Introduction: Navigating the Global Market for pvc extractor tool

In the rapidly evolving landscape of global trade, sourcing reliable PVC extractor tools poses a significant challenge for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe expand their operations, the need for efficient and durable tools to remove broken PVC components has never been more critical. This guide aims to equip buyers with the essential knowledge to navigate the complexities of the PVC extractor tool market, ensuring they make informed purchasing decisions that enhance their operational efficiency.

Our comprehensive guide covers various aspects of PVC extractor tools, including types and specifications, key applications in irrigation and plumbing, and practical tips for supplier vetting. By examining the features and benefits of popular models, such as the Orbit and Superior Tool extractors, we provide insights into selecting tools that meet specific operational needs. Furthermore, we delve into cost considerations, ensuring that buyers can balance quality with budget constraints.

By understanding the global market dynamics and leveraging the actionable insights presented in this guide, B2B buyers will be empowered to make strategic decisions that not only meet their immediate requirements but also support long-term growth and sustainability. Whether you are a procurement manager in Nigeria or a purchasing agent in Germany, this guide serves as your roadmap to successfully sourcing high-quality PVC extractor tools tailored to your business needs.

Understanding pvc extractor tool Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Nipple Extractor | Designed for 1/2″ and 3/4″ PVC fittings; rubberized grip handle | Irrigation systems, plumbing maintenance | Pros: Easy to use, prevents damage to fittings. Cons: Limited to specific sizes. |

| Riser Extractor | Sharp teeth for secure grip; durable zinc construction | Sprinkler systems, outdoor applications | Pros: Effective for broken risers, robust design. Cons: May require additional force for stubborn fittings. |

| Pipe Nipple Extraction Set | Includes multiple sizes; versatile for various pipe types | Plumbing, construction, maintenance | Pros: Multi-functional, cost-effective. Cons: Can be bulkier to carry around. |

| Specialty Extractor Tool | T-handle design for better torque; often includes interchangeable heads | HVAC systems, plumbing | Pros: Enhanced leverage, adaptable design. Cons: Complexity may deter inexperienced users. |

| Heavy-Duty PVC Extractor | Constructed from high-quality steel; designed for frequent use | Industrial applications, large projects | Pros: Long-lasting, withstands heavy use. Cons: Higher upfront cost, may be overkill for small jobs. |

What Are the Characteristics of Plastic Nipple Extractors?

Plastic nipple extractors are specifically designed to remove broken or stuck PVC fittings, particularly in irrigation systems. They typically accommodate sizes of 1/2″ and 3/4″, making them a staple for landscaping and plumbing professionals. Their rubberized grip enhances user comfort, allowing for easy handling during extended use. B2B buyers should consider the extractor’s compatibility with existing fittings and whether it meets the specific requirements of their projects.

How Do Riser Extractors Differ in Functionality?

Riser extractors feature sharp teeth that bite into the plastic, making them particularly effective for removing broken risers from sprinkler systems. Constructed from durable materials like zinc, these tools are designed for outdoor applications where rust and wear could be concerns. B2B buyers should evaluate the extractor’s ease of use and whether its design aligns with the frequency of use in their operations, as well as the specific conditions of their work environment.

Why Consider a Pipe Nipple Extraction Set?

A pipe nipple extraction set is advantageous for businesses that require versatility across multiple pipe sizes. These sets often include various tools to accommodate different diameters, making them suitable for plumbing, construction, and maintenance tasks. While they can be bulkier, the multi-functional nature of these sets can provide cost savings and reduce the need for multiple individual tools. Buyers should assess their specific job requirements to determine if the investment in a set is justified.

What Are the Benefits of Using Specialty Extractor Tools?

Specialty extractor tools often come with a T-handle design, which provides better torque and leverage, making them suitable for tough extraction tasks. These tools may include interchangeable heads, allowing for adaptability across different applications, including HVAC and plumbing. While they offer enhanced functionality, their complexity might deter less experienced users. B2B buyers should weigh the need for advanced features against the skill level of their workforce.

When Should Businesses Invest in Heavy-Duty PVC Extractors?

Heavy-duty PVC extractors are built from high-quality steel, making them ideal for industrial applications where tools face rigorous use. Their durability ensures they can withstand the demands of large projects, but they often come with a higher upfront cost. Businesses engaged in extensive plumbing or construction work should consider investing in these extractors to ensure longevity and reliability. Evaluating the frequency and scale of use will help determine if this investment aligns with operational needs.

Key Industrial Applications of pvc extractor tool

| Industry/Sector | Specific Application of PVC Extractor Tool | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Irrigation and Landscaping | Removing broken PVC risers from sprinkler systems | Reduces downtime and labor costs, improving operational efficiency | Durability, size compatibility (1/2″ and 3/4″), and ease of use |

| Construction and Building | Extracting damaged PVC fittings in plumbing installations | Minimizes disruption in project timelines and reduces repair costs | Material quality, tool longevity, and supplier reliability |

| Oil and Gas | Maintenance of PVC piping systems in refineries | Enhances safety and operational reliability by ensuring proper maintenance | Compliance with international standards and regional regulations |

| Water Supply Management | Repairing municipal water systems using PVC fittings | Ensures uninterrupted water supply, improving community service | Availability of bulk purchasing options and local support services |

| Agricultural Equipment | Maintaining irrigation systems for large farms | Increases crop yield through efficient water management | Product availability in local markets and compatibility with existing systems |

How is the PVC Extractor Tool Used in Irrigation and Landscaping Applications?

