Contents

Manufacturing Insight: Que Significa Cnc

Understanding CNC Machining and Honyo Prototype’s Precision Manufacturing Capabilities

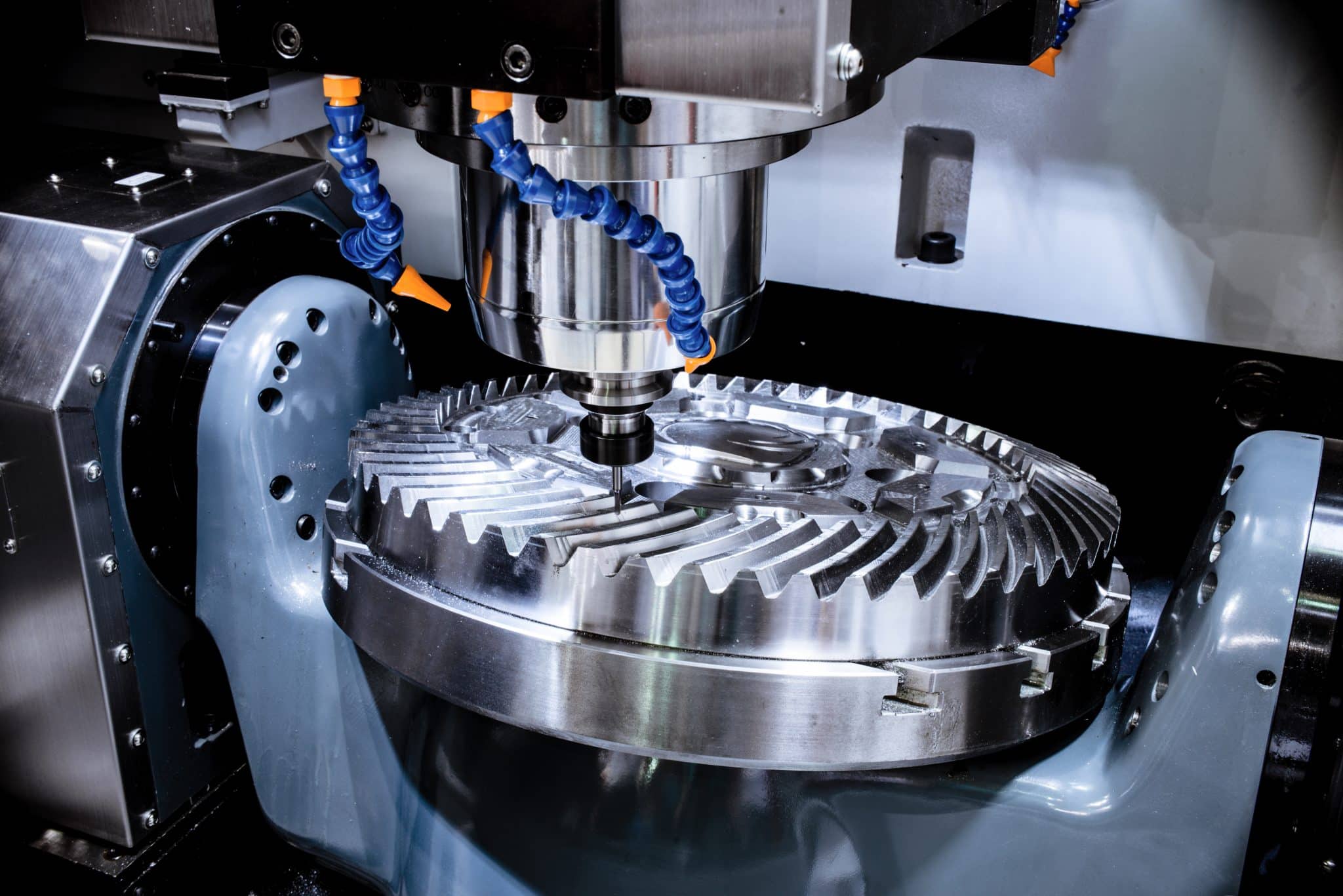

“Que significa CNC” translates to “what does CNC mean” in English. CNC stands for Computer Numerical Control, a foundational manufacturing technology where pre-programmed software dictates the precise movement of industrial machinery. This process enables the automated production of complex, high-tolerance components from materials like metal, plastic, and composites, ensuring repeatability and accuracy unattainable through manual operation. At Honyo Prototype, we leverage advanced CNC machining—including 3-axis, 4-axis, and 5-axis milling, as well as precision turning—to transform your engineering designs into functional prototypes and low-to-mid volume production parts with exceptional surface finishes and tight tolerances.

