Introduction: Navigating the Global Market for pvc transparent sheet

In today’s competitive global market, sourcing high-quality PVC transparent sheets can pose significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With applications ranging from signage and protective barriers to packaging and construction materials, the demand for versatile and durable PVC sheets is on the rise. This guide aims to equip international buyers with essential insights into the diverse types of PVC transparent sheets available, their various applications, and critical factors to consider when selecting suppliers.

Navigating the complexities of pricing, quality standards, and supplier reliability is crucial for making informed purchasing decisions. Within this comprehensive resource, we will delve into the different grades and specifications of PVC sheets, explore their manufacturing processes, and highlight the importance of vetting suppliers to ensure compliance with regional regulations and quality assurance. Additionally, we will address cost considerations, providing practical tips on negotiating and securing the best deals.

By empowering B2B buyers with the knowledge and tools needed to make strategic purchasing decisions, this guide serves as a valuable resource for those seeking to optimize their supply chains and leverage the advantages offered by PVC transparent sheets in their respective markets. Whether you are based in bustling cities like Ho Chi Minh or São Paulo, understanding these dynamics will enable you to thrive in the evolving landscape of global trade.

Understanding pvc transparent sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clear PVC Sheets | High light transmission, rigid structure | Signage, displays, protective barriers | Pros: Excellent visibility; Cons: Limited UV resistance |

| Expanded PVC Sheets | Lightweight, closed-cell structure | Construction, signage, interior design | Pros: Easy to handle; Cons: Lower impact resistance |

| Rigid PVC Sheets | High impact resistance, chemical stability | Industrial applications, chemical handling | Pros: Durable and robust; Cons: Heavier than other options |

| Foam PVC Sheets | Lightweight, easy to cut and fabricate | Exhibits, interior decor, crafting | Pros: Cost-effective and versatile; Cons: Less rigid than solid PVC |

| UV-Stabilized PVC Sheets | Enhanced UV resistance, durable for outdoor use | Outdoor signage, greenhouse covers | Pros: Long-lasting under sunlight; Cons: Generally more expensive |

What are Clear PVC Sheets and Their B2B Applications?

Clear PVC sheets are characterized by their high light transmission and rigidity, making them ideal for applications requiring visibility and strength. They are commonly used in signage, displays, and protective barriers, where clarity is crucial. B2B buyers should consider the thickness and treatment options available, as these can affect durability and suitability for specific environments. While clear PVC provides excellent visibility, its limited UV resistance can be a drawback for outdoor applications.

How Do Expanded PVC Sheets Compare to Other Types?

Expanded PVC sheets are unique due to their lightweight and closed-cell structure, which makes them easy to handle and fabricate. They are widely used in construction, signage, and interior design, where a balance of strength and weight is essential. Buyers should evaluate the specific application needs, as expanded PVC offers good insulation properties but may lack the impact resistance found in rigid sheets. Its ease of use and cost-effectiveness make it a popular choice in many projects.

What Makes Rigid PVC Sheets Essential for Industrial Use?

Rigid PVC sheets are known for their high impact resistance and chemical stability, making them suitable for industrial applications where durability is paramount. They are often used in chemical handling and various manufacturing processes. Buyers should prioritize specifications such as thickness and chemical resistance ratings when selecting rigid PVC for their operations. Although these sheets are heavier, their robustness justifies the investment for demanding environments.

Why Choose Foam PVC Sheets for Versatile Applications?

Foam PVC sheets are lightweight and easy to cut, making them an excellent choice for exhibitions, interior decor, and crafting. Their versatility and cost-effectiveness appeal to a wide range of industries, particularly for temporary or less demanding applications. However, buyers should be aware that foam PVC is less rigid compared to solid PVC options, which may limit its use in certain structural applications. Evaluating the intended use will help in selecting the right material.

What are the Advantages of UV-Stabilized PVC Sheets?

UV-stabilized PVC sheets are designed to withstand prolonged exposure to sunlight, making them ideal for outdoor signage and greenhouse covers. Their enhanced UV resistance ensures longevity and durability in outdoor environments. For B2B buyers, the key consideration is the cost, as these sheets may be more expensive than standard options. However, the investment can lead to significant savings over time due to reduced replacement and maintenance needs.

Key Industrial Applications of pvc transparent sheet

| Industry/Sector | Specific Application of PVC Transparent Sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Transparent barriers for construction sites | Enhances safety by providing visibility while protecting workers from debris | Thickness and UV resistance to withstand outdoor conditions |

| Food & Beverage | Protective barriers in food processing areas | Maintains hygiene standards while allowing visibility for monitoring processes | Compliance with food safety regulations and easy cleaning features |

| Retail & Advertising | Display cases and signage | Attracts customers with clear visibility of products while protecting them | Clarity, thickness, and the ability to print graphics directly on the sheet |

| Healthcare | Sneeze guards and protective screens | Provides a barrier to reduce the transmission of germs, ensuring safety for patients and staff | Chemical resistance and ease of cleaning to maintain sterile environments |

| Manufacturing | Component covers and protective shields | Protects sensitive equipment from dust and damage, prolonging lifespan | Durability under mechanical stress and compatibility with adhesives for assembly |

How is PVC Transparent Sheet Utilized in Construction Projects?