In the irrigation and landscaping sector, the PVC extractor tool is invaluable for removing broken risers from sprinkler systems. This tool allows technicians to avoid digging up the entire assembly, saving both time and labor costs. By efficiently extracting damaged components, businesses can reduce downtime and maintain consistent irrigation schedules, which is critical for plant health. Buyers in regions like Africa or South America should consider tools that are durable enough to withstand outdoor conditions and have a good grip for ease of use.

What Role Does the PVC Extractor Tool Play in Construction and Building Projects?

In construction, the PVC extractor tool is essential for quickly addressing issues with damaged fittings in plumbing systems. By enabling the removal of broken pipes without extensive repairs, this tool helps to minimize disruptions in project timelines. For international buyers, particularly in Europe and the Middle East, sourcing high-quality tools that comply with local standards is crucial. Additionally, suppliers should provide clear specifications on tool longevity and compatibility with various pipe sizes.

How is the PVC Extractor Tool Utilized in the Oil and Gas Industry?

The oil and gas industry relies on the PVC extractor tool for the maintenance of piping systems in refineries. This tool allows maintenance teams to efficiently remove damaged PVC fittings, thus enhancing safety and ensuring operational reliability. For international buyers, especially in regions like the Middle East, compliance with safety regulations and the availability of robust tools designed for harsh environments are key considerations when sourcing these products.

How Does the PVC Extractor Tool Contribute to Water Supply Management?

Municipal water supply systems benefit significantly from the PVC extractor tool, which is used to repair and maintain PVC fittings. Efficient repairs help to ensure an uninterrupted water supply, which is vital for community health and service. Buyers in Africa and South America should prioritize sourcing tools that are readily available and compatible with their existing systems. Local suppliers can provide valuable support and maintenance services, enhancing the overall reliability of water management operations.

What is the Importance of the PVC Extractor Tool in Agricultural Equipment Maintenance?

In agriculture, maintaining irrigation systems is crucial for maximizing crop yields. The PVC extractor tool allows farmers to quickly address issues with broken fittings, ensuring that water management systems function effectively. For agricultural businesses, especially in regions with varying climate conditions, sourcing tools that are resistant to wear and tear is essential. Buyers should also consider the availability of these tools in local markets to facilitate timely repairs and maintenance.

3 Common User Pain Points for ‘pvc extractor tool’ & Their Solutions

Scenario 1: Difficulty in Removing Stubborn PVC Fittings

The Problem:

B2B buyers often encounter situations where they need to replace or repair PVC fittings, but broken or stubborn risers make extraction nearly impossible. This can lead to delays in project timelines and increased labor costs, particularly when workers have to dig up surrounding soil or use improvised methods that risk damaging the existing fittings. The frustration of dealing with stuck nipples can result in wasted resources and affect overall project efficiency.

The Solution:

To effectively tackle this challenge, it is crucial to invest in a high-quality PVC extractor tool specifically designed for this purpose. Look for models that feature sharp teeth and a rubberized grip, which can securely bite into the broken riser without damaging the surrounding fittings. For instance, tools like the Superior Tool 1/2″ and 3/4″ PVC Nipple Extractor are designed to quickly and efficiently remove broken risers without the need for extensive excavation. When using the tool, ensure that it is fully inserted into the broken section before applying a counterclockwise rotation to maximize grip and leverage. Regular maintenance of the extractor, including cleaning after each use, will also prolong its lifespan and ensure optimal performance.

Scenario 2: High Replacement Costs Due to Improper Tools

The Problem:

Many buyers in the B2B sector find themselves spending significantly on replacement parts due to the use of inadequate tools for PVC extraction. Using the wrong tool can lead to damage not only to the fittings but also to surrounding infrastructure, leading to costly repairs. This is particularly common in large-scale irrigation projects where efficiency and cost-effectiveness are paramount. The lack of proper tools can result in project delays, increased labor costs, and ultimately, dissatisfied clients.

The Solution:

To mitigate these risks, it is essential to specify and source the right PVC extractor tools that match the requirements of your specific projects. Investing in multi-size extractor sets can provide flexibility across various applications, reducing the need to purchase multiple tools. Additionally, consider suppliers who offer tools with durable construction and ergonomic designs, as these features can enhance usability and reduce the risk of damage during extraction. Educating your team on the proper usage of these tools can also play a vital role in preventing mishaps and ensuring that projects stay on schedule and within budget.

Scenario 3: Limited Availability of Quality Tools in International Markets

The Problem:

International B2B buyers, particularly in regions like Africa and South America, often struggle with limited access to quality PVC extractor tools. This scarcity can lead to reliance on inferior products that may not meet professional standards, resulting in inefficient operations and compromised project outcomes. The challenge is exacerbated by shipping delays and the added costs of importing tools that may not be readily available in local markets.

