Contents

Manufacturing Insight: Prototype Sheet Metal Parts

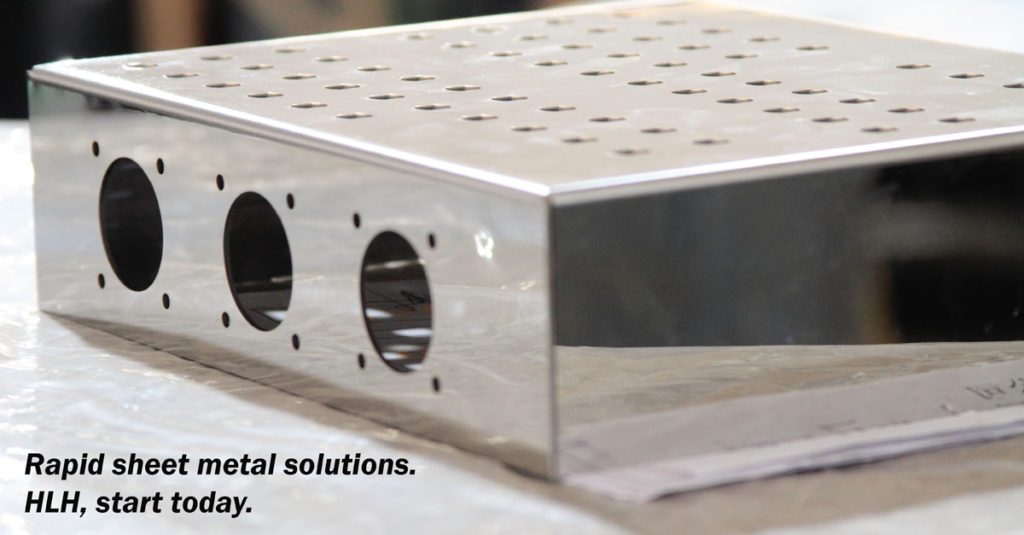

Accelerate Your Product Development with Precision Sheet Metal Prototypes

At Honyo Prototype, we understand that rapid iteration and functional validation are critical to successful product development. Our dedicated sheet metal fabrication services empower engineering teams to transform conceptual designs into high-fidelity, production-intent prototypes with exceptional speed and accuracy. Unlike standard volume manufacturers, we optimize our processes specifically for low-volume prototyping, ensuring you receive dimensionally precise, fully assembled components that mirror end-product performance—without the delays or cost overruns typical of traditional fabrication partners.

Our end-to-end capabilities span laser cutting, CNC punching, precision bending, welding, and finishing across a comprehensive range of materials including aluminum alloys, stainless steel, cold-rolled steel, and copper. We maintain tight tolerances down to ±0.005 inches and support complex geometries, multi-stage assemblies, and secondary operations such as tapping, countersinking, and surface treatments. This technical depth ensures your prototype not only meets design specifications but also provides reliable data for design validation, fit-checks, and performance testing under real-world conditions.

Material and Process Capabilities Summary

| Parameter | Specification |

|——————–|———————————————–|

| Material Thickness | 0.020″ – 0.250″ (0.5mm – 6.35mm) |

| Tolerance | ±0.005″ (0.13mm) on critical features |

| Max Part Size | 48″ x 96″ (1219mm x 2438mm) |

| Key Processes | Laser Cutting, CNC Punching, Press Brake Forming, MIG/TIG Welding |

Eliminate quoting bottlenecks with Honyo’s Online Instant Quote platform. Upload your STEP or DXF file, specify material and finish requirements, and receive a detailed, binding price and lead time estimate in under 60 seconds—24/7. This transparency accelerates procurement cycles, allowing your team to validate budgets and iterate designs faster than ever before. Combined with our engineering review feedback and dedicated project management, we ensure your sheet metal prototypes move seamlessly from digital model to physical validation, reducing time-to-market without compromising on quality or manufacturability. Partner with Honyo to turn your design challenges into competitive advantages.

Technical Capabilities

Technical specifications for prototype sheet metal parts at Honyo Prototype are optimized for precision, repeatability, and rapid turnaround. Our capabilities in laser cutting, bending, and welding support a range of materials including aluminum, steel, and select thermoplastics such as ABS and nylon—though the latter are typically processed via CNC machining or 3D printing rather than traditional sheet metal methods.