In the construction industry, PVC transparent sheets are often employed as protective barriers around construction sites. They provide visibility for onlookers while safeguarding workers from falling debris and harsh weather conditions. The sheets are typically available in various thicknesses and UV-resistant options, which are crucial for outdoor applications. Buyers from regions like Africa and South America should prioritize sourcing sheets that can withstand local weather variations and meet regional safety regulations.

What Role Does PVC Transparent Sheet Play in Food & Beverage Processing?

In food processing environments, PVC transparent sheets are used to create protective barriers that allow for visibility while maintaining hygiene. These sheets are essential for preventing contamination while enabling staff to monitor processes. Compliance with food safety standards is vital, so international buyers must ensure that the sheets are made from materials that are easy to clean and resistant to chemical cleaning agents. This is particularly important in the Middle East, where stringent food safety regulations are enforced.

How is PVC Transparent Sheet Transforming Retail & Advertising?

Retailers utilize PVC transparent sheets for display cases and signage, enhancing product visibility and attractiveness. The ability to print graphics directly on these sheets allows businesses to customize their displays effectively. For B2B buyers, sourcing sheets with excellent clarity and appropriate thickness is critical to ensure durability and aesthetic appeal. Companies in Europe and Brazil should also consider the environmental impact of the materials used, opting for suppliers with sustainable practices.

Why are PVC Transparent Sheets Essential in Healthcare Settings?

In healthcare facilities, PVC transparent sheets are commonly used for sneeze guards and protective screens to minimize germ transmission. Their chemical resistance and ease of cleaning make them ideal for maintaining sterile environments. Buyers in the healthcare sector must prioritize sourcing sheets that comply with health regulations and can withstand frequent disinfection. This is particularly relevant for regions like the Middle East, where healthcare standards are exceptionally high.

How Do PVC Transparent Sheets Benefit Manufacturing Operations?

Manufacturers use PVC transparent sheets to cover and protect sensitive equipment from dust and physical damage. These sheets help prolong the lifespan of machinery and components. When sourcing, buyers should focus on the durability of the sheets under mechanical stress and their compatibility with adhesives for easy assembly. For international buyers from Africa and South America, understanding local manufacturing standards and environmental conditions will help in selecting the right products for their needs.

3 Common User Pain Points for ‘pvc transparent sheet’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Thickness of PVC Transparent Sheet

The Problem: Many B2B buyers, particularly those in manufacturing and construction, struggle to identify the correct thickness of PVC transparent sheets for their specific applications. A wrong choice can lead to structural weaknesses or inadequate transparency, impacting both the functionality and aesthetic of the final product. For instance, a buyer may need a sheet for a high-traffic area that requires more durability than a standard thickness offers, yet they often find suppliers with limited options or unclear specifications.

The Solution: To effectively source the right thickness, buyers should first assess the specific requirements of their project, including load-bearing capacity and environmental exposure. Consult technical datasheets from manufacturers, which often provide detailed information on the mechanical properties and recommended applications for different thicknesses. Additionally, consider working with suppliers who offer customizable options or a wide range of thicknesses. Establishing a partnership with a reliable supplier that provides samples can help buyers evaluate the material’s suitability before making bulk purchases.

Scenario 2: Inconsistent Quality in PVC Transparent Sheets

The Problem: Buyers often encounter issues with the quality consistency of PVC transparent sheets across different suppliers. Variations in clarity, strength, and chemical resistance can lead to significant problems in applications such as signage or protective barriers. For example, a company that produces display cases may receive a batch of sheets that do not meet their standards, leading to increased costs and delays.

The Solution: To mitigate quality inconsistencies, B2B buyers should prioritize sourcing from reputable suppliers with a strong track record in the industry. Request quality certifications, such as ISO standards, and inquire about their quality control processes. Implementing a standardized testing procedure upon receipt of materials can further ensure that the sheets meet the required specifications. Establishing long-term relationships with trusted manufacturers can also lead to better quality assurance and reduced risk of receiving subpar materials.

Scenario 3: Challenges with Fabrication and Installation of PVC Transparent Sheets

The Problem: Fabrication and installation of PVC transparent sheets can present challenges for buyers unfamiliar with the material. Common issues include difficulty in cutting, bonding, and achieving the desired finish. For instance, a company attempting to create custom displays may find that the sheets crack during cutting or that adhesives fail to bond properly, leading to wasted materials and labor costs.

The Solution: To address these fabrication challenges, buyers should invest time in understanding the best practices for working with PVC transparent sheets. This includes using the right tools designed for cutting rigid plastics and selecting adhesives that are specifically formulated for PVC. Suppliers often provide technical support or detailed guides on the fabrication process, so leveraging these resources can be beneficial. Training staff on the correct handling and installation techniques can also minimize errors and enhance efficiency. Additionally, considering pre-fabricated options or collaborating with experienced fabricators can save time and ensure a professional finish.