The Solution:

One effective approach is to partner with reputable suppliers who specialize in exporting high-quality tools to international markets. Establishing relationships with manufacturers that offer bulk purchasing options can also yield cost savings and ensure a steady supply of essential tools. Furthermore, consider localizing your procurement strategy by identifying regional distributors who carry quality products. This can significantly reduce shipping times and costs. Additionally, leverage online platforms that cater to B2B buyers, offering detailed specifications, user reviews, and competitive pricing, ensuring that you are making informed decisions when sourcing PVC extractor tools. Engaging in community forums or industry networks can also provide insights into the best suppliers and tools suited for your specific needs.

Strategic Material Selection Guide for pvc extractor tool

What Are the Common Materials Used in PVC Extractor Tools?

When selecting a PVC extractor tool, the choice of material significantly influences its performance, durability, and suitability for specific applications. Below is an analysis of four common materials used in the manufacturing of PVC extractor tools, focusing on their properties, pros and cons, and considerations for international B2B buyers.

1. Zinc Alloy

Key Properties: Zinc alloy is known for its excellent corrosion resistance, particularly in outdoor environments. It can withstand moderate temperatures and is relatively strong, making it suitable for tools that require a firm grip and durability.

Pros & Cons: The primary advantage of zinc alloy is its resistance to rust and corrosion, which extends the tool’s lifespan. However, it can be more expensive than other materials and may not perform well under extreme temperatures, limiting its use in hot climates.

Impact on Application: Zinc alloy extractors are particularly effective for outdoor irrigation applications where exposure to moisture is common. They are compatible with PVC fittings and do not damage the threads during extraction.

International Considerations: Buyers in regions like Germany and Nigeria should ensure that the zinc alloy meets local compliance standards, such as DIN for Germany. Corrosion resistance is crucial in humid climates, making this material a preferred choice for many.

2. Steel

Key Properties: Steel, especially stainless steel, offers high tensile strength and durability. It can handle high-pressure applications and is resistant to deformation, making it ideal for heavy-duty use.

Pros & Cons: The durability of steel is its strongest point, as it can withstand rigorous use without significant wear. However, it is prone to rust if not properly coated, and the manufacturing process can be complex and costly.

Impact on Application: Steel extractors are suitable for various applications, including those involving high-pressure water systems. They can effectively handle tough extraction tasks without bending or breaking.

International Considerations: Buyers from South America and the Middle East should be aware of the need for protective coatings to prevent rust in humid environments. Compliance with ASTM standards is often required for industrial applications.

3. Plastic (Polypropylene or PVC)

Key Properties: Plastic materials, such as polypropylene or PVC, are lightweight and resistant to chemicals, making them suitable for specific applications. They can withstand moderate temperatures and are easy to mold into intricate designs.

Pros & Cons: The lightweight nature of plastic tools makes them easy to handle and transport, reducing shipping costs. However, they may not be as durable as metal options and can wear down more quickly under heavy use.

Impact on Application: Plastic extractors are effective for light-duty tasks and are particularly useful in environments where chemical exposure is a concern. They are compatible with PVC fittings and do not risk damaging them during use.

International Considerations: Buyers in Africa should ensure that the plastic used complies with local environmental regulations, as some plastics may not be suitable for all applications. Standards such as JIS may also apply.

4. Aluminum

Key Properties: Aluminum is lightweight, resistant to corrosion, and has good thermal conductivity. It can handle moderate pressures and is often anodized for additional protection against corrosion.

Pros & Cons: The main advantage of aluminum is its lightweight nature, making it easy to use for extended periods. However, it may not be as strong as steel and can be more expensive than plastic options.

Impact on Application: Aluminum extractors are suitable for various applications, including irrigation and plumbing, where weight is a concern. They can effectively remove stuck PVC fittings without damaging them.

International Considerations: Buyers in Europe should consider the recycling aspect of aluminum, as it is highly recyclable and can meet sustainability goals. Compliance with EU regulations regarding materials is also essential.

Summary Table of Material Selection for PVC Extractor Tools

| Material | Typical Use Case for PVC Extractor Tool | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Zinc Alloy | Outdoor irrigation applications | Excellent corrosion resistance | Higher cost, limited temperature range | Medium |

| Steel | Heavy-duty extraction tasks | High durability and strength | Prone to rust, complex manufacturing | High |

| Plastic | Light-duty tasks, chemical exposure | Lightweight and easy to handle | Less durable, wears down quickly | Low |

| Aluminum | General plumbing and irrigation | Lightweight and corrosion-resistant | Not as strong as steel, higher cost | Medium |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions when sourcing PVC extractor tools, taking into account performance requirements, cost considerations, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc extractor tool

What Are the Main Stages of Manufacturing PVC Extractor Tools?

The manufacturing process for PVC extractor tools typically involves several key stages, each critical to producing a high-quality product.