Below is a summary of technical specifications relevant to each process and compatible materials:

| Process | Material Compatibility | Thickness Range | Tolerance (Typical) | Feature Details | Notes |

|---|---|---|---|---|---|

| Laser Cutting | Aluminum (5052, 6061), Mild Steel (CRS, HR), Stainless Steel (304, 316) | 0.5 mm – 25 mm | ±0.1 mm | Clean edges, minimal burr; kerf allowance ~0.2 mm; complex geometries supported | Not recommended for ABS/nylon due to thermal degradation; use CNC routing instead |

| CNC Bending | Aluminum, Mild Steel, Stainless Steel | 0.8 mm – 12 mm | ±0.2° angular, ±0.2 mm linear | Bend radius minimum = 1× material thickness; tooling selection based on part geometry | Limited by tool availability and form factor; flange length ≥ 3× material thickness recommended |

| MIG/TIG Welding | Aluminum, Mild & Stainless Steel | 1.0 mm – 20 mm | ±0.5 mm post-weld | Full or stitch welds; post-weld grinding/filing available; distortion controlled via fixturing | Not applicable to ABS/nylon; thermoplastics require hot gas or ultrasonic welding if needed |

| Material Notes | ABS, Nylon | Sheet form: 1–10 mm | N/A | Not processed via standard sheet metal techniques; machined or 3D printed instead | Used for non-structural, insulating, or wear-resistant prototypes; not compatible with laser cutting or bending |

Note: While ABS and nylon may be supplied in sheet form, they are not compatible with high-temperature processes such as laser cutting or welding due to melting, warping, and hazardous fume generation. These materials are typically handled using alternative fabrication methods better suited to thermoplastics.

From CAD to Part: The Process

Honyo Prototype Sheet Metal Prototyping Process: From CAD to Delivery

Our streamlined sheet metal prototyping workflow is engineered for speed, accuracy, and manufacturability assurance. This process eliminates traditional quoting bottlenecks while ensuring your design is production-ready before metal is cut. Here is the detailed sequence:

CAD Upload and Initial Processing

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, DXF, DWG) via our secure customer portal. Our system performs an immediate automated geometry validation check, confirming file integrity and basic dimensional compliance with sheet metal fabrication principles. This step filters out common file errors before progression, preventing downstream delays.

AI-Assisted Quoting Engine

Validated CAD data enters our proprietary AI quoting system. This engine analyzes geometric complexity, material requirements, feature density (holes, bends, cutouts), and surface finish specifications against real-time machine capability databases and material cost feeds. Crucially, the AI cross-references historical production data from thousands of prior sheet metal jobs. The output is a detailed, transparent quote within 2 business hours, including itemized costs for laser cutting, CNC punching, bending, finishing, and assembly. The AI flag identifies potential high-risk features requiring DFM intervention, setting clear expectations upfront.

Expert-Led DFM Analysis and Collaboration

Every quote triggers mandatory DFM review by our senior sheet metal engineers. This is not an automated check; it is a value-engineering consultation. Engineers assess bend radii relative to material thickness, hole-to-edge and hole-to-bend spacing, flange length feasibility, tooling constraints for complex bends, and manufacturability of cutouts. We identify opportunities to reduce cost or lead time without compromising function—such as standardizing bend radii or adjusting relief notches. A formal DFM report with specific, actionable recommendations is provided. Clients can approve the original design, implement our suggestions, or discuss alternatives via direct engineer consultation. This collaborative step prevents costly revisions during production.