Strategic Material Selection Guide for pvc transparent sheet

What Are the Key Properties of PVC Transparent Sheets?

PVC (Polyvinyl Chloride) transparent sheets are widely recognized for their versatility and performance in various applications. They exhibit excellent mechanical strength, resistance to chemicals, and good light transmission, making them suitable for diverse environments. The temperature resistance of PVC sheets typically ranges from -15°C to +60°C, which allows them to perform well in many industrial settings. Additionally, they have low moisture absorption (approximately 0.2%), which enhances their durability in humid conditions.

What Are the Pros and Cons of Using PVC Transparent Sheets?

Pros:

- Durability: PVC sheets are resistant to impact, chemicals, and weather, making them ideal for outdoor applications and environments where exposure to corrosive substances is a concern.

- Cost-Effectiveness: Compared to other transparent materials like acrylic or polycarbonate, PVC sheets are generally more affordable, providing a budget-friendly option for businesses.

- Ease of Fabrication: They can be easily cut, drilled, and bonded using conventional tools and adhesives, simplifying the manufacturing process.

Cons:

- Temperature Limitations: While PVC can withstand moderate temperatures, it begins to soften at around 200°F (93°C) and becomes viscous by 350°F (177°C), which may limit its use in high-temperature applications.

- Limited UV Resistance: PVC sheets can degrade when exposed to prolonged sunlight unless treated, which may necessitate additional protective coatings for outdoor applications.

- Environmental Concerns: The production and disposal of PVC can raise environmental issues, prompting some companies to seek more sustainable alternatives.

How Do PVC Transparent Sheets Impact Specific Applications?

The chemical resistance of PVC makes it suitable for applications in the chemical industry, where exposure to acids and alkalis is common. Its transparency and rigidity allow for effective use in signage and display cases, where visibility is crucial. However, in regions with high UV exposure, such as parts of Africa and South America, additional UV stabilization may be required to ensure longevity.

What Should International B2B Buyers Consider When Selecting PVC Transparent Sheets?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of local compliance standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), or JIS (Japanese Industrial Standards). Understanding these standards is critical for ensuring product quality and compatibility with regional regulations. Additionally, buyers should consider the availability of materials in their local markets, as shipping costs and lead times can significantly affect project timelines and budgets.

Summary Table of Material Selection for PVC Transparent Sheets

| Material | Typical Use Case for PVC Transparent Sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rigid PVC | Signage, display cases | High impact resistance | Limited UV resistance | Low |

| Expanded PVC | Lightweight applications | Lightweight and easy to handle | Lower strength compared to rigid PVC | Medium |

| Clear PVC | Chemical containment, protective barriers | Excellent chemical resistance | Temperature limitations | Medium |

| PVC with UV Stabilizers | Outdoor signage, greenhouse applications | Enhanced durability in sunlight | Higher cost due to additional treatments | High |

This guide provides a strategic overview of PVC transparent sheets, highlighting the materials’ properties, advantages, and considerations for international buyers. Understanding these factors can help businesses make informed decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc transparent sheet

What Are the Main Stages in the Manufacturing Process of PVC Transparent Sheets?

The production of PVC transparent sheets involves several critical stages, each designed to ensure the final product meets industry standards for quality and performance. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The process begins with sourcing high-quality raw materials, primarily polyvinyl chloride (PVC) resin. Additives such as plasticizers, stabilizers, and colorants may be incorporated to enhance properties like flexibility, durability, and UV resistance. These materials are mixed in precise proportions to ensure uniformity and quality. This step may involve the use of advanced blending techniques, including high-shear mixing, to achieve a homogeneous mixture. -

Forming Techniques

The prepared material undergoes various forming techniques to shape it into sheets. The most common methods include extrusion and calendering. In extrusion, the PVC mixture is melted and forced through a die to form a continuous sheet. This method allows for precise thickness control and can produce large volumes efficiently. Calendering involves passing the material through rollers to achieve the desired thickness and smoothness. This technique is particularly effective for producing thinner sheets with a high-quality finish. -

Assembly

For applications that require specific characteristics, sheets may undergo additional processes like lamination or co-extrusion. These techniques combine multiple layers of materials to enhance performance attributes such as impact resistance and thermal insulation. This assembly stage is crucial for ensuring the sheets meet specific client requirements for various applications, from signage to protective barriers. -

Finishing Processes

The finishing stage involves cutting, trimming, and surface treatment of the sheets to ensure they meet dimensional specifications and aesthetic requirements. Common finishing techniques include polishing, which enhances clarity and gloss, and applying protective coatings to improve UV resistance and scratch resistance. These steps are vital for ensuring that the final product is not only functional but also visually appealing.

How Is Quality Assurance Ensured in PVC Transparent Sheet Production?

Quality assurance is a critical component of the manufacturing process for PVC transparent sheets, ensuring that products meet both international and industry-specific standards.