-

Material Preparation: The process begins with the selection of high-quality materials, primarily durable steel or zinc, depending on the tool’s intended use and design specifications. Manufacturers often source materials from certified suppliers to ensure compliance with industry standards. The materials are then cut and treated to prepare them for forming.

-

Forming Techniques: Once the materials are prepared, various forming techniques come into play. For example, steel may be forged or stamped into specific shapes, while zinc components are often cast. These methods allow for precision and consistency in the dimensions of the extractor tools, which is crucial for their functionality.

-

Assembly: After forming, the components are assembled. This may involve welding, fastening, or using adhesives, depending on the design. The assembly stage is critical, as it ensures that all parts fit together seamlessly and function as intended. Manufacturers may also include ergonomic features, such as rubberized grips, to enhance user comfort and efficiency.

-

Finishing Processes: The final stage in manufacturing involves finishing processes like polishing, coating, or painting. These not only improve the tool’s appearance but also enhance its resistance to corrosion and wear. For instance, a dipped handle may be applied to provide better grip and durability.

How Is Quality Assurance Implemented in PVC Extractor Tool Manufacturing?

Quality assurance is a cornerstone of manufacturing, particularly for tools that must meet stringent performance standards.

-

International Standards Compliance: Many manufacturers adhere to international quality standards such as ISO 9001, which focuses on quality management systems. This certification assures B2B buyers that the manufacturer has implemented effective processes to ensure product quality.

-

Industry-Specific Certifications: Depending on the market, tools may also need to comply with industry-specific certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) for applications in the petroleum industry. These certifications often require rigorous testing and documentation.

-

Quality Checkpoints: Quality control (QC) involves several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): During production, operators conduct regular checks to monitor the quality of the work being performed.

– Final Quality Control (FQC): Finished products undergo thorough inspections to verify they meet all specifications before shipment.

What Common Testing Methods Are Used for PVC Extractor Tools?

Testing methods are vital for ensuring that the tools perform reliably under various conditions. Common methods include:

-

Dimensional Inspection: Tools are measured against precise specifications to ensure they fit standard sizes and can effectively interact with PVC fittings.

-

Functional Testing: This involves simulating the tool’s use in real-world conditions to verify its effectiveness in extracting broken risers without damaging the fittings.

-

Durability Testing: Tools undergo stress tests to evaluate their resistance to wear and tear over time. This can involve repeated use simulations to assess longevity.

-

Corrosion Resistance Testing: Given that many tools are used in outdoor environments, testing for resistance to rust and corrosion is essential. This often involves exposing the tool to saline or acidic environments and observing any degradation.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures is crucial for ensuring product reliability and compliance with local standards. Here are effective strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control systems in place. This firsthand observation can provide insights into the supplier’s operational integrity.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their quality control measures, including test results and compliance certificates. This transparency is essential for buyers to make informed decisions.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control practices. These agencies often have established protocols for assessing compliance with international standards.

-

Reviewing Certifications: Buyers should verify the authenticity of certifications like ISO 9001, CE, or API by checking with the issuing bodies. This step helps ensure that the supplier genuinely meets the claimed standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control. Understanding these nuances can greatly enhance procurement strategies:

-

Regulatory Variations: Different regions may have varying regulations regarding tool specifications and safety standards. Buyers should familiarize themselves with local requirements and ensure that suppliers can meet these standards.

-

Cultural Considerations: Communication barriers and cultural differences can impact negotiations and quality expectations. Building relationships with suppliers and understanding their operational culture can lead to better outcomes.

-

Logistics and Shipping: The quality of tools can be affected during shipping. Buyers should ensure that suppliers have adequate packaging and handling procedures to protect products during transit.

-

After-Sales Support: Quality assurance does not end at delivery. Buyers should assess the supplier’s after-sales support, including warranty provisions and responsiveness to quality issues that may arise post-purchase.

By understanding the manufacturing processes and quality assurance practices behind PVC extractor tools, B2B buyers can make informed decisions that align with their operational needs and standards, ultimately leading to successful procurement outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc extractor tool’

In this practical sourcing guide, we provide a step-by-step checklist designed to help B2B buyers effectively procure PVC extractor tools. Whether you are operating in Africa, South America, the Middle East, or Europe, following this checklist will ensure you make informed decisions that meet your operational needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements of the PVC extractor tool you need. This includes the size (e.g., 1/2 inch and 3/4 inch), material (e.g., durable steel or zinc), and specific features (e.g., rubberized grips or sharp teeth for better grip). Defining these specifications helps streamline the selection process and ensures compatibility with your existing systems.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify suppliers known for high-quality PVC extractor tools. Look for suppliers with a solid reputation in the industry, positive customer reviews, and a portfolio of successful projects. Utilize platforms like trade directories, industry forums, and recommendations from colleagues to compile a list of potential suppliers.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their experience with exporting tools to your location, and inquire about their customer service and support capabilities. This due diligence reduces risks associated with supplier reliability.

Step 4: Request Samples and Demonstrations

Once you’ve narrowed down your choices, request samples or demonstrations of the PVC extractor tools. Testing the tools firsthand allows you to evaluate their effectiveness, ergonomics, and durability. Pay attention to how well they perform in real-world conditions, as this can significantly impact your operational efficiency.

