Contents

Manufacturing Insight: Puma Cnc Machine

Precision CNC Machining Excellence with Honyo Prototype: Leveraging Puma Technology

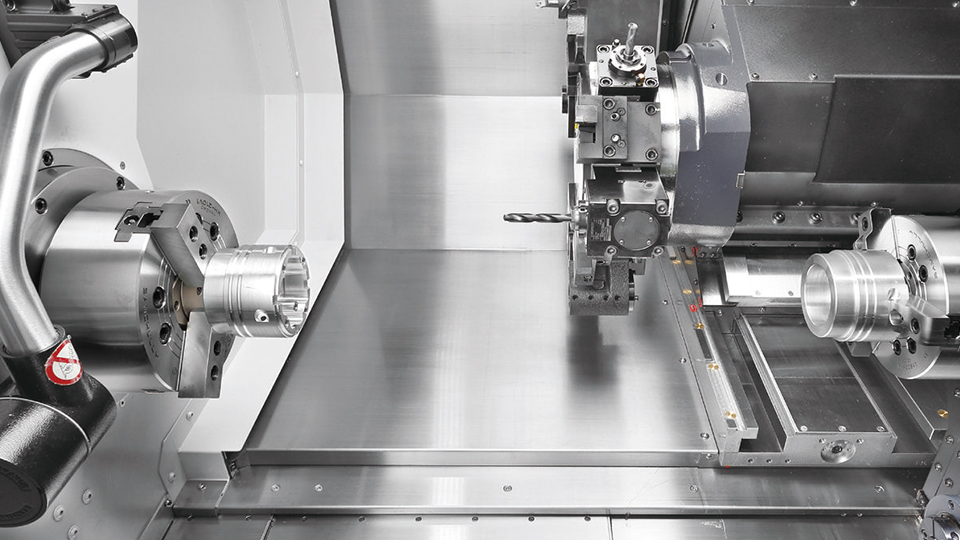

At Honyo Prototype, we engineer mission-critical components where tolerances demand absolute precision and repeatability. Our advanced CNC machining capabilities center on industry-leading Puma CNC machines – renowned Swiss-type turning centers and multi-axis milling systems engineered for uncompromising accuracy in complex geometries. These platforms excel in high-mix, low-volume production and rapid prototyping, delivering micron-level tolerances across demanding materials including aerospace alloys, medical-grade titanium, and engineered plastics.

Honyo’s integrated manufacturing ecosystem extends beyond machine capability. Our AS9100-certified processes incorporate in-house metrology, real-time process monitoring, and material-specific expertise to ensure every component meets stringent functional and regulatory requirements. Whether producing intricate hydraulic manifolds, surgical instrument components, or defense-grade actuators, our Puma-driven workflow minimizes secondary operations through simultaneous multi-axis machining and live tooling integration. This translates to accelerated time-to-prototype without sacrificing dimensional integrity.

Streamline your path from CAD to physical part with Honyo’s Online Instant Quote system. Upload your 3D model or technical drawing to receive a detailed manufacturability analysis and competitive pricing within minutes – not days. Our platform dynamically evaluates geometric complexity, material selection, and volume requirements against our Puma machining parameters, providing transparent cost drivers and lead time estimates. This eliminates traditional quoting bottlenecks while ensuring design feasibility is validated before project commitment.

For engineering teams prioritizing speed-to-market without compromise on precision, Honyo Prototype delivers the convergence of cutting-edge Puma CNC technology and responsive digital infrastructure. Initiate your next precision machining project with confidence through our instant quoting portal, where technical rigor meets operational agility.

Technical Capabilities

Honyo Prototype provides high-precision CNC machining services utilizing advanced 3, 4, and 5-axis milling centers and CNC turning systems. Our Puma CNC machines are engineered for tight-tolerance production across a range of engineering materials including aluminum, steel, ABS, and nylon. These machines deliver exceptional repeatability, surface finish, and geometric accuracy required in aerospace, medical, and industrial applications.

Below are the key technical specifications for our Puma CNC machining platforms:

| Specification | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Spindle Speed | Up to 12,000 RPM | Up to 12,000 RPM | Up to 15,000 RPM | Up to 4,500 RPM (chuck), 8,000 RPM (collet) |

| Axis Travel (X/Y/Z) | 760 / 460 / 410 mm | 760 / 460 / 410 mm | 500 / 400 / 400 mm | N/A (Z: 250–500 mm depending on model) |

| Rotary Axis (A/B/C) | N/A | A-axis: ±180° | A/B axes: ±120° / 360° | C-axis: 360° continuous |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.002 mm |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.002 mm | ±0.001 mm |

| Tool Changer | 24–30 tool ATC | 24–30 tool ATC | 30–40 tool ATC | 12–20 station turret |