-

International Standards for Quality Assurance

Manufacturers often adhere to quality management standards such as ISO 9001, which outlines criteria for a quality management system (QMS). This standard is recognized globally and emphasizes continuous improvement, customer satisfaction, and effective process management. Compliance with ISO standards is essential for B2B buyers as it signifies that the manufacturer has a structured approach to quality. -

Industry-Specific Certifications

Depending on the application, additional certifications may be required. For example, sheets used in construction may need CE marking, which indicates compliance with European health, safety, and environmental protection standards. In the oil and gas sector, API (American Petroleum Institute) certifications might be necessary for products exposed to harsh chemicals. Buyers should inquire about these certifications to ensure the product’s suitability for their specific applications. -

Quality Control Checkpoints

Quality control (QC) is integrated into various stages of the manufacturing process through multiple checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected upon receipt to ensure they meet specified quality standards before processing begins.

– In-Process Quality Control (IPQC): During manufacturing, periodic inspections are conducted to monitor parameters such as thickness, clarity, and surface finish. Any deviations are promptly addressed to prevent defects.

– Final Quality Control (FQC): The finished products undergo rigorous testing to verify they meet all specifications. This may include visual inspections, dimensional checks, and performance tests such as impact resistance and UV stability.

What Common Testing Methods Are Used in PVC Sheet Quality Assurance?

To ensure that PVC transparent sheets meet quality standards, various testing methods are employed throughout the manufacturing process. These include:

- Mechanical Testing: Evaluating tensile strength, impact resistance, and flexibility to ensure the material can withstand its intended use.

- Chemical Resistance Testing: Exposing the sheets to various chemicals to assess their durability and resistance to degradation.

- Dimensional Testing: Checking the thickness, length, and width of sheets to ensure they conform to specified tolerances.

- Optical Testing: Measuring light transmission and clarity to confirm that the sheets meet transparency requirements for applications like signage and displays.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of their suppliers to ensure they receive high-quality products. Here are some effective strategies:

-

Supplier Audits

Conducting on-site audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. During these audits, buyers can assess compliance with international standards and industry-specific regulations. This direct engagement can also foster stronger relationships and facilitate better communication. -

Requesting Quality Reports

Suppliers should be able to provide documentation related to their quality control processes, including test results and compliance certificates. Buyers should request these documents to verify that the products meet the required specifications. -

Third-Party Inspections

Engaging independent third-party inspection services can further validate the quality of products. These organizations can perform unbiased assessments of the manufacturing processes and final products, ensuring compliance with industry standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate several nuances related to quality control, especially when sourcing PVC transparent sheets from different regions:

- Regulatory Variations: Different countries have varying regulations regarding product safety and quality. Buyers should familiarize themselves with local standards in their target markets, such as REACH in Europe, which governs chemical safety.

- Cultural Considerations: Understanding cultural differences in business practices can facilitate smoother negotiations and improve collaboration with suppliers. Building trust and maintaining open communication are critical for successful partnerships.

- Logistics and Supply Chain Issues: Quality can also be affected by transportation and storage conditions. Buyers should inquire about how suppliers manage logistics to ensure that products are delivered in optimal condition.

In summary, a comprehensive understanding of the manufacturing processes and quality assurance practices for PVC transparent sheets is crucial for B2B buyers. By being informed about these aspects, buyers can make better purchasing decisions and establish reliable partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc transparent sheet’

Introduction

This sourcing guide is designed to assist B2B buyers in procuring PVC transparent sheets effectively. It outlines essential steps to ensure that you select the right product and supplier, ultimately enhancing your procurement process while minimizing risks.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s vital to clearly define your technical requirements for PVC transparent sheets. Consider factors such as thickness, transparency level, and chemical resistance. Understanding these specifications will help you communicate effectively with suppliers and ensure you receive materials that meet your operational needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of PVC transparent sheets. Utilize online marketplaces, industry directories, and trade shows to compile a list of candidates. Evaluate their reputation by checking reviews and ratings to ensure they have a track record of delivering quality products.

Step 3: Verify Supplier Certifications

✅ Verify Supplier Certifications

Check that your chosen suppliers possess relevant certifications that demonstrate their compliance with international standards. Certifications such as ISO 9001 for quality management and material safety data sheets (MSDS) for chemical handling are critical. This ensures that the materials you procure are safe and reliable for your applications.

Step 4: Request Samples for Evaluation

Before placing a large order, always request samples of the PVC transparent sheets. This step allows you to assess the quality and suitability of the material for your specific use case. Examine the samples for clarity, thickness, and flexibility to ensure they meet your expectations.

Step 5: Inquire About Customization Options

If your project requires specific dimensions or additional features, inquire about customization options. Many suppliers offer tailored solutions, such as cut-to-size sheets or specific finishes like UV stabilization. Customization can enhance the functionality of the sheets for your unique applications.

Step 6: Discuss Pricing and Payment Terms

Engage in discussions regarding pricing structures and payment terms with potential suppliers. It’s essential to understand the total cost, including shipping and handling fees. Additionally, inquire about payment options, such as upfront payments or credit terms, to align with your financial capabilities.