Step 5: Check Certifications and Compliance

Verify that the suppliers provide the necessary certifications and compliance with international standards relevant to your market. Certifications may include ISO, CE, or other regional standards that ensure product quality and safety. This step is crucial to mitigate potential legal issues and ensure the tools meet your region’s regulations.

Step 6: Negotiate Terms and Pricing

Engage in negotiations to secure favorable terms and pricing. Discuss bulk purchasing discounts, payment terms, and shipping arrangements. Building a strong relationship with your supplier can lead to better pricing and priority service in the future, so consider long-term partnerships when negotiating.

Step 7: Plan for After-Sales Support and Warranty

Inquire about after-sales support and warranty options. A reliable supplier should offer a clear warranty policy and responsive customer service for troubleshooting and maintenance. Understanding these terms upfront ensures you have recourse if any issues arise with the tools after purchase.

By following this checklist, B2B buyers can ensure they procure the right PVC extractor tools that meet their operational needs while establishing a strong relationship with trustworthy suppliers.

Comprehensive Cost and Pricing Analysis for pvc extractor tool Sourcing

Understanding the cost structure and pricing dynamics of PVC extractor tools is crucial for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. This analysis delves into the various components affecting the cost and pricing of these tools, as well as tips for buyers to enhance their procurement strategies.

What Are the Key Cost Components for PVC Extractor Tools?

-

Materials: The primary materials used in PVC extractor tools include durable metals like zinc or steel, and sometimes high-quality plastics. The choice of material directly impacts both the performance and longevity of the tool. Higher-grade materials may incur a higher upfront cost but can lead to lower replacement frequency and maintenance expenses.

-

Labor: Labor costs vary by region and can significantly influence the overall cost structure. In countries with higher wage standards, labor costs for manufacturing may be a significant portion of the total expense. Conversely, sourcing from regions with lower labor costs can provide savings but may come with trade-offs in quality or reliability.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce these costs, allowing suppliers to offer competitive pricing.

-

Tooling: Tooling costs relate to the equipment and molds required to produce extractor tools. Custom designs or specialized features can increase tooling expenses, affecting the overall price.

-

Quality Control (QC): Ensuring that tools meet safety and performance standards incurs costs. Rigorous QC processes are essential, especially for tools used in critical applications, but they can add to the price.

-

Logistics: The cost of transporting goods from the manufacturer to the buyer’s location can vary widely based on distance, shipping method, and customs duties. International shipping adds complexity and potential delays, necessitating careful planning.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can vary depending on the supplier’s market position and competition.

How Do Price Influencers Impact PVC Extractor Tool Costs?

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Suppliers may offer discounts for larger orders, making it beneficial for buyers to forecast demand accurately.

-

Specifications and Customization: Customized tools tailored to specific applications may have higher costs due to additional engineering and production requirements. Buyers should weigh the benefits of customization against the potential for increased expenses.

-

Materials and Quality Certifications: Tools made from higher-quality materials or those with certifications (e.g., ISO standards) may command a premium price. Buyers should assess the importance of these factors against their budget.

-

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers with a track record of quality may charge more, but they can also offer better warranty terms and customer support.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) can help buyers manage costs related to shipping, insurance, and risk. Selecting the right Incoterm can affect total landed costs significantly.

What Are the Best Practices for Buyers to Optimize Costs?

-

Negotiation: Leverage volume commitments and long-term relationships to negotiate better pricing. Suppliers are often willing to offer discounts for loyal customers.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, replacement frequency, and operational costs. Investing in higher-quality tools may yield savings over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local market conditions that can influence pricing. Establishing relationships with local distributors can help mitigate some of these risks.

-

Market Research: Stay informed about market trends and competitor pricing to make informed purchasing decisions. Regularly reviewing supplier offerings can help identify potential savings.

In conclusion, understanding the comprehensive cost structure and pricing dynamics of PVC extractor tools empowers international B2B buyers to make strategic purchasing decisions. By considering various cost components and influencers, and employing effective procurement strategies, buyers can achieve significant cost savings and ensure they acquire the best tools for their operational needs.

Alternatives Analysis: Comparing pvc extractor tool With Other Solutions

Exploring Alternatives to PVC Extractor Tools

In the realm of maintenance and repair, especially in irrigation and plumbing, selecting the right tool is crucial. While the PVC extractor tool is a popular choice for removing broken PVC nipples, several alternative solutions can achieve similar objectives. This section compares the PVC extractor tool with two viable alternatives: the manual wrench method and the use of heat application techniques. Understanding the strengths and weaknesses of each option will enable B2B buyers to make informed decisions based on their specific needs.