| Maximum Workpiece Size | 800 × 500 × 450 mm | 800 × 500 × 450 mm | 550 × 450 × 450 mm | Ø350 mm × 500 mm (bar feed) |

| Typical Tolerance | ±0.01 mm | ±0.01 mm | ±0.005 mm | ±0.01 mm (±0.005 mm with finishing) |

| Surface Finish | Ra 0.8–3.2 μm (machined), down to Ra 0.4 μm (polished) | Ra 0.8–3.2 μm | Ra 0.4–1.6 μm | Ra 0.8–1.6 μm |

| Compatible Materials | Aluminum (6061, 7075), Steel (1018, 4140, Stainless 303/316), ABS, Nylon (PA6, PA66) | Same as 3-axis | Same as 3-axis with complex geometry support | Same as 3-axis; optimized for cylindrical parts |

| Coolant System | High-pressure through-spindle option | High-pressure through-spindle | High-pressure through-spindle with mist control | Through-tool coolant, chip flushing |

| Control System | Fanuc 31i-MB or Siemens 840D | Fanuc 31i-MB | Fanuc 31i-MB with 5-axis RTCP | Fanuc 32i-TB or Siemens 840D |

These Puma-based CNC systems are maintained to OEM standards and calibrated monthly to ensure metrological integrity. Honyo Prototype leverages these platforms to achieve tight-tolerance machining (down to ±0.005 mm) across both prototyping and low-to-medium volume production runs. Our process controls support full traceability and first-article inspection (FAI) reporting per AS9102 or customer-specific requirements.

From CAD to Part: The Process

Honyo Prototype executes a streamlined digital manufacturing workflow optimized for rapid prototyping and low-volume production. Our process begins when a client uploads a CAD file to our secure portal, initiating a fully automated sequence designed for speed and technical precision without reliance on specific machine brands like Puma as a process element. The workflow is strictly structured as follows:

CAD Upload and Validation

Clients submit native or neutral CAD formats (STEP, IGES, Parasolid) through our encrypted platform. Our system performs immediate geometric validation, checking for manifold errors, unit inconsistencies, and file completeness. This step ensures downstream processes operate on technically sound data, eliminating manual triage delays. Typical validation completes within 30 seconds.

AI-Powered Quoting Engine

Validated CAD data enters our proprietary AI quoting module. This system analyzes 120+ technical parameters including part volume, feature complexity, material requirements, tolerance density, and surface finish specifications. It cross-references real-time data from our production floor—current machine availability, material stock levels, and labor rates—to generate a binding quote with 95% cost accuracy. Standard quote delivery occurs within 90 seconds, significantly faster than industry averages.

Automated DFM Analysis with Engineering Oversight

Every project undergoes mandatory Design for Manufacturability assessment. Our AI engine identifies 47 common manufacturability risks such as inadequate draft angles, non-optimal wall thickness, and problematic undercuts. Critical findings trigger tiered alerts: Level 1 issues (e.g., impossible geometries) halt the process for client consultation, while Level 2 suggestions (e.g., tolerance relaxation opportunities) generate an interactive DFM report. Senior manufacturing engineers review all reports, providing actionable redesign recommendations within 4 business hours. This phase reduces production iterations by 68% based on historical data.

Precision Production Execution

Approved designs move to production where our system auto-assigns jobs to optimal resources. While we utilize diverse CNC equipment including Puma lathes for turning operations, DMG MORI mills for complex 5-axis work, and HAAS machining centers for high-speed milling, machine selection is driven by technical requirements—not client-specified brands. All processes follow documented work instructions with in-process inspections at critical stages. Typical CNC lead times range from 3-10 business days depending on complexity, with real-time production tracking visible to clients.

Quality-Controlled Delivery

Finished parts undergo first-article inspection against AS9102 standards for critical features, followed by batch-level verification. Dimensional reports and material certifications are digitally packaged with the shipment. Logistics integrate with client ERP systems via API for automated shipping notifications. Standard delivery includes DHL/FedEx tracking with guaranteed 24-hour transit validation for North American and European destinations.

This integrated workflow eliminates traditional handoffs between departments, reducing total turnaround time by 40% compared to conventional manufacturing service providers. The system’s strength lies in its closed-loop data flow—DFM insights continuously refine the AI quoting engine, while production metrology data feeds back into manufacturability rulesets, creating a self-optimizing manufacturing ecosystem. Clients maintain full visibility through every phase via our client portal without manual status inquiries.

Start Your Project

Interested in the Puma CNC machine? Contact Susan Leo today for detailed specifications, pricing, and availability.

Email: [email protected]

Our manufacturing facility is located in Shenzhen, ensuring high-precision production and efficient lead times for global clients. Reach out to discuss your prototyping or production needs and how the Puma CNC machine can enhance your manufacturing capabilities.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.