Step 7: Establish Clear Communication Channels

Once you select a supplier, establish clear communication channels to facilitate smooth interactions. Agree on points of contact, preferred communication methods, and response times. Maintaining open lines of communication is crucial for addressing any issues that may arise during the procurement process.

By following these steps, B2B buyers can navigate the procurement of PVC transparent sheets more effectively, ensuring they make informed decisions that align with their operational requirements and budgetary constraints.

Comprehensive Cost and Pricing Analysis for pvc transparent sheet Sourcing

What Are the Key Cost Components in Sourcing PVC Transparent Sheets?

When sourcing PVC transparent sheets, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: PVC is a relatively low-cost plastic, but prices can fluctuate based on global oil prices and the availability of raw materials. For transparent sheets, the quality of PVC affects cost; higher clarity and impact resistance typically demand a premium.

-

Labor: Labor costs can vary significantly depending on the region of production. Automated manufacturing processes can reduce labor costs, but regions with lower labor costs may offer competitive pricing without compromising quality.

-

Manufacturing Overhead: This encompasses facility costs, utilities, and equipment maintenance. Efficient manufacturing processes and economies of scale can help lower these costs, impacting the final price of the sheets.

-

Tooling: Custom tooling for specific sheet sizes or specifications can add to initial costs. However, if a buyer commits to larger volume orders, they might negotiate shared tooling costs with suppliers, making it more cost-effective.

-

Quality Control (QC): Ensuring that the sheets meet specific quality standards is essential, especially for applications in industries like construction or food packaging. Rigorous QC processes may increase costs, but they can also prevent costly returns or failures in the field.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and Incoterms. Buyers should consider both domestic and international shipping options to optimize costs.

-

Margin: Suppliers will add a margin based on their operational costs and market positioning. Understanding the competitive landscape can provide leverage during negotiations.

How Do Price Influencers Affect the Sourcing of PVC Transparent Sheets?

Several factors influence the pricing of PVC transparent sheets. These include volume/MOQ, specifications/customization, materials, quality certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Larger orders generally result in lower per-unit costs. Minimum order quantities (MOQ) can also affect pricing; suppliers often set MOQs to ensure profitability.

-

Specifications/Customization: Custom sizes, thicknesses, or finishes can lead to increased production costs. Buyers should balance their specific needs with the potential for higher prices.

-

Materials: The choice of materials can impact price. For instance, sheets with additional UV resistance or specific chemical properties may come at a premium.

-

Quality/Certifications: Certifications such as ISO or compliance with industry standards can affect the price. While these certifications may increase costs, they often lead to better product reliability.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Established suppliers may charge more due to their quality assurance, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: The agreed-upon shipping terms can significantly affect the total cost. Understanding the responsibilities of both buyer and seller under various Incoterms is essential to avoid unexpected charges.

What Tips Can Help Buyers Negotiate Better Prices for PVC Transparent Sheets?

B2B buyers should consider several strategies to enhance cost-efficiency and negotiate better pricing:

-

Build Relationships: Establishing a solid relationship with suppliers can lead to better pricing and service. Suppliers are more likely to offer discounts or favorable terms to reliable customers.

-

Negotiate Terms: Always negotiate payment terms, delivery schedules, and pricing. Flexibility in payment can sometimes lead to lower prices.

-

Consider Total Cost of Ownership: Evaluate not just the purchase price but also the long-term costs associated with shipping, handling, and potential defects. A lower price might not always equate to better value.

-

Leverage International Dynamics: For buyers in Africa, South America, and the Middle East, consider the implications of currency exchange rates and political stability on costs. Understanding local market conditions can provide an edge in negotiations.

-

Be Informed: Stay updated on market trends and price fluctuations. Knowledge about competitor pricing can strengthen your negotiating position.

Conclusion

In summary, while PVC transparent sheets offer a range of applications and advantages, understanding the comprehensive cost structure and price influencers is essential for B2B buyers. By employing strategic negotiation techniques and being aware of the total cost of ownership, buyers can make informed sourcing decisions that align with their operational needs and budget constraints. Always consider the indicative nature of pricing, as fluctuations can occur based on market conditions and supplier dynamics.

Alternatives Analysis: Comparing pvc transparent sheet With Other Solutions

When selecting materials for transparent applications, B2B buyers often face a range of options. PVC transparent sheets are popular due to their versatility and cost-effectiveness, but several alternative materials can also meet similar needs. This analysis will compare PVC transparent sheets against polycarbonate sheets and acrylic sheets, providing insights into their performance, costs, ease of implementation, maintenance requirements, and best use cases.

| Comparison Aspect | PVC Transparent Sheet | Polycarbonate Sheet | Acrylic Sheet |

|---|---|---|---|

| Performance | High impact resistance, good chemical resistance | Excellent impact resistance, UV resistant | Good optical clarity, less impact resistance than polycarbonate |

| Cost | Generally low-cost | Moderate to high cost | Moderate cost |

| Ease of Implementation | Easy to fabricate and bond | Requires specialized tools for cutting and shaping | Easy to cut and shape, but may require special adhesives |

| Maintenance | Low maintenance | Low maintenance, but can scratch easily | Moderate maintenance, prone to scratching |

| Best Use Case | Indoor applications, signage | Outdoor applications, safety barriers | Display cases, decorative applications |

What Are the Pros and Cons of Polycarbonate Sheets as an Alternative?