| Comparison Aspect | PVC Extractor Tool | Manual Wrench Method | Heat Application Technique |

|---|---|---|---|

| Performance | High efficiency for removing broken PVC fittings with minimal effort. | Moderate efficiency; depends on user skill and strength. | High efficiency but may damage surrounding materials if not controlled properly. |

| Cost | Generally ranges from $4.83 to $81.48, depending on the brand and pack size. | Low cost; typically under $20 for a basic wrench set. | Moderate cost; requires a heat gun or torch, typically between $30 and $100. |

| Ease of Implementation | User-friendly, designed specifically for PVC, easy to operate. | Requires more physical effort and skill; can be cumbersome in tight spaces. | Requires experience to avoid damage; not suitable for all environments. |

| Maintenance | Low maintenance; durable materials ensure longevity. | Minimal maintenance; however, wear and tear can occur with frequent use. | Moderate; tools need to be checked for safety and functionality regularly. |

| Best Use Case | Best suited for irrigation systems and plumbing where PVC fittings are prevalent. | Suitable for general plumbing tasks and where space allows. | Ideal for installations where PVC fittings are fused or stuck due to heat. |

In-Depth Analysis of Alternatives

Manual Wrench Method

The manual wrench method involves using a standard wrench to grip and twist the broken PVC nipple. While it is a cost-effective solution, it requires significant physical effort and skill, which can be a drawback, particularly in tight or awkward spaces. The performance can vary widely based on the user’s ability to leverage the tool effectively. This method is best for general plumbing tasks but may not be suitable for specialized applications, such as irrigation systems where PVC fittings are common.

Heat Application Technique

Heat application involves using a heat gun or torch to soften the PVC, making it easier to remove the broken nipple. This method can be highly effective but carries risks, such as damaging the surrounding materials if not executed with precision. It requires a level of expertise to ensure that the heat is applied evenly and safely. The cost of equipment can be moderate, and the technique is best used in situations where fittings are fused or severely stuck, making traditional extraction methods ineffective.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate tool or method for PVC nipple extraction, B2B buyers should consider factors such as performance, cost, ease of use, and maintenance. The PVC extractor tool stands out for its specialized design and efficiency in handling PVC fittings, making it an excellent choice for irrigation and plumbing applications. However, alternatives like the manual wrench method and heat application technique offer viable options depending on the specific context of use. Ultimately, understanding the unique requirements of the job at hand will empower buyers to make the best choice for their operational needs.

Essential Technical Properties and Trade Terminology for pvc extractor tool

What Are the Essential Technical Properties of a PVC Extractor Tool?

When selecting a PVC extractor tool for industrial or commercial applications, understanding its technical specifications is crucial for ensuring optimal performance and longevity. Here are some of the critical properties to consider:

-

Material Composition

The most common materials used in PVC extractor tools are durable steel or zinc. Steel provides strength and longevity, while zinc offers corrosion resistance, making it suitable for outdoor use. The choice of material affects not only the tool’s durability but also its weight and ease of handling. In B2B contexts, investing in high-quality materials can minimize replacement costs and reduce downtime. -

Size Compatibility

PVC extractor tools typically accommodate specific sizes, such as 1/2-inch and 3/4-inch fittings. Proper size compatibility is essential for effective operation, allowing the tool to securely grip and remove broken or stuck risers without damaging surrounding fittings. For buyers, ensuring that the tool matches their existing systems can streamline maintenance processes and reduce the risk of costly errors. -

Grip Design

Many PVC extractors feature ergonomic grips, often rubberized or plastic-coated, designed for comfort and enhanced control. A good grip reduces hand fatigue and increases precision during use, which is particularly important in large-scale operations where multiple extrications may be required. Choosing tools with superior grip design can lead to improved worker productivity and safety. -

Tooth Design

The tooth configuration of an extractor tool significantly impacts its effectiveness. Tools equipped with sharp, angled teeth are engineered to bite into the PVC material securely, facilitating easier removal of stuck components. For B2B buyers, understanding tooth design can help in selecting tools that minimize the risk of breakage and ensure a smooth extraction process. -

Weight and Portability

The weight of the extractor tool can affect its usability, especially in field applications. Lightweight tools are easier to transport and maneuver, making them more favorable for on-site work. For businesses operating in diverse environments, portability becomes a key factor in optimizing workflow and efficiency.

Which Trade Terminology Should B2B Buyers Understand When Purchasing a PVC Extractor Tool?

Navigating the procurement landscape requires familiarity with key industry terminology. Here are some essential terms every buyer should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that may be marketed by another company under its own brand. In the context of PVC extractor tools, buyers may seek OEM products for guaranteed quality and compatibility with their existing systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to assess inventory costs and negotiate better pricing terms. This can affect budget planning and inventory management for businesses. -

RFQ (Request for Quotation)

An RFQ is a formal document requesting price quotes from suppliers. It is essential for B2B procurement, enabling buyers to compare costs and terms from multiple vendors. A well-structured RFQ can lead to better negotiation outcomes and more favorable contract terms. -

Incoterms (International Commercial Terms)

These are a set of international rules that define the responsibilities of buyers and sellers in the shipping of goods. Familiarity with Incoterms is vital for B2B buyers engaged in international trade, as they clarify liability, shipping costs, and risk management. -

Lead Time

This term refers to the time taken from the placement of an order to its delivery. Understanding lead times is important for inventory planning and ensuring that operations are not disrupted due to delays in receiving essential tools like PVC extractors. -

Warranty and Return Policy

Knowing the warranty period and return policy of a product is crucial for risk management in procurement. It protects buyers against defective products and ensures that they can make informed decisions based on the supplier’s reliability and customer service.