Precision Production Execution

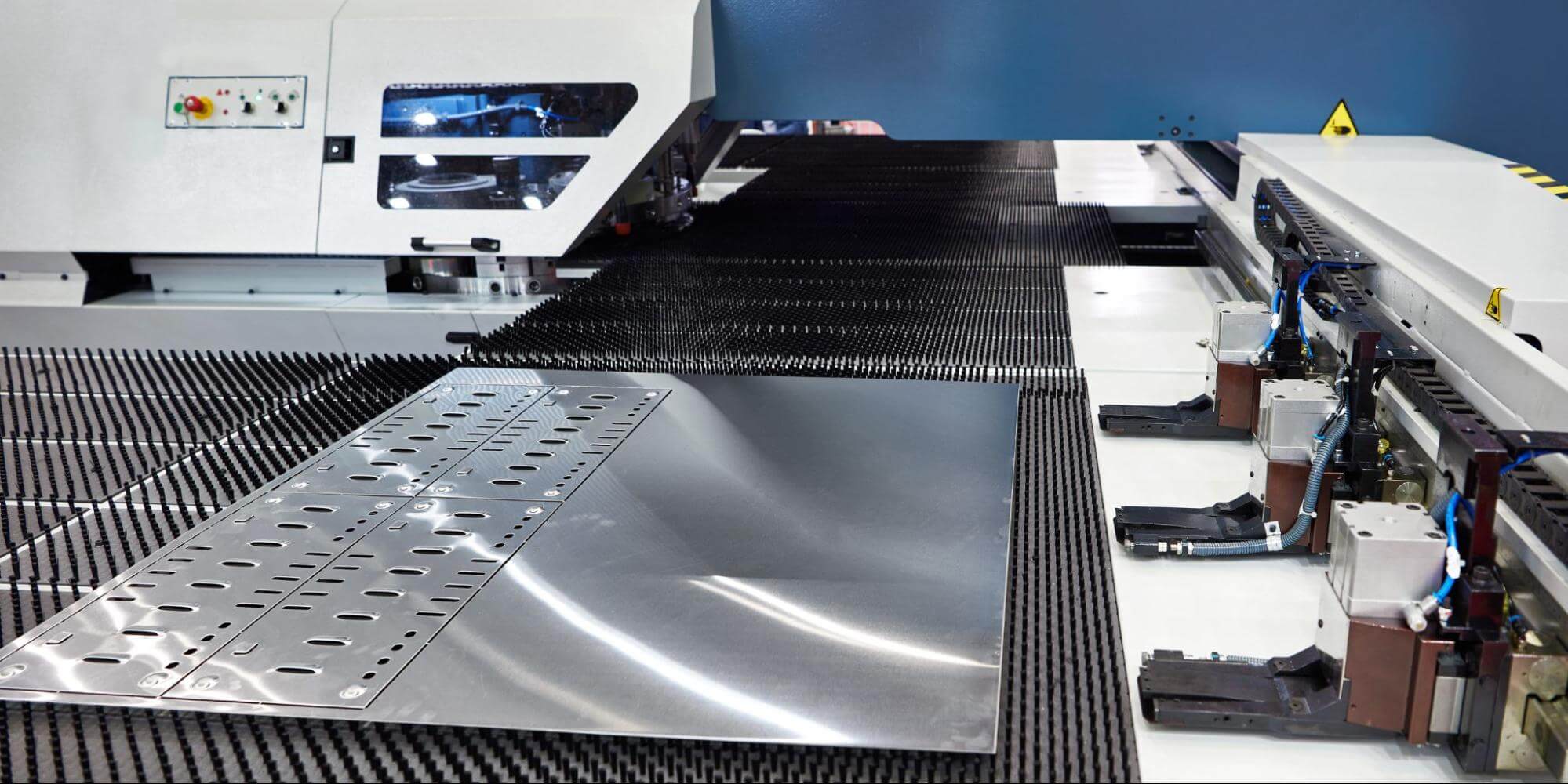

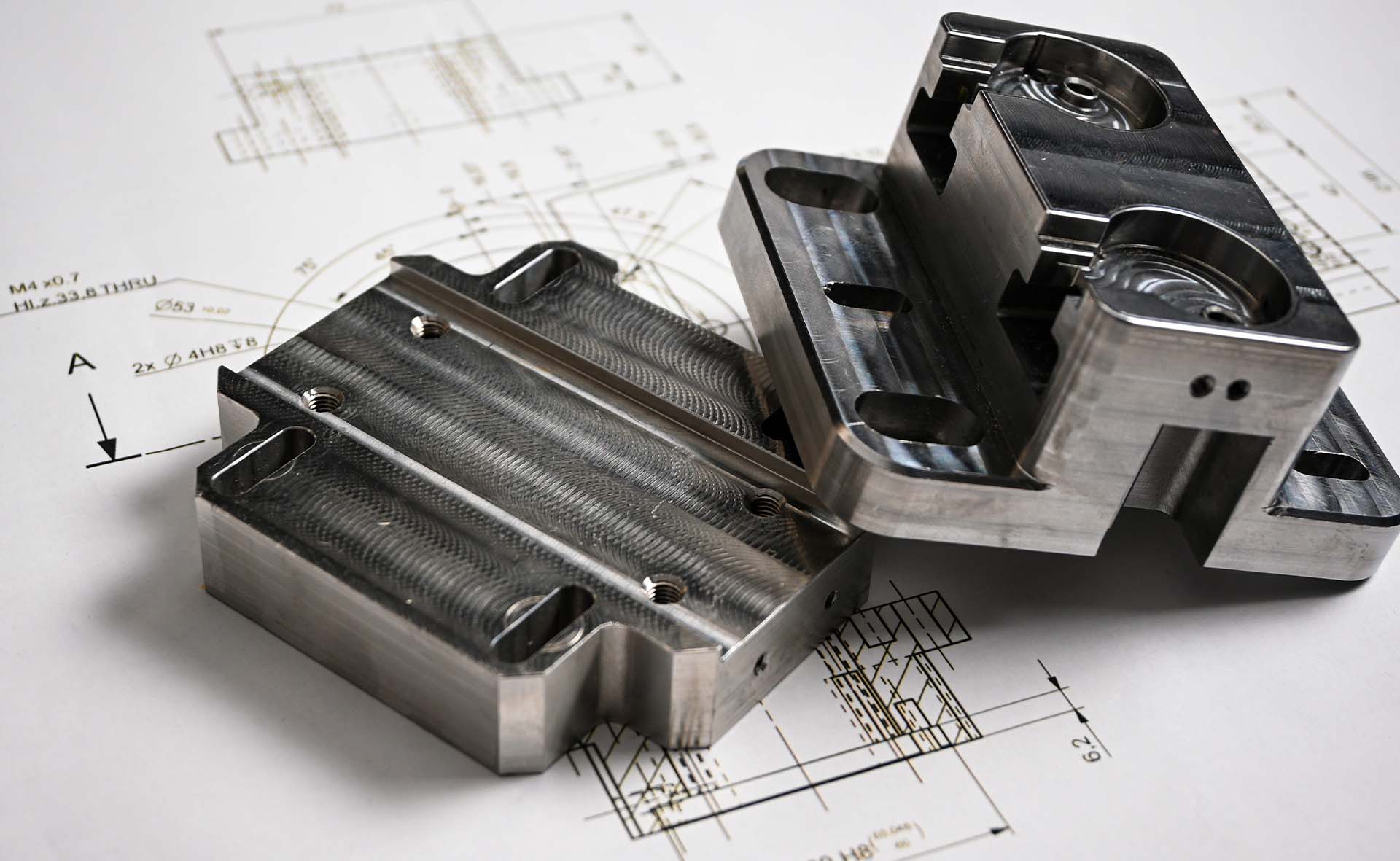

Approved designs move to our dedicated prototype cell. Material is selected per specification (common alloys: 5052-H32, 6061-T6, 304/316 Stainless, Mild Steel) with full material certification. Cutting utilizes hybrid laser/punch technology: CO2/fiber lasers for intricate contours and high-speed CNC turrets for high-volume perforations or standard cutouts. Bending employs precision CNC press brakes with coining capabilities for tight tolerances (±0.005″ typical). All processes adhere to ASME Y14.5 GD&T standards. In-process inspections verify critical dimensions at key stages, documented via digital first-article inspection reports.

Quality Control and Delivery

Final parts undergo comprehensive verification: dimensional checks against CAD using CMM or optical comparators, visual inspection for surface defects, and verification of bend angles and flatness. All prototypes ship with a complete documentation package including FAI report, material certs, and as-built dimensional summary. Standard lead time is 5-7 business days from DFM approval, with expedited options available. Parts are packaged to prevent transit damage, with kitting for multi-part assemblies.

Critical DFM Focus Areas in Sheet Metal Prototyping

Understanding common failure points drives our DFM rigor. The table below contrasts typical pitfalls versus Honyo’s mitigation approach:

| Design Challenge | Common Industry Issue | Honyo’s DFM Resolution Strategy |