Polycarbonate sheets are renowned for their exceptional impact resistance, making them an excellent choice for applications where durability is critical. They also provide UV protection, making them suitable for outdoor installations. However, the cost is generally higher than PVC, which may be a limiting factor for budget-conscious buyers. Additionally, while they are easy to maintain, polycarbonate can scratch easily, requiring careful handling and potential additional costs for protective coatings.

How Do Acrylic Sheets Compare with PVC Transparent Sheets?

Acrylic sheets offer excellent optical clarity and are available in a variety of colors and finishes. They are easier to work with than polycarbonate, allowing for straightforward cutting and shaping. However, acrylic is less impact-resistant compared to both PVC and polycarbonate, which can be a disadvantage in high-traffic or high-stress environments. Furthermore, acrylic can be prone to scratching, necessitating more frequent maintenance to keep it looking pristine.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Choosing the right transparent sheet solution depends on specific application requirements. If budget constraints are a primary concern, PVC transparent sheets offer an economical option with adequate performance for indoor applications. For environments requiring high impact resistance and UV stability, polycarbonate may be the best choice despite the higher cost. Conversely, if optical clarity and aesthetic appeal are paramount, acrylic sheets might be favored, keeping in mind the need for careful handling to avoid scratches. Ultimately, buyers should consider the specific use case, budget, and maintenance capabilities when making their decision.

Essential Technical Properties and Trade Terminology for pvc transparent sheet

What Are the Key Technical Properties of PVC Transparent Sheets?

When sourcing PVC transparent sheets, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the specific formulation of polyvinyl chloride used in manufacturing the sheets. Different grades can affect properties such as impact resistance, flexibility, and chemical resistance. For B2B buyers, selecting the right material grade is vital, as it determines the sheet’s suitability for specific applications, from signage to industrial use.

2. Thickness

The thickness of PVC sheets typically ranges from 1/8 inch to 1/2 inch or more. This specification is critical as it influences the sheet’s strength, durability, and application. Thicker sheets generally offer better impact resistance and are preferred for high-stress environments. Buyers must assess their requirements carefully to avoid overpaying for unnecessary thickness or compromising on durability.

3. Tensile Strength

Tensile strength measures how much pulling force a material can withstand before breaking. For PVC transparent sheets, high tensile strength is essential, particularly in applications that require structural integrity, such as protective barriers or displays. Understanding this property helps buyers ensure that the selected sheets can endure their intended use without failure.

4. Chemical Resistance

PVC sheets exhibit varying degrees of resistance to chemicals, including acids and alkalis. This property is critical for industries such as pharmaceuticals and manufacturing, where exposure to harsh substances is common. Buyers should verify chemical compatibility to prevent degradation and ensure longevity in their applications.

5. Impact Resistance

Impact resistance gauges the sheet’s ability to withstand mechanical shock without cracking or breaking. For applications such as safety shields or protective covers, high impact resistance is non-negotiable. B2B buyers should prioritize sheets with superior impact resistance to reduce the risk of damage during use.

6. UV Stability

UV stability refers to a material’s ability to resist degradation from ultraviolet light exposure. This property is particularly important for outdoor applications where PVC sheets may be exposed to sunlight. Selecting UV-stable sheets can significantly enhance durability and reduce replacement costs over time.

What Are Common Trade Terms Associated with PVC Transparent Sheets?

Understanding industry jargon is essential for effective communication in B2B transactions. Here are some common terms relevant to PVC transparent sheets:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are marketed by another company. In the context of PVC sheets, OEMs may produce custom sheets based on client specifications, making it important for buyers to clarify their requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is crucial for buyers to ensure they can meet their project needs without overcommitting to excess inventory. It also helps in budgeting and planning purchases.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For PVC sheets, issuing an RFQ allows buyers to gather competitive quotes, ensuring they make informed decisions based on price and value.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms helps B2B buyers navigate shipping logistics and costs associated with PVC sheets.

5. Lead Time

Lead time is the period between placing an order and receiving the product. For B2B buyers, knowing the lead time for PVC sheets is essential for project planning and ensuring timely delivery, especially when working on tight deadlines.

6. Fabrication

Fabrication refers to the process of cutting, shaping, and assembling materials to create a final product. Buyers should be aware of the fabrication capabilities of PVC sheets to determine how easily they can be customized for specific applications.

By understanding these properties and trade terms, B2B buyers can confidently navigate the procurement process for PVC transparent sheets, ensuring they select the right products for their specific needs.

Navigating Market Dynamics and Sourcing Trends in the pvc transparent sheet Sector

What Are the Key Trends Shaping the PVC Transparent Sheet Market?