By understanding these properties and terminologies, B2B buyers can make informed decisions that enhance operational efficiency and reduce costs in their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the pvc extractor tool Sector

What Are the Current Market Dynamics and Key Trends in the PVC Extractor Tool Sector?

The global market for PVC extractor tools is experiencing significant growth driven by increasing demand from various sectors, including agriculture, construction, and plumbing. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe look to optimize irrigation and plumbing systems, the need for efficient and reliable extractor tools has surged. Key trends include the rise of automation and smart technology in tools, which enhance efficiency and reduce labor costs. Additionally, the growing emphasis on DIY projects has led to a higher demand for user-friendly tools that can be easily operated by non-professionals.

Emerging technologies such as augmented reality (AR) are being integrated into product design and marketing, allowing buyers to visualize tool applications before purchase. Moreover, the trend towards e-commerce has transformed sourcing practices, with more B2B buyers leveraging online platforms to compare prices and specifications, facilitating smarter purchasing decisions. The market is also witnessing a shift towards multi-functional tools that combine various capabilities, making them more versatile for different applications. This innovation not only meets the needs of diverse buyers but also reduces the need for multiple purchases, providing better value.

How Does Sustainability and Ethical Sourcing Impact the PVC Extractor Tool Sector?

Sustainability and ethical sourcing are becoming increasingly critical in the PVC extractor tool sector. The environmental impact of plastic manufacturing has prompted buyers to seek products made from recycled materials or those that adhere to eco-friendly manufacturing processes. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to reducing their carbon footprint and minimizing waste throughout their supply chains.

Ethical sourcing practices are essential for fostering trust and transparency in business relationships. Buyers are encouraged to inquire about the sourcing of materials, labor practices, and the overall environmental policies of their suppliers. Certifications such as ISO 14001 for environmental management and various green certifications can serve as indicators of a supplier’s commitment to sustainability. By aligning with suppliers that prioritize these principles, B2B buyers not only enhance their brand reputation but also contribute to broader sustainability goals in their respective regions.

How Has the PVC Extractor Tool Evolved Over Time?

The evolution of PVC extractor tools reflects broader advancements in technology and materials. Initially designed for simple extraction tasks, these tools have significantly improved in terms of design, durability, and efficiency. Early models often featured basic grips and limited functionality, while modern iterations incorporate ergonomic designs, high-strength materials, and multi-functional capabilities.

As irrigation and plumbing systems have become more complex, the demand for specialized tools that can handle specific tasks—such as removing broken risers without damaging fittings—has increased. Innovations in manufacturing processes, such as the use of high-quality steel and rubberized grips, have further enhanced tool performance and user experience. This evolution has positioned PVC extractor tools as essential components in modern irrigation and plumbing practices, catering to a diverse range of B2B buyers across various sectors.

Frequently Asked Questions (FAQs) for B2B Buyers of pvc extractor tool

-

How do I solve the issue of removing broken PVC risers?

To effectively remove broken PVC risers, using a specialized PVC extractor tool is essential. These tools are designed with sharp teeth that grip the broken pipe securely, allowing for easy removal without damaging the fitting threads. Ensure you select the appropriate size for your risers, typically 1/2″ or 3/4″. Additionally, using a tool with a comfortable grip can enhance leverage, making the extraction process smoother and more efficient. -

What is the best PVC extractor tool for irrigation applications?

The best PVC extractor tool for irrigation applications should be sturdy and designed specifically for outdoor use. Look for tools that feature a rubberized grip for comfort and a durable steel or zinc construction for longevity. Models like the Orbit 1/2 in. and 3/4 in. extractor are highly rated for their effectiveness in removing broken risers from sprinkler systems. It’s also beneficial to choose a tool that can handle multiple sizes of risers to accommodate different projects. -

What are the typical minimum order quantities (MOQs) for PVC extractor tools?

Minimum order quantities (MOQs) for PVC extractor tools can vary significantly depending on the supplier and the specific model. Generally, MOQs may range from a single unit for small businesses to larger quantities of 50 or more for bulk purchases. It is advisable to negotiate MOQs with suppliers, especially if you require customization or specific branding for your tools, to align with your business needs. -

How can I vet suppliers of PVC extractor tools?

Vetting suppliers involves several steps. Start by researching their reputation through customer reviews and industry feedback. Request product samples to assess quality before committing to a larger order. Verify their compliance with international standards and regulations, especially if sourcing from overseas. Establishing direct communication can also provide insights into their reliability and customer service. Lastly, consider their logistics capabilities to ensure they can meet your delivery timelines. -

What payment terms are common when sourcing PVC extractor tools internationally?

Common payment terms in international sourcing include options like letter of credit, advance payment, and open account. Many suppliers may request a deposit (often 30% to 50%) upfront, with the balance due upon shipment or delivery. It’s crucial to negotiate terms that provide security for both parties, such as using escrow services for larger transactions. Understanding the currency exchange rates and potential tariffs is also important for budgeting your purchase effectively. -

What quality assurance measures should I look for in PVC extractor tools?