Our end-to-end CNC services are engineered for speed and reliability, supporting industries from aerospace to medical devices where dimensional integrity is non-negotiable. To accelerate your project timeline, Honyo Prototype offers an Online Instant Quote system. Upload your CAD file, specify materials and quantities, and receive a detailed, transparent cost estimate within minutes—no manual back-and-forth required. This streamlined approach eliminates procurement delays, allowing engineering teams to iterate faster and move from concept to physical part efficiently.

For technical specifications and capability details, refer to our CNC machining parameters below:

| Parameter | Capability Range |

|---|---|

| Tolerance | ±0.005 mm to ±0.025 mm |

| Materials | Aluminum, Steel, Titanium, Plastics, Brass |

| Max Work Envelope | 1000 x 600 x 500 mm |

| Lead Time | As fast as 3 business days |

Honyo Prototype delivers CNC solutions where precision meets agility, ensuring your components meet exacting standards without compromising speed to market.

Technical Capabilities

The phrase “que significa cnc” translates from Spanish to “what does CNC mean.” In a technical manufacturing context, CNC stands for Computer Numerical Control, referring to automated machine tools guided by programmed code (typically G-code) to produce high-precision parts. Below are the technical specifications relevant to CNC machining processes, with a focus on 3-axis, 4-axis, and 5-axis milling, CNC turning, tight tolerance capabilities, and common materials processed such as aluminum, steel, ABS, and nylon.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Motion Axes | X, Y, Z | X, Y, Z, and rotary A-axis (rotates around X) | X, Y, Z, and two rotary axes (e.g., A and B) | X (radial), Z (axial), with spindle rotation |

| Typical Tolerance | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) | ±0.005 mm (±0.0002″) |

| Tight Tolerance Capability | Up to ±0.0025 mm (±0.0001″) | Up to ±0.0025 mm (±0.0001″) | Up to ±0.0025 mm (±0.0001″) | Up to ±0.0025 mm (±0.0001″) |

| Surface Finish (Typical) | 0.8–3.2 µm Ra | 0.8–3.2 µm Ra | 0.4–1.6 µm Ra | 0.8–1.6 µm Ra |

| Max Material Removal Rate | High (optimized for prismatic parts) | Moderate (with added indexing capability) | Moderate (complex toolpaths reduce speed) | High (for cylindrical geometries) |

| Setup Complexity | Low | Moderate | High | Low to Moderate |

| Common Applications | Flat surfaces, slots, holes | Indexing features, angled holes | Complex contours, aerospace components | Shafts, bushings, threaded parts |

| Aluminum Machinability | Excellent | Excellent | Excellent | Excellent |

| Steel Machinability | Good (varies by alloy) | Good | Good | Good |

| ABS Machinability | Very Good (low melting point) | Very Good | Very Good | Good (chip control critical) |

| Nylon Machinability | Good (tends to deflect, requires sharp tools) | Good | Good | Good |

Material Notes

Aluminum (e.g., 6061, 7075) is widely used in CNC due to its excellent machinability, light weight, and good strength-to-density ratio. Steel alloys (e.g., 4140, 1018) offer high strength and wear resistance but require more robust tooling and slower speeds. ABS is a thermoplastic with good dimensional stability and ease of machining, ideal for prototypes. Nylon (e.g., PA6, PA66) is tougher and more abrasion-resistant but requires sharp cutting tools and proper chip evacuation due to its tendency to deform under pressure.