The global PVC transparent sheet market is experiencing robust growth driven by several key factors. One significant driver is the increasing demand for versatile, lightweight, and durable materials across various sectors, including construction, automotive, and packaging. The construction industry, particularly in emerging markets in Africa and South America, is witnessing a surge in demand for PVC sheets due to their excellent weather resistance and ease of installation. Furthermore, technological advancements in production processes are leading to enhanced product quality and the introduction of specialized sheets, such as those with improved UV resistance or flame retardant properties.

Emerging trends in B2B sourcing are also notable. International buyers are increasingly leveraging digital platforms for procurement, enabling streamlined ordering processes and enhanced supplier transparency. This trend is particularly relevant in regions like Europe and the Middle East, where digital transformation is reshaping traditional supply chains. Additionally, sustainability is becoming a paramount consideration, with businesses seeking suppliers who prioritize eco-friendly materials and practices. As a result, suppliers who adopt green certifications and demonstrate a commitment to ethical manufacturing are gaining a competitive edge in the market.

How Does Sustainability Impact the PVC Transparent Sheet Sector?

Sustainability is becoming a critical factor in the sourcing of PVC transparent sheets. The environmental impact of plastic production and disposal has led to increased scrutiny from both consumers and regulatory bodies. Consequently, B2B buyers are prioritizing suppliers who adopt sustainable practices, such as using recycled materials or implementing energy-efficient production methods. Companies that can provide transparency in their supply chain, showcasing their commitment to reducing carbon footprints, are more likely to attract environmentally conscious clients.

The importance of ethical sourcing cannot be overstated. Buyers are increasingly looking for suppliers who adhere to ethical labor practices and demonstrate social responsibility. Certifications such as ISO 14001 for environmental management and other green certifications can serve as important indicators of a supplier’s commitment to sustainability. Furthermore, the introduction of bio-based PVC alternatives is gaining traction, offering a more sustainable option for buyers looking to reduce their environmental impact while still benefiting from the durability and versatility of PVC materials.

How Has the PVC Transparent Sheet Market Evolved Over Time?

The PVC transparent sheet market has a rich history that dates back to the mid-20th century when PVC became widely recognized for its versatility and cost-effectiveness. Initially used primarily in construction and packaging, advancements in manufacturing technology have expanded its applications to include signage, displays, and even medical devices. Over the decades, the material has evolved to meet changing market demands, with innovations leading to the development of clearer, more durable sheets that can withstand harsh environmental conditions.

Today, PVC transparent sheets are not only valued for their practical applications but also for their aesthetic qualities, making them popular in design and architectural projects. As sustainability concerns rise, the industry is poised for further evolution, with a shift towards more environmentally friendly production processes and materials. This ongoing transformation presents significant opportunities for international B2B buyers to source products that align with both their functional needs and corporate sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of pvc transparent sheet

-

How do I ensure the quality of PVC transparent sheets from suppliers?

To ensure quality, request samples before placing a bulk order. Look for certifications such as ISO or ASTM standards that confirm the material’s durability and chemical resistance. Additionally, consider conducting third-party quality assurance inspections during production and before shipment. Establish clear quality control parameters with your supplier, including thickness, transparency, and resistance to impact and chemicals, to avoid discrepancies. -

What is the best thickness for PVC transparent sheets in industrial applications?

The optimal thickness for PVC transparent sheets depends on the specific application. Generally, 1/8 inch to 1/2 inch thickness is suitable for most industrial uses, providing a balance between strength and flexibility. For applications requiring higher impact resistance, such as signage or protective barriers, thicker sheets (up to 1 inch) may be necessary. Always consult with your supplier to match the sheet thickness with your project’s requirements. -

What are the common uses of PVC transparent sheets in various industries?

PVC transparent sheets are versatile and used across multiple industries. Common applications include protective barriers in healthcare settings, signage in retail environments, and covers for greenhouse structures. They are also popular in packaging, furniture design, and as components in machinery due to their chemical resistance and durability. Understanding your industry’s specific needs will help you select the right product. -

What are the minimum order quantities (MOQs) for PVC transparent sheets?

Minimum order quantities can vary significantly between suppliers. Typically, MOQs for PVC transparent sheets range from 100 to 500 sheets, depending on the thickness and customization options. Always clarify MOQs before engaging in negotiations to avoid unexpected costs. Some suppliers may offer flexibility for smaller orders, especially for first-time buyers or in the case of custom orders. -

How can I customize PVC transparent sheets for my business needs?

Customization options for PVC transparent sheets include varying thicknesses, cut-to-size dimensions, and surface treatments (e.g., UV stabilization or anti-glare coatings). Many suppliers also offer printing services for branding or specific graphics. When discussing customization, provide detailed specifications and consider requesting prototypes to ensure the final product meets your expectations. -

What payment terms are typically offered by suppliers of PVC transparent sheets?

Payment terms can vary based on the supplier and your relationship with them. Common terms include net 30 or net 60, requiring payment within 30 or 60 days of invoice. Some suppliers may require a deposit upfront, especially for custom orders. Always negotiate terms that align with your cash flow and consider establishing a credit line for future purchases to streamline transactions. -

What logistics considerations should I keep in mind when importing PVC transparent sheets?

