Introduction: Navigating the Global Market for pu sheet

In today’s competitive landscape, sourcing polyurethane sheets (PU sheets) that meet specific operational needs can be a daunting task for international B2B buyers. The challenge often lies in identifying reliable suppliers who provide high-quality products that align with diverse application requirements across various industries. This guide aims to simplify that process, offering a comprehensive exploration of PU sheets, including their types, applications, supplier vetting strategies, and cost considerations.

By delving into the properties and benefits of PU sheets—such as their exceptional durability, abrasion resistance, and versatility—this guide equips buyers from Africa, South America, the Middle East, and Europe, including regions like Nigeria and Vietnam, with the insights needed for informed purchasing decisions. Whether you are in aerospace, automotive, manufacturing, or other sectors, understanding the nuances of PU sheet specifications and supplier capabilities is crucial to optimizing your procurement strategy.

With actionable insights and expert recommendations, this guide not only highlights the diverse applications of PU sheets—from prototyping and bumpers to vibration dampening and weatherproofing—but also provides a framework for assessing supplier reliability. By the end of this guide, B2B buyers will be empowered to navigate the global market with confidence, ensuring they select the right materials to enhance their operational efficiency and product performance.

Understanding pu sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Cast Urethane | High abrasion and chemical resistance, customizable colors | Prototyping, bumpers, seals | Pros: Versatile, strong; Cons: Limited thickness options. |

| High-Durometer Urethane | Rigid and durable, ideal for heavy load applications | Metal fabrication, industrial machinery | Pros: Excellent load-bearing; Cons: Less flexibility. |

| Soft Urethane Sheets | Lower hardness, enhanced flexibility, shock-absorbing | Noise dampening, cushioning pads | Pros: Great for vibration control; Cons: Not suitable for heavy wear. |

| Colored Urethane Sheets | Available in various colors for aesthetic applications | Custom machinery parts, decorative elements | Pros: Customizable; Cons: May have longer lead times. |

| Specialty Urethane Sheets | Tailored formulations for specific industry needs | Aerospace, foodservice, military applications | Pros: Highly specialized; Cons: Higher cost and longer manufacturing time. |

What Are the Characteristics of Standard Cast Urethane Sheets?

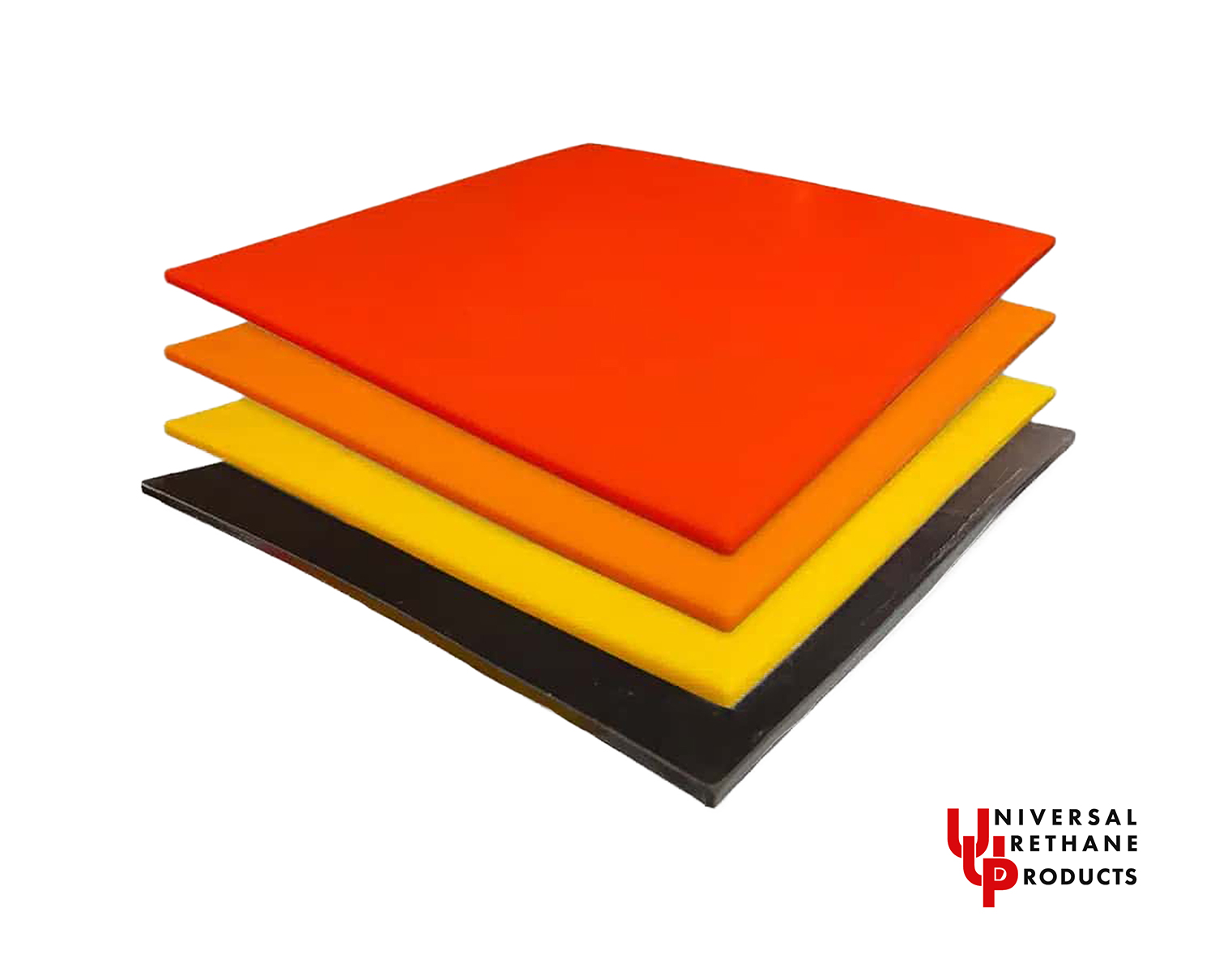

Standard cast urethane sheets are renowned for their high abrasion and chemical resistance, making them a popular choice across various industries. Available in multiple colors and thicknesses, these sheets are particularly suitable for applications such as prototyping, bumpers, and seals. When purchasing, buyers should consider the specific thickness and durometer required for their application, as these sheets offer a balance of durability and versatility.