|---|---|---|

| Bend Relief | Tearing at internal corners during bending | Mandate reliefs ≥ material thickness; optimize geometry |

| Minimum Flange Length | Inability to form short flanges on press brake | Redesign flanges to exceed machine minimums or suggest alternative forming |

| Hole-to-Bend Spacing | Distortion of holes near bend lines | Enforce minimum distance = 2.5x material thickness + bend radius |

| Complex Cutout Geometry | Excessive laser cutting time/cost | Recommend simplification or hybrid punch/laser approach |

| Material Grain Direction | Bend cracking in critical applications | Specify grain orientation relative to bend axis in documentation |

This integrated process ensures your sheet metal prototype arrives as a true functional representation—not just a visual model—ready for validation testing or as a benchmark for future production. By embedding engineering expertise at the DFM stage and leveraging data-driven quoting, we eliminate the rework cycle common in prototype manufacturing, delivering higher fidelity parts faster while reducing your development risk.

Start Your Project

Looking to prototype sheet metal parts with precision and speed? Partner with Honyo Prototype for rapid, high-quality sheet metal prototyping services. Our in-house manufacturing facility in Shenzhen ensures tight tolerances, fast turnaround, and scalable solutions from concept to production.

Contact Susan Leo today at [email protected] to discuss your project requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.