Tight Tolerance Considerations

Achieving tight tolerances (±0.0025 mm or better) requires thermal stability, high machine rigidity, precision tooling, and in-process metrology. 5-axis systems allow for single-setup machining of complex geometries, reducing cumulative error. CNC turning centers with live tooling can perform mill-turn operations to maintain tight alignment between turned and milled features.

These specifications reflect standard industrial capabilities at precision CNC job shops such as Honyo Prototype, which specialize in low-volume, high-accuracy component manufacturing for aerospace, medical, and industrial sectors.

From CAD to Part: The Process

Honyo Prototype CNC Manufacturing Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for CNC machining services, designed to minimize lead times while ensuring precision and manufacturability. The process begins when a client uploads a CAD file to our secure portal, triggering automated validation for format compatibility (STEP, IGES, Parasolid) and geometric integrity. Validated files proceed directly to our proprietary AI quoting engine, which analyzes over 200 manufacturability parameters—including material selection, tolerance stack-ups, feature complexity, and machine accessibility—to generate a detailed technical quote within 2 business hours. This AI system integrates real-time data from our machine shop floor, material inventory, and historical production metrics to ensure accurate cost and lead time projections.

Following client approval of the quote, the Design for Manufacturability (DFM) phase commences. Unlike conventional post-quote DFM reviews, Honyo embeds DFM analysis within the quoting AI, providing actionable feedback during quotation. Engineers then collaborate with the client to resolve critical issues such as thin-wall instabilities, non-optimal toolpaths, or unachievable tolerances, iterating until the design meets both functional and production requirements. This concurrent engineering approach reduces revision cycles by up to 70% compared to sequential workflows.

Production leverages our network of 85+ CNC machines (3-axis to 5-axis mills, lathes with live tooling) across three ISO 9001:2015-certified facilities. Each job undergoes rigorous pre-production calibration, including tooling validation, fixture design review, and first-article inspection planning. Machining adheres to AS9100 aerospace-grade traceability protocols, with real-time in-process metrology using FARO arms and Zeiss CMMs for critical dimensions. All operations follow documented work instructions derived from the DFM-validated design, ensuring consistency from prototype to low-volume production.

Delivery encompasses final quality assurance, packaging, and logistics coordination. Every shipment includes a full inspection report (per ASME Y14.5), material certificates, and first-article test data. Honyo manages global freight with climate-controlled options for sensitive materials, providing clients with real-time shipment tracking and customs documentation. Typical lead times from CAD upload to delivery range from 5–15 business days, contingent on part complexity and material availability.

Process Phase Timelines and Outputs

| Phase | Key Activities | Primary Output | Typical Duration |

|---|---|---|---|

| CAD Upload | Format validation; geometry integrity check | Validated CAD file; error log | <1 hour |

| AI Quote | Automated DFM analysis; cost/lead time modeling | Technical quote with manufacturability insights | 2 business hours |

| DFM | Engineering collaboration; design iteration | Approved manufacturing-ready design | 1–3 business days |

| Production | Machine setup; in-process inspection; finishing | Precision-machined parts with QA data | 3–10 business days |

| Delivery | Final inspection; packaging; logistics dispatch | Shipment with full documentation | 1–2 business days |

This integrated methodology ensures clients receive production-ready CNC components with reduced time-to-market, validated quality, and transparent process visibility at every stage. Honyo’s closed-loop system captures post-delivery feedback to continuously refine AI prediction accuracy and process efficiency.

Start Your Project

If you’re wondering “qué significa CNC”, CNC stands for Control Numérico Computarizado, a manufacturing process used to automate machine tools with precision through computer programming. At Honyo Prototype, we specialize in CNC machining services with advanced capabilities to deliver high-quality prototypes and production parts.

Our state-of-the-art factory is located in Shenzhen, China, a global hub for rapid manufacturing and innovation. With strict quality control and fast turnaround times, we support clients across industries including automotive, medical, aerospace, and consumer electronics.

For more information or to request a quote, contact Susan Leo at [email protected]. Let us help you bring your designs to life with precision CNC machining.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.