How Do High-Durometer Urethane Sheets Stand Out?

High-durometer urethane sheets are characterized by their rigidity and ability to withstand significant loads, making them ideal for metal fabrication and industrial machinery applications. Buyers should prioritize their load-bearing requirements and consider the hardness level needed to ensure optimal performance. While these sheets provide excellent durability, they lack the flexibility found in softer variants, which may limit their use in certain applications.

What Are the Benefits of Using Soft Urethane Sheets?

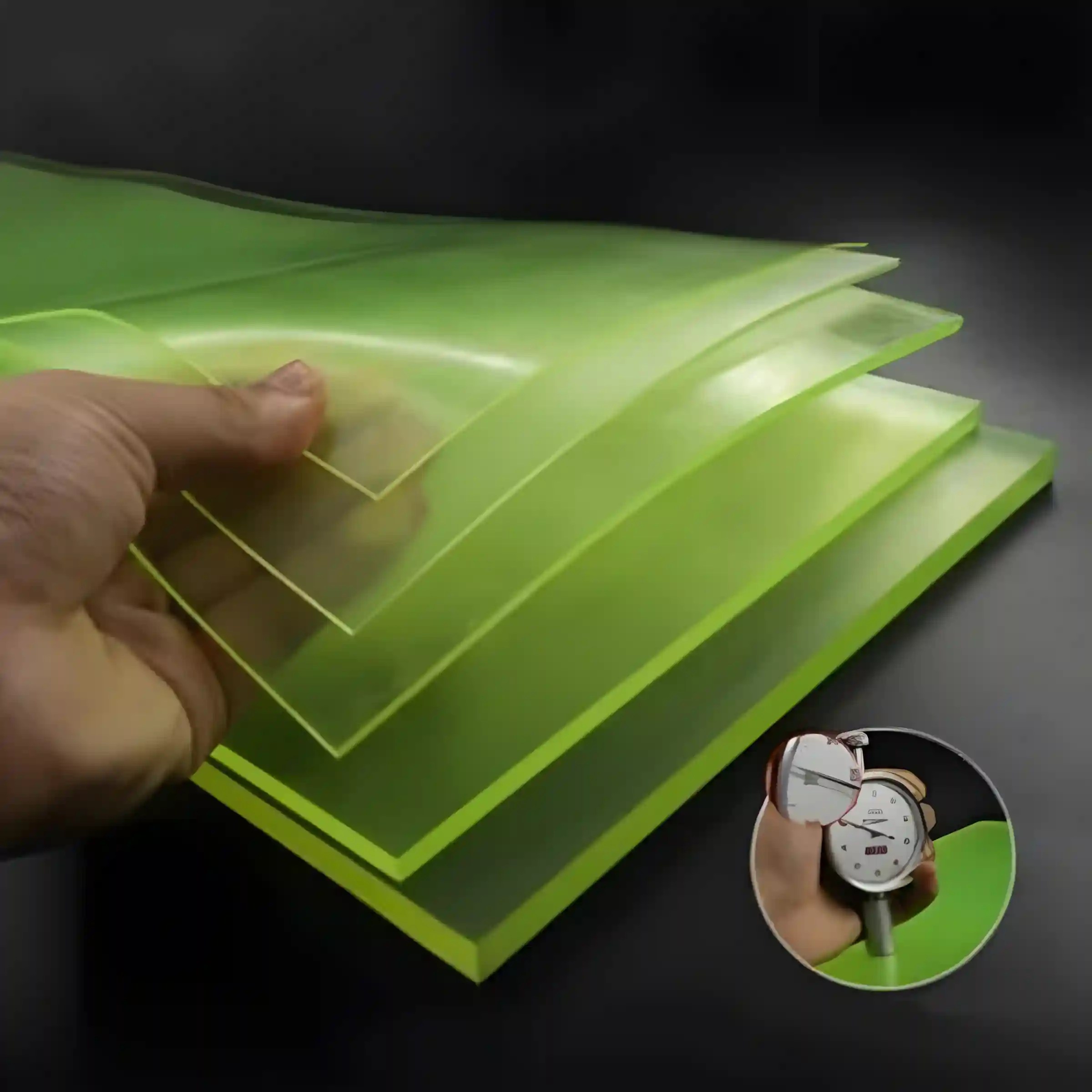

Soft urethane sheets offer lower hardness levels, enhancing flexibility and shock absorption, making them perfect for noise dampening and cushioning applications. Their ability to absorb vibrations makes them a valuable asset in environments with heavy machinery. Buyers should evaluate the specific use case to ensure that the softer material will meet performance requirements, as these sheets are not suited for high-wear applications.

Why Choose Colored Urethane Sheets?

Colored urethane sheets allow for aesthetic customization, making them ideal for custom machinery parts and decorative elements. While they offer the same durability as standard sheets, buyers should be aware that colored options may come with longer lead times and potentially higher costs. It’s essential to assess whether the visual appeal justifies any additional investment in time and resources.

What Should Buyers Know About Specialty Urethane Sheets?

Specialty urethane sheets are formulated to meet specific industry needs, such as aerospace, foodservice, or military applications. These tailored solutions provide unique advantages, but buyers should be prepared for higher costs and longer manufacturing times. When considering specialty sheets, it’s crucial to clearly define the performance requirements and ensure that the supplier can meet these specifications without compromising quality.

