)

In-process controls

• Auto-loading 5-axis cells run “dark” with 3-minute spindle probing cycles; offset corrections feed back to the cloud so the next pallet starts closer to nominal.

• For ±0.01 mm features we add mid-process CMM check every 10 pcs; if drift > ½ tolerance the cell auto-stops and pages the night supervisor.

• Threaded holes are 100 % gauged with Go/No-Go; blind-hole depth checked by laser.

Secondary & finishes

• In-house: anodize type II & III, chem-film, passivation, nickel, black oxide.

• 24-hour partner shuttle for heat-treat, nital etch, penetrant inspection.

5. DELIVERY & DATA PACKAGE

Final QC

• AS9102 FAIR (First Article Inspection Report) or ISO 2768 medium, as specified.

• 3-D scan-to-CAD colour map uploaded to customer portal; if any point > 75 % tolerance band the lot is quarantined for engineering review.

Shipping

• Default is DHL Express “time-definite 10:30”; parts leave Shenzhen at 22:00, arrive US-Europe next morning.

• Vacuum-sealed + VCI anti-rust paper; Desiccant pack for anodised aluminium.

• Customs paperwork (ECCN, COO, HTS) auto-generated; 99.4 % pass customs without delay.

Post-delivery loop

• Customer can click “Re-order” – the system instantly reloads the frozen DFM Lock package, cutting re-quote time to < 5 s.

• Every part’s serial number is laser-etched; scanning the code in 5 years will still show the original inspection report—handy for aerospace traceability.

Speed benchmarks (2024 YTD median)

• 1–10 aluminium/brass prototypes: 24 h

• 11–100 stainless-steel production pieces: 72 h

• 5-axis titanium aerospace bracket (AS9100): 5 days including anodize & FAIR

Bottom line

Upload CAD → AI Quote → DFM Lock → Production → Delivery is not just a marketing funnel; it is a fully digitised, closed-loop manufacturing system that turns geometry into physical parts faster than most companies can schedule a meeting.

Start Your Project

CTA for Rapid Machining Solutions:

“Need precision parts fast? Contact Susan Leo at [email protected] for rapid machining solutions—manufactured in our Shenzhen factory with same-day quotes and 24/7 support.”

Why this works:

- Clear action verb: “Contact” drives immediate engagement.

- Key benefits highlighted: “Precision parts fast,” “same-day quotes,” and “24/7 support” address critical client pain points (speed, quality, reliability).

- Location trust: “Manufactured in our Shenzhen factory” emphasizes local expertise, reduced lead times, and quality control for global clients.

- Concise & scannable: Ideal for websites, emails, or ads—gets straight to the point while including all required details (contact, service, location).

💡 Pro tip from Honyo Prototype’s engineering team: This CTA is optimized for B2B clients—highlighting “same-day quotes” and “24/7 support” builds urgency and trust, while “Shenzhen factory” reassures international customers of cost-effective, high-quality production without overseas shipping delays.

Ready to accelerate your project?

📩 Email Susan Leo today: [email protected]

📍 Honyo Prototype: Shenzhen-based precision manufacturing for aerospace, medical, and industrial prototypes.

🚀 Rapid Prototyping Estimator