When sourcing PVC extractor tools, ensure that the supplier follows strict quality assurance protocols. Look for certifications that indicate adherence to industry standards, such as ISO certifications. Request detailed product specifications and test reports to confirm the durability and functionality of the tools. Additionally, inquire about their return and warranty policies, as these can provide peace of mind regarding the quality of the products you receive. -

How do shipping and logistics work for international orders of PVC extractor tools?

Shipping and logistics for international orders typically involve coordinating with freight forwarders or logistics companies. It’s essential to clarify shipping costs, delivery times, and responsibilities for customs clearance. Suppliers may offer different shipping methods, such as air or sea freight, depending on your urgency and budget. Ensure you understand the Incoterms (International Commercial Terms) agreed upon, as they dictate the responsibilities of both buyer and seller during the shipping process. -

Can PVC extractor tools be customized for branding or specific needs?

Yes, many suppliers offer customization options for PVC extractor tools, including branding, color, and packaging. Customization can enhance your brand visibility and meet specific customer requirements. Discuss your needs with the supplier during the negotiation phase to determine the feasibility and associated costs. Keep in mind that custom orders may have longer lead times and higher MOQs, so plan accordingly to align with your business strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Pvc Extractor Tool Manufacturers & Suppliers List

1. Orbit – 1/2 and 3/4 Pipe Nipple Extraction Tool

Domain: dripirrigation.com

Registered: 1997 (28 years)

Introduction: Product Name: 1/2″ and 3/4″ Pipe Nipple Extraction Tool

Model Number: R850

Manufacturer: Orbit

Manufacturer Number: 26076

Price: $5.00

Shipping: Free shipping on orders over $50 (excluding tax & shipping)

Features:

– Tapered, toothed end for gripping broken risers or tees

– Comfortable rubberized grip

– Works with both 1/2″ and 3/4″ risers/nipples

– Comes with two removable insert tool heads for …

2. Larsen Supply – PVC Red Sprinkler Pipe Nipple Extractor

Domain: walmart.com

Registered: 1995 (30 years)

Introduction: This company, Larsen Supply – PVC Red Sprinkler Pipe Nipple Extractor, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Expressions Ltd – Z Poolform PVC Form Extractor Tool

Domain: expressions-ltd.com

Registered: 2008 (17 years)

Introduction: {“product_name”: “Z Poolform PVC Form Extractor Tool”, “price”: “$69.09”, “description”: “Extractor Tool for Z Poolform PVC Forms. Z Poolforms are a reusable PVC form system used to create decorative concrete copings for swimming pools. Interchangeable form liners allow for a variety of different edge profiles and textures. Contractors should consider purchasing a few Extractor Tools, as removal o…

4. Acme Tools – Superior PVC Nipple Extractor 5270

Domain: acmetools.com

Registered: 2003 (22 years)

Introduction: Superior Tool 1/2 Inch and 3/4 Inch PVC Nipple Extractor 5270

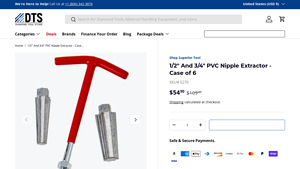

5. Superior Tool – PVC Nipple Extractor Case of 6

Domain: diamondtoolstore.com

Registered: 2000 (25 years)

Introduction: 1/2″ And 3/4″ PVC Nipple Extractor – Case of 6

SKU# 5270

Price: $54.90 (originally $109.80)

Description: Superior Tool’s® PVC Nipple Extractors remove broken 1/2″ and 3/4″ risers from PVC fittings. This tool eliminates the need to dig up fittings to remove broken risers. Extractors fit into the T-handle and can also be used to install and tighten new risers. Features high-quality materials and dur…

Strategic Sourcing Conclusion and Outlook for pvc extractor tool

Why is Strategic Sourcing Essential for PVC Extractor Tools?

In summary, the strategic sourcing of PVC extractor tools is crucial for international B2B buyers seeking reliability and efficiency in their operations. Key takeaways highlight the importance of selecting high-quality tools that ensure durability and effectiveness, particularly in irrigation and plumbing applications. The range of available products, from specialized extractor sets to versatile tools like the Orbit models, provides options tailored to diverse needs and environments.

Investing in high-quality PVC extractor tools not only enhances operational efficiency but also minimizes downtime and reduces long-term costs associated with tool replacement and maintenance. As buyers navigate the global marketplace, prioritizing suppliers who demonstrate commitment to quality, innovation, and customer support is vital.

What Does the Future Hold for PVC Extractor Tools?

Looking ahead, the demand for advanced and reliable PVC extractor tools will continue to grow, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As industries evolve and adapt to new technologies, international B2B buyers are encouraged to stay informed about the latest product developments and sourcing strategies. By forging strong partnerships with reputable suppliers, businesses can ensure they are well-equipped to meet future challenges and capitalize on opportunities within their markets. Take the next step in optimizing your sourcing strategy today.