Key Industrial Applications of pu sheet

| Industry/Sector | Specific Application of pu sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Vibration dampening in aircraft components | Reduces noise and enhances passenger comfort, improving safety. | Ensure compliance with aviation standards; consider weight and durability. |

| Metal Fabrication | Die cutting and forming tools | Increases tool lifespan and reduces maintenance costs. | Look for abrasion resistance and custom thickness options. |

| Automotive | Bumpers and shock absorbers | Enhances vehicle performance and safety by absorbing impacts. | Evaluate hardness and load-bearing capacity for specific vehicle models. |

| Food Processing | Sealing and weatherproofing applications | Ensures hygiene and safety in food handling environments. | Source FDA-compliant materials; consider temperature resistance. |

| Marine | Protective liners for boats | Extends equipment life and protects against harsh marine conditions. | Assess chemical resistance and UV stability for long-term use. |

How is PU Sheet Used in the Aerospace Industry?

In the aerospace sector, PU sheets are utilized for vibration dampening in aircraft components. By absorbing vibrations and noise, these sheets contribute to a more comfortable passenger experience and enhance safety by preventing fatigue in structural components. International buyers, especially from regions like Africa and the Middle East, should prioritize suppliers who meet stringent aviation standards and can provide lightweight options to optimize fuel efficiency.

What Role Does PU Sheet Play in Metal Fabrication?

In metal fabrication, PU sheets serve as essential die cutting and forming tools. Their superior abrasion resistance extends tool life, thereby reducing maintenance and replacement costs significantly. For buyers in South America and Europe, sourcing PU sheets with specific thickness and hardness levels is crucial to match the demands of their machinery and production processes, ensuring efficiency and cost-effectiveness.

How Do Automotive Applications Benefit from PU Sheets?

Automotive manufacturers use PU sheets for bumpers and shock absorbers, which enhance vehicle performance by effectively absorbing impacts. This application not only improves safety but also contributes to the longevity of vehicle components. Buyers should consider the hardness and load-bearing capacity of PU sheets to ensure compatibility with different vehicle models, particularly in regions like Nigeria and Vietnam where diverse automotive needs exist.

Why are PU Sheets Important in Food Processing?

In the food processing industry, PU sheets are vital for sealing and weatherproofing applications. They ensure that food handling environments maintain hygiene and safety, critical for compliance with health regulations. International buyers should seek FDA-compliant PU sheets that can withstand varying temperature conditions, ensuring both safety and durability in their operations.

How are PU Sheets Used in Marine Applications?

PU sheets are extensively used as protective liners in marine applications, shielding equipment from harsh conditions such as saltwater and UV exposure. This application significantly extends the lifespan of marine equipment. Buyers should evaluate the chemical resistance and UV stability of PU sheets to ensure they can withstand the rigors of marine environments, particularly in regions with challenging weather conditions.

3 Common User Pain Points for ‘pu sheet’ & Their Solutions

Scenario 1: Sourcing High-Quality PU Sheets for Diverse Applications

The Problem: B2B buyers often struggle with sourcing polyurethane sheets that meet their specific requirements for various applications. Factors such as varying hardness, thickness, and chemical resistance can lead to confusion and frustration. For instance, a manufacturing company in Nigeria might need a specific durometer for shock absorption in automotive parts, but they face challenges in finding a reliable supplier that can provide consistent quality and timely delivery.

The Solution: To address this issue, buyers should conduct thorough research to identify suppliers that specialize in custom polyurethane sheets. Start by creating a list of potential vendors and reviewing their product specifications, focusing on durometer ratings and material properties relevant to your application. Engage directly with suppliers to discuss your needs and request samples to evaluate the material’s performance. Additionally, consider suppliers that offer a range of customization options, allowing you to specify color, thickness, and hardness. This proactive approach not only ensures you receive a product tailored to your needs but also builds a relationship with suppliers who understand your business requirements.

Scenario 2: Managing Inventory and Lead Times for PU Sheet Procurement

The Problem: Many B2B buyers face the challenge of managing inventory levels and lead times when procuring polyurethane sheets. For example, a construction company in South America may experience delays in project timelines due to extended lead times for PU sheets, impacting their ability to complete projects on schedule. This can lead to increased costs and lost business opportunities.

The Solution: To mitigate these challenges, businesses should implement a just-in-time (JIT) inventory system that aligns procurement with project schedules. Collaborate closely with suppliers to establish realistic lead times and stock levels that match your production needs. Consider negotiating agreements for pre-ordered stock, allowing you to maintain a buffer inventory without overcommitting resources. Additionally, utilizing a local supplier can drastically reduce lead times and shipping costs, enabling faster project execution. Regular communication with your suppliers can also help you stay informed about any potential delays or issues, allowing you to adjust your plans accordingly.

Scenario 3: Ensuring Proper Use and Application of PU Sheets

The Problem: Another significant pain point for B2B buyers is the improper use and application of polyurethane sheets, which can lead to product failure and increased costs. For instance, a food processing facility in Europe might utilize PU sheets for conveyor belts without fully understanding the material’s chemical resistance properties, resulting in premature wear and costly replacements.

The Solution: To avoid such pitfalls, it is crucial for buyers to educate themselves on the specific properties of polyurethane sheets and their appropriate applications. Begin by consulting technical datasheets and manufacturer guidelines to understand the limitations and capabilities of the material. Conduct training sessions for your team to ensure everyone is aware of best practices in handling and applying PU sheets. Additionally, consider seeking expert advice from suppliers who can provide insights on the optimal usage of their products in your industry. By investing in education and training, businesses can enhance the performance of PU sheets, minimize waste, and ultimately reduce operational costs.

Strategic Material Selection Guide for pu sheet

What Are the Key Properties of Polyurethane Sheets?

Polyurethane (PU) sheets are increasingly recognized for their versatility in various industrial applications. Their key properties include excellent abrasion resistance, high load-bearing capacity, and a broad hardness range (40A to 90D). These characteristics make PU sheets suitable for high-wear applications, such as bumpers, pads, and seals. Additionally, they exhibit good chemical resistance, making them suitable for environments where exposure to oils, greases, and other chemicals is common. The temperature resistance of PU sheets can reach up to 200°F (93°C), which is advantageous in applications involving heat exposure.