When importing PVC transparent sheets, consider shipping costs, customs duties, and delivery times. Ensure that your supplier provides detailed shipping options and documentation, including a bill of lading and commercial invoice. Partnering with a reliable freight forwarder can help navigate logistics complexities and ensure timely delivery. Familiarize yourself with import regulations specific to your country to avoid delays. -

How do I vet suppliers for PVC transparent sheets to ensure reliability?

To vet suppliers, research their business history, customer reviews, and production capabilities. Request references from previous clients and inquire about their quality control processes. Engage in direct communication to assess their responsiveness and willingness to provide information. Additionally, consider visiting their facilities if feasible, or request a virtual tour to better understand their operations and product quality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Pvc Transparent Sheet Manufacturers & Suppliers List

1. ePlastics – Clear PVC Sheets

Domain: eplastics.com

Registered: 1998 (27 years)

Introduction: This company, ePlastics – Clear PVC Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

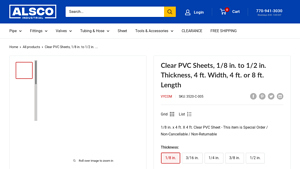

2. Clear PVC Pipe – Clear PVC Sheets

Domain: clearpvcpipe.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “Clear PVC Sheets”, “Thickness Options”: [“1/8 in.”, “3/16 in.”, “1/4 in.”, “3/8 in.”, “1/2 in.”], “Width”: “4 ft.”, “Length Options”: [“4 ft.”, “8 ft.”], “Prices”: {“1/8 in. x 4 ft. x 4 ft.”: “$95.54”, “1/8 in. x 4 ft. x 8 ft.”: “$182.39”, “3/16 in. x 4 ft. x 4 ft.”: “$144.00”, “3/16 in. x 4 ft. x 8 ft.”: “$273.84”, “1/4 in. x 4 ft. x 4 ft.”: “$192.00”, “1/4 in. x 4 ft. x 8 ft.”:…

3. Professional Plastics – PVC Sheet Optically Clear

Domain: professionalplastics.com

Registered: 1997 (28 years)

Introduction: PVC Sheet Optically Clear is a high-quality, transparent sheet made from polyvinyl chloride (PVC). It offers excellent clarity and is suitable for various applications, including displays, signage, and protective barriers. The sheets are lightweight, durable, and resistant to impact and chemicals. They can be easily fabricated, cut, and shaped to meet specific project requirements. Available in va…

4. Interstate Plastics – PVC Extruflex Flexible Clear Film Sheet Rolls

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “PVC Extruflex Flexible Clear Film Sheet Rolls”, “sizes”: [{“thickness”: “.060”, “width”: “48”, “length”: “60ft”}, {“thickness”: “.080”, “width”: “48”, “length”: “60ft”}, {“thickness”: “.120”, “width”: “48”, “length”: “60ft”}, {“thickness”: “.160”, “width”: “48”, “length”: “60ft”}], “price”: “$492.04”, “warnings”: [“This product can expose you to chemicals including Polyvinyl Chlo…

5. Clearly Plastic – PVC Foam Sheets

Domain: clearlyplastic.com

Registered: 2017 (8 years)

Introduction: This company, Clearly Plastic – PVC Foam Sheets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Curbell Plastics – PVC Type 1 Clear Sheet

Domain: curbellplastics.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “PVC Type 1, Sheet, Clear”,”Item Number”: “W01-06190″,”Dimensions”: {“Thickness”: “0.125 in”,”Width”: “48 in”,”Length”: “96 in”},”Price”: “$173.09 /each”,”Material”: “PVC Type 1″,”Color”: “Clear”,”Performance Characteristics”: {“Chemical Resistance”: “Superior chemical resistance”,”Impact Strength”: “Favorable impact strength”,”Flame Retardant”: “UL 94 V-0 rating”,”Machinability”:…

7. Walmart – Clear PVC Sheet A4 Size

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Walmart – Clear PVC Sheet A4 Size, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Gteek – Clear PVC Sheets

Strategic Sourcing Conclusion and Outlook for pvc transparent sheet

In the evolving landscape of PVC transparent sheet sourcing, strategic decisions can significantly impact operational efficiency and cost-effectiveness. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should prioritize suppliers who offer diverse product options, including chemical-resistant and expanded PVC sheets. Understanding the specific applications—ranging from signage to industrial components—will allow businesses to leverage the unique properties of PVC, such as its strength, versatility, and ease of fabrication.

As the demand for eco-friendly materials rises, buyers should also consider suppliers committed to sustainable practices. This not only aligns with global environmental standards but can also enhance brand reputation and customer loyalty.

Looking ahead, the market for PVC sheets is poised for growth, driven by advancements in manufacturing technologies and increased applications across various industries. Engaging with reliable suppliers who can provide tailored solutions will be crucial for businesses aiming to stay competitive. Now is the time to assess your sourcing strategies and explore opportunities that can lead to long-term partnerships and innovation in your operations. Take action today to secure your supply chain and ensure your business is well-positioned for future success.