What Are the Advantages and Disadvantages of Using PU Sheets?

When evaluating PU sheets from a B2B perspective, several pros and cons emerge.

Advantages:

– Durability: PU sheets outlast traditional materials like rubber, often by four times, making them a cost-effective choice in the long run.

– Customizability: They can be tailored in terms of color, thickness, and hardness, allowing businesses to meet specific application requirements.

– Lightweight: PU sheets are easy to transport and handle, reducing shipping costs.

Disadvantages:

– Cost: While PU sheets can be more expensive upfront than rubber, their longevity often offsets this initial investment.

– Manufacturing Complexity: Custom formulations may require more complex manufacturing processes, leading to longer lead times.

How Do PU Sheets Impact Specific Applications?

The impact of PU sheets on various applications is significant. For instance, in industries like aerospace and automotive, where vibration dampening is critical, PU sheets provide superior performance compared to traditional materials. Their ability to absorb shocks and reduce noise makes them ideal for components in engines and machinery. Additionally, PU sheets are compatible with a wide range of media, including oils and chemicals, which is crucial for sectors like food service and manufacturing.

What Should International B2B Buyers Consider When Sourcing PU Sheets?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several considerations are paramount. Compliance with international standards such as ASTM, DIN, or JIS is essential to ensure product quality and safety. Buyers should also be aware of local regulations regarding material properties, especially in industries like food service and aerospace. Understanding the local market preferences, such as color and hardness specifications, can also facilitate smoother transactions and better product fit.

Summary Table of PU Sheet Materials

| Material | Typical Use Case for pu sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard PU | Bumpers, pads, seals | High abrasion resistance | Higher initial cost compared to rubber | Medium |

| Custom PU | Prototyping, specialized applications | Tailored properties for specific needs | Longer lead times due to custom manufacturing | High |

| High-Durometer PU | Heavy machinery components, industrial applications | Exceptional load-bearing capabilities | Limited flexibility compared to lower durometers | Medium |

| Low-Durometer PU | Vibration dampening, cushioning | Greater elasticity and shock absorption | Less durable in high-wear applications | Low |

This analysis provides a comprehensive overview of polyurethane sheets, highlighting their properties, advantages, disadvantages, and considerations for international buyers, enabling informed decision-making in material selection.

In-depth Look: Manufacturing Processes and Quality Assurance for pu sheet

What Are the Main Stages of PU Sheet Manufacturing?

Manufacturing polyurethane (PU) sheets involves a series of critical stages that ensure the final product meets the desired specifications for various industrial applications. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The manufacturing process begins with the selection and preparation of raw materials, primarily polyols and isocyanates. These chemicals are carefully measured and blended to create the desired polyurethane formulation. The preparation phase also includes quality checks on the raw materials to ensure they meet industry standards. This step is crucial as the properties of the final PU sheet, such as hardness, elasticity, and chemical resistance, depend significantly on the quality of the raw materials used.

How Is PU Sheet Formed?

Once the materials are prepared, they undergo the forming process. This can involve various techniques, such as casting, extrusion, or compression molding.

-

Casting: This is one of the most common methods for producing PU sheets. The mixed polyurethane is poured into molds and allowed to cure, resulting in sheets of varying thicknesses.

-

Extrusion: This process involves forcing the polyurethane mixture through a die to create continuous sheets, which can then be cut to size.

-

Compression Molding: Here, the polyurethane is placed in a heated mold, where heat and pressure are applied to form the sheets.

Each method has its advantages, and the choice depends on the specific requirements of the application, such as thickness, hardness, and volume.

What Assembly and Finishing Techniques Are Used?

After forming, the sheets may go through an assembly phase, where they are cut, shaped, or laminated to meet specific customer requirements. This can involve additional processes like die-cutting for intricate shapes or adding adhesives for multi-layer constructions.

The finishing stage includes surface treatments to enhance properties such as abrasion resistance, UV stability, and aesthetics. Common finishing techniques include sanding, coating, or applying protective films. This stage is vital for ensuring the PU sheets can withstand the conditions they will face in their intended applications.

How Is Quality Assurance Implemented in PU Sheet Production?

Quality assurance (QA) is an integral part of the PU sheet manufacturing process, ensuring that the products meet international standards and customer expectations. The QA process typically follows several checkpoints:

What International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 play a crucial role in ensuring consistent quality in manufacturing processes. ISO 9001 sets the framework for a quality management system (QMS) that emphasizes customer satisfaction and continuous improvement. Other relevant certifications may include:

-

CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

-

API Certification: Relevant for products used in the oil and gas industry, ensuring compliance with industry-specific quality standards.

These certifications provide B2B buyers with a level of assurance regarding the quality and reliability of the PU sheets they are sourcing.

What Are the Key Quality Control Checkpoints?

Quality control (QC) in PU sheet manufacturing involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from the established standards early, allowing for corrective actions.

-

Final Quality Control (FQC): Before shipment, finished products undergo rigorous testing and inspection to verify they meet the required specifications and standards.

What Common Testing Methods Are Used for PU Sheets?

To ensure the quality and performance of PU sheets, various testing methods are employed, including:

-

Hardness Testing: Measuring the durometer (Shore A or D) to determine the hardness of the PU sheet.

-

Tensile Strength Testing: Evaluating the material’s ability to withstand tension before failing.

-

Abrasion Resistance Testing: Assessing how well the PU sheet can resist wear from friction.

-

Chemical Resistance Testing: Determining the sheet’s ability to withstand exposure to various chemicals without degrading.

These tests help ensure that the PU sheets can perform effectively in their intended applications.

How Can B2B Buyers Verify Supplier QC Processes?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are some effective methods:

-

Conducting Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This can include reviewing their QMS documentation and observing production processes.

-

Requesting Quality Reports: Buyers should ask suppliers for documentation related to quality control, including test results, certifications, and compliance records.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures and product quality.

What Are the QC Nuances for International B2B Buyers?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in international trade is essential. Different regions may have varying standards and regulations, which can affect product compliance and marketability.

Buyers should be aware of:

-

Regional Compliance Standards: Familiarizing themselves with the specific regulations and certifications required in their target markets can prevent costly compliance issues.

-

Supplier Capabilities: Assessing a supplier’s ability to meet international quality standards is crucial. This includes understanding their production capacity, technological capabilities, and past performance in similar markets.

-

Cultural Considerations: Building strong relationships with suppliers can enhance communication and cooperation, leading to better quality assurance outcomes.

By paying attention to these aspects, B2B buyers can ensure they are sourcing high-quality PU sheets that meet their specific needs while minimizing risks associated with international procurement.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pu sheet’

Introduction

This guide serves as a comprehensive checklist for B2B buyers interested in sourcing polyurethane (PU) sheets. Whether you are in manufacturing, automotive, or any other industry that requires durable and versatile materials, this step-by-step approach will help you navigate the complexities of procurement. By following these steps, you will ensure that you select the right PU sheet for your specific applications while working with reputable suppliers.

Step 1: Define Your Technical Specifications

Clearly articulate the requirements for your PU sheet. This includes dimensions, thickness, color, and durometer hardness, which determines the sheet’s flexibility and durability. Knowing these specifications upfront will help you communicate effectively with suppliers and ensure that the products meet your operational needs.

- Example Specifications:

- Thickness: 1/8” to 1”

- Durometer: 40A to 90A

- Color: Black, red, or custom options

Step 2: Research Potential Suppliers

Identify and compile a list of potential suppliers who specialize in PU sheets. Look for manufacturers with a proven track record and extensive product lines. Online directories, trade shows, and industry referrals can provide valuable insights into reputable suppliers.

- Key Considerations:

- Geographic location for shipping efficiency

- Industry experience and product range

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that the suppliers possess relevant certifications that guarantee product quality and compliance with industry standards. Certifications such as ISO 9001 can indicate a commitment to quality management systems.

- What to Check:

- Quality assurance practices

- Compliance with safety regulations

Step 4: Request Samples for Testing

Always request samples of the PU sheets for evaluation before placing a bulk order. This allows you to assess the material’s performance in your specific applications, including its abrasion resistance and chemical stability.

- Testing Focus Areas:

- Load-bearing capacity

- Resistance to wear and tear

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing, shipping costs, and payment terms. Be cautious of prices that seem unusually low, as they may reflect lower quality. Look for value rather than just the cheapest option.

- Considerations for Negotiation:

- Bulk order discounts

- Payment flexibility

Step 6: Check Customer Reviews and References

Research customer feedback and testimonials to gauge the reliability of the suppliers. Directly contacting previous clients can provide insights into the supplier’s service quality, responsiveness, and product performance.

- What to Ask References:

- Satisfaction with product quality

- Timeliness of delivery

Step 7: Finalize Your Order and Monitor Delivery

Once you have selected a supplier, finalize your order by confirming all specifications and terms. Keep an open line of communication with the supplier during the production and shipping phases to ensure timely delivery and address any issues that arise.

- Delivery Monitoring Tips:

- Track shipping updates

- Prepare for quality checks upon receipt

By following this checklist, you can streamline the sourcing process for PU sheets, ensuring you make informed decisions that align with your business needs.

Comprehensive Cost and Pricing Analysis for pu sheet Sourcing

What Are the Key Cost Components in PU Sheet Manufacturing?

When sourcing polyurethane (PU) sheets, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The quality of raw materials significantly impacts pricing. Polyurethane offers a range of formulations, including variations in hardness (durometer) and color, which can alter material costs. High-grade materials may command a premium but provide better performance and longevity.

-

Labor: Labor costs vary by region and manufacturer. In regions with higher labor costs, such as Europe, the overall pricing for PU sheets may increase. Conversely, manufacturers in lower-cost labor markets may offer competitive pricing, but it’s essential to assess quality.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help keep these costs down, benefiting the buyer.

-

Tooling: Customization often requires specialized tooling, which can add to the upfront costs. However, investing in tooling may yield significant long-term savings, particularly for high-volume orders.

-

Quality Control (QC): Ensuring that products meet required specifications incurs additional costs. Buyers should evaluate suppliers’ QC processes to minimize the risk of defects, which can lead to increased costs down the line.

-

Logistics: Shipping costs are influenced by distance, weight, and shipping method. For international buyers, understanding Incoterms is essential to assess who bears the shipping costs and risks.

-

Margin: Suppliers will include a profit margin in their pricing. This can vary widely based on market conditions and competition.

How Do Price Influencers Affect PU Sheet Sourcing?

Several factors can influence the pricing of PU sheets, including:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often lead to volume discounts, making it more cost-effective for buyers. It’s advisable to plan procurement strategically to take advantage of these discounts.

-

Specifications and Customization: Custom formulations for specific applications may incur additional costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: Premium materials and certifications (such as ISO) typically increase costs but may be necessary for specific industries like aerospace or food service. Buyers should weigh the benefits of certifications against their budget constraints.

-

Supplier Factors: The reputation and reliability of a supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

What Are the Best Buyer Tips for Cost-Efficient PU Sheet Sourcing?

To maximize value when sourcing PU sheets, consider the following strategies:

-

Negotiate Prices: Don’t hesitate to negotiate terms with suppliers. Building a relationship can lead to better pricing over time, especially if you anticipate repeat orders.

-

Evaluate Total Cost of Ownership (TCO): Focus on the long-term value rather than the initial purchase price. Consider factors such as durability, maintenance costs, and potential downtime caused by inferior products.

-

Understand Pricing Nuances for International Sourcing: International buyers should be aware of currency fluctuations, tariffs, and trade regulations that could impact costs. Engaging with suppliers who offer stable pricing can mitigate some of these risks.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local manufacturers can reduce shipping costs and lead times. Local suppliers may also better understand regional regulations and market needs.

Conclusion: Navigating PU Sheet Pricing for B2B Success

Understanding the comprehensive cost and pricing landscape for PU sheets is vital for international B2B buyers. By analyzing cost components, recognizing price influencers, and employing strategic sourcing tips, buyers can make informed decisions that enhance their purchasing power and ensure product quality. Always remember that prices can vary significantly based on specifications and supplier factors, so conducting thorough market research is essential for achieving the best value.

Alternatives Analysis: Comparing pu sheet With Other Solutions

Exploring Alternatives to PU Sheet Solutions

When considering materials for industrial applications, it is essential to evaluate alternatives to polyurethane (PU) sheets. These alternatives may offer different benefits depending on specific project requirements, performance needs, and budget constraints. This analysis will compare PU sheets against two viable alternatives: rubber sheets and polycarbonate sheets. By examining key aspects of performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make more informed decisions.

| Comparison Aspect | ‘Pu Sheet’ | Rubber Sheets | Polycarbonate Sheets |

|---|---|---|---|

| Performance | High abrasion and chemical resistance; customizable hardness | Good flexibility; lower abrasion resistance | Excellent impact resistance; good clarity |

| Cost | $63.09 – $1,820.39 per sheet | Generally lower cost, $20 – $100 per sheet | Moderate to high cost, $50 – $150 per sheet |

| Ease of Implementation | Machinable and easy to cut; customizable sizes | Easy to cut and shape; widely available | Requires specialized tools for cutting; less flexible |

| Maintenance | Low maintenance; durable and long-lasting | Moderate maintenance; can degrade over time | Low maintenance; resistant to yellowing and UV |

| Best Use Case | High-wear applications in manufacturing, prototyping, and automotive | General cushioning, sealing, and gaskets | Safety glazing, protective covers, and lighting |

Pros and Cons of Rubber Sheets

Rubber sheets are a common alternative to PU sheets, known for their flexibility and cost-effectiveness. They are ideal for applications requiring cushioning or sealing. However, while they are generally less expensive, rubber sheets often lack the abrasion resistance and durability of PU sheets. Additionally, they can degrade faster when exposed to oils, UV light, or harsh chemicals, which may lead to increased replacement costs over time. Their best use cases include general-purpose applications such as gaskets and insulation.

Pros and Cons of Polycarbonate Sheets

Polycarbonate sheets offer remarkable impact resistance and clarity, making them a popular choice for applications requiring transparency and durability, such as safety glazing. They can withstand significant force without breaking, which is beneficial in environments prone to impact. However, polycarbonate sheets can be more expensive and require specialized tools for cutting and installation. They are also less flexible than PU sheets, limiting their use in applications requiring custom shapes or configurations. Their best use cases include protective barriers, safety equipment, and architectural applications.

Choosing the Right Material for Your Application

Selecting the appropriate material for industrial applications requires careful consideration of various factors, including performance requirements, budget constraints, and the specific application context. While PU sheets excel in high-wear environments due to their superior abrasion resistance and customization options, rubber sheets and polycarbonate sheets offer unique advantages in terms of cost and impact resistance. By evaluating these alternatives against your specific needs, B2B buyers can make informed decisions that align with their operational goals and budgetary limitations.

Essential Technical Properties and Trade Terminology for pu sheet

What Are the Key Technical Properties of PU Sheets That B2B Buyers Should Know?

When evaluating polyurethane (PU) sheets for industrial applications, understanding their critical technical properties is essential for making informed purchasing decisions. Here are some of the most important specifications:

1. Material Grade

Material grade indicates the formulation of the polyurethane, which affects its mechanical properties. PU sheets come in various grades, such as cast or extruded, each offering different characteristics in terms of durability, flexibility, and chemical resistance. For B2B buyers, selecting the right material grade is crucial to ensure the product can withstand specific operational conditions, such as exposure to chemicals or extreme temperatures.

2. Durometer Hardness

Durometer hardness measures the material’s firmness, typically using the Shore A or Shore D scale. This specification ranges from soft (40A) to very hard (90A). Understanding durometer is vital for applications requiring specific levels of cushioning or rigidity, such as vibration dampening or load-bearing tasks. Selecting the correct durometer can significantly affect the performance and longevity of the PU sheet in its intended application.

3. Thickness Tolerance

Thickness tolerance refers to the permissible variation in the sheet’s thickness. Common tolerances might be +/- 0.030 inches for thinner sheets. For B2B applications, precise thickness is essential, especially in industries where fit and function are critical, such as metal fabrication or die cutting. Inaccurate thickness can lead to component failures or increased manufacturing costs.

4. Chemical Resistance

Polyurethane sheets exhibit varying levels of resistance to chemicals, oils, and greases. This property is particularly important in industries like food service, automotive, and manufacturing, where exposure to harsh substances is common. Understanding the chemical resistance of PU sheets helps B2B buyers select materials that will not degrade or lose functionality over time, thus ensuring operational reliability.

5. Temperature Resistance

PU sheets can withstand a range of temperatures, typically up to 200 degrees Fahrenheit. This property is critical for applications in environments with fluctuating temperatures or where heat build-up is a concern. B2B buyers should evaluate temperature resistance to prevent material failure, which can lead to costly downtime or safety hazards.

6. Impact Resistance

Impact resistance measures how well a material can absorb energy from sudden forces without breaking. PU sheets generally have excellent impact resistance, making them ideal for applications such as bumpers or protective barriers. For businesses, choosing materials with high impact resistance can lead to reduced maintenance costs and extended product lifespan.

What Are the Common Trade Terms Related to PU Sheets?

Understanding industry-specific terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms associated with PU sheets:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of PU sheets, OEMs may require customized materials for specific applications, making it crucial for suppliers to understand these needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for B2B buyers as it affects inventory management and procurement strategies. Knowing the MOQ can help businesses plan their purchasing more effectively and avoid excess stock.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers requesting price quotes for specific products or services. This process is crucial for comparing costs and terms across different suppliers, enabling informed decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to clarify shipping, insurance, and delivery responsibilities, thus avoiding disputes and ensuring smooth transactions.

5. Lead Time

Lead time is the time taken from placing an order to receiving it. For B2B buyers, understanding lead times is crucial for planning and ensuring that projects stay on schedule. Shorter lead times can enhance competitiveness and customer satisfaction.

By grasping these technical properties and trade terms, B2B buyers can make better-informed decisions, optimizing their procurement processes for polyurethane sheets.

Navigating Market Dynamics and Sourcing Trends in the pu sheet Sector

What Are the Current Market Dynamics and Key Trends Influencing the PU Sheet Sector?

The polyurethane (PU) sheet market is witnessing robust growth driven by increasing demand across diverse industries such as automotive, aerospace, and manufacturing. The material’s superior properties, including abrasion resistance, chemical stability, and versatility in applications, position it as a preferred alternative to traditional materials like rubber and plastic. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the PU sheet market presents significant opportunities. Emerging economies are ramping up manufacturing capabilities, leading to heightened demand for durable materials that can withstand harsh operating conditions.

Key trends influencing this market include the rise of customization in product offerings. Manufacturers are increasingly providing tailored PU sheets in various colors, thicknesses, and durometers to meet specific client requirements. Additionally, advancements in B2B technology such as online sourcing platforms and automated order fulfillment systems are streamlining procurement processes, allowing buyers to access a wider range of products with minimal lead times. Moreover, the shift towards digital solutions in supply chain management enhances visibility and efficiency, enabling buyers to make informed purchasing decisions.

How Are Sustainability and Ethical Sourcing Impacting PU Sheet Procurement?

As sustainability becomes a core focus for businesses globally, the PU sheet sector is also adapting to these changes. Buyers are increasingly concerned about the environmental impact of their sourcing decisions, leading to a demand for sustainable and ethically sourced materials. Manufacturers are responding by exploring greener alternatives in their production processes, such as using recycled materials or adopting eco-friendly manufacturing techniques.

Certifications such as ISO 14001 and other environmental labels are becoming essential for suppliers aiming to attract international buyers. These certifications demonstrate a commitment to reducing environmental impact and promoting sustainable practices. Furthermore, the use of bio-based polyurethanes is gaining traction, offering a more sustainable option without compromising the performance characteristics that make PU sheets desirable. Buyers focusing on sustainability can enhance their brand reputation and meet the growing consumer demand for responsible sourcing.

What Is the Brief History and Evolution of PU Sheets Relevant to B2B Buyers?

The evolution of polyurethane sheets dates back to the mid-20th century when polyurethane was first developed as a versatile polymer. Initially used primarily in foam products, advancements in manufacturing techniques led to the development of PU sheets, which began to gain popularity in various industrial applications due to their unique properties. Over the decades, innovations in chemical formulations and production methods have significantly improved the performance of PU sheets, making them suitable for high-wear applications across multiple sectors.

By the late 20th century, PU sheets became recognized for their durability, flexibility, and resistance to environmental factors, leading to widespread adoption in industries such as automotive, aerospace, and consumer goods. As global markets have expanded, the demand for PU sheets has surged, prompting manufacturers to enhance customization options and develop sustainable solutions. This historical context underscores the significance of PU sheets as a reliable choice for international B2B buyers looking to invest in high-quality materials that support operational efficiency and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of pu sheet

-

How do I choose the right durometer for my polyurethane sheet needs?

Selecting the appropriate durometer is crucial for ensuring the performance of your polyurethane sheet in specific applications. Durometer measures the hardness of the material; softer sheets (40A-60A) are ideal for applications requiring flexibility and shock absorption, while harder sheets (60D and above) provide durability and wear resistance. Consider the operational environment and the forces the sheet will encounter. If you’re uncertain, consult with suppliers who can recommend suitable options based on your specific application requirements. -

What are the common applications for polyurethane sheets in various industries?

Polyurethane sheets are versatile and used across multiple industries, including aerospace, automotive, manufacturing, and food service. Common applications include bumpers, pads, seals, and vibration dampeners. Their excellent abrasion resistance and ability to withstand harsh chemicals make them suitable for die-cutting materials, surface liners, and energy absorption components. Understanding your industry needs will help you select the right specifications for your project. -

What minimum order quantities (MOQs) should I expect when sourcing PU sheets?

Minimum order quantities can vary significantly between suppliers, typically ranging from 2 to 10 sheets, depending on the thickness and customization requirements. It’s essential to communicate your needs directly with suppliers to understand their policies and see if they offer flexibility for smaller orders, especially for prototyping or testing applications. Some manufacturers may allow for lower MOQs for standard sizes or colors, so inquire about options before committing. -

What customization options are available for polyurethane sheets?

Many manufacturers offer customization for polyurethane sheets, including variations in color, thickness, and durometer. Custom formulations can also be created to meet specific chemical resistance or temperature requirements. Discussing your unique application needs with suppliers can lead to tailored solutions that enhance performance. Be prepared to provide detailed specifications to ensure that the customized product meets your expectations. -

How do I ensure the quality of polyurethane sheets from international suppliers?

To ensure quality, it’s vital to vet suppliers thoroughly. Check for certifications that demonstrate compliance with international standards, such as ISO or ASTM. Request product samples to assess material properties before placing a bulk order. Additionally, consider suppliers that provide transparent testing and quality assurance documentation, and inquire about their manufacturing processes. Engaging in regular communication can also help maintain quality assurance throughout the sourcing process. -

What payment terms are typically offered by suppliers of PU sheets?

Payment terms can vary widely among suppliers, ranging from upfront payment to net 30 or net 60 terms. Many international suppliers may require a deposit upfront, especially for custom orders. It’s crucial to clarify payment conditions before finalizing any agreements. Additionally, consider utilizing secure payment methods and contracts that protect both parties, ensuring a smooth transaction experience. -

What logistics considerations should I keep in mind when importing polyurethane sheets?

When importing PU sheets, consider shipping methods, lead times, and potential customs duties. Work with suppliers who have experience in international shipping and can provide clarity on delivery timelines. Ensure that you understand your country’s import regulations and tariffs, which can impact overall costs. Collaborating with a reliable freight forwarder can streamline the logistics process and help you navigate complexities. -

How can I address potential issues with delivery delays or product discrepancies?

To mitigate issues related to delivery delays or product discrepancies, establish clear communication channels with your supplier. Set realistic timelines and confirm shipping methods in advance. In the event of discrepancies, refer to your purchase agreement and communicate promptly with the supplier to resolve the issue. Building a strong relationship with your suppliers can facilitate quicker resolutions and enhance your overall sourcing experience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Pu Sheet Manufacturers & Suppliers List

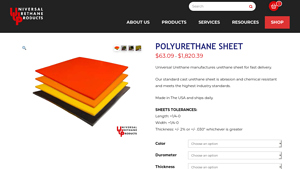

1. Universal Urethane – Polyurethane Sheet

Domain: universalurethane.com

Registered: 1999 (26 years)

Introduction: Product Name: Polyurethane Sheet

Price Range: $63.09 – $1,820.39

Manufacturing Location: Toledo, Ohio, USA

Key Features:

– Abrasion and chemical resistant

– Custom formulations and colors available

– High heat resistance (up to 200 degrees Fahrenheit)

– Lightweight and easy to transport

– High load-bearing ability

– Machinable and resilient

– Cost-effective

Available Sizes:

– Thickness: 0.125″ …

2. The Rubber Company – PU Sheeting

Domain: therubbercompany.com

Registered: 2013 (12 years)

Introduction: {“Item Code”: “PU-SHEETING”, “Key Features”: [“Flexible and versatile”, “Superior load bearing”, “Resistant to abrasion, moisture, oil, mildew and many potentially corrosive chemicals”], “Temperature Range”: “-30°C to +80°C (+100°C short term)”, “Product Description”: “Extensive range of polyurethane sheets for various applications with diverse options in hardness and colours.”, “Specifications”: …

3. Polymer Shapes – Polyurethane Plastic Solutions

Domain: polymershapes.com

Registered: 2000 (25 years)

Introduction: Polyurethane (PU) Plastic Sheet, Rod, & Tube – Rigid polyurethane (PU) offers excellent chemical resistance and superior impact strength. Available in opaque and translucent grades. Benefits include excellent mechanical properties, a variety of colors (Natural, Black, Red, Green, White, Yellow, Blue), and different grades (40 – 95 Durometer). Sizes include sheets (12″ x 12″, 12″ x 24″, 24″ x 24″, …

4. Gteek – PU Polyurethane Solutions

5. Lisen – Polyurethane Sheets

Domain: lisenpu.com

Registered: 2025 (0 years)

Introduction: Polyurethane Sheet – Lisen Polyurethane Products

Min. Order Quantity: 5 rolls

Packaging: Pallet

Delivery Time: 12 Working Days

Port: Shanghai/Ningbo

Payment Terms: T/T, Western Union, Paypal

Specifications:

– Commonly used to replace traditional rubber and plastic sheets.

– Better wear resistance, tear resistance, resilience, chemical and oil resistance than rubber.

– Machinable with low noise and…

6. Interstate Plastics – Polyurethane Sheet

Domain: interstateplastics.com

Registered: 1997 (28 years)

Introduction: Product: Polyurethane Sheet

Pricing: Call for pricing at (888) 768-5759

Warning: This product can expose you to chemicals including Urethane, CAS 51-79-6, known to the State of California to cause cancer and birth defects or other reproductive harm. For more information, visit www.P65Warnings.ca.gov.

Caution: May have sharp edges and points; handle with care to avoid injury.

Disclaimer: Interstate…

7. U.S. Plastic Corp – Polyurethane Sheet, Rod & Shapes

Domain: usplastic.com

Registered: 1996 (29 years)

Introduction: Polyurethane Sheet, Rod & Shapes Category | U.S. Plastic Corp. | High load bearing capacity | Excellent tear resistance | Abrasion, oil, and solvent resistant | High resistance to sunlight and weather conditions | Superior sound dampening properties | Great electrical insulating properties | Applications: gaskets, seals, gears, wheels, bearings, bumpers, drive belts, valve seats, noise damper, chu…

Strategic Sourcing Conclusion and Outlook for pu sheet

What Are the Key Benefits of Strategic Sourcing for PU Sheet?

In today’s competitive landscape, strategic sourcing of polyurethane (PU) sheets is essential for international B2B buyers looking to enhance their operations. The durability, flexibility, and chemical resistance of PU sheets make them superior alternatives to traditional materials like rubber and plastic. By leveraging custom formulations and various durometers, businesses can tailor PU sheets to meet specific industrial needs, ensuring optimal performance in applications such as metal fabrication, vibration dampening, and prototyping.

How Can International Buyers Capitalize on PU Sheet Opportunities?

For buyers in Africa, South America, the Middle East, and Europe, the strategic sourcing of PU sheets not only leads to cost savings but also improves supply chain resilience. Engaging with reliable manufacturers who offer fast delivery and custom solutions is vital. This approach can significantly reduce downtime and enhance productivity across various sectors, including automotive, aerospace, and manufacturing.

What’s Next for PU Sheet Sourcing?

As demand for high-performance materials continues to rise, the outlook for PU sheets remains promising. International buyers are encouraged to explore partnerships with reputable suppliers who can provide innovative solutions tailored to regional challenges. By prioritizing strategic sourcing, businesses can ensure they remain competitive and equipped to meet evolving market demands. Engage with suppliers today to discover how PU sheets can